Ply-rolling pack for pack ply-rolling of titanium alloy sheet

A technology of titanium alloy plates and stacked rolling ladles, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as mutual movement of titanium alloy core plates, folding of core titanium alloy plates, and cracking of cladding , to achieve the effect of uniform size, good performance, and avoid pitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

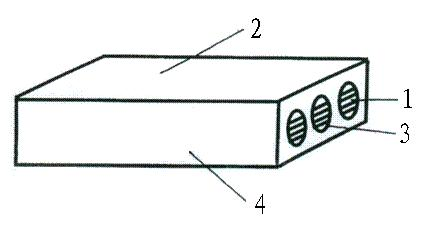

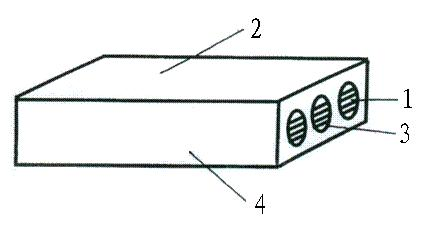

[0016] A rolling package for cladding and rolling titanium alloy sheets, the structure of which comprises: a rolling core block 1—a square block-shaped core block formed by directly stacking titanium alloy plates; a rolling covering sleeve 2— The cladding sleeve includes cladding steel plates attached to the uppermost and lowermost titanium alloy plates of the stacked rolling core block, side sealing steel plates attached to the side of the stacked rolling core block, and the steel plates are welded to each other to form a square cladding , and a through hole 3 is opened on the opposite pair of side sealing steel plates.

[0017] During production, 2~6 layers of titanium alloy sheets with a thickness of 1.5~20mm are stacked and placed as stacked rolling core blocks, and no release agent is used between the core sheets of titanium alloy sheets; Steel plate; After assembling and clamping the clad steel plate and the titanium alloy core plate, use 5~20mm thick steel plate 3 as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com