Self-operated three-way valve used for coolant circulating type machine room special machine

A self-operated, three-way valve technology, applied to multi-way valves, refrigerators, fluid circulation arrangements, etc., can solve the problems of refrigerant pressure drop, compressor 10 exhaust temperature rise, solenoid valve failure, etc., to achieve partial Reduced resistance, improved reliability, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

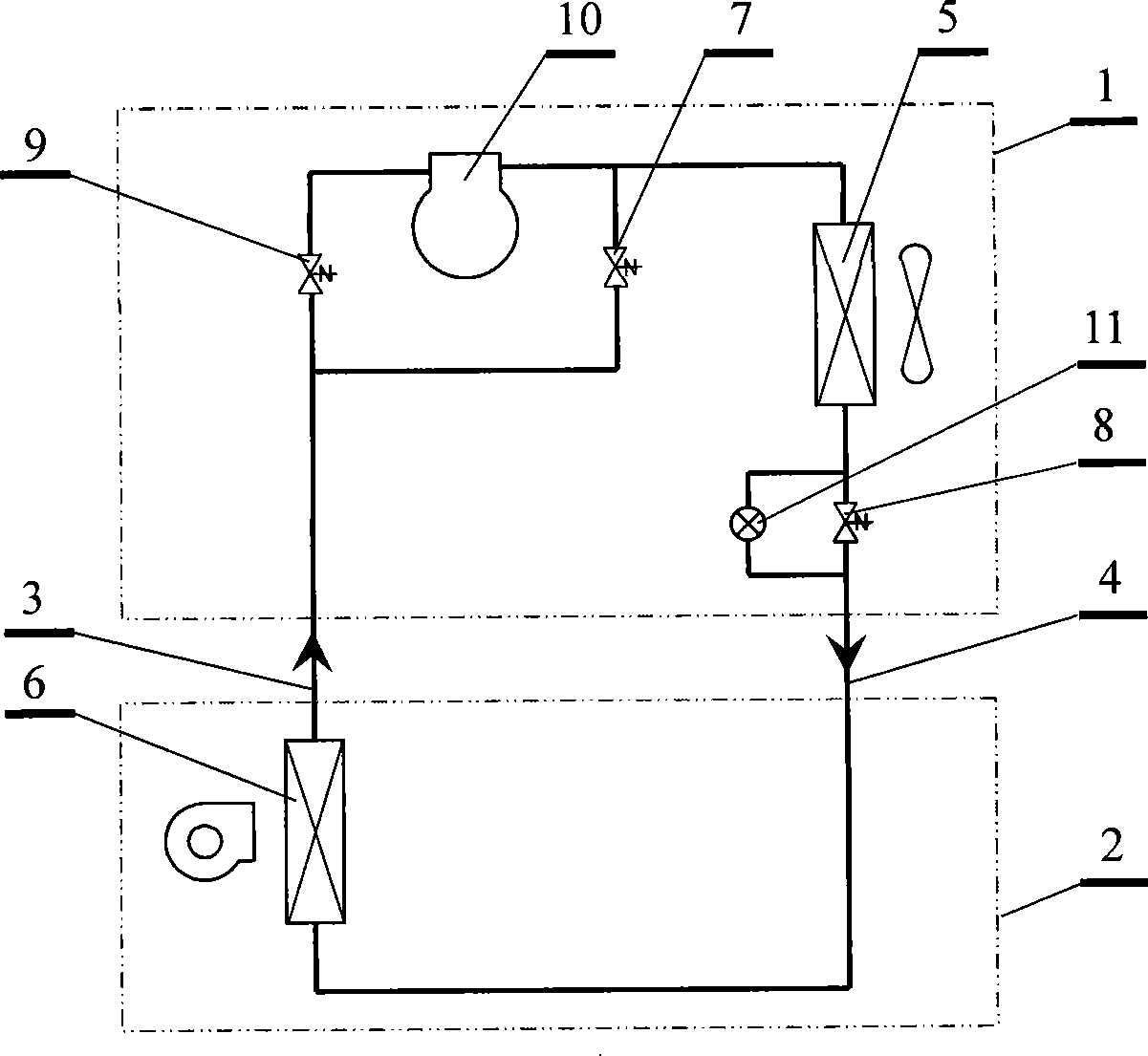

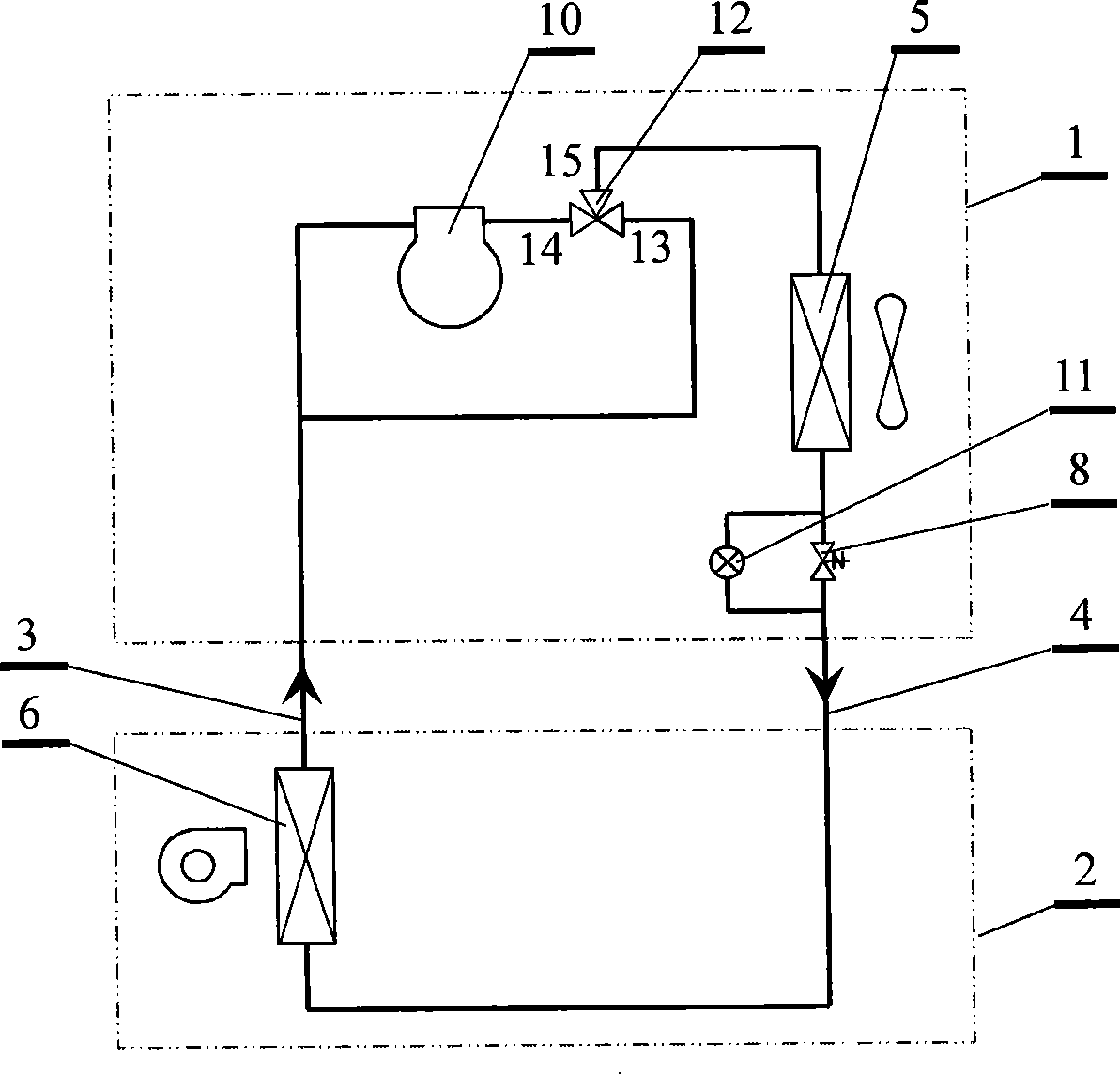

Method used

Image

Examples

Embodiment 1

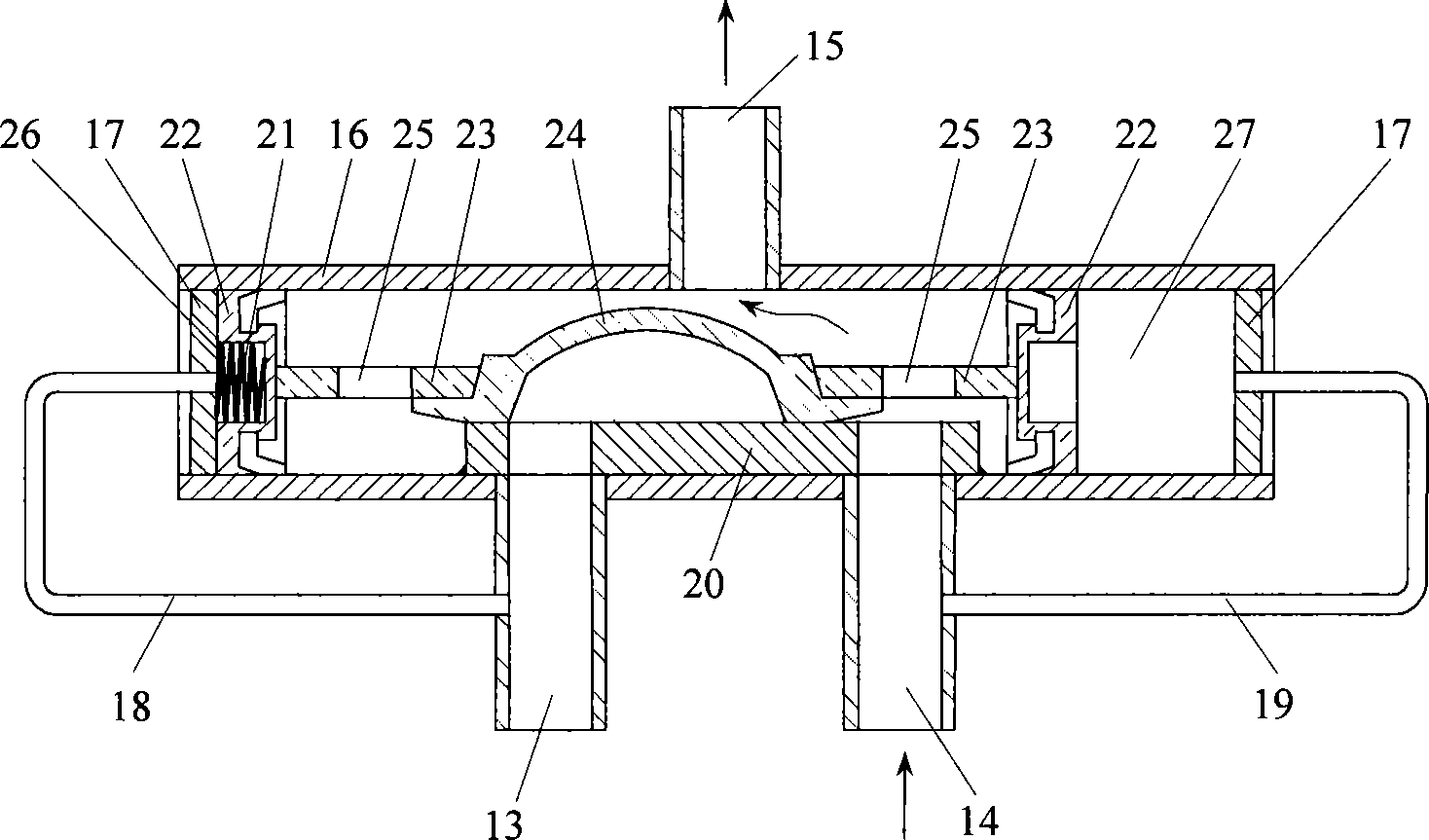

[0031] image 3 and Figure 4 It shows the structural characteristics and working state of a self-operated three-way valve with a thrust spring in the low-pressure chamber, in which image 3 It is the valve position state of the self-operated three-way valve during the refrigerant refrigeration cycle; Figure 4 It is the valve position state of the self-operated three-way valve when the refrigerant naturally circulates.

[0032]The self-operated three-way valve used for the special machine room with refrigerant circulation and use includes a valve body 16, a low-pressure inlet pipe 13, a high-pressure inlet pipe 14 and an exhaust pipe 15; the valve body 16 is provided with an axially moving piston assembly, The valve seat 20 and the slide valve 24 that moves on the valve seat are provided with two through holes, which are aligned with the low-pressure intake pipe 13 and the high-pressure intake pipe 14; the piston assembly consists of two pistons 22 and two pistons and slide...

Embodiment 2

[0036] Figure 5 It shows the structural features of a self-operated three-way valve with push springs and tension springs respectively arranged in the low-pressure chamber 26 and high-pressure chamber 27. The state in the figure is the valve position state when the special machine in the machine room is in the natural circulation of refrigerant.

[0037] In this embodiment, the spring 21 in the self-operated three-way valve 12 is a combined spring composed of a thrust spring 21a arranged in the low-pressure chamber 26 and a tension spring 21b arranged in the high-pressure chamber 27. The thrust spring 21a and the tension spring The acting force of 21b is in the same direction, which is exactly the same as the effect of using the thrust spring 21a in the low-pressure chamber 26 alone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com