Foam concrete for wet-spraying support of coal mine and preparation method thereof

A technology of foam concrete and wet spraying, which is applied in the field of concrete, can solve the problems of unguaranteed rebound rate, insufficient viscosity and uniformity of spraying, increase the dispersion of foam concrete viscosity, etc., and achieve cost saving, airtightness and uniformity Good performance and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of foam concrete used for coal mine wet shotcrete support, it is made up of following raw materials by weight percentage:

[0033] Raw material parts by weight

[0034] (1) Gelling material:

[0035]Cement 200 parts

[0036] 30 parts of fly ash

[0037] (2) 110 parts of water

[0038] (3) Additives:

[0039] Glue 40 parts

[0040] 35 parts of water reducer

[0041] Accelerator 90 parts

[0042] Fiber 95 parts

[0043] Cellulose 110 parts

[0044] (4) 13 parts of blowing agent.

[0045] The preparation method of above-mentioned foamed concrete:

[0046] 1. Pretreatment of raw materials, removing hard blocks in cementitious materials, etc., to prevent them from depositing in the foam slurry;

[0047] 2. Dosage: Weigh each component according to the ratio;

[0048] 3. Feeding and mixing: Add cement, fly ash, part of water, glue, water reducing agent, fiber and cellulose to the mixer in sequence and mix well;

[00...

Embodiment 2

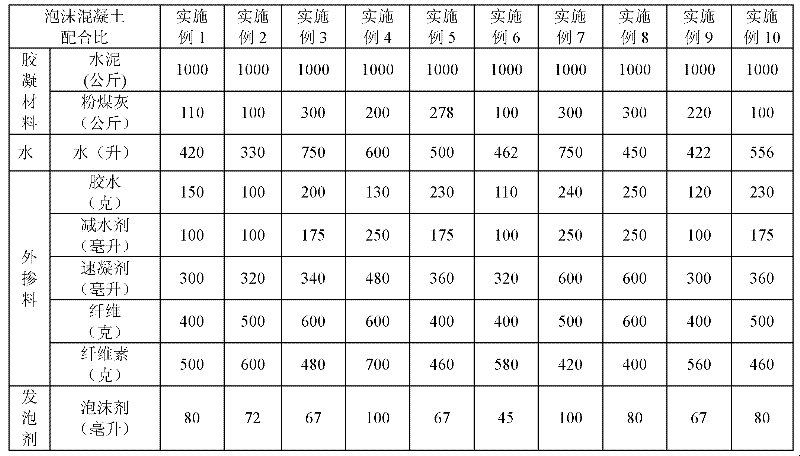

[0052] The formula is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0054] The formula is shown in Table 1, and the preparation method is the same as in Example 1.

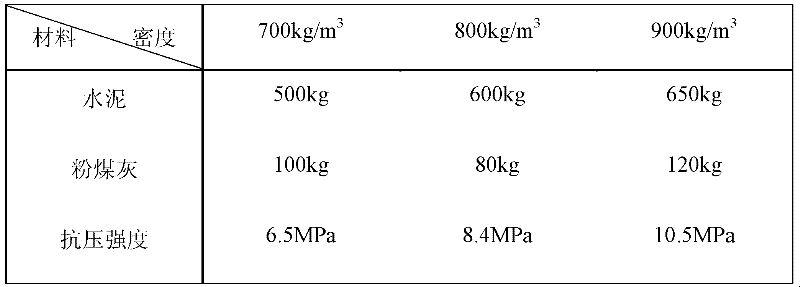

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com