Patents

Literature

33results about How to "Overcome heat retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

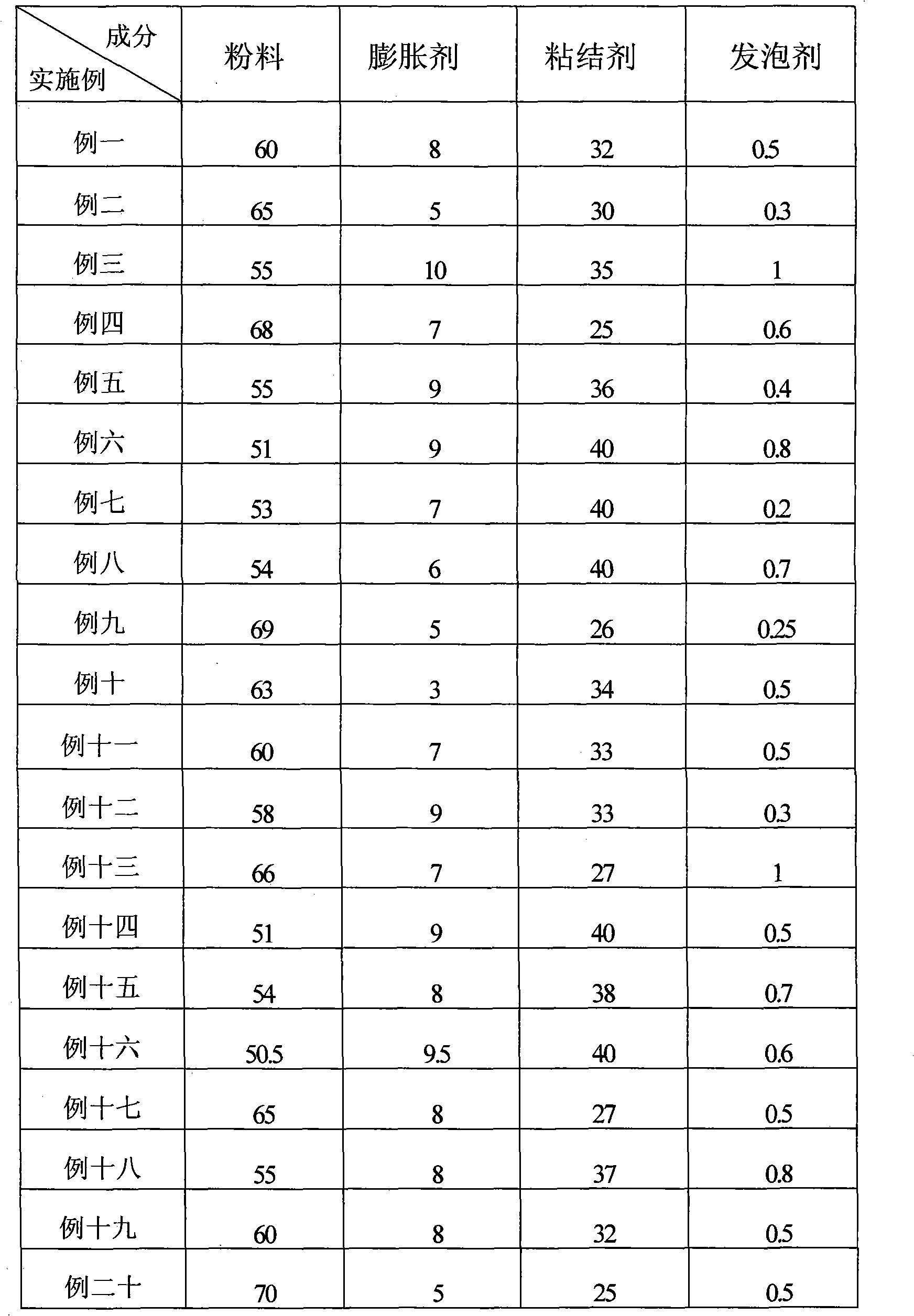

Ultra-microporous lightweight insulated firebrick and manufacture method thereof

The invention discloses an ultra-microporous lightweight insulated firebrick and a manufacture method thereof. The ultra-microporous lightweight insulated firebrick is prepared by the following raw materials in percentage by weight: powder mainly comprising 50-70 Al2O3 and SiO2, 5-10 expanding agent, 25-40 caking agent and 0.2-1.0 external foaming agent. The manufacture method comprises the following steps: uniformly mixing and stirring the raw materials into pasty material; mixing the foaming agent and water according to a ratio of 1: (15-20); adding the mixture to the pasty material to mix uniformly; then, casting into brick blanks; and drying and keeping the brick blanks at a temperature of 1200-1600 DEG C for 6-8 hours. The firebrick has the advantages of high compressive strength, low coefficient of heat conductivity and low linear change ratio and can be directly used for a fireproof coating of thermal equipment so that the product has the lightweight insulation and fireproofness functions and good insulation effect and is beneficial to energy saving and environmental protection. Compared with the prior art, the invention has obvious economic benefits.

Owner:郑州东方炉衬材料有限公司

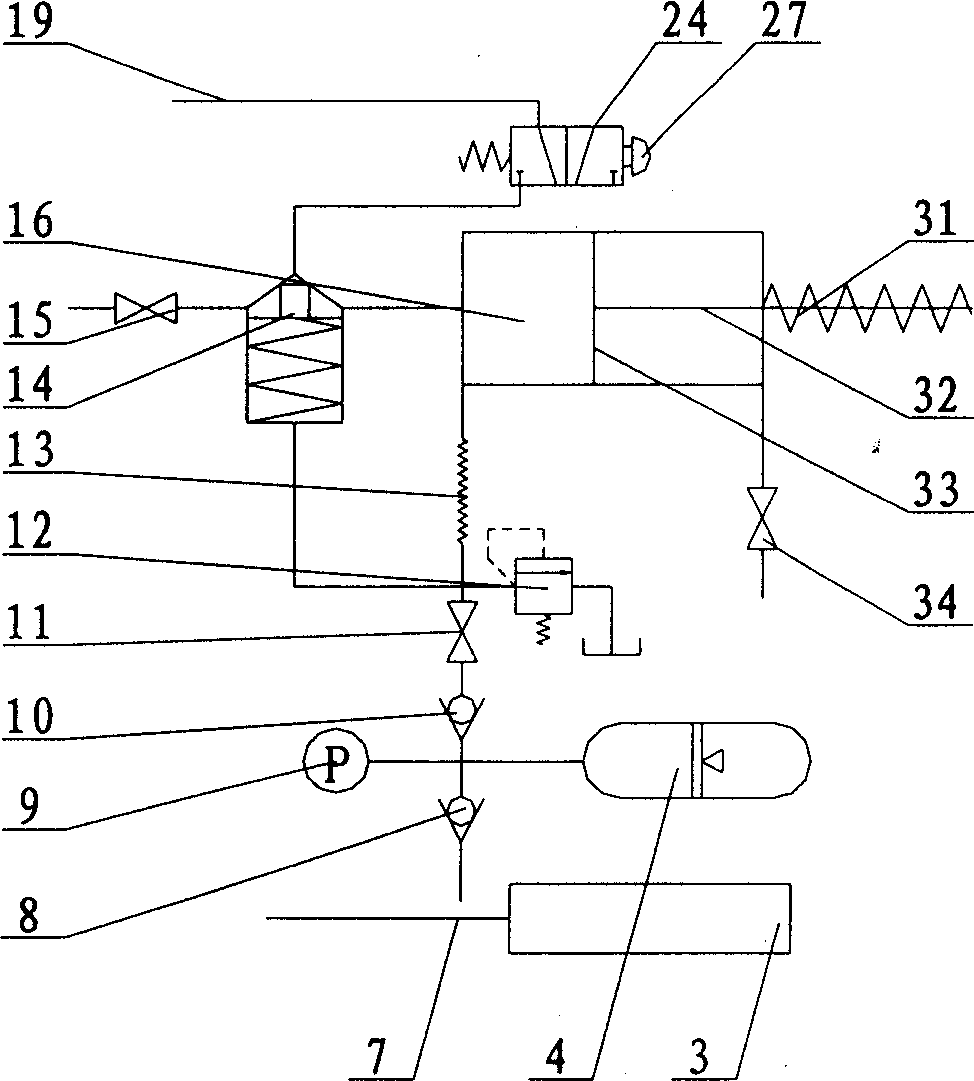

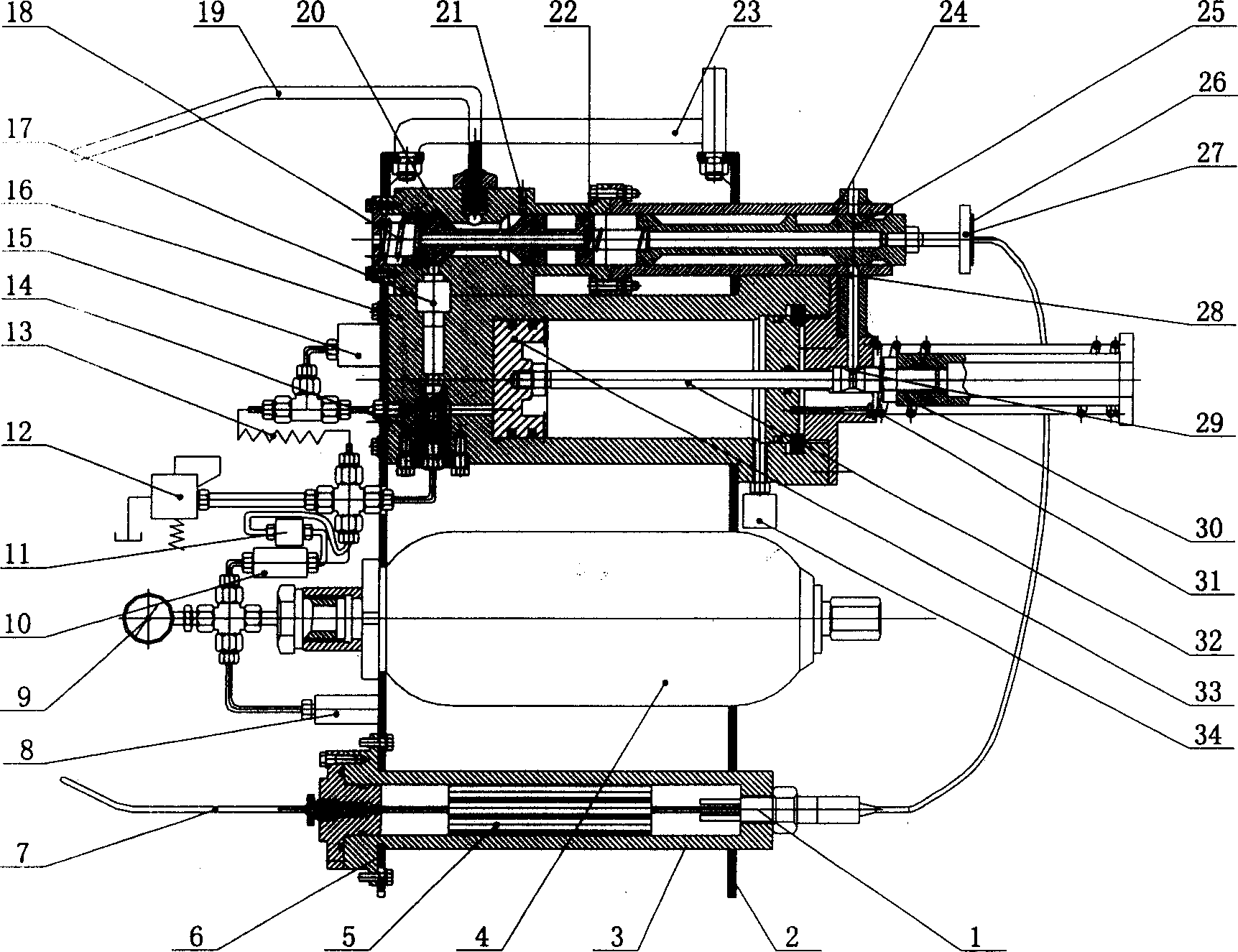

Hand held type deep sea hydrothermal fidelity sampler

InactiveCN1554934AOvercoming the inability to maintain pressureOvercome heat retentionWithdrawing sample devicesHand heldEngineering

The high-fidelity hand held deep sea hydrothermal fluid sampler includes control cavity, sampling barrel, energy accumulator and circuit cavity fixed into one integral. The control cavity is provided with water sucking tube, relieving port, axial spring, conic valve, control valve core and sampling triggering screw possessing one end exposed outside the cavity and wound ICL coil. The sampling barrel has piston and piston rod connected via non-return valve with the control cavity. The energy accumulator has one path communicated with sea water via the non-return valve and the other path communicated with the sampling barrel via the non-return valve and cut-off valve. The circuit cavity is provided with hydrothermal fluid probe for detecting the temperature of the fluid and circuit board with output connected to the ICL coil. The sampler has high strength, light weight, maximum sampling water depth of 7000, maximum holding pressure of 70 MPa and highest sampling temperature of 400 deg.c.

Owner:ZHEJIANG UNIV

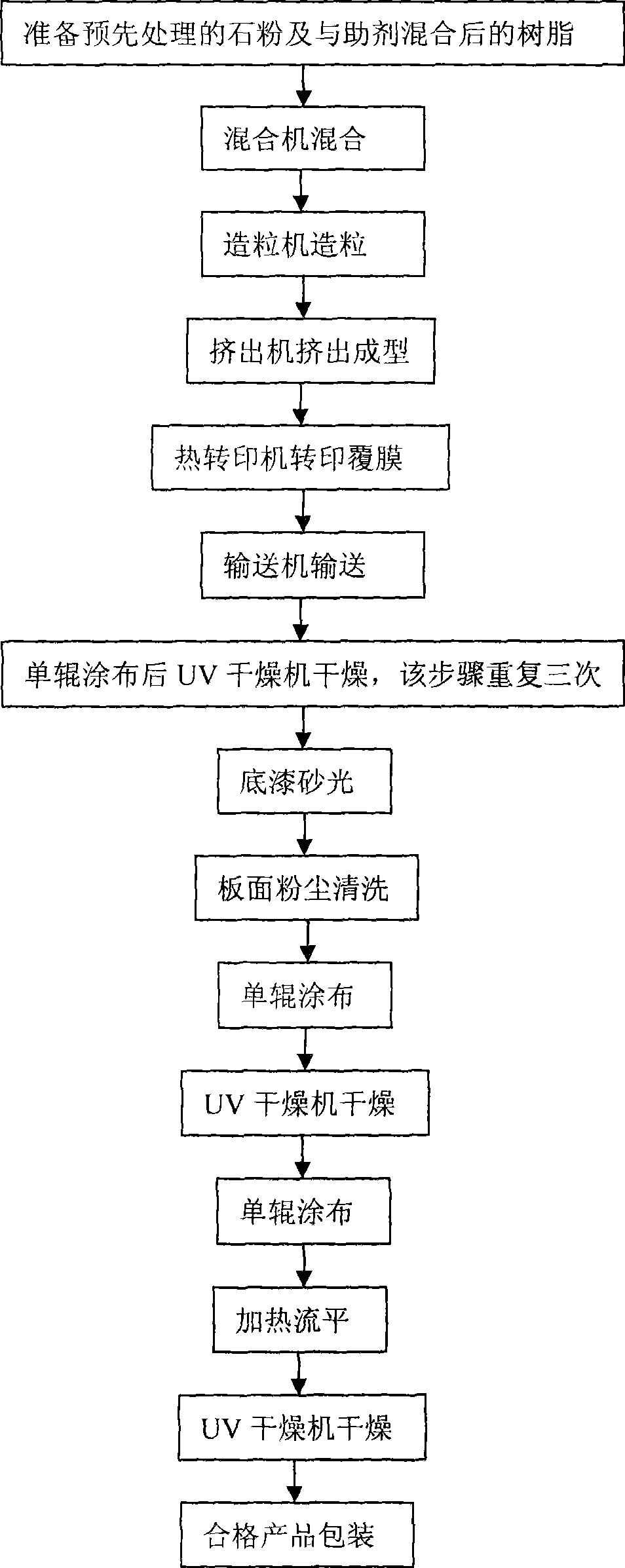

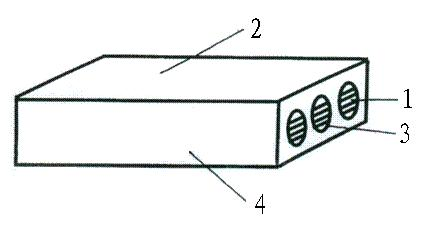

High strength waterproof stone-wood floor and technique for producing the same

InactiveCN101481232AOvercome fear of waterOvercoming deformationSolid waste managementPolyvinyl chlorideHigh intensity

The invention discloses a high-strength waterproof stone-wood floorboard which is prepared from the following raw materials by weight parts: 45 to 65 weight parts of stone powder, 20 to 30 weight parts of PVC resin, 2 to 5 weight parts of UV resistant agent, 1 to 2 weight parts of stearic acid, 2 to 5 weight parts of coupling agent, 3 to 5 weight parts of CPE, 3 to 5 weight parts of dibutyl ester and 2 to 4 weight parts of antioxidizer. The invention also discloses a production technology for the high-strength waterproof stone-wood floorboard. The high-strength waterproof stone-wood floorboard also has the advantages of low cost, heat insulation, environmental protection, waste reutilization and the like.

Owner:SHENZHEN KELAX COMPOUND MATERIAL

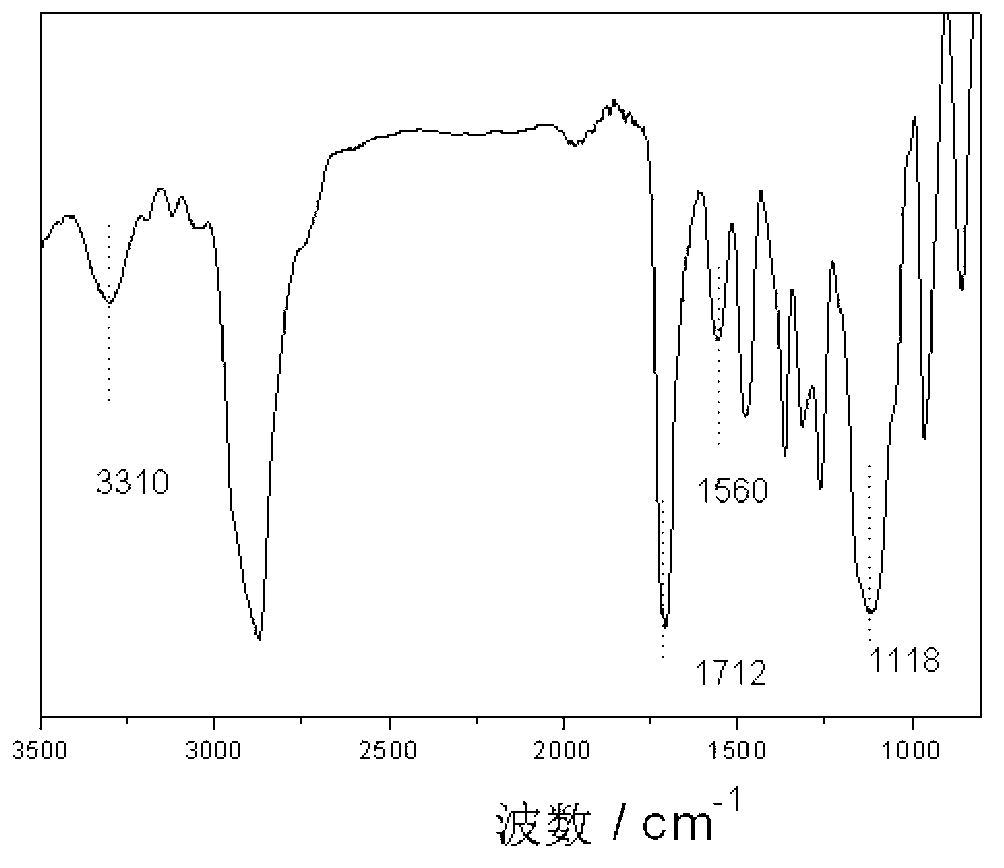

Ply-rolling pack for pack ply-rolling of titanium alloy sheet

InactiveCN102107225AAvoid local flow asynchronyAvoid pitting and other defectsAuxillary arrangementsMetal rolling arrangementsTitanium alloyComposite material

The invention discloses a ply-rolling pack for pack ply-rolling of a titanium alloy sheet, and relates to the ply-rolling pack which is used in the production process of rolling the titanium alloy sheet by a ply-rolling method. The ply-rolling pack is characterized by comprising a ply-rolling pack core block and a ply-rolling pack cover, wherein the ply-rolling pack core block is a square core block which is formed by directly laminating titanium alloy sheets; the ply-rolling pack cover comprises surface covering steel sheets and lateral sealing steel sheets; the surface covering steel sheets are attached to the outside the uppermost layer of titanium alloy sheet and the lowermost layer of titanium alloy sheet of the ply-rolling pack core block; the lateral sealing steel sheets are attached to the side faces of the ply-rolling pack core block; the steel sheets are mutually welded to form a square pack cover; and a pair of opposite lateral sealing steel sheets are provided with through holes. Through the ply-rolling pack, the problems of pack breaking, cracking, moving and folding of a core sheet, piling and the like in the hot rolling process can be solved, and finally the titanium alloy sheet with uniform size and high performance is machined.

Owner:BAOJI TITANIUM IND

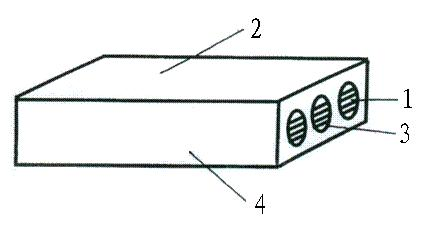

Insulated fireproof material of polyurethane cement foam and preparation method of insulated fireproof material

InactiveCN102701687AOvercome strengthOvercome heat retentionCeramicwareFoaming agentUltimate tensile strength

The invention discloses an insulated fireproof material of polyurethane cement foam and a preparation method of the insulated fireproof material. The insulated fireproof material comprises 50-70 parts of cement, 27-32 parts of water, 1.5-2 parts of foaming agent, 0.2-0.5 parts of early strength agent, 0.5-1.5 parts of water reducer and 5-25 parts of soluble polyurethane. The insulated fireproof material of polyurethane cement foam disclosed by the invention is prepared by the processes of leading in a lot of miniature, stable and sealed air bubbles and a little of polyurethane into cement, and uniformly dispersing the air bubbles and polyurethane in cement matrix. The insulated fireproof material overcomes the defects that inorganic material is easy to pulverize, low in strength and poor in heat preservation effect, and has the advantages of light material, sound insulation, thermostability, large elasticity modulus, corrosion resistance, durability and the like.

Owner:安徽省思维新型建材有限公司

Method for preparing TC4 titanium alloy wire

InactiveCN103406386ASave energyImprove the working environment on siteLiquid surface applicatorsCoatingsTectorial membraneTitanium alloy

The invention provides a method for preparing TC4 titanium alloy wire, which comprises the following steps: after annealing, placing an annealed titanium alloy wire blank into a container containing coating agent for heating and stewing, so as to ensure that the titanium alloy wire blank is coated by a protecting film layer; then placing the titanium alloy wire blank onto a linear wire drawing machine for continuous cold drawing. Through the adoption of the process, the linear velocity of the titanium alloy wire blank can be 16 to 40 m / min during cold drawing, so that the production efficiency is greatly improved; the yield is high; both the dimensional precision and surface quality of the titanium alloy wire are effectively guaranteed.

Owner:BAOJI ZHONGYUAN METAL PROCESSING

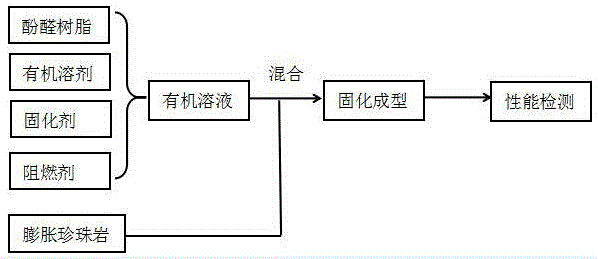

Modified phenolic resin composite thermal insulation material and preparation method thereof

The invention provides a modified phenolic resin composite thermal insulation material which is prepared from the following raw materials in parts by weight: 30-70 parts of epoxy modified phenolic resin, 30-50 parts of coated expanded perlite, 10-20 parts of straw, 2-5 parts of adhesive, 1-3 parts of water repellent, 0.1-1 part of curing agent, 0.1-1 part of lubricant and 0.1-1 part of toughening agent. A preparation method comprises the following steps of: 1) weighing the phenolic resin, coated expanded perlite, straw, adhesive, water repellent, curing agent, lubricant and toughening agent according to the proportion, mixing and stirring uniformly, and putting into a steel mould; and 2) performing hot compression moulding in the conditions that the compression ratio is 1.6-2.4 and the hot compression moulding temperature is 210-240 DEG C, and preserving pressure for 1.5-2.5h to obtain the modified phenolic resin composite thermal insulation material. The thermal insulation material integrates the advantages of low heat conductivity coefficient of an organic thermal insulation material and high strength and difficulty in combustion of an inorganic thermal insulation material.

Owner:滦县盛泽保温科技有限公司

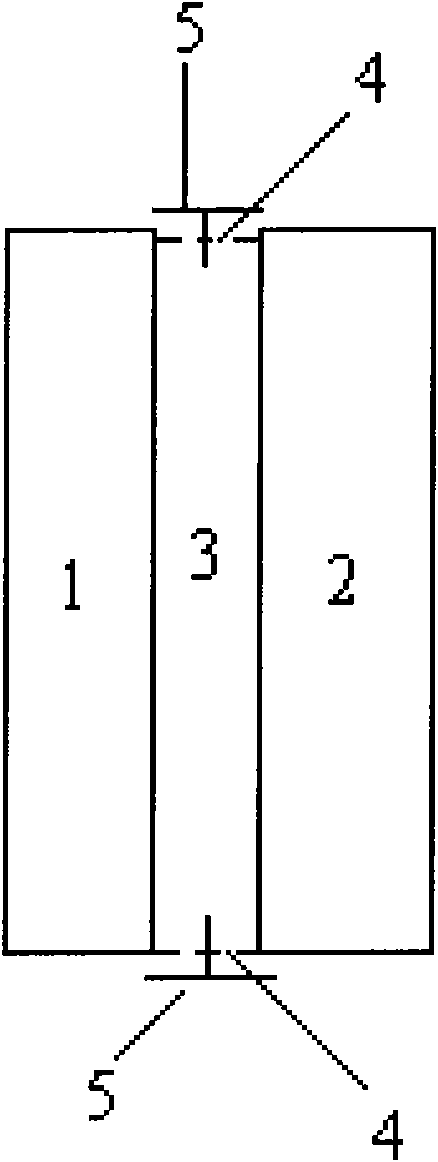

Two-layer wall of building

The invention discloses a two-layer wall of a building. The two-layer wall comprises an outer wall and an inner wall, wherein a ventilation hollow layer is arranged between the inner and outer walls; air adjusting holes are formed at the upper and lower parts of the inner and outer walls; and an opening / closing device for adjusting the air flow is arranged on each air adjusting hole. The two-layer wall disclosed by the invention reduces the energy consumption of the building by use of a hollow ventilation structure of the wall, can adjust the air flow through the air adjusting holes and the opening / closing devices according to the needs, overcomes the shortcomings of the heat insulation wall of the existing building, and has positive significance for reducing the heat effect of the building wall, thereby being a novel energy-saving wall.

Owner:张逊

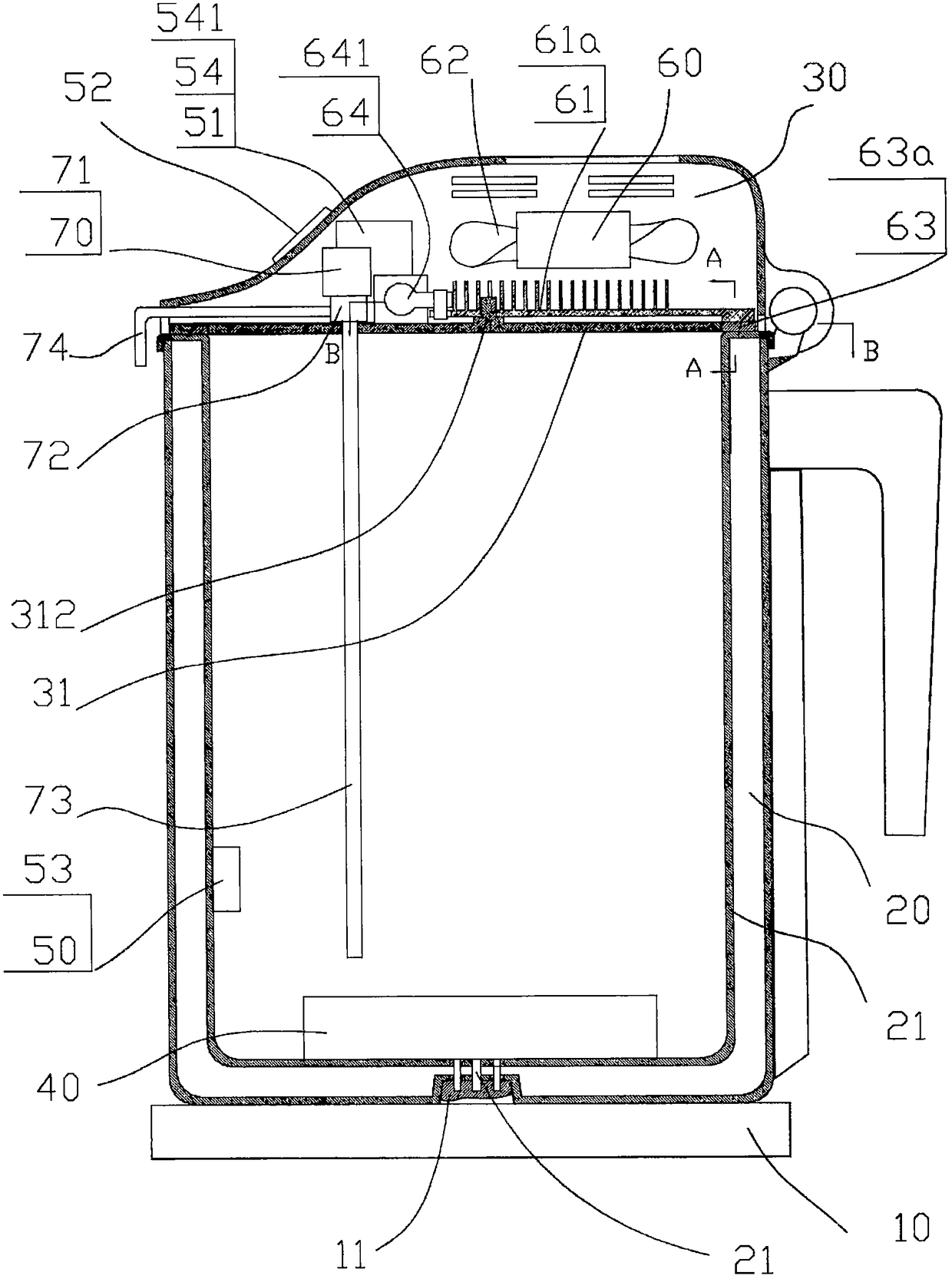

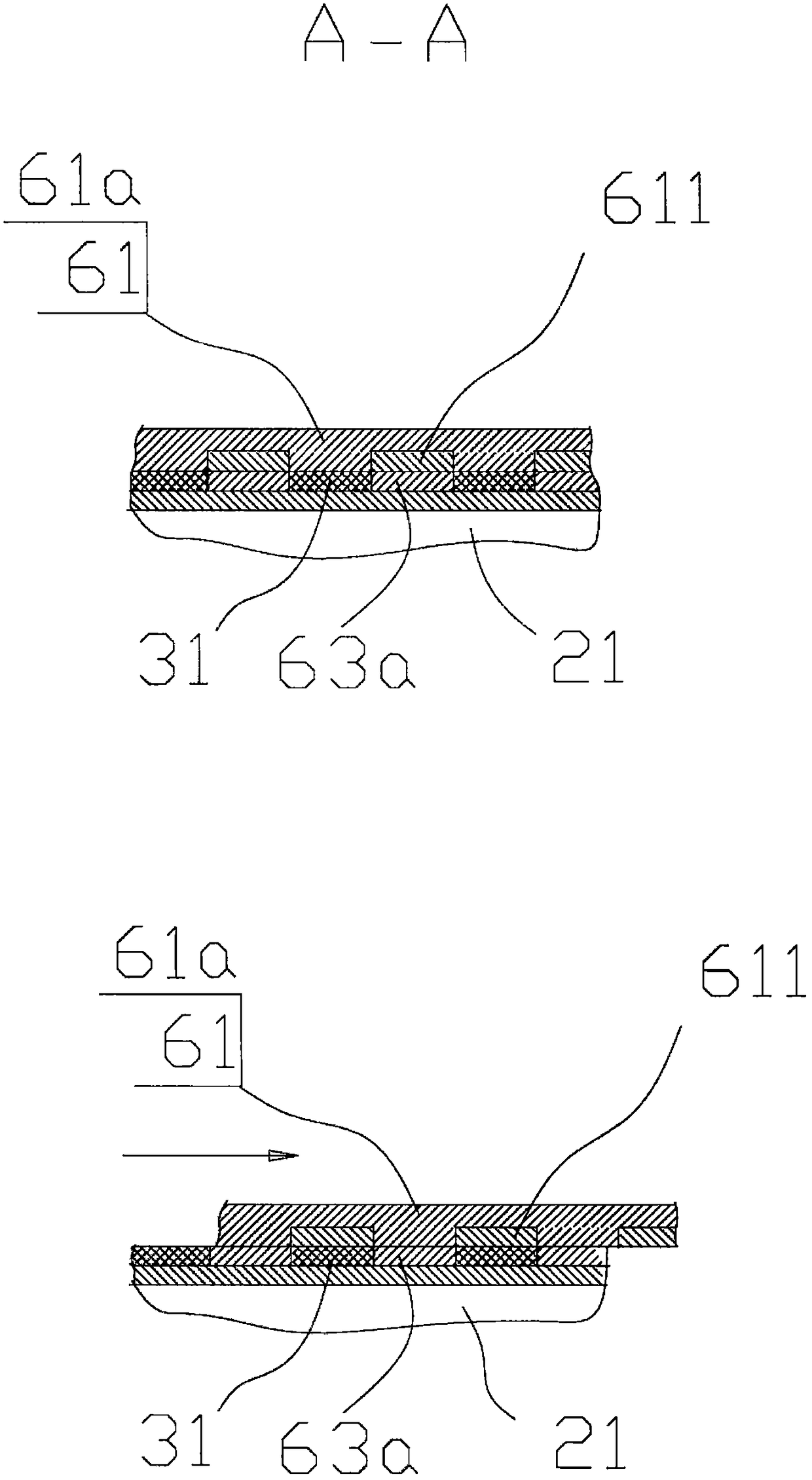

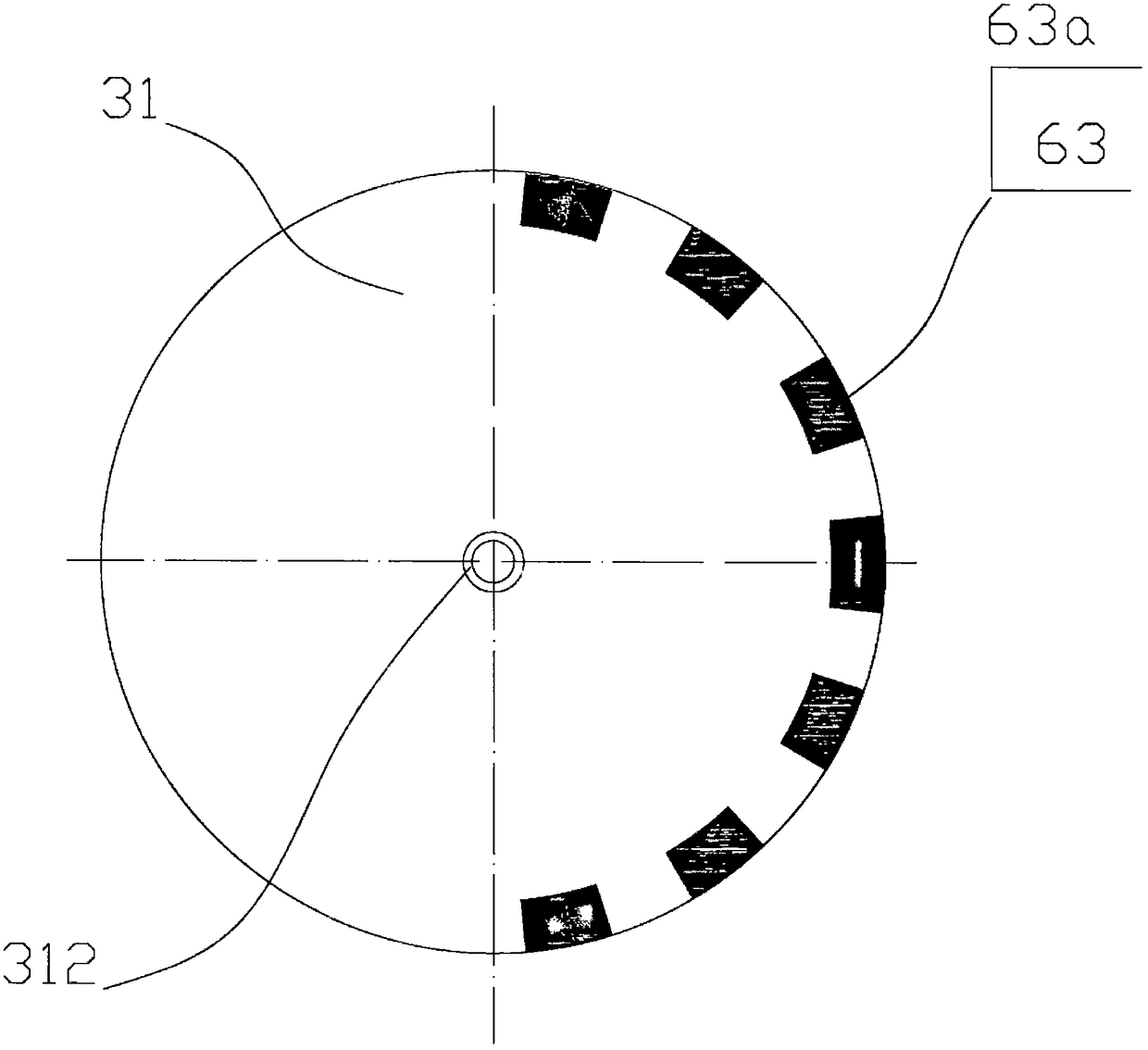

Temperature-adjusting electric kettle

InactiveCN108903632AOvercoming the inability to cool down quicklyOvercome heat retentionCooking-vessel materialsWater-boiling vesselsElectricityEngineering

The invention discloses a temperature-adjusting electric kettle, and relates to an electric kettle for home use. The electric kettle is used for boiling water and for conducting rapid cooling and long-time heat preservation. The electric kettle comprises a base, a kettle cover, a kettle cover, an electric heating tray, an electric control device, a heat radiating device and a driving device, wherein the electric control device comprises a control circuit board, a control panel and a temperature sensor; the heat radiating device comprises heat radiating fins, a heat radiating fan and a heat-conductive element; and in a mode of driving the heat-radiating fins or the heat-conductive element by virtue of the driving device, switching between water heat conduction and an insulating state in theheat-radiating fins and the kettle body is achieved. The wall of the kettle body is of a jacketed structure; and the interior of the jacket is vacuumized. By virtue of the temperature sensor, commands are transmitted to the control circuit board, so as to achieve working procedures of heating and boiling water, forcibly and rapidly cooling boiling water, insulating water temperature which is setfor a long time and compensating heat and heating-up; shortcomings of existing electric kettles which cannot conduct rapid cooling and cannot preserve heat for a long time can be overcome; user's timeof waiting for natural cooling-down of the boiling water can be shortened, and electric energy of repeatedly conducting boiling can be also saved; and meanwhile, harm of 'thousand-boiling water' to people's health can be avoided.

Owner:深圳市鼎研科技有限公司

Organic/inorganic compound thermal insulation material and preparation method

InactiveCN106084632AOvercome strengthOvercoming poor aging resistanceThermal insulationInorganic compound

The invention belongs to the field of a thermal insulation material and preparation thereof. The invention discloses a compound thermal insulation material taking phenolic resin and expanded perlite as main raw materials and a preparation method of the compound thermal insulation material. The preparation method comprises the following steps: uniformly mixing phenolic resin, expanded perlite and fire retardant; filling into a mould; solidifying and forming at a certain temperature for a period of time. Thermoset phenolic resin is selected as the phenolic resin and the dosage is 20wt%-70wt%; perlite in bulk density of 90-120kg / m3 is selected as the expanded perlite and the dosage is 30wt%-80wt%; half-dry pressing is performed under the forming temperature of 100 DEG C for forming time of 2h; the apparent density of the sample is 200-360Kg / m3, the compressive strength is 0.8-1.2MPa, the breaking strength is 0.4-0.7MPa and the combustion performance is B1 level; the overall performance of the material is between the organic and inorganic thermal insulation materials at present. The compound thermal insulation material provided by the invention has the advantages of low heat conductivity coefficient of organic thermal insulation materials and high strength and difficulty in burning of the inorganic thermal insulation material.

Owner:UNIV OF JINAN

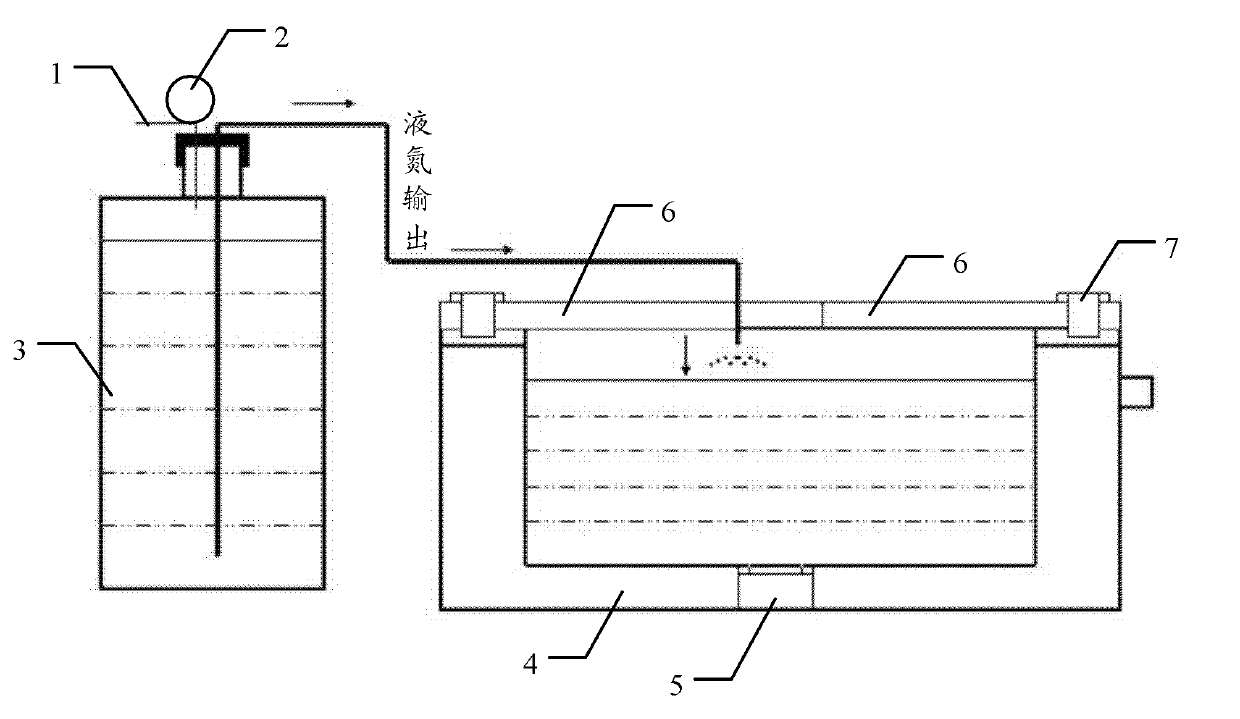

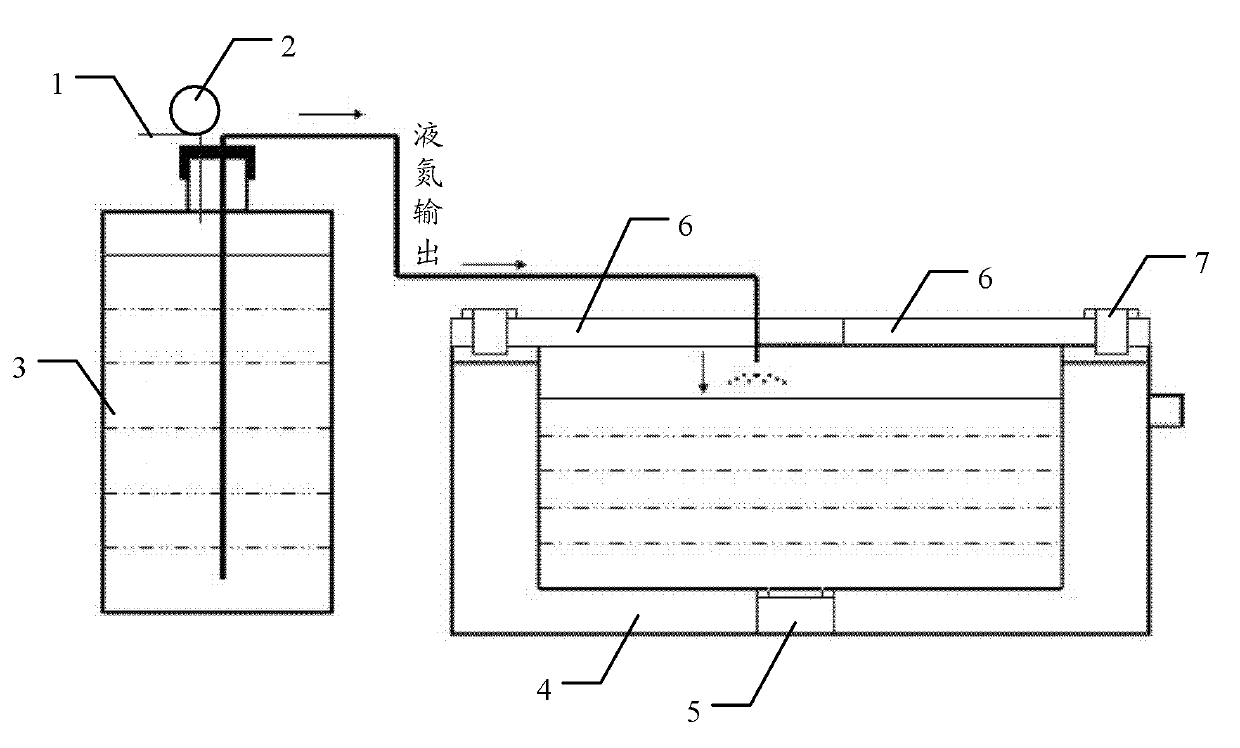

Device for providing low-temperature environment

InactiveCN102166538AAvoid deformationImprove insulation effectHeating or cooling apparatusLiquid nitrogenChemistry

The invention discloses a device for providing a low-temperature environment, comprising a liquid nitrogen storing component, a liquid nitrogen delivery pipe and a liquid nitrogen insulating component, wherein a liquid nitrogen output end of the liquid nitrogen storing component is connected with a liquid nitrogen filling opening of the liquid nitrogen insulating component through the liquid nitrogen delivery pipe. The device for providing a low-temperature environment can overcome the defects of weak pressure-bearing capacity, poor insulation effect, deformation and the like in the prior art, thereby realizing the advantages of strong pressure-bearing capacity, good insulation effect and no deformation.

Owner:LANZHOU UNIVERSITY

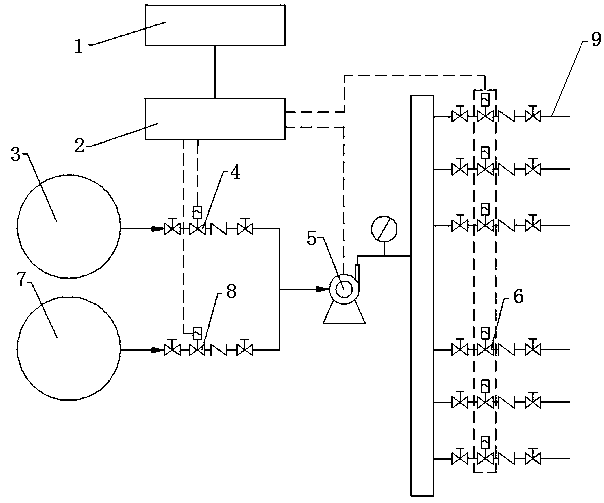

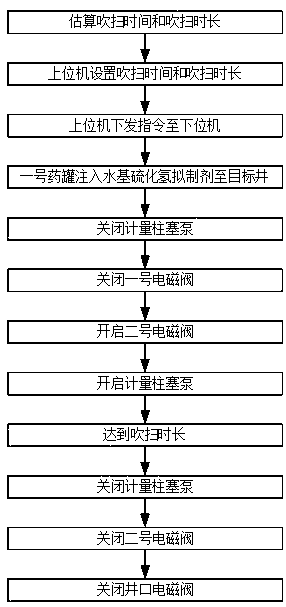

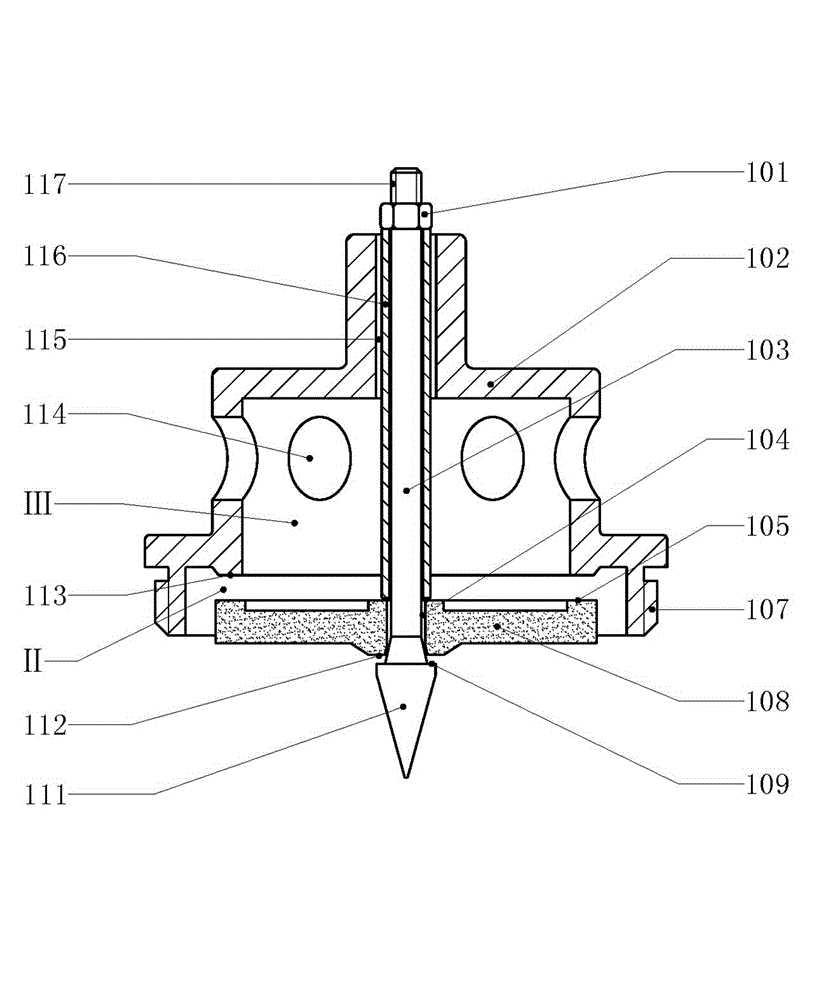

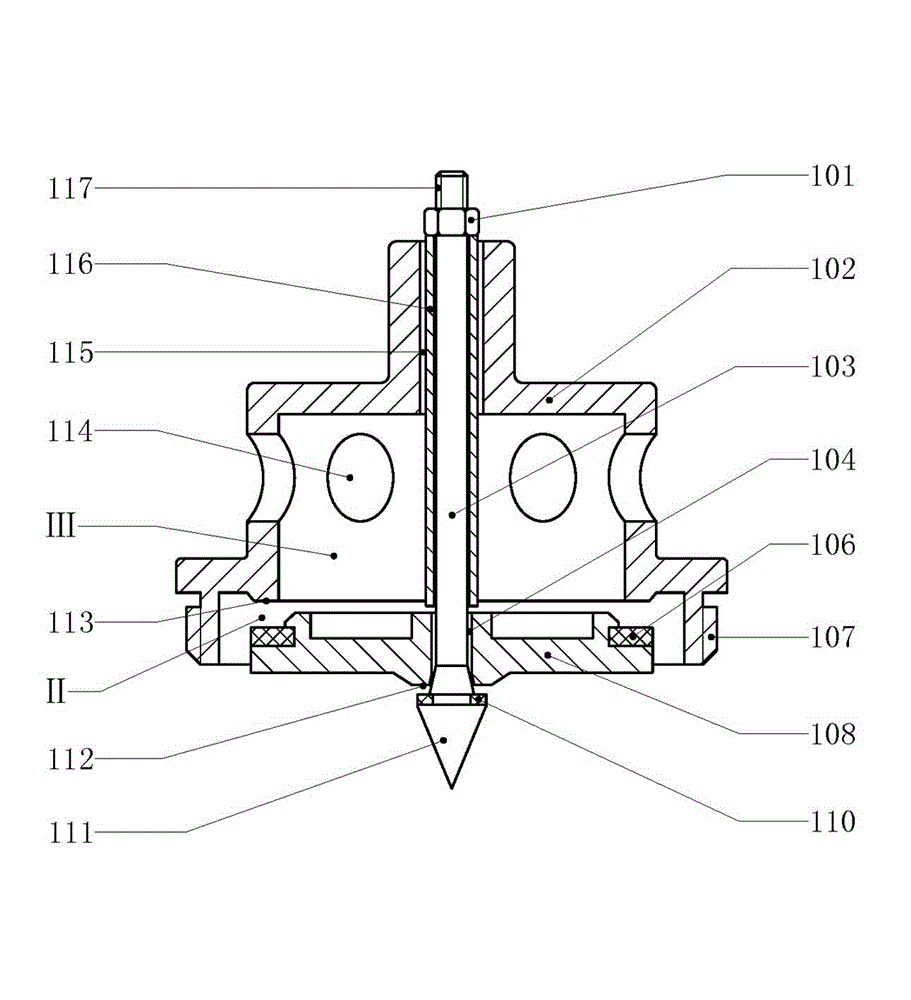

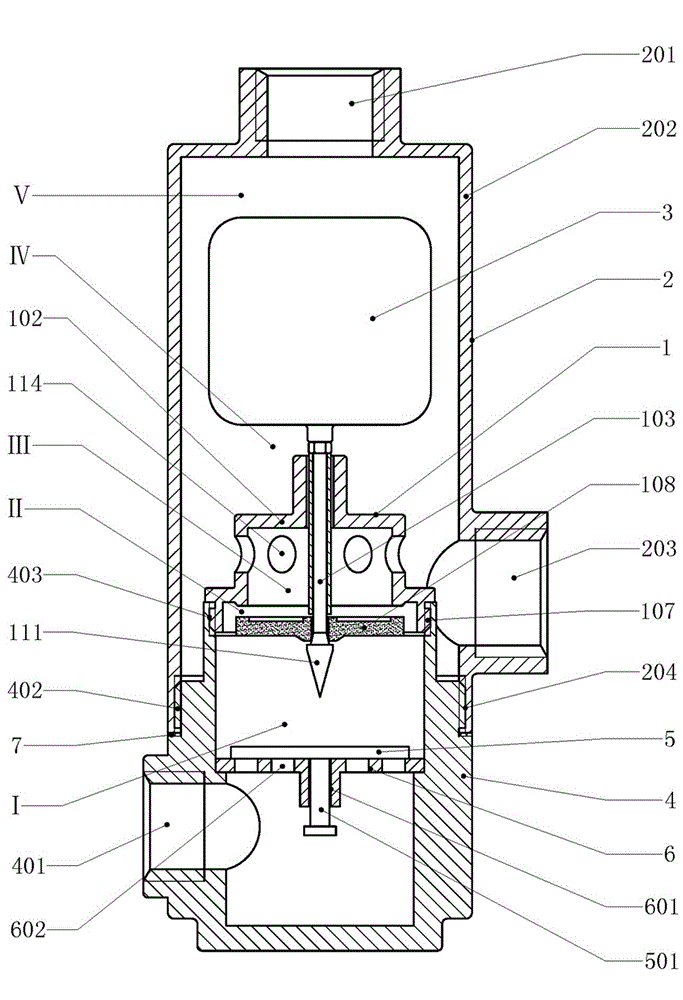

Antifreeze device for dual-reagent oil well wellhead dosing pipeline and antifreeze method

ActiveCN110485967ATo achieve anti-freeze blockageOvercome heat retentionCleaning apparatusWaxLine tubing

The invention provides an antifreeze device for a dual-reagent oil well wellhead dosing pipeline and an antifreeze method. During operation, purge time only needs to be set on a remote control terminal, an oil-based anti-wax remover with the antifreeze property is utilized to purge an entire dosing pipeline system, and after the dosing pipeline is filled with the oil-based anti-wax remover, an RTUcontrols a metering plunger pump and other solenoid valves to close to complete antifreeze. The disadvantages of large amount of construction and high energy consumption due to the fact that a dosingpipeline from a previous dosing device to a wellhead adopts heat tapes to perform antifreeze and heat preservation are overcome. Only the RTU is required to perform simple solenoid valve and pump control according to a program, and the antifreeze and anti-blockage of the pipeline can be realized. The operation is simple, the structure of the dosing device is greatly simplified, energy consumptionis saved, the construction cost is reduced, and on-site reliable operation of the dosing device in winter is ensured.

Owner:PETROCHINA CO LTD

Phenolic resin composite heat insulation material and preparation method thereof

InactiveCN106221120AOvercome heat retentionOvercome fire resistanceCarbon nanofiberP-Toluenesulfonic acid

The invention relates to a heat insulation material, and discloses a phenolic resin composite heat insulation material. The heat insulation material is prepared from, by weight, 50-100 parts of phenolic resin, 20-50 parts of film coated expanded perlite, 10-30 parts of pentane, 5-10 parts of p-toluenesulfonic acid, 1-5 parts of carbon nanofiber, 3-10 parts of surfactant and 0.5-3 parts of flexibilizer. The invention further provides a preparation method of the phenolic resin composite heat insulation material. The phenolic resin composite heat insulation material has the advantages of being good in heat insulation performance, flame retardance, fireproof performance and long-time anti-aging performance, stable in size, good in mechanical strength and the like; the production method is simple, capable of achieving continuous automatic production and suitable for being applied and popularized.

Owner:黄宝兴

Tandem built-in valve and liquid level control valve

InactiveCN103335114AImprove efficiencyEasy to useOperating means/releasing devices for valvesLift valveCircular discSolar water

The invention discloses a tandem built-in valve and relates to an automatic water replenishing valve. The tandem built-in valve mainly comprises a valve seat, a main valve plate and a pressure relief spool. The main valve plate is a disc body structure. A round through hole is formed in the center of the main valve plate. The valve seat is a circular cap structure. A sliding way for a connecting rod is arranged in the axial center of the rear end of the valve seat. The pressure relief spool is a cylindrical or conical structure. The connecting rod is connected rearwards from the center of the bottom end of the conical structure. After the connecting rod penetrates through the circular through hole in the center of the main valve plate, the connecting rod penetrates out from the sliding way in the center of the rear end of the valve seat. The circular through hole in the center of the main valve plate forms a pressure relief passage. A water flow through hole is formed on a wall body behind the sealing surface b of the valve seat. An assembling interface a is arranged at the front end of the valve seat and is connected to the lower valve body of a liquid level control valve. The tandem built-in valve is suitable for water tanks of solar water heaters and centralized heat supply systems, water towers of industrial and mining enterprises, firefighting water ponds and boiler water replenishing tanks.

Owner:深圳市金润建设工程有限公司

Building insulation board and preparation method thereof

The invention discloses a building insulation board. The building insulation board is characterized by being prepared from the following raw materials in parts by weight: 20-30 parts of walnut shell powder or coconut shell powder, 5-10 parts of polymer micro-hollow microspheres, 5-10 parts of hollow tubular carbon nanofibers, 2-5 parts of a double-shell hollow spherical organic metal framework, 10-20 parts of brucite fibers, 40-50 parts of Portland cement, 5-10 parts of steel fibers, 5-10 parts of hollow glass fibers, 5-10 parts of an adhesive material, 1-5 parts of an additive and 15-25 partsof water. The invention also discloses a preparation method of the building insulation board. According to the building thermal insulation board disclosed by the invention, the characteristics of light weight, high strength, fire resistance, self heat preservation, decoration, water resistance, sound insulation, antifreeze performance, low shrinkage rate, convenient preparation, greenness and environment friendliness are integrated into a whole, preparation cost is good, the thermal insulation effect is good, overall comprehensive performance is excellent, bending resistance is good, and theservice life is long.

Owner:大庆悦众塑料制品有限公司

Protective energy-saving high-pressure boiler

InactiveCN102908048AGood insulation performanceSlow down heat dissipationCooking utensils shields/jacketsPressure-cookersThermal insulationPlastic materials

The invention provides a protective energy-saving high-pressure boiler comprising a boiler body and a boiler lid matched with the boiler body, wherein the boiler lid is also provided with a housing; the housing is composed of a shell and an inner sleeve sleeved with the shell and is internally provided with a sealed cavity; the housing is provided with a valve position hole for avoiding a pressure-limiting valve; and a steam discharging clearance is arranged between the valve position hole and the peripheral side of a valve bonnet. The inner side of the housing is provided with a diversion trench for discharging oil and water. Thermal insulation materials can be filled in the cavity of the housing. The boiler body is provided with a thermal insulation cylinder made of foamed plastic material, and the lower part of the boiler body is provided with a thermal insulation sleeve gasket sleeved on the bottom of the high-pressure boiler and made of the foamed plastic material. The high-pressure boiler provided by the invention overcomes defects easily existed in the traditional thermal insulation technology, has more ideal protection, energy-saving and thermal insulation effects and is beneficial to energy conservation and emission reduction so as to have popularization and application values.

Owner:戴梦云

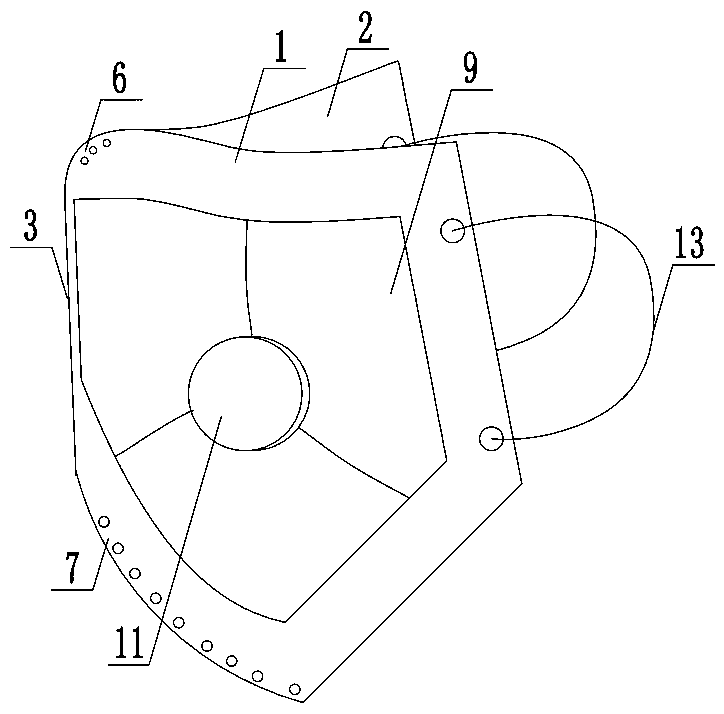

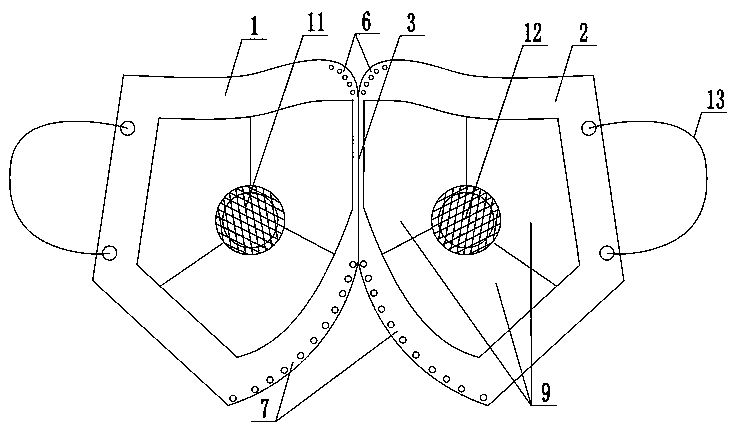

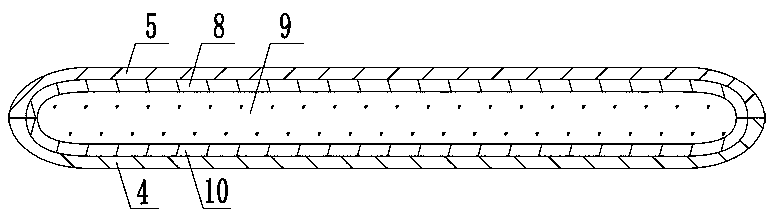

Heating mask

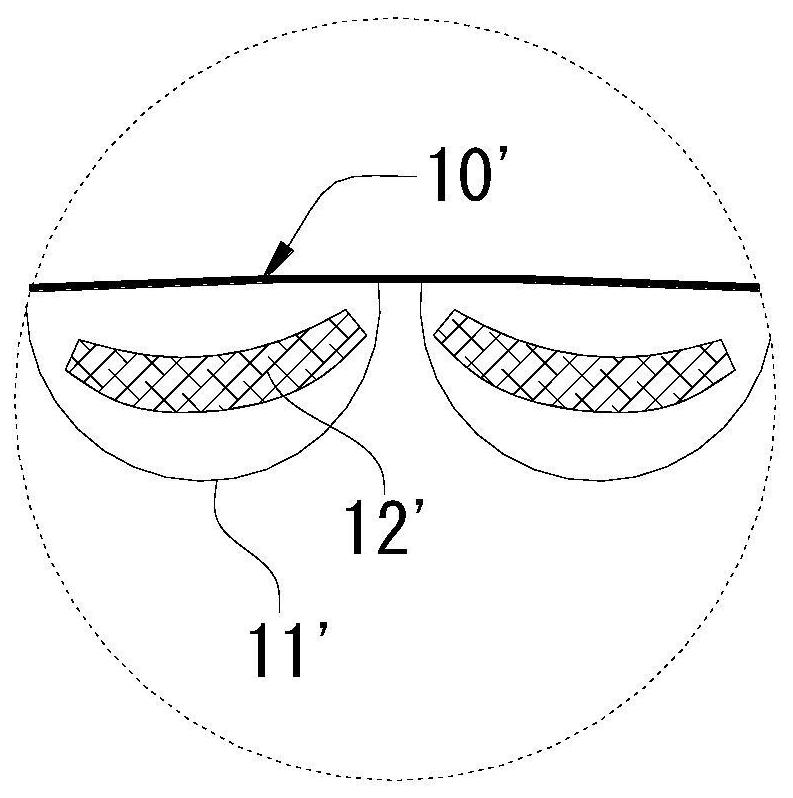

PendingCN110477486AAvoid the phenomenon of fallingImprove securityGarment special featuresProtective garmentHeating timeRespirator

The invention relates to a heating mask. The heating mask comprises a mask main body, the mask main body comprises a left mask body, a right mask body and a connecting part, wherein the left mask bodyand the right mask body are symmetrically arranged on two sides of the connecting part, each of the left mask body and the right mask body comprises an inner layer and an outer layer, the edge of theinner layer attaches to the edge of the outer layer, one side edges of the upper ends of the left mask body and the right mask body are in arc transition to form upper jaw parts, one side edges of the lower ends of the left mask body and the right mask body are in arc transition to form lower jaw parts, the upper jaw parts on two sides are connected, and the low jaw parts on two sides are connected; a heating area is formed between the non-edge position of the inner layer and the non-edge position of the outer layer, and an outer film layer, a heating mixed powder layer and an inner film layer are arranged in the heating area; and filtering units are arranged on the left mask body and the right mask body, and fixing belts are arranged on the left mask body and the right mask body. The heating mask is good in heating effect and long in heating time, the discomfort of a user can be alleviated, and the purpose of auxiliary treatment is achieved.

Owner:HENAN SUPER ASIA MEDICAL EQUIP

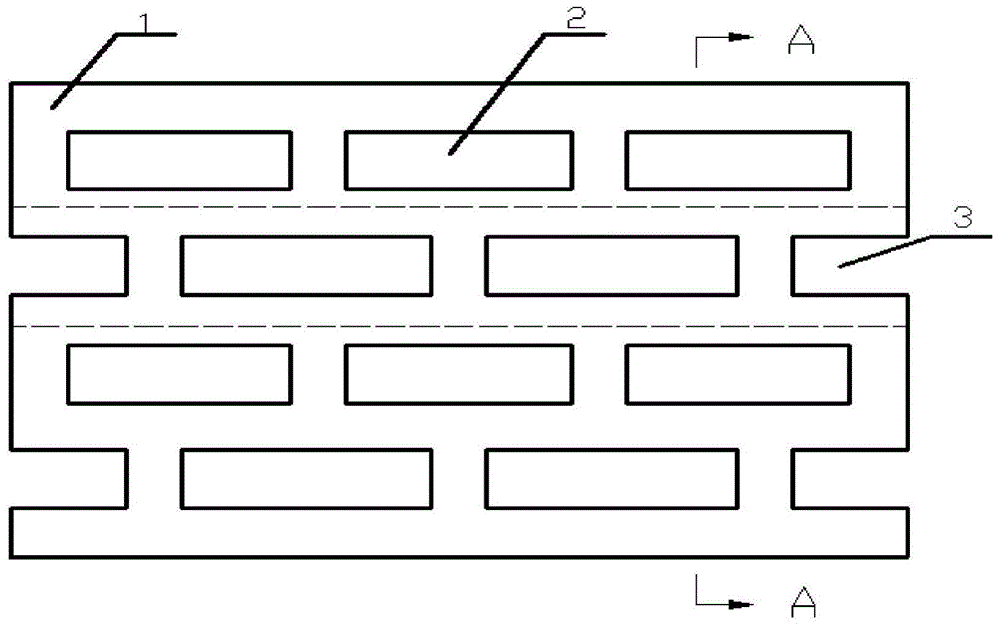

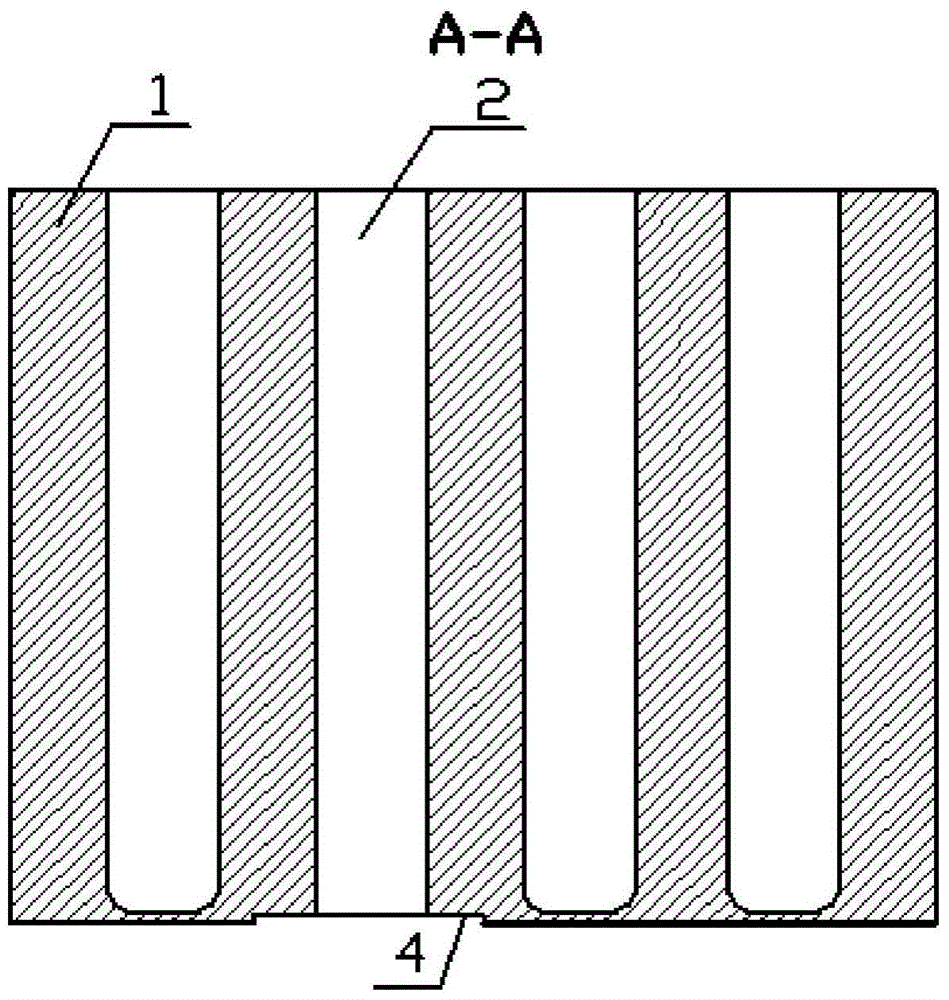

Ceramisite concrete self-heat-preservation masonry structure

InactiveCN105133780AReduce dosageReduce volumeConstruction materialThermal insulationExpanded clay aggregate

The invention discloses a ceramisite concrete self-heat-preservation masonry structure constructed through building blocks. Vertical hole grooves are formed in the self-heat-preservation building blocks. Opening grooves are formed in the outer side faces of the self-heat-preservation building blocks. Each self-heat-preservation building block comprises a blocking section in the middle and base body sections on the two sides of the blocking section. The hole grooves in the base body sections are blind holes with the tops closed. The hole grooves in the blocking sections are through holes. The blocking sections of every two horizontal adjacent self-heat-preservation building blocks are correspondingly arranged. The opening grooves of every two horizontal adjacent self-heat-preservation building blocks are correspondingly formed. A closed through hole formed by every two adjacent opening grooves is filled with a heat preservation material. Heat preservation plates are laid on the upper sides of the blocking sections. The ceramisite concrete self-heat-preservation masonry structure has the advantages that the building blocks have a good heat preservation and thermal insulation effect themselves, the cold and hot bridge effect of longitudinal and transverse mortar joint parts is effectively blocked through the design of structure heat preservation, and the requirement for saving energy by 65% to 75% can be achieved by painting buildings and inner faces and outer faces of walls only through ordinary building mortar.

Owner:SOUTHEAST UNIV

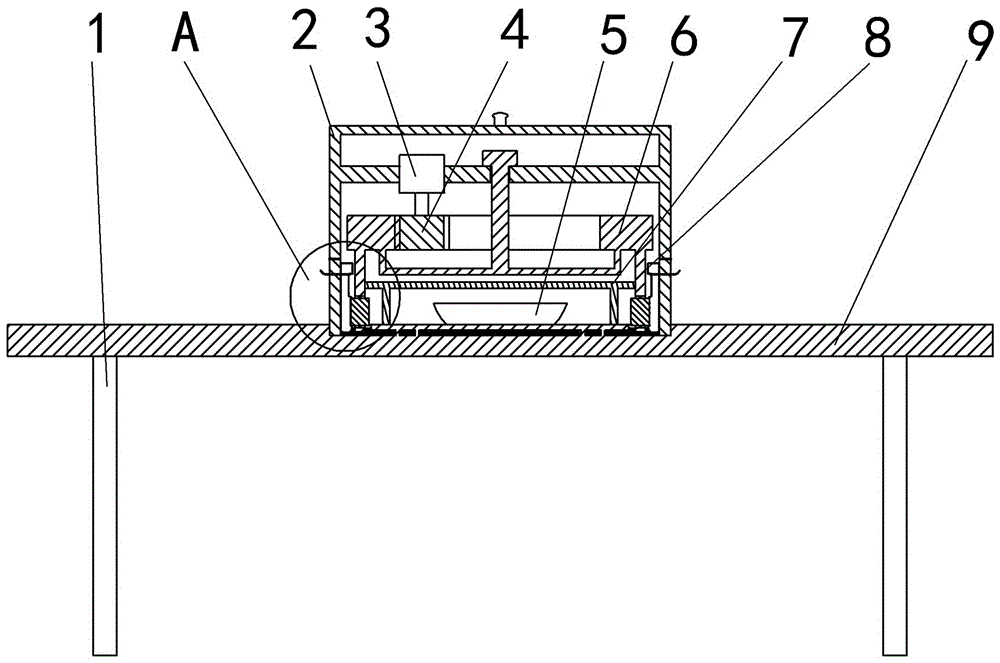

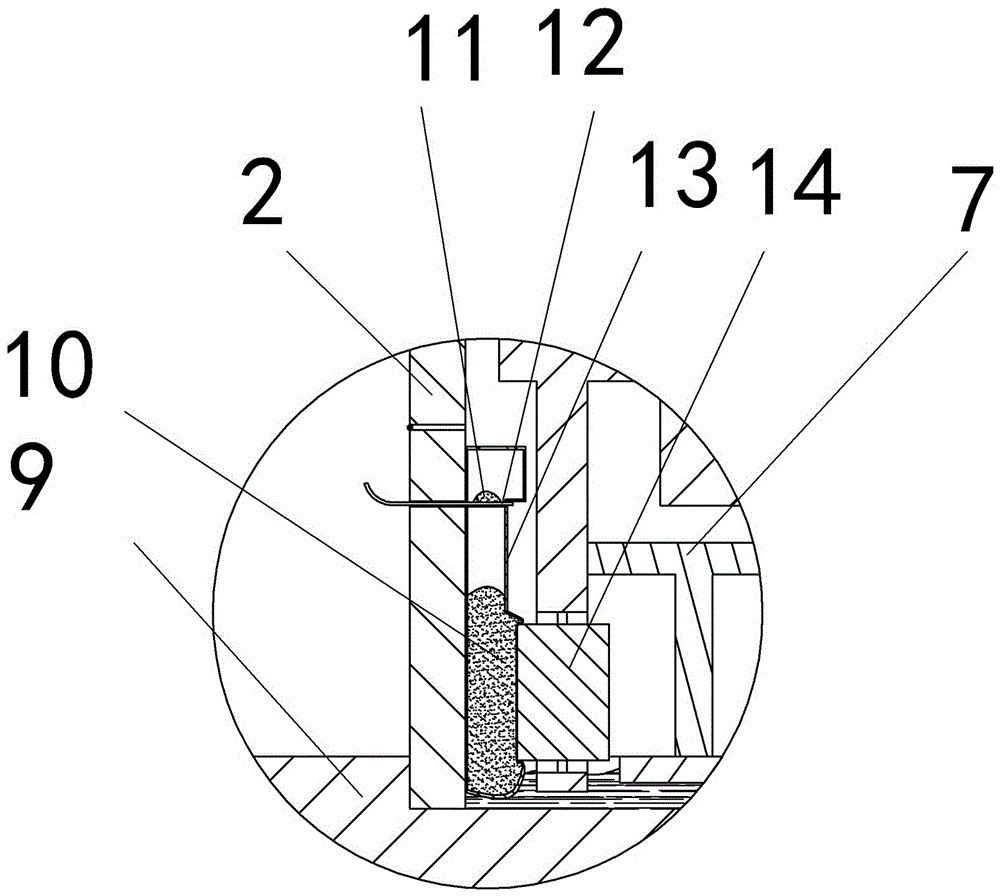

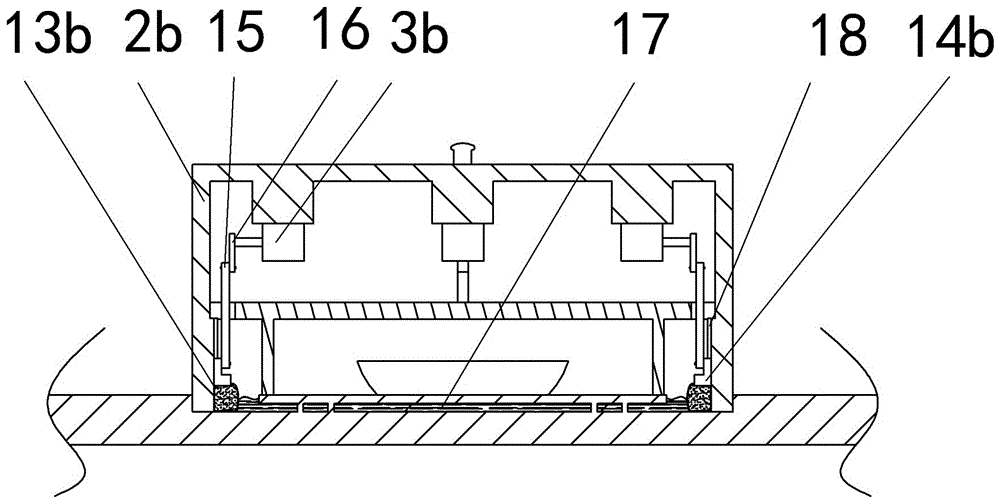

Thermal insulation table

ActiveCN107173995AOvercome heat retentionOvercome the problem that people who come home late can only eat cold dishesServing tablesThermal insulationEngineering

The invention belongs to the field of other table utensils, and particularly discloses a thermal insulation table. The thermal insulation table comprises a thermal insulation cover and a rotary driving device, wherein a water channel is formed in the tabletop; a spontaneous heating bag is arranged in the thermal insulation cover and is located in the water channel; the rotary drive device is connected with a pressing part for intermittently pressing the spontaneous heating bag; a separating part is detachably arranged in the spontaneous heating bag; thermal insulation powder and a thermal insulation additive are contained in the spontaneous heating bag; the thermal insulation power is located at the lower art of the separating part; and the thermal insulation additive is located at the upper part of the separating part. Air in the thermal insulation cover is heated by using the spontaneous heating bag to carry out thermal insulation or to heat dishes in the thermal insulation cover. The problem that an existing table cannot carry out thermal insulation on the dishes and people who come home late can only eat cold dishes is solved.

Owner:CHONGQING JIANLONG FURNITURE CO LTD

Composite light energy-saving thermal-insulation material and preparation method thereof

InactiveCN105110753AImprove insulation effectReduce weightSolid waste managementCalcium silicateThermal insulation

The invention discloses a composite light energy-saving thermal-insulation material and a preparation method thereof. The preparation method comprises 1, respectively crushing diatomite, meerschaum powder and calcium carbide, 2, respectively weighing 4-12 parts by weight of micro-porous calcium silicate, 4-9 parts by weight of alumina silicate fibers, 5-12 parts by weight of diatomite, 2-6 parts by weight of meerschaum powder and 3-6 parts by weight of calcium carbide, and carrying out mechanical stirring to obtain a uniform mixture, 3, adding 6-15 parts of polyamide 610, 3-8 parts of jute fibers, 4-9 parts of Teflon, 3-7 parts of dimethyl phthalate and 4-10 parts of polytrimethylene terephthalate fibers into the mixed powder obtained by the step 2, and carrying out heating stirring, and 4, carrying out pressing molding on the mixed materials, and then carrying out cooling to a room temperature so that the composite light energy-saving thermal-insulation material is obtained. The composite light energy-saving thermal-insulation material has the characteristics of light weight, compression resistance and thermal insulation.

Owner:SUZHOU KEMIAO NEW MATERIAL

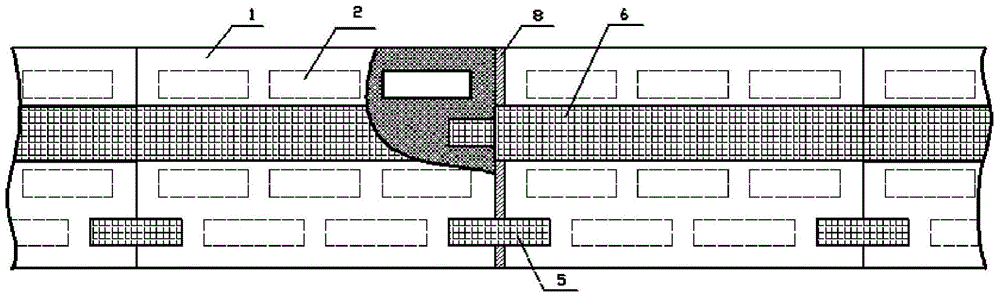

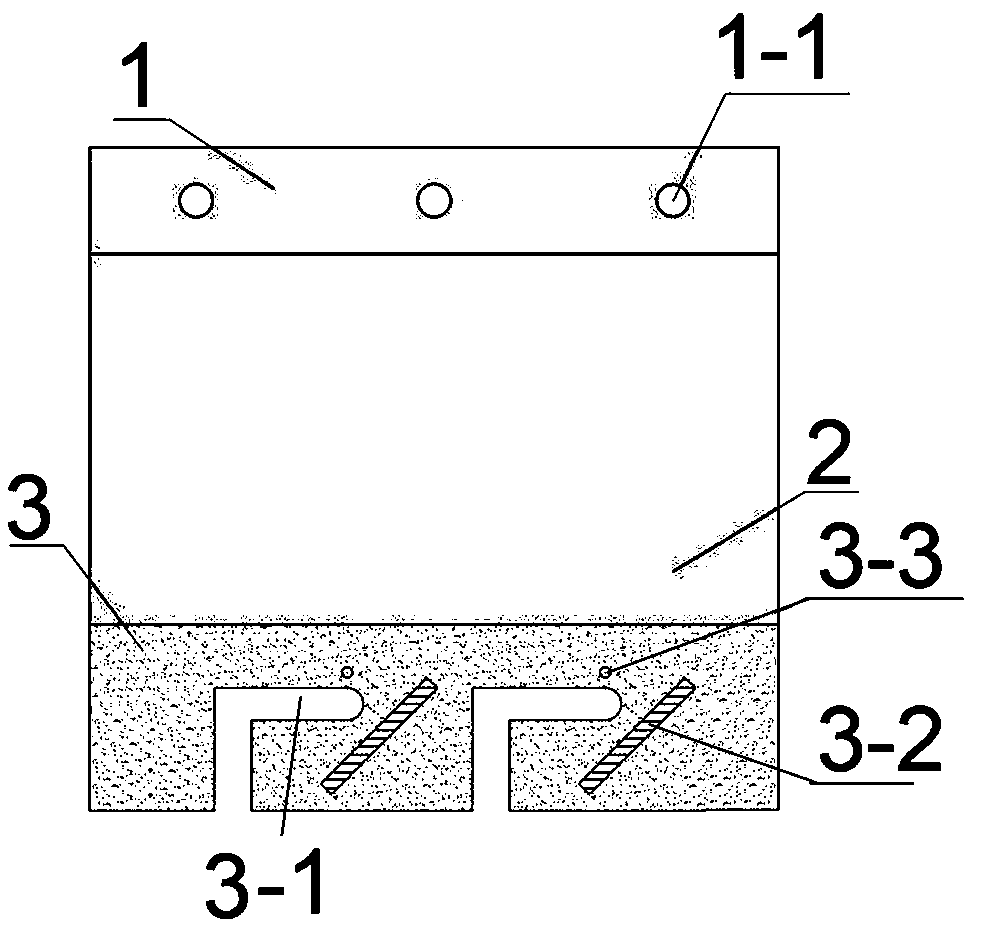

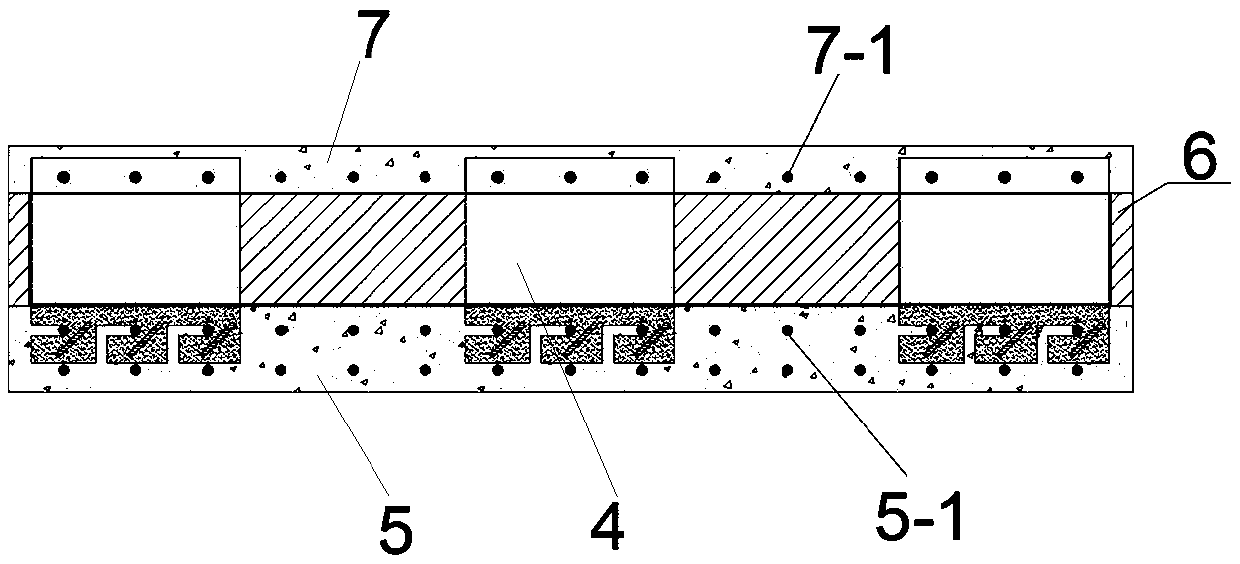

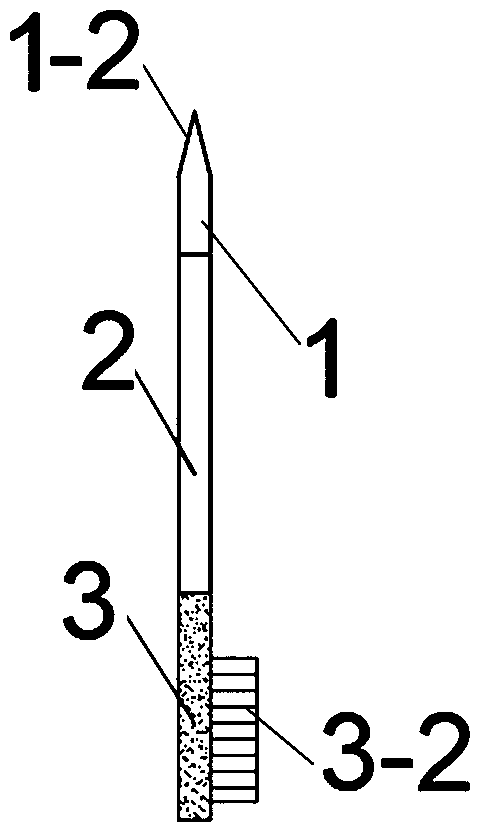

Connecting plate, multiplayer composite heat-preservation wall comprising same and construction method of multiplayer composite heat-preservation wall

The invention discloses a connecting plate, a multiplayer composite heat-preservation wall comprising the same and a construction method of the multiplayer composite heat-preservation wall. The connecting plate comprises an upper-layer steel bar connecting area, a blade part arranged on the top face of the upper-layer steel bar connecting area, a middle-layer heat-preservation layer connecting area and a lower-layer steel bar connecting area, and the upper-layer steel bar connecting area is provided with two or more connecting holes used for allowing steel bars to penetrate; and the lower-layer steel bar connecting area comprises two or more steel bar clamping grooves, local reinforcing bars and steel bar binding wire holes, the two or more steel bar clamping grooves are formed in the lower part of the lower-layer steel bar connecting area at intervals, the steel bar binding wire holes are formed in the positions, close to one side of the middle-layer heat-preservation layer connectingarea, above the steel bar clamping grooves, and the local reinforcing bars are parallelly arranged in the lower-layer steel bar connecting area at intervals. The connecting plate is ingenious in design, simple in structure and good in forming effect. The problems that a fiber reinforced plastic connecting part in the present stage is low in strength and cannot connect thick heat-preservation layers, and a cold bridge is prone to occurring during using of steel are solved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

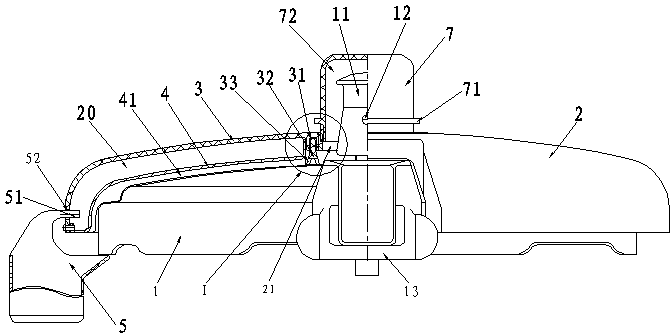

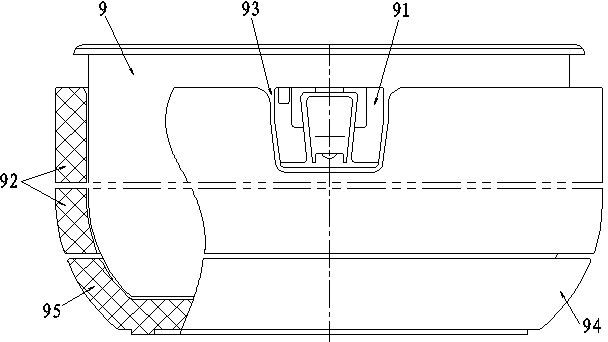

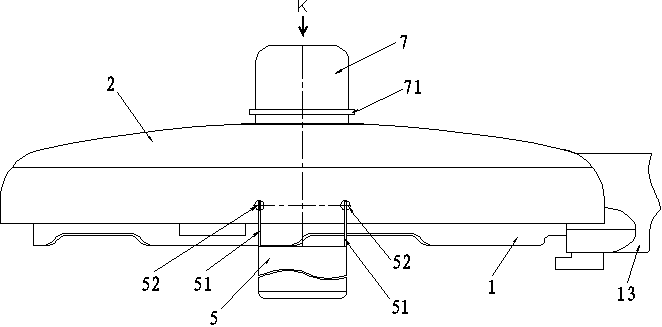

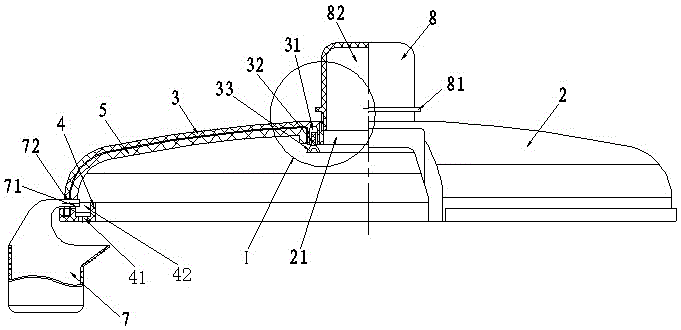

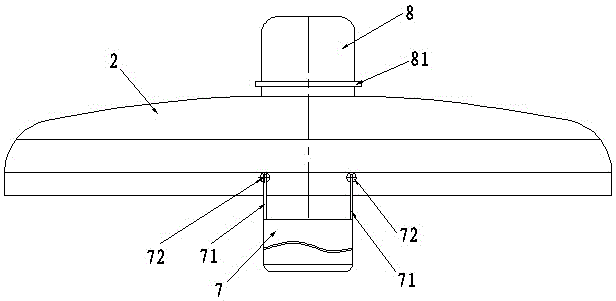

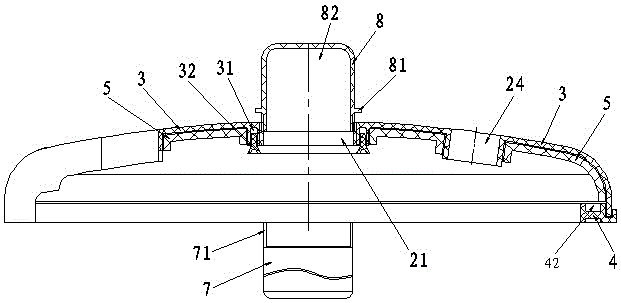

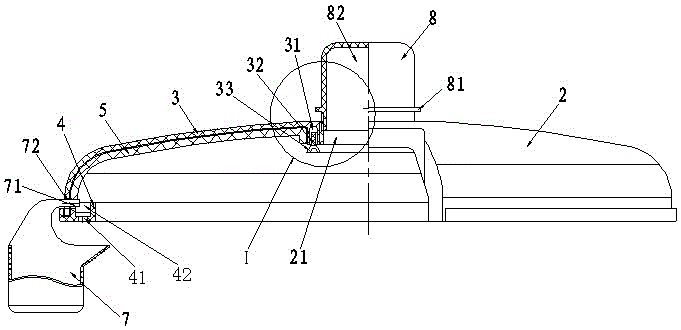

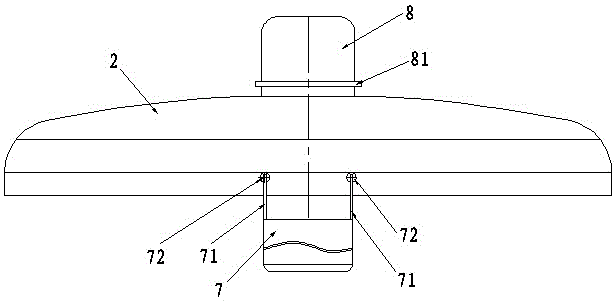

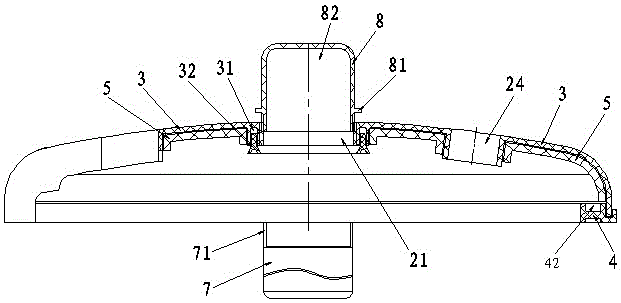

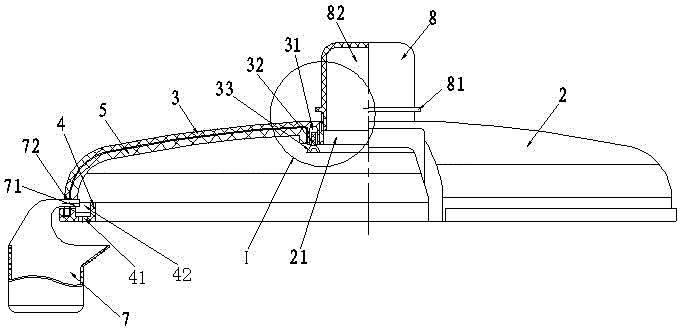

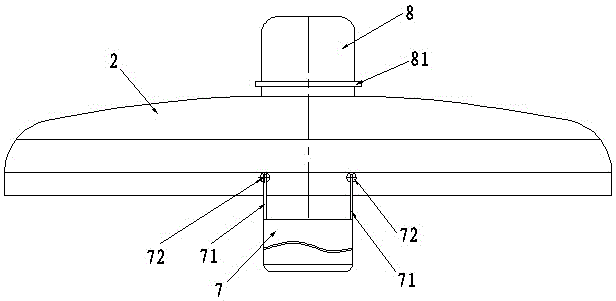

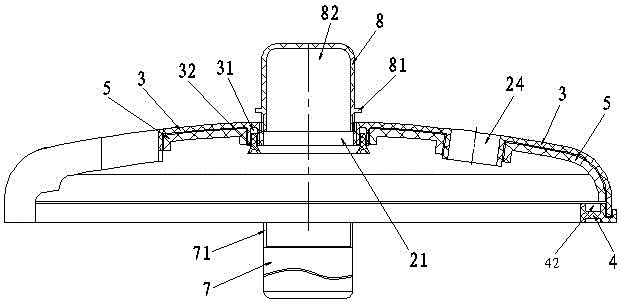

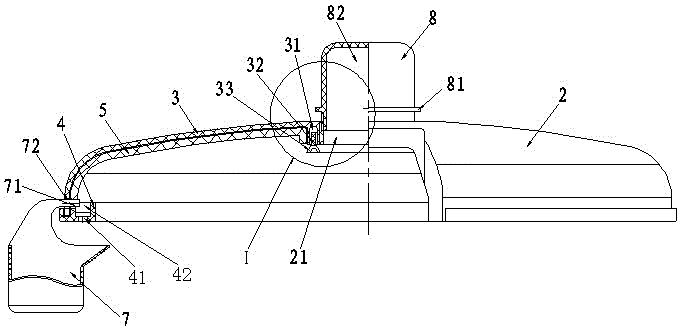

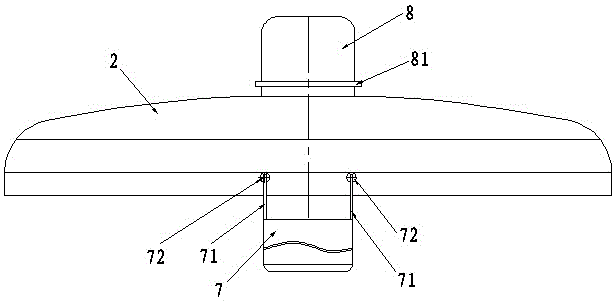

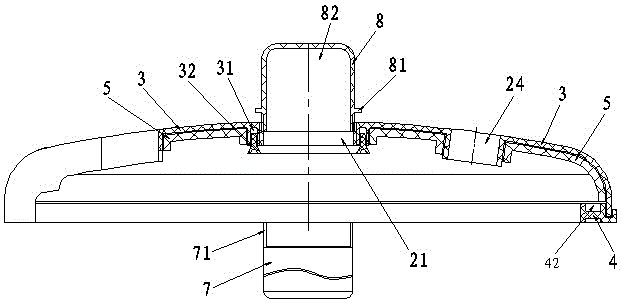

Protective energy-saving cover of pressure cooker

InactiveCN105725764AImprove the protective effectReduce surface temperatureCooking-vessel materialsCooking utensils shields/jacketsEngineeringOil water

The invention provides a protective energy-saving cover of a pressure cooker. The protective energy-saving cover comprises a cooker cover 1 composed of a cover handle, a pressure-limiting valve and other safety components. The cooker cover 1 is provided with a casing 2 composed of a shell 3 and a side enclosing sleeve 4. The shell 3 and the side enclosing sleeve 4 are made of plastics. The side enclosing sleeve 4 and the shell 3 are closely matched, and the side enclosing sleeve 4, the shell 3 and the cooker cover 1 are sealed. The shell 3 is provided with a clearance hole 22, a valve position hole 21 and other receding hole grooves. The casing 2 and the cooker cover 1 form a cavity 23. The peripheral edge of the upper end of the valve position hole 21 is not higher than the lower edge of a cap hole 12. A gap exists between the lower end face of the valve position hole 21 and the surface of the cooker cover 1. The side enclosing sleeve 4 is provided with a discharge port 41. An oil water cup 7 is arranged in the outlet position of the discharge port 41. The shell 3 is provided with a cover cap 8. A lining 5 is arranged on the inner side wall of the shell 3. The protective energy-saving cover is adopted to the pressure cooker, and when the protective energy-saving cover is used for cooking, the protective energy-saving cover has the good safety protection function and the energy-saving and heat-preserving effects, is beneficial to energy conservation and emission reduction and has application and popularization value.

Owner:戴梦云

Protective energy-saving cover of pressure cooker

InactiveCN105725767AImprove the protective effectReduce surface temperatureCooking utensils shields/jacketsPressure-cookersRubber ringEngineering

The invention provides a protective energy-saving cover of a pressure cooker. The protective energy-saving cover comprises a cooker cover 1 composed of a cover handle, a pressure-limiting valve and other safety components. The cooker cover 1 is provided with a casing 2 composed of a shell 3 and a side enclosing sleeve 4. The shell 3 and the side enclosing sleeve 4 are made of plastics. The side enclosing sleeve 4 and the shell 3 are closely matched, and the side enclosing sleeve 4, the shell 3 and the cooker cover 1 are sealed. The shell 3 is provided with a clearance hole 22, a valve position hole 21 and other receding hole grooves. The casing 2 and the cooker cover 1 form a cavity 23. The peripheral edge of the upper end of the valve position hole 21 is not higher than the lower edge of a cap hole 12. The lower end of the valve position hole 21 is provided with a loop groove 31, a rubber ring 32 and an overflow port 33 of the rubber ring 32. The side enclosing sleeve 4 is provided with a discharge port 41 and a flow guide groove 42. An oil water cup 7 is arranged in the outlet position of the discharge port 41. The shell 3 is provided with a cover cap 8. A lining 5 is arranged in the shell 3. The protective energy-saving cover is adopted to the pressure cooker, and when the protective energy-saving cover is used for cooking, the protective energy-saving cover has the good safety protection function and the energy-saving and heat-preserving effects, is beneficial to energy conservation and emission reduction and has application and popularization value.

Owner:戴梦云

Protective energy-saving hood of pressure cooker

InactiveCN105725756AReduce surface temperatureImprove the protective effectCooking utensils shields/jacketsPressure-cookersEngineeringEnergy conservation

The invention provides a protective energy-saving hood of a pressure cooker.The protective energy-saving hood of the pressure cooker comprises a housing 2 composed of shells 3 and side encircling sleeves 4; the shells 3 and the side encircling sleeves 4 are both made from plastic cement; the side encircling sleeves 4 are closely matched with the shells 3 and sealed to a cooker cover 1; each shell 3 is provided with a clearance groove 22, a valve position hole 21 and other clearance hole grooves, and the lower end faces of the clearance hole grooves are sealed to the surface of the cooker cover 1; a closed cavity 23 is defined by the housing 2 and the cooker cover 1; the peripheral edge of the upper end of each valve position hole 21 is not higher than the lower edge of a cap hole 12; an interval is set between the lower end face of each valve position hole 21 and the surface of the cooker cover 1; each side encircling sleeve 4 is provided with a flow discharge port 41; each shell 3 is provided with a hood cap 8 matched with the corresponding valve position hole 21; the inner side wall of each shell 3 is provided with a liner 5 made from foaming plastic cement.The protective energy-saving hood is used on the pressure cooker cover in a matched mode and has the safety protection effect and the energy-saving and heat-preserving effects, cooking of the pressure cooker can be made convenient, and the protective energy-saving hood facilitates energy conservation and emission reduction, so that the protective energy-saving hood has application and popularization value.

Owner:戴梦云

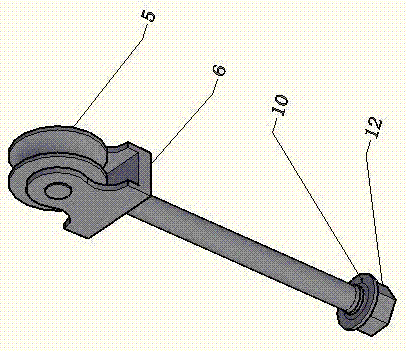

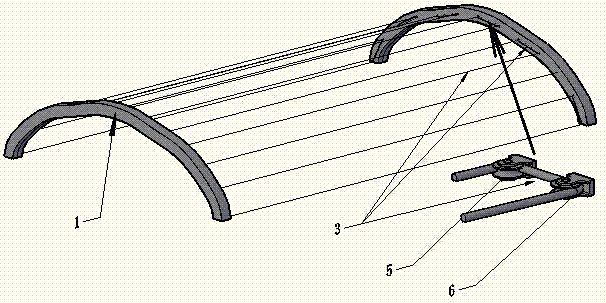

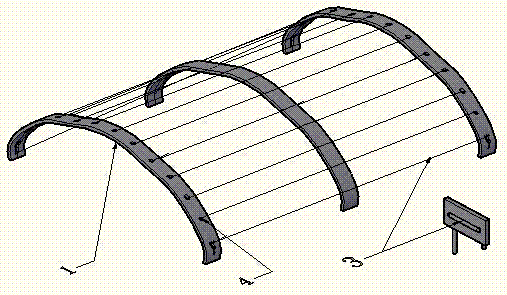

Vertical support efficient insulating plastic greenhouse with ultra-long service life

InactiveCN107094532AImprove insulation effectHigh light transmittanceClimate change adaptationGreenhouse cultivationGreenhouseTransmittance

The invention provides a vertical support efficient insulating plastic greenhouse with ultra-long service life, solving the problems of low light transmittance, poor heat insulating ability and high cost for constructing the greenhouse bodies of common greenhouses. A greenhouse body is formed by reciprocatingly connecting stay wires on frames, wherein the frames comprise end frames and intermediate frames and the frames can be configured into transparent plate structures so that the greenhouse body has higher light transmittance; the multilayered structure of frames and the stay wires increase the heat insulating ability. The greenhouse is low in construction cost and has service life as long as 100 years and above.

Owner:邱自文

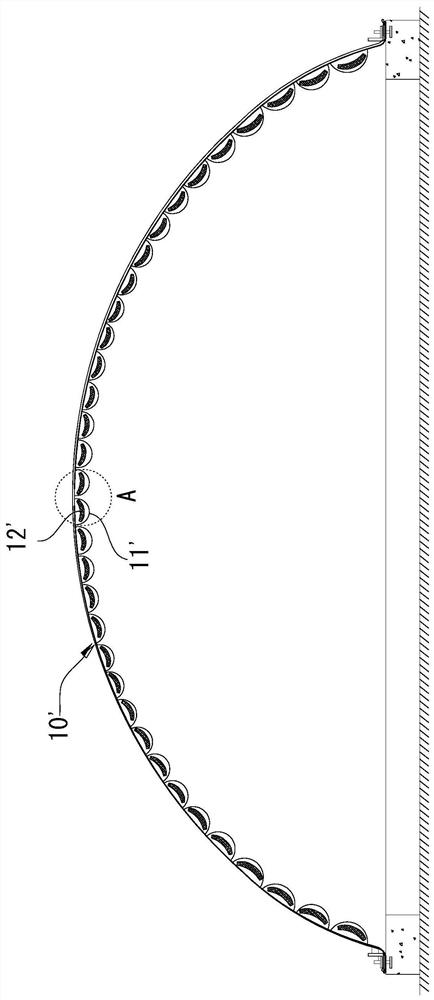

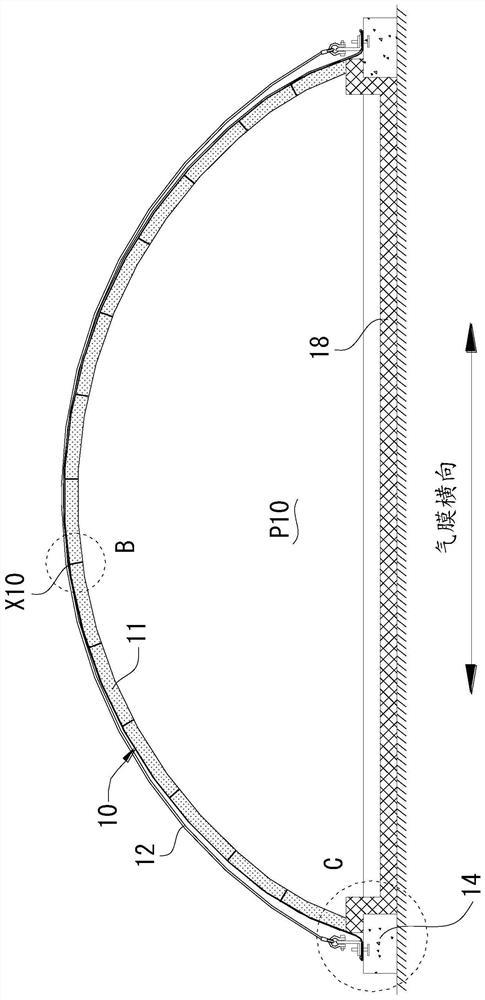

Large-span gas film ultralow-temperature environment heat insulation device

InactiveCN113152680AGood insulation performanceLow thermal conductivityArched structuresVaulted structuresAdhesiveEngineering

The invention discloses a large-span gas film ultralow-temperature environment heat insulation device. The large-span gas film ultralow-temperature environment heat insulation device comprises a gas film and a heat insulation pasting material layer, wherein the edge of the gas film is sealed on a base body to define a building space; the heat insulation material pasting layer is located in the building space, and the heat insulation material pasting layer is pasted on the inner wall of the gas film through an adhesive. The large-span gas film ultralow-temperature environment heat insulation device is good in heat insulation and heat preservation effect and is particularly suitable for ultralow-temperature environments such as refrigeration houses and ski fields, the requirement for the heat insulation and heat preservation effect in the environments is met, and the energy consumption and the operation cost are reduced; in addition, the service life is long, and the structure is simple.

Owner:SHENZHEN ZHONGDE MEMBRANE STRUCTURE CO LTD

Preparation method of environment-friendly and sound-insulating wood-plastic wall material

The invention discloses a preparation method of an environment-friendly and sound-insulating wood-plastic wall material. The preparation method comprises steps as follows: a, wood fiber materials, montmorillonite, wood leftover materials, manganolite, fluorapatite, Jutecell fibers, antimony trioxide, silicone powder, silkworm excrement, carbonized graphite and vermiculite powder are added to a high-speed mixer, a coupling agent solution is dropwise added, the mixture is heated and stirred, and a mixture M is obtained; b, after the mixture M is cooled, sebacic acid dibutyl ester, azelaic acid dibutoxy ethyl ester, butyl acrylate, diisopropylbenzene hydroperoxide, dioctyl phthalate and maleic anhydride grafted polyethylene are added, the mixture is stirred uniformly, and a mixture N is obtained; c, the mixture N is extruded and granulated, and master batch is obtained; d, the master batch obtained in the step c is processed and formed, and the wood-plastic wall material is obtained. According to the prepared wood-plastic wall material, the problems that a conventional sound-insulating wall material is prone to ageing and has poor thermal insulation and sound insulation effects are solved.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Protective energy-saving hood of pressure cooker

InactiveCN105725761AReduce surface temperatureImprove the protective effectCooking utensils shields/jacketsPressure-cookersEngineeringEnergy conservation

The invention provides a protective energy-saving hood of a pressure cooker.The protective energy-saving hood of the pressure cooker comprises a housing 2 composed of shells 3 and side encircling sleeves 4; the side encircling sleeves 4 are closely matched with the shells 3 and sealed to a cooker cover 1; each shell 3 is provided with a clearance groove 22, a valve position hole 21 and other clearance hole grooves; a cavity 23 is defined by the housing 2 and the cooker cover 1; the peripheral edge of the upper end of each valve position hole 21 is not higher than the lower edge of a cap hole 12; an interval is set between the lower end face of each valve position hole 21 and the surface of the cooker cover 1; each side encircling sleeve 4 is provided with a flow discharge port 41 and a flow guiding groove 42; the outlet position of each flow discharge port 41 is provided with an oil and water cup (7); each shell 3 is provided with a hood cap 8 matched with the corresponding valve position hole 21; the inner side wall of each shell 3 is provided with a liner 5 made from foaming plastic cement.The protective energy-saving hood is used on the pressure cooker cover in a matched mode and has the safety protection effect and the energy-saving and heat-preserving effects, cooking of the pressure cooker can be made convenient, and the protective energy-saving hood facilitates energy conservation and emission reduction, so that the protective energy-saving hood has application and popularization value.

Owner:戴梦云

Method of preparing light insulating batten from salt gypsum and plant straws and light insulating batten prepared thereby

The invention discloses a method of preparing a light insulating batten from salt gypsum and plant straws and the light insulating batten prepared thereby. A raw material is prepared from a main material and auxiliary materials. The main material is prepared from the following components in percent by weight: 40-60wt% of salt gypsum, 30-45wt% of building gypsum and 10-15wt% of white cement. The raw material is prepared from the auxiliary materials in percent by weight: 1-3wt% of plant straws, 0.15-0.20wt% of a retarder, 0.05-0.20wt%of fibers, 0.5-2.0wt% of a water reducer and 0.3-1.0wt% of anactivator. The method comprises the following steps: first, uniformly mixing the retarder, the water reducer and the activator; adding the mixture into water which accounts for 20-30wt% of total weight of the main material to be stirred; then successively adding residual materials; uniformly stirring the mixture in a stirrer; adding the mixture into a mold; maintaining the mold to a regulated age;and removing the mold and airing the mixture to obtain the light insulating batten. The light insulating batten is free of radioactivity, good in insulating effect and high in compressive strength, and the production cost of the light insulating batten is lowered.

Owner:HENAN UNIV OF URBAN CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com