Method for preparing TC4 titanium alloy wire

A technology of titanium alloy wire and titanium alloy, which is applied to the device and coating of the surface coating liquid, can solve the problems of poor dimensional accuracy of the wire, hidden dangers in subsequent processes, insufficient lubrication, etc., and achieve dimensional accuracy and surface quality Guarantee, reduce production cost and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

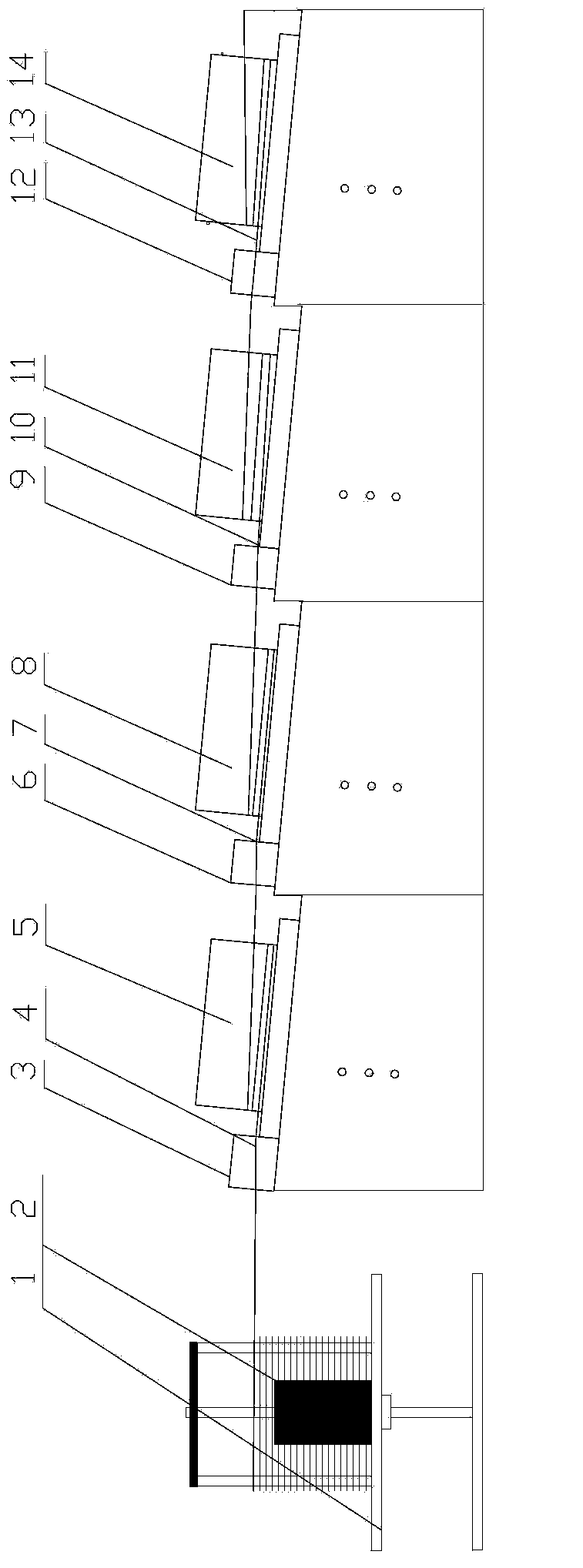

Image

Examples

preparation example Construction

[0028] The preparation method of TC4 titanium alloy wire, the diameter of the wire blank is 6mm, and the diameter of the finished wire is 2.5mm:

[0029] 1) Put a plurality of titanium alloy wire blanks (¢6mm) on the annealing rack, put them into the well-type electric furnace and heat them to 680°C-745°C, keep them warm for 2 hours, take them out, and air-cool to room temperature;

[0030] 2) Put the coating agent with a mass concentration of 20% into the container, put the titanium alloy wire billet (¢6mm) at room temperature into the container, immerse it and heat it to 100°C, take it out after holding it for 15 minutes, and put it in a box-type electric furnace to bake Dry and cool to normal temperature to coat the surface of the titanium alloy wire billet with a protective film;

[0031] 3) Put the titanium alloy wire billet (¢6mm) covered with a protective film on the rack, and install four wire drawing dies with apertures of ¢5.5mm, ¢5.0mm, ¢4.5mm, and ¢4.0mm respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com