Organic/inorganic compound thermal insulation material and preparation method

A technology of composite thermal insulation materials and main raw materials, which is applied in the field of thermal insulation materials and their preparation, can solve the problems of thermal insulation performance degradation of final expanded perlite products, thermal insulation performance degradation, foam body damage, etc., and achieves adjustable and easy performance indicators. control, good fire resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

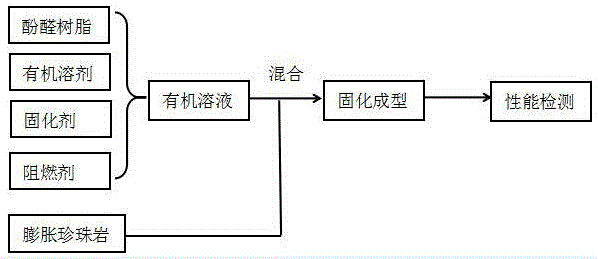

Method used

Image

Examples

Embodiment 1

[0028] (1) Dilute the thermosetting phenolic resin with 30% ethanol; choose a bulk density of 90~120 kg / m 3 Spherical closed-cell expanded perlite; choose silicone water repellent, benzenesulfonic acid and phosphoric acid as curing agent, red phosphorus and ammonium polyphosphate as flame retardant, KH550 coupling agent;

[0029] (2) According to the mass fraction of resin 50%, expanded perlite 50%, additives accounting for 58% of phenolic resin (including 1% of benzenesulfonic acid, 5% of phosphoric acid, 2% of KH550, and 50% of flame retardant) to prepare raw materials;

[0030] (3) After mixing various additives and phenolic resin evenly, add expanded perlite to the above mixture, stir well and put it into a steel mold;

[0031] (4) Put the compacted material into a drying oven and cure it at 100°C for 3 hours to obtain a composite insulation board with phenolic resin and perlite as the main raw materials;

[0032] (5) The obtained phenolic resin / perlite composite insulati...

Embodiment 2

[0034] (1) Dilute the thermosetting phenolic resin with 30% ethanol; choose a bulk density of 90~120 kg / m 3 Spherical closed-cell expanded perlite; choose silicone water repellent, benzenesulfonic acid and phosphoric acid as curing agent, red phosphorus and ammonium polyphosphate as flame retardant, KH550;

[0035] (2) According to the mass fraction of phenolic resin resin 50%, expanded perlite 50%, additives accounted for 62% of phenolic resin (including benzenesulfonic acid 4%, phosphoric acid 4%, KH550 4%, flame retardant 50%) to prepare raw materials;

[0036] (3) After mixing various additives and phenolic resin evenly, add expanded perlite to the above mixture, stir well and put it into a steel mold;

[0037] (4) Put the compacted material into a drying oven and cure it at 100°C for 3 hours to obtain a composite insulation board with phenolic resin and perlite as the main raw materials;

[0038] (5) The obtained phenolic resin / perlite composite insulation material sampl...

Embodiment 3

[0040] (1) Dilute the thermosetting phenolic resin with 30% ethanol; choose a bulk density of 90-120 kg / m 3 Spherical closed-cell expanded perlite; choose silicone water repellent, benzenesulfonic acid and phosphoric acid as curing agent, red phosphorus and ammonium polyphosphate as flame retardant, KH550;

[0041] (2) According to the mass fraction of phenolic resin 45%, expanded perlite 55%, additives accounted for 39% of phenolic resin (including benzenesulfonic acid 2%, phosphoric acid 5%, KH550 2%, flame retardant 30%) to prepare raw materials;

[0042] (3) After mixing various additives and phenolic resin evenly, add expanded perlite to the above mixture, stir well and put it into a steel mold;

[0043] (4) Put the compacted material into a drying oven and cure it at 100°C for 3 hours to obtain a composite insulation board with phenolic resin and perlite as the main raw materials;

[0044] (5) The obtained phenolic resin / perlite composite insulation material sample has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com