Tandem built-in valve and liquid level control valve

A series, valve plate technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problem of wasting water resources, save time, overcome lax and tight closing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

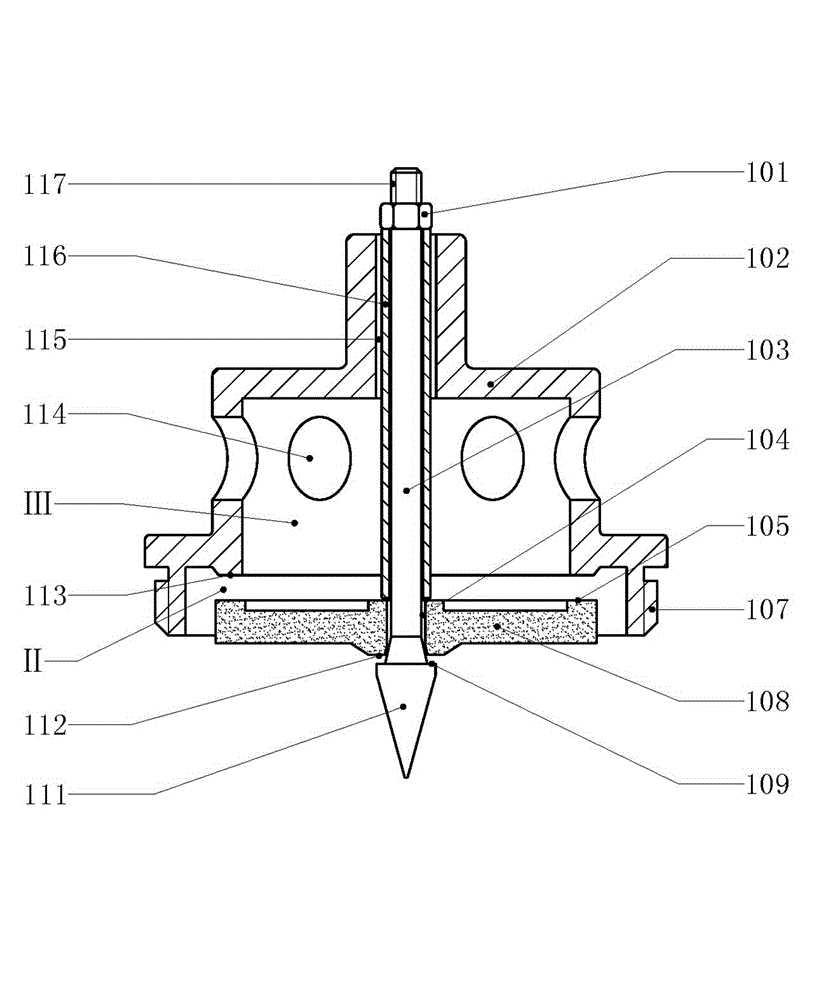

Embodiment 1

[0016] Embodiment 1 Attached figure 1 In the shown embodiment, the tandem built-in valve is mainly composed of a valve seat (102), a main valve plate (108) and a pressure relief valve core (111). The front end of the built-in valve faces downward, and the pressure relief valve core (111) passes through The connecting rod (103) connects the main valve plate (108) and the valve seat (102) in coaxial series from bottom to top, wherein the main valve plate (108) is a disc structure, and the center of the main valve plate (108) has A circular through hole; the valve seat (102) is a dome structure, and the axial center of the rear end of the valve seat (102) has a slideway (115) for the connecting rod; the pressure relief valve core (111) is a cone structure, and the connecting rod (103) is connected from the center of the rear end of the cone; the connecting rod (103) on the pressure relief valve core (111) passes through the circular through hole in the center of the main valve pl...

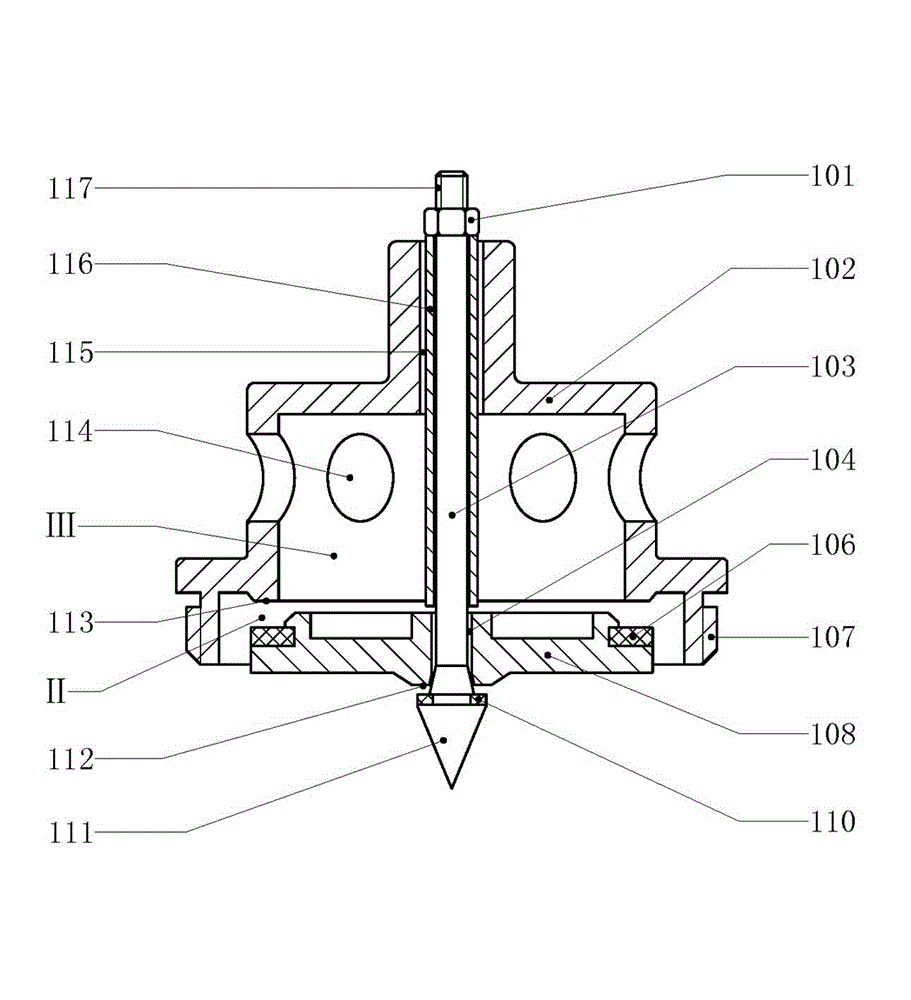

Embodiment 2

[0017] Embodiment 2 Attached figure 2 In the shown embodiment, on the basis of the first embodiment, the sealing surface a (105) on the main valve plate (108) is replaced by the rubber gasket a (106), and on the rear end surface of the main valve plate (108) There is an annular bayonet, and the rubber pad a (106) is fixed by the annular bayonet; there are snap rings and rubber pad b (110) on the annular end face of the rear end of the pressure relief valve core (111), and the rubber pad b (110) is fixed by The snap ring is fixed, and the rubber pad b (110) is matched with the sealing surface d (112) at the front end of the main valve plate (108). Other features of this embodiment are the same as those of the first embodiment and will not be repeated here.

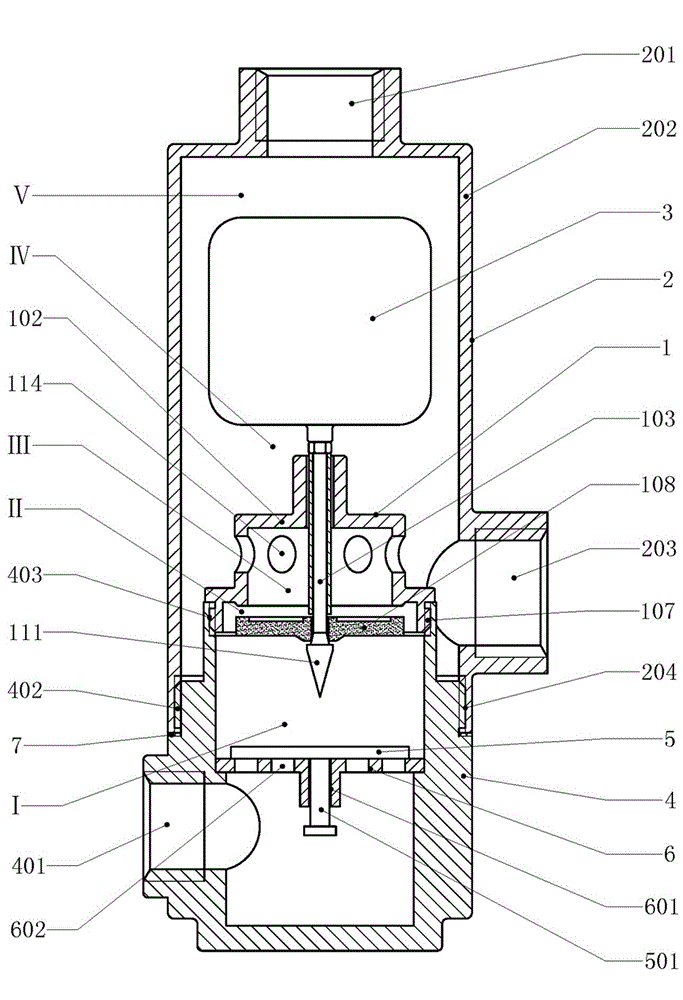

Embodiment 3

[0018] Example 3 Attached image 3In the shown embodiment, the liquid level control valve is mainly composed of a built-in valve (1), an upper valve body (2), a float (3) and a lower valve body (4), wherein the built-in valve (1) is a series structure, The built-in valve (1) consists of a valve seat (102), a main valve plate (108) and a pressure relief valve core (111). The main valve plate (108) is a disc structure, and the center of the main valve plate (108) has a The circular through hole in the center of the main valve plate (108) constitutes the pressure relief channel (104), and the peripheral annular end surface of the front end of the pressure relief channel (104) forms the sealing surface d (112). The outer ring-shaped end surface of the valve end constitutes the sealing surface a (105); the valve seat (102) is a dome structure, and there is a slideway (115) of the connecting rod in the center of the rear end of the valve seat (102), and the valve seat (102) There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com