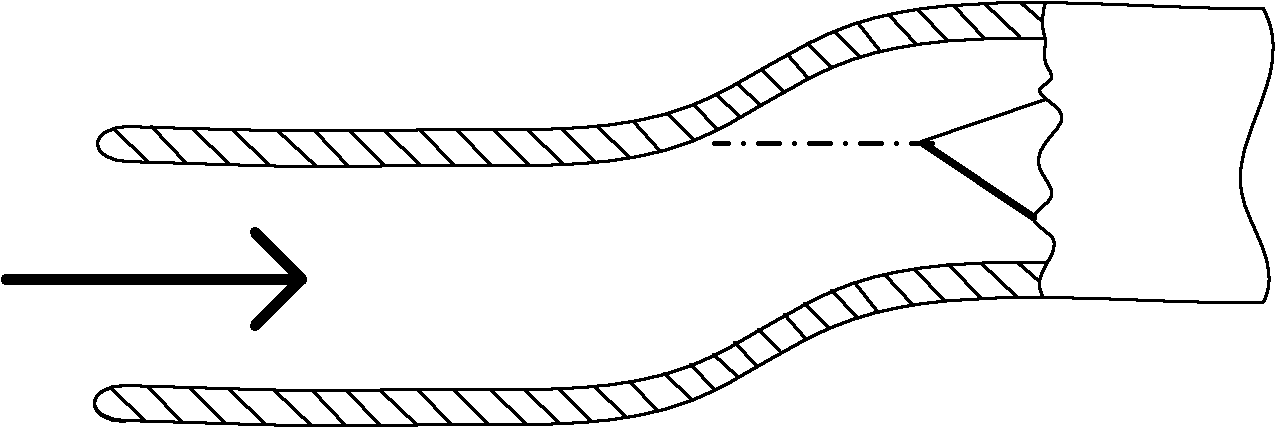

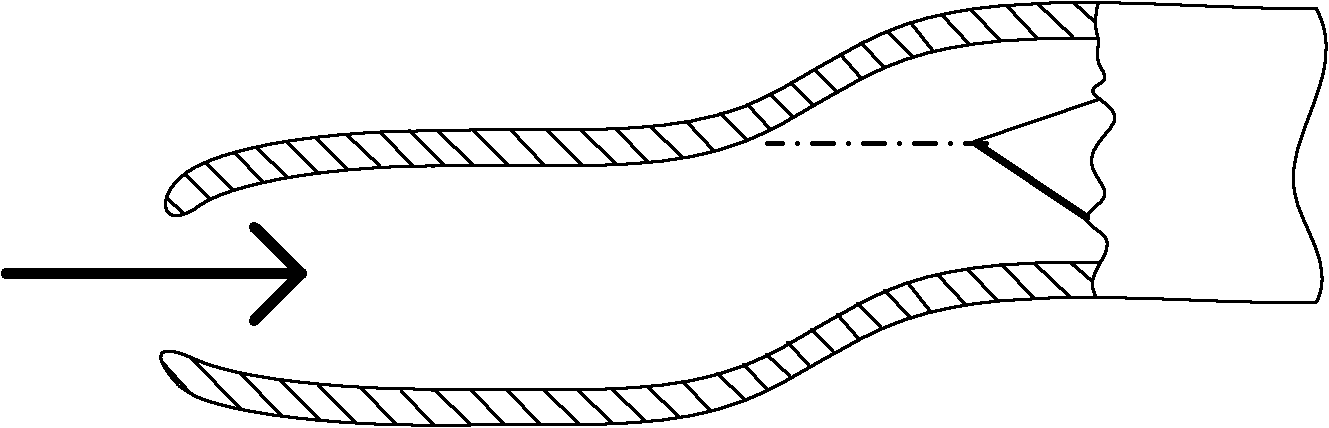

Shape memory polymer pipeline and use of shape memory polymer pipeline as aircraft engine intake

A memory polymer, aircraft engine technology, applied in the direction of engine components, air intakes of turbine/propulsion devices, hoses, etc., which can solve the problem of inconsistency in passing capacity requirements, changing the shape of the air intake, and inability to deform as required, etc. problems, to achieve the effect of improving aerodynamic performance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment 1: The shape memory polymer pipeline described in this embodiment is made of shape memory composite material, and the shape memory composite material is composed of 5 to 98 parts of shape memory polymer material, 2 to 95 parts of It consists of reinforcing phase material and 0-100 parts of resistance heating material. Such as carbon fiber reinforced epoxy resin shape memory polymer composite material, when the carbon fiber content is 20%, the elastic modulus of the material is 30GPa.

specific Embodiment approach 2

[0016] Embodiment 2: The shape-memory composite material in this embodiment is composed of 40-90 parts of shape-memory polymer material, 10-60 parts of reinforcing phase material and 1-99 parts of resistance heating material. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The shape-memory composite material in this embodiment is composed of 50 parts of shape-memory polymer material, 50 parts of reinforcement phase material and 10 parts of resistance heating material by volume. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com