Liquid crystal display panel

A technology of liquid crystal display panels and array substrates, applied in nonlinear optics, instruments, optics, etc., can solve problems such as insufficient elasticity, and achieve the effect of improving stability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

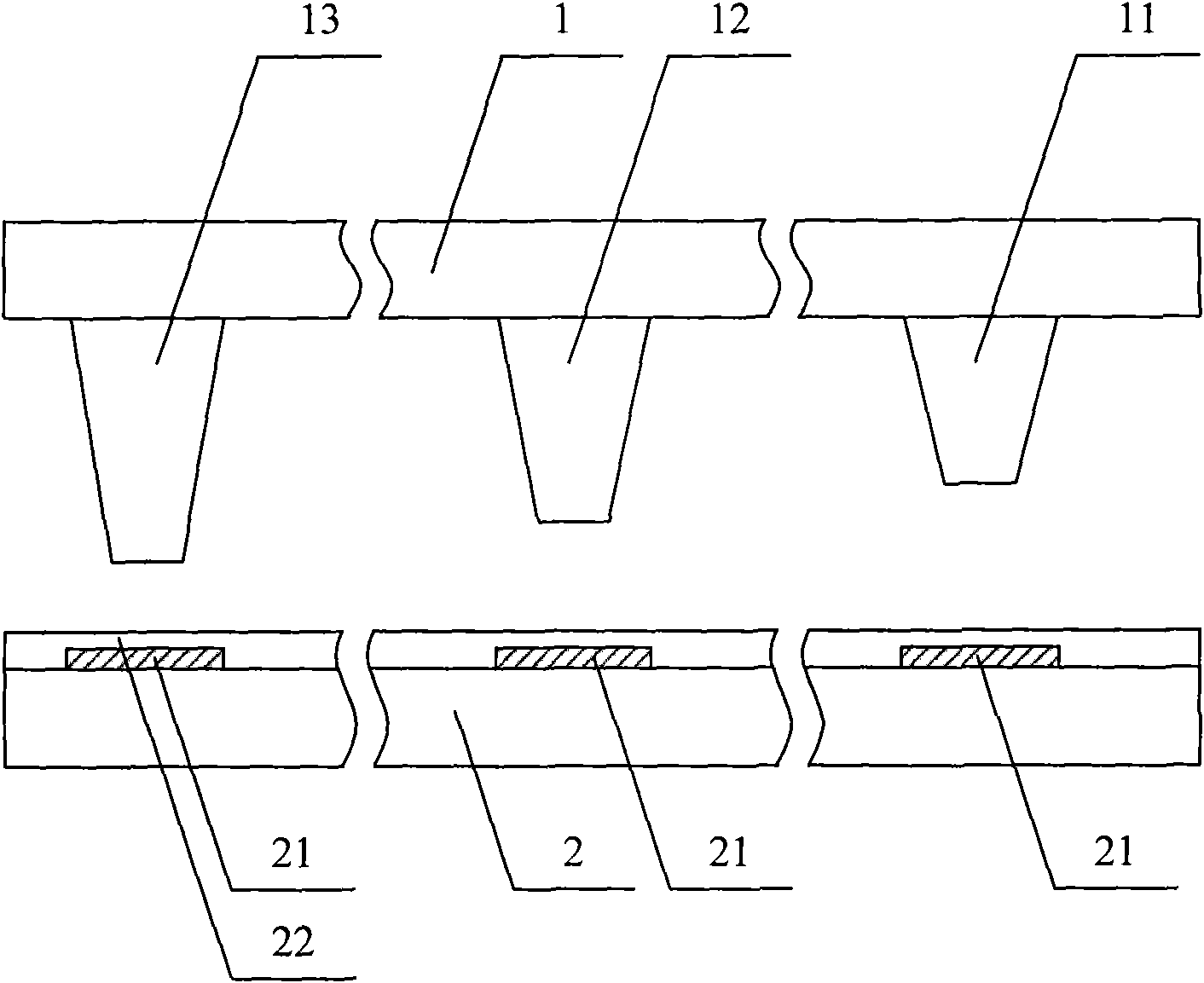

[0039] figure 2 It is a schematic diagram of the first embodiment of the liquid crystal display panel of the present invention. Such as figure 2 As shown, the liquid crystal display panel of this embodiment includes: an array substrate 2 and a color filter substrate 1, and the color filter substrate 1 includes: a main columnar spacer 12 that provides a first elastic force at a set gap and a spacer less than the set gap. A sub-columnar spacer 11 that provides the second elastic force under a certain gap; a super-columnar spacer 13 that provides the third elastic force under the set gap is also provided on the non-gravity water ripple area of the color filter substrate; Wherein, the third elastic force is greater than the first elastic force. Specifically: the height of the super column spacer 13 is greater than the height of the main column spacer 12; the height of the main column spacer 12 is greater than the height of the auxiliary column spacer 11; The columnar spacer...

no. 4 example

[0053] Figure 5 It is a schematic diagram of the fourth embodiment of the liquid crystal display panel of the present invention. Such as Figure 5 As shown, the liquid crystal display panel of this embodiment includes: an array substrate 2 and a color filter substrate 1, and the color filter substrate 1 includes: a main columnar spacer 12 that provides a first elastic force at a set gap and a spacer less than the set gap. A sub-columnar spacer 11 that provides the second elastic force under a certain gap; a super-columnar spacer 13 that provides the third elastic force under the set gap is also provided on the non-gravity water ripple area of the color filter substrate; Wherein, the third elastic force is greater than the first elastic force. Specifically: the height of the super-columnar spacer 13 is equal to the height of the main column spacer 12; the height of the main column spacer 12 is equal to the height of the secondary column spacer 11; The surface of the area ...

no. 5 example

[0057] Image 6 It is a schematic diagram of the fifth embodiment of the liquid crystal display panel of the present invention. Such as Image 6 As shown, the liquid crystal display panel of this embodiment includes: an array substrate 2 and a color filter substrate 1, and the color filter substrate 1 includes: a main columnar spacer 12 that provides a first elastic force at a set gap and a spacer less than the set gap. A sub-columnar spacer 11 that provides the second elastic force under a certain gap; a super-columnar spacer 13 that provides the third elastic force under the set gap is also provided on the non-gravity water ripple area of the color filter substrate; Wherein, the third elastic force is greater than the first elastic force. Specifically: the height of the super column spacer 13 is higher than the height of the main column spacer 12; the height of the main column spacer 12 is higher than the height of the auxiliary column spacer 11; The surface of the area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com