Spinning device

A spinning device and spinning technology, which are applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of large operation, cost, connection that cannot form a pressure seal, etc., and achieve the effect of small force consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

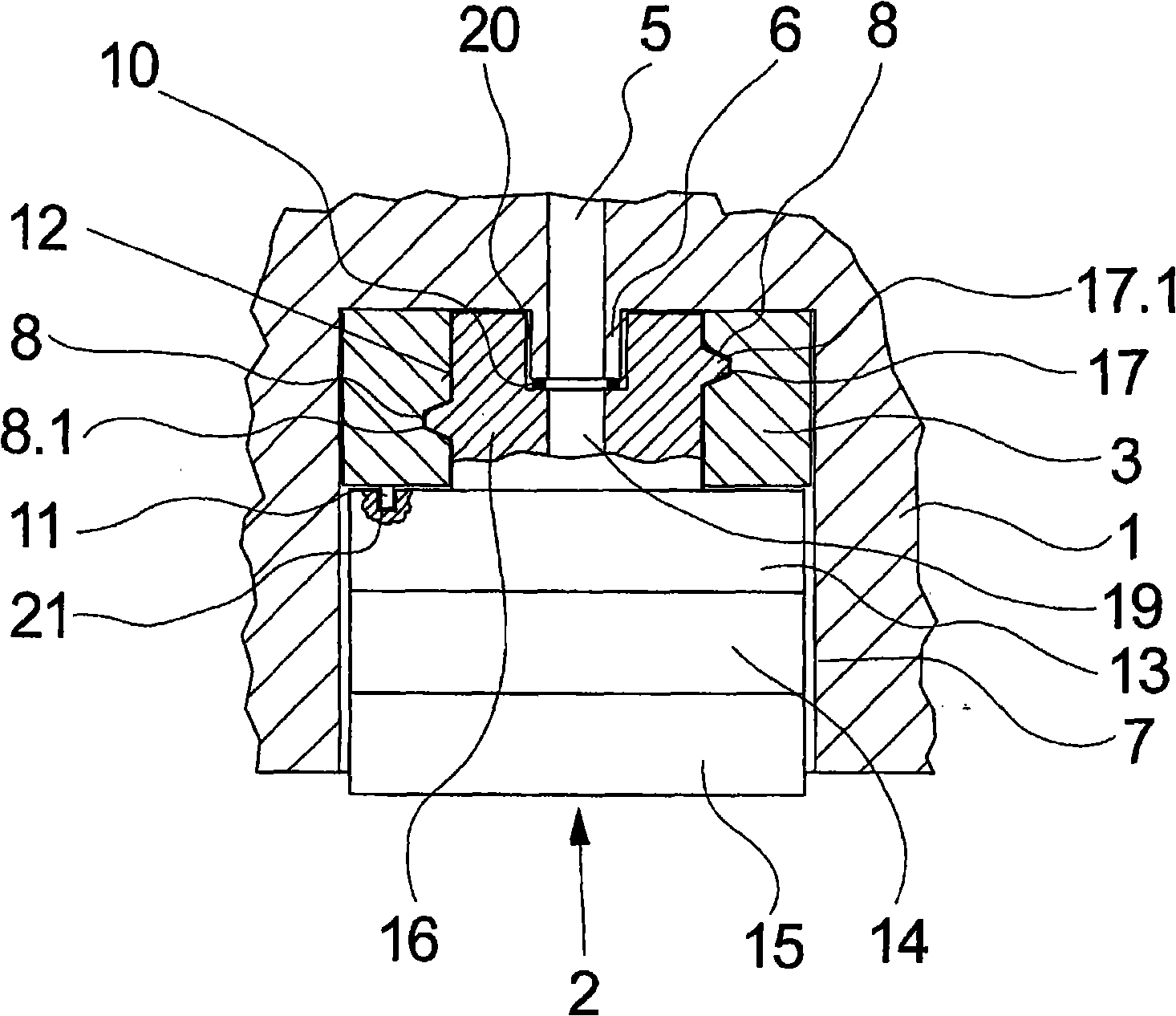

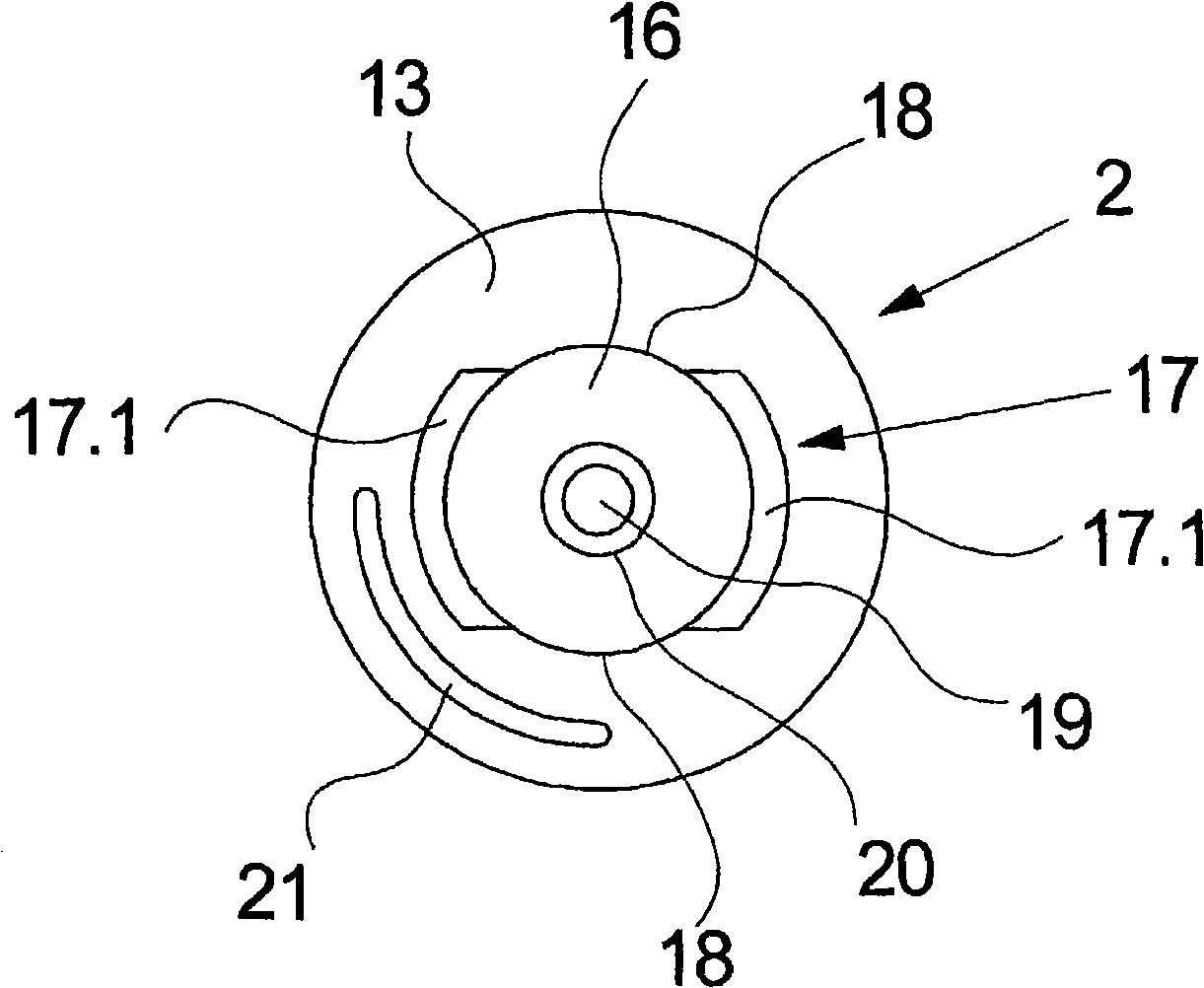

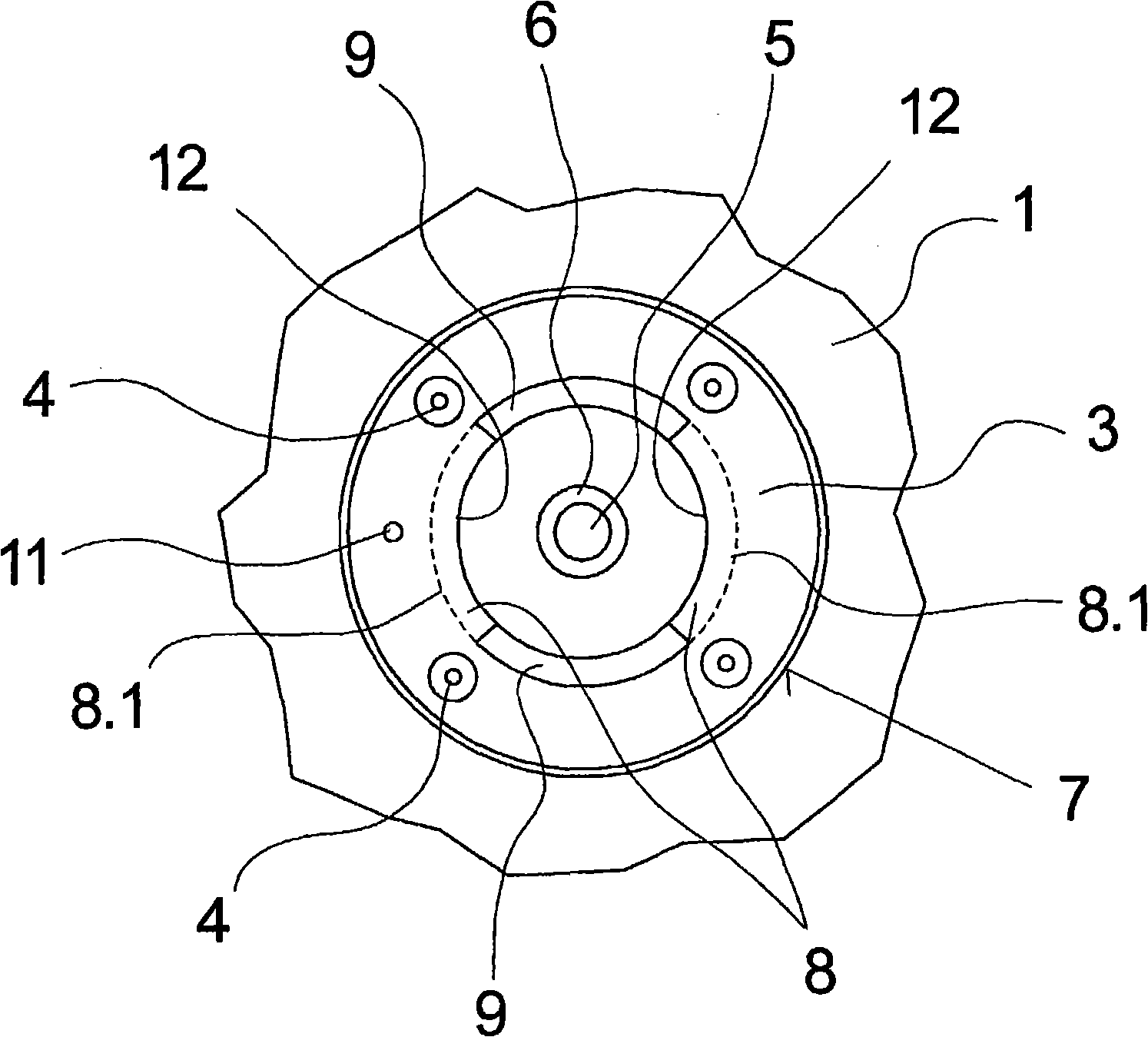

[0027] Figures 1 to 3 A first embodiment of the spinning device according to the invention is shown in several illustrations. figure 1 shows a schematic transverse cross-sectional view, figure 2 shows a top view of the spinning nozzle assembly, while image 3 Shows a top view of the underside of the nozzle holder. If it is not clear which figure is referred to, the following description applies to both figures.

[0028] The exemplary embodiment comprises a nozzle holder 1 which has a melt connection. The nozzle holder 1 is only partially shown in this exemplary embodiment. Typically such nozzle holders are elongated in order to accommodate a plurality of spinning nozzle assemblies on the underside.

[0029] The nozzle holder 1 is connected via a melt connection 5 via a melt line, not shown here, to a melt source. A nozzle receiving opening 7 is formed on the underside of the nozzle holder 1 for receiving the spinning nozzle assembly 2 . The nozzle receiving opening 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com