Connecting plate, multiplayer composite heat-preservation wall comprising same and construction method of multiplayer composite heat-preservation wall

A technology of connecting plates and connecting areas, which is applied in the field of multi-layer composite thermal insulation walls and its construction, can solve the problems of low strength, easy cold bridges, and inability to connect insulation layers, etc., and achieve good forming effects, tight connection effects, Various layout effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

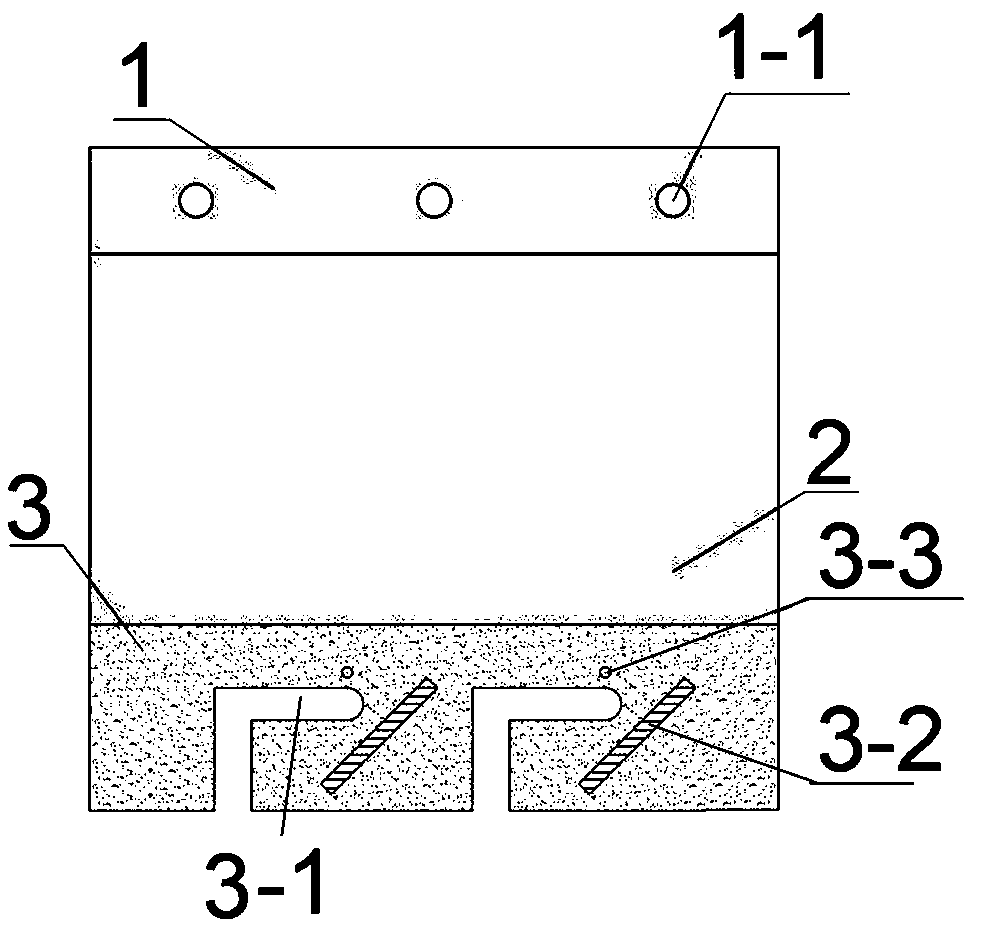

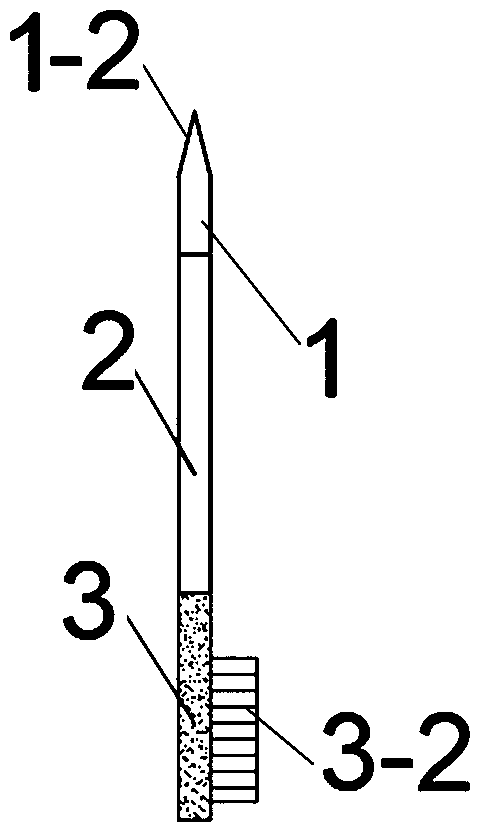

[0043] Such as figure 1 Said, the present invention provides the connection plate 4 that thickness is 5-10mm, and connection plate 4 comprises upper layer steel bar connection area 1, is arranged on upper layer steel bar connection area 1 top surface length and is 10mm blade portion 1-2, middle layer insulation layer connection area 2 and the lower reinforcement connection area 3, the upper reinforcement connection area 1 is provided with at least two connection holes 1-1 for passing through the reinforcement, and the distance between adjacent connection holes 1-1 is 150mm or 200mm. The lower reinforcement connection area 3 includes a straight or L-shaped reinforcement slot 3-1, a local reinforcing bar 3-2 and a reinforcement binding hole 3-3. There are two reinforcement slots 3-1 and they are arranged at intervals in the lower layer. In the lower part of the reinforcement connection area 3, the distance between adjacent reinforcement grooves 3-1 is 150 mm or 200 mm.

[0044]...

Embodiment 2

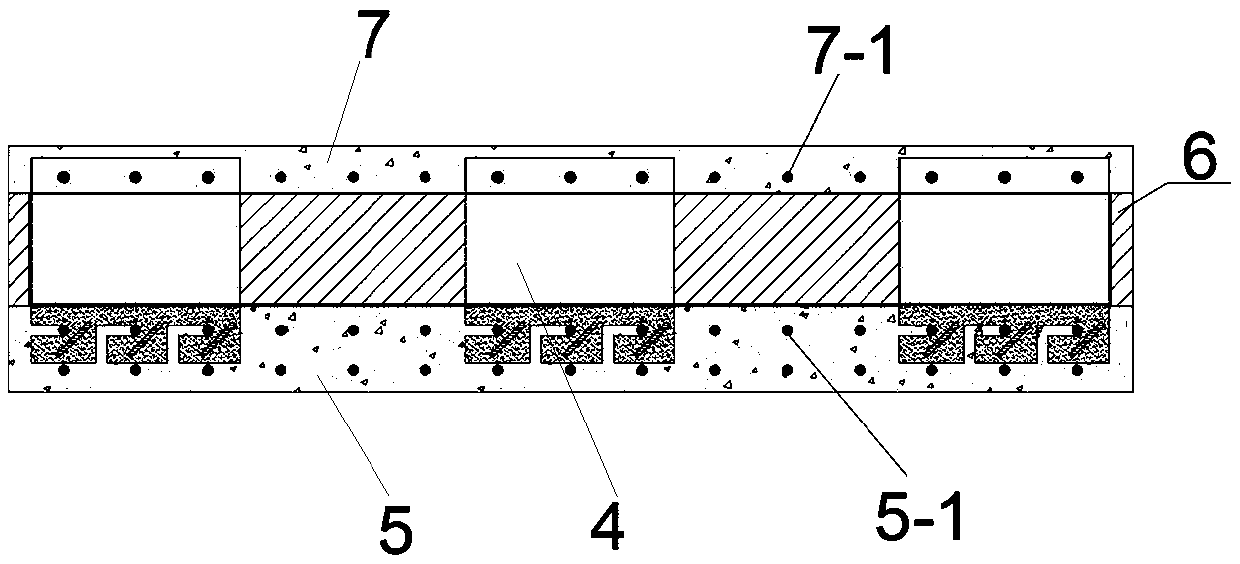

[0060] Example 2, such as Figure 5 As shown, the construction method and construction method of the connecting plate and the multi-layer composite thermal insulation wall are the same as in Embodiment 1, the difference is that the lower reinforcement connecting area 3 of the connecting plate 4 includes a straight steel bar clamping groove 3-1 and Two L-shaped reinforcement slots 3-1.

[0061] The connecting plate 4 is applied to the sandwich composite thermal insulation wall, in which the thickness of the concrete outer leaf plate is 50mm, the thickness of the insulation layer 6 is 250mm, the thickness of the inner leaf plate 5 is 100mm, the outer leaf plate adopts single-layer reinforcement, the spacing between steel bars is 150mm, and the inner leaf plate 5 Double-layer reinforcement is adopted, and the spacing between steel bars is 150mm.

[0062] The fiber-reinforced plastic connecting plate 4 used has a length of 400mm, a height of 330mm, a thickness of 5mm, a spacing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com