Vertical support efficient insulating plastic greenhouse with ultra-long service life

A technology with ultra-long life and longitudinal support, which is applied in greenhouse cultivation, horticulture, climate change adaptation, etc. It can solve the problems of inconvenient rolling and retracting operation of the inner film, poor heat preservation of the greenhouse, and decrease of light transmittance, and achieves the goal of overcoming heat preservation. Incomparable with light transmittance, convenient ventilation management, and improved thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] To build a shed with a reinforced concrete frame and steel cable stays, take a width of 10 meters and a length of 50 meters as an example. This kind of shed has a low cost and a long service life. The pulley and tight wire structure can have a service life of more than 100 years at most, and the construction is relatively convenient. Ordinary ground piles or spiral ground piles can be used for the ground fixing structure. The screw piles are easy to remove and can completely avoid damage to the cultivated land caused by the remaining ground piles during reconstruction or relocation.

[0020] Such as figure 1 Shown: the cross-section of the reinforced concrete outer frame is 150X150mm, and there are four 10mm rebars and several stirrups inside, and the ground pile is also a reinforced concrete structure inserted into the ground about 3 to 4 meters. It can be poured in a well or driven into the ground with a pile driver . The cross-section is also 150X150mm or slightly ...

Embodiment 2

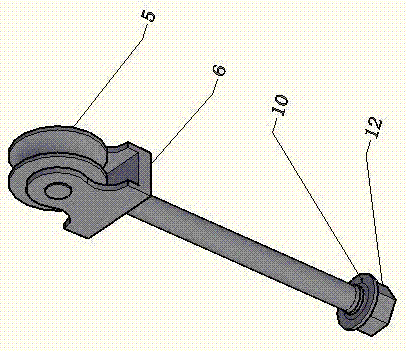

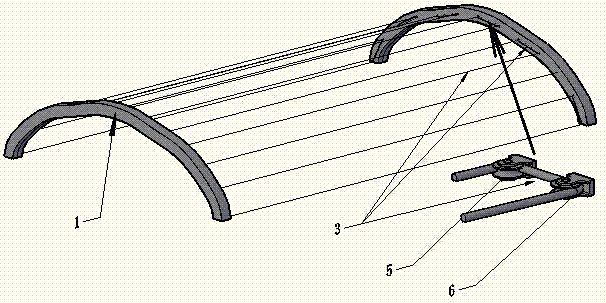

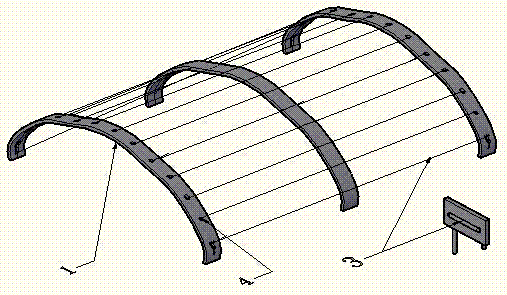

[0027] Build a shed with a transparent plastic frame. This frame is light-transmitting and can use more frames to increase the length of the greenhouse. Such as Figure 4 The connection relationship between the shown steel cable and the frame is that the steel cable with a hole is vertically arranged on the frame to pass from the top of the frame to the bottom and connect to the next hole to pass from the bottom to the top. Corner pulleys or slip rings are fixed on the holes to reduce the friction between the steel cable and the frame. The corner pulleys are multiple pulley blocks fixed at a certain angle to guide the steel cables. It is fixed on the frame. Other structures are basically the same as those in the first implementation example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com