Ratchet spanner

A ratchet wrench and driving part technology, applied in the field of ratchet wrenches, can solve the problems of cracking, fracture in adjacent parts, insufficient structural strength of parts, etc., and achieve the effects of good structural strength, easy processing and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The ratchet wrench of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can implement according to the description of this embodiment.

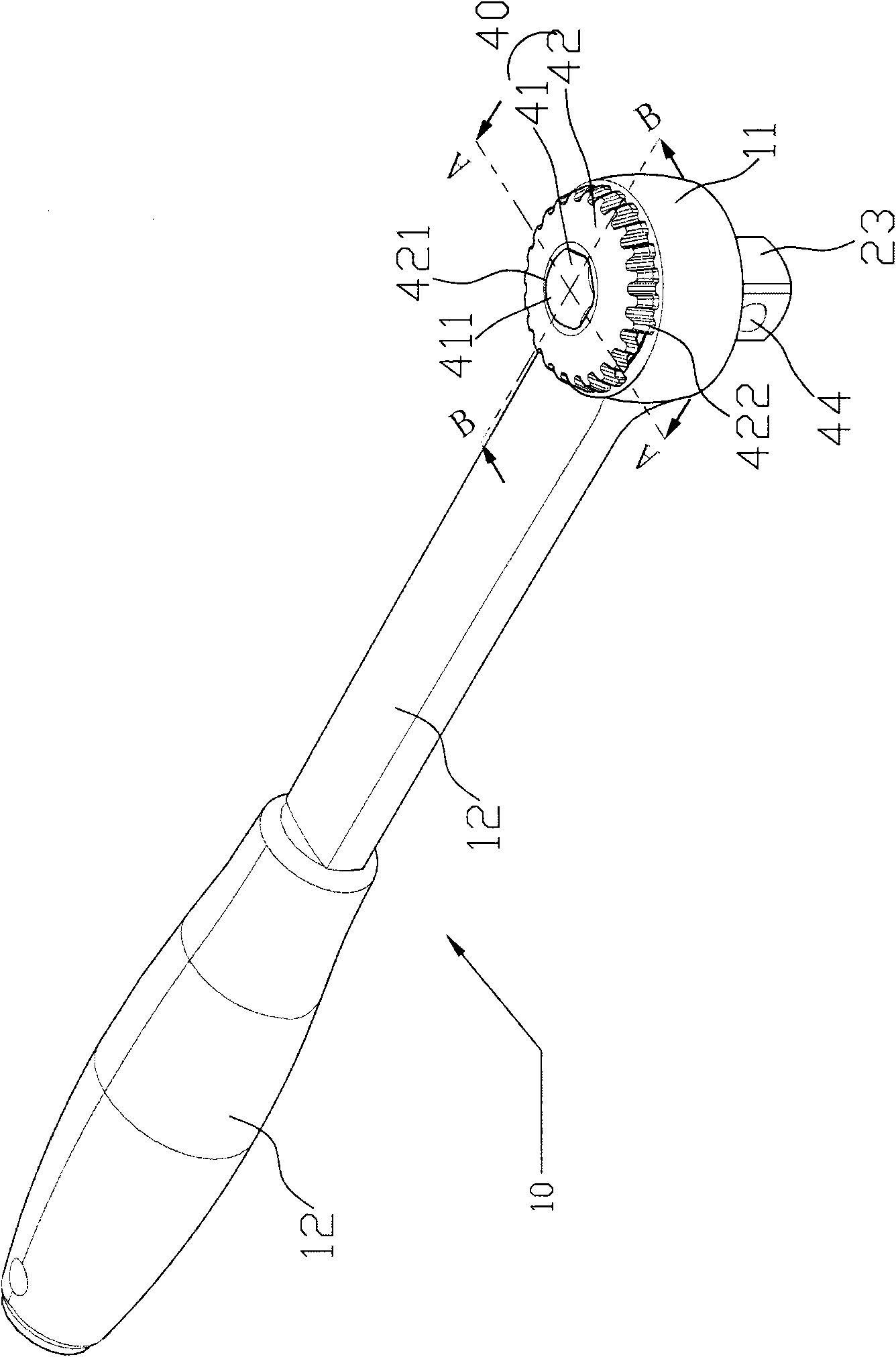

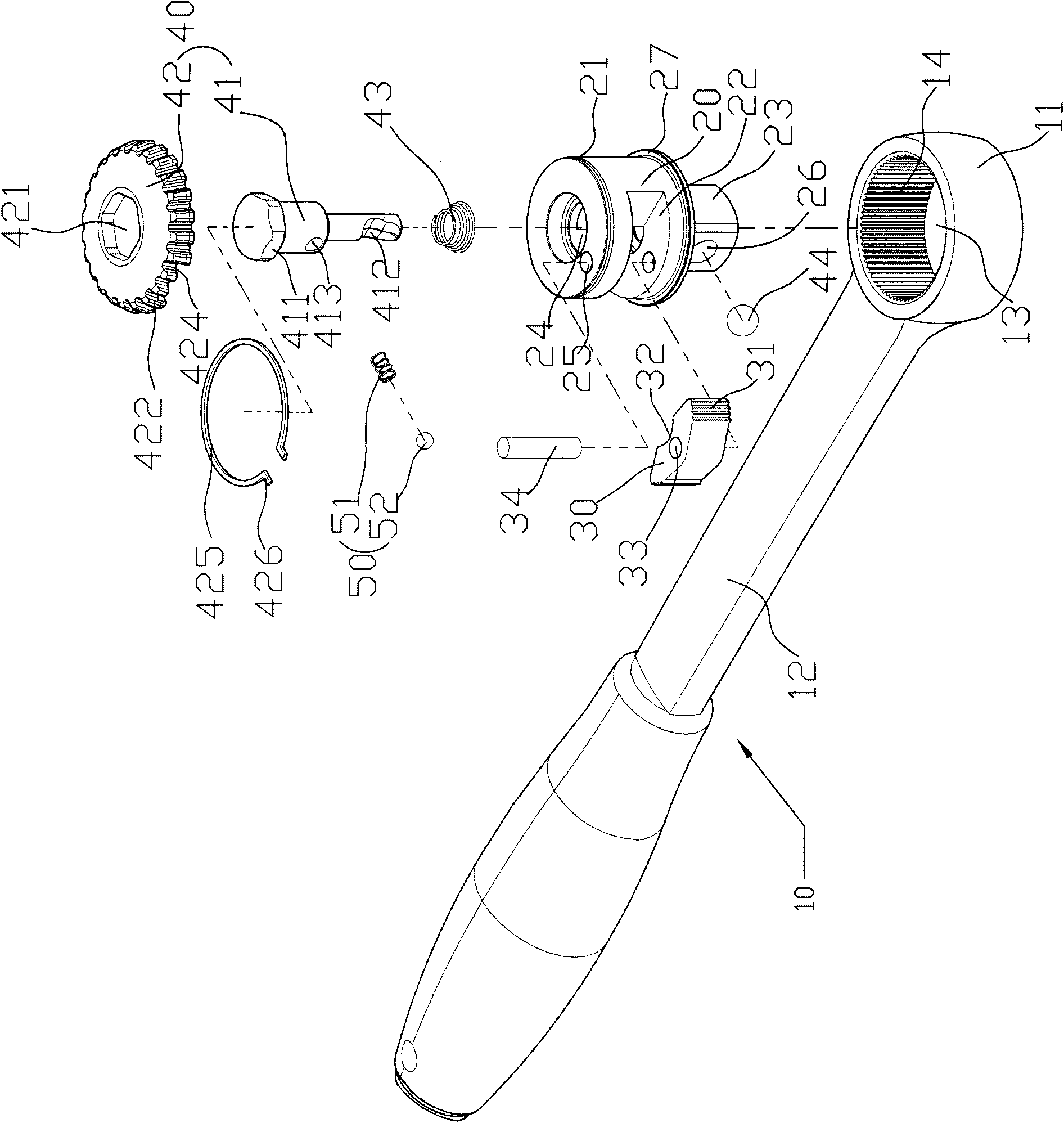

[0034] figure 1 and figure 2 It is the first preferred embodiment of the ratchet wrench of the present invention, which includes a main body 10 , a driving member 20 , at least one latching member 30 , a reversing device 40 and a top latching device 50 .

[0035] One end of the main body 10 is provided with a head 11 , and the head 11 is connected with a holding part 12 . The head 11 is provided with a longitudinal perforation 13, and its inner edge is provided with longitudinal teeth 14. In the first embodiment of the present invention, the head 11 is circular.

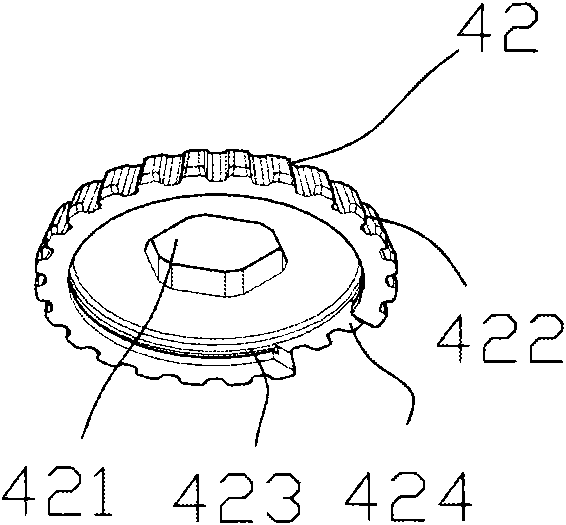

[0036] Also refer to Figure 4 and Figure 5 , one end of the driving member 20 is rotatably disposed in the through hole 13 of the head 11 of the main body 10, the outer edge of the end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com