Narrow distillate alpha-olefin derived alkylbenzene sulfonate and its synthesis method and uses

A technology of alkylbenzene sulfonate and narrow fractions, applied in the direction of sulfonate preparation, drilling composition, chemical instruments and methods, etc., can solve unfavorable large-scale production and application, product quality control problems, synthetic raw materials Complicated composition and other issues, to achieve the effects of large-scale production and application, easy control of product quality, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A certain amount of benzene was added into a three-necked flask, and the catalyst anhydrous aluminum trichloride (AlCl 3 ), under stirring, slowly add the narrow fraction α-olefins whose average number of carbon atoms is sixteen and whose carbon number distribution is not more than 3 carbon atoms, the molar ratio of the three is 10:0.3:1, and the temperature is controlled at 10-30°C About 17 hours of reaction. Pour the reaction mixture into crushed ice, let stand to separate layers, and use 5-20wt% Na for the oil phase 2 CO 3 solution, and then washed three times with water until neutral. The organic phases were combined, dried with anhydrous calcium chloride, filtered, and the low-boiling substances were distilled off with a water pump, and then distilled under reduced pressure to obtain the intermediate product hexadecylbenzene.

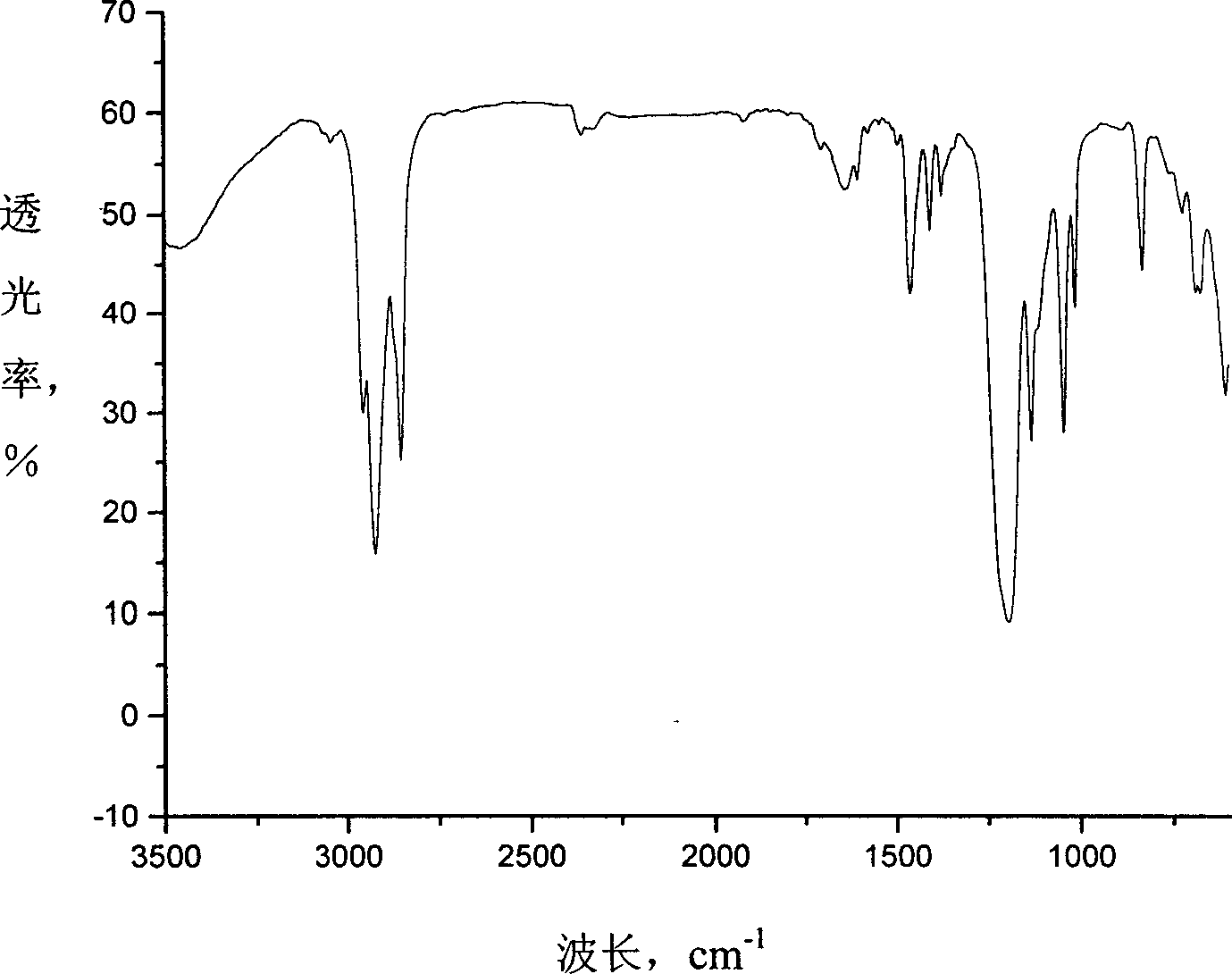

[0039] Take a certain amount of synthesized hexadecylbenzene in a three-necked flask, add fuming sulfuric acid dropwise to the stirred h...

Embodiment 2

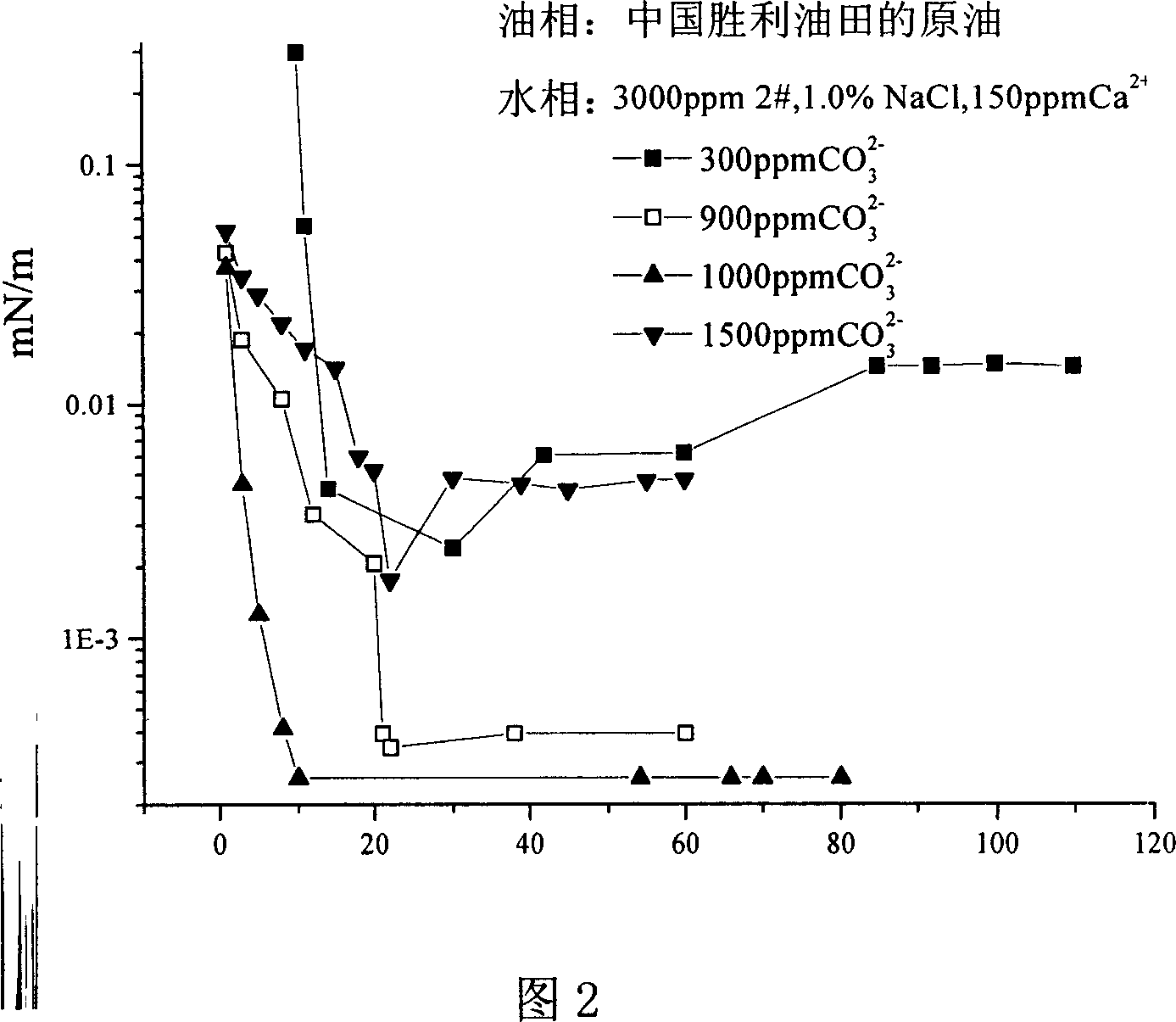

[0042] In Example 1, the narrow fraction α-olefin with an average number of carbon atoms of sixteen and a distribution of carbon numbers of no more than 3 carbon atoms is replaced by an average number of carbon atoms of eighteen and a distribution of no more than 3 carbon atoms. Narrow cut α-olefins, other conditions and operating methods are the same as in Example 1 to obtain product 2# product octadecylbenzenesulfonate. Add 10000ppm NaCl, 150ppm Ca to 2# product 2+ , the product concentration is 3000ppm, the alkali concentration is 900ppm~1500ppm Na 2 CO 3 When , the ultra-low interfacial tension with crude oil from Shengli Oilfield in China is reached, as shown in Figure 2. Add 10000ppm NaCl, 150ppm Ca to 2# product 2+ , 600ppmCO 3 2- , 1000ppmHPAM, the product concentration is 700ppm, and the crude oil of Shengli Oilfield in China reaches ultra-low interfacial tension, see Figure 7 .

Embodiment 3

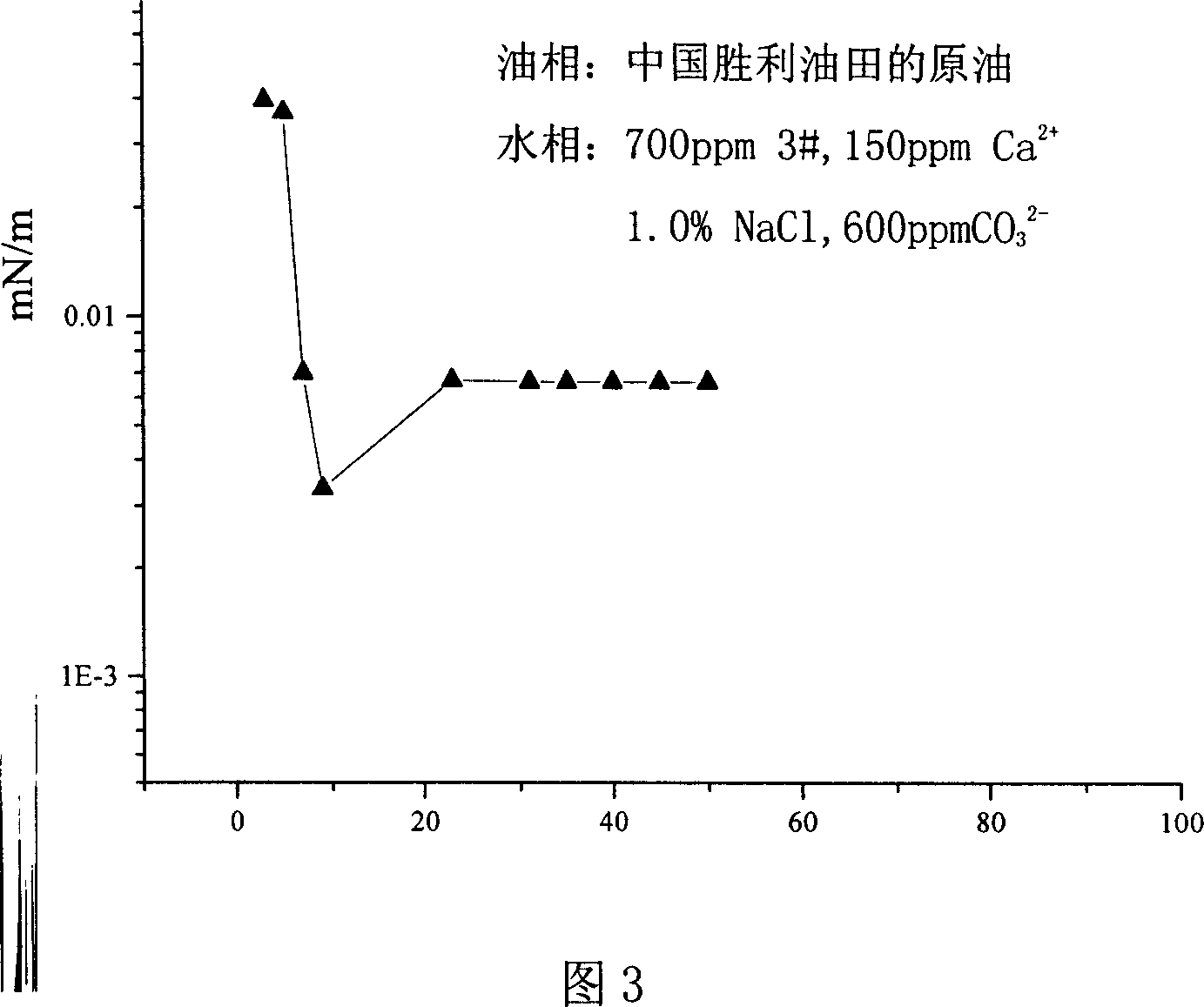

[0044] In Example 1, the narrow cut α-olefins with an average number of carbon atoms of sixteen and a distribution of carbon numbers of no more than 3 carbon atoms were replaced by an average number of carbon atoms of fourteen and a distribution of no more than 3 carbon atoms. Narrow cut α-olefins, benzene is replaced by m-xylene, other conditions and operating methods are the same as in Example 1, and product 3# product tetradecyldimethylbenzenesulfonate is obtained. Add 10000ppmNaCl, 150ppm Ca in 3# product 2+ , 600ppmCO 3 2- , the product concentration is 700ppm, and the crude oil from Shengli Oilfield in China has reached ultra-low interfacial tension, see Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com