Ramie / terylene double fabric for textile wall cloth and curtain cloth and preparing method thereof

A technology of double-layer fabric and manufacturing method, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problems of shrinkage, easy wrinkling, poor elastic elongation, etc., and achieve the effects of improved hygroscopicity, soft luster and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: ramie / polyester double-layer fabric curtain cloth I and manufacture method thereof

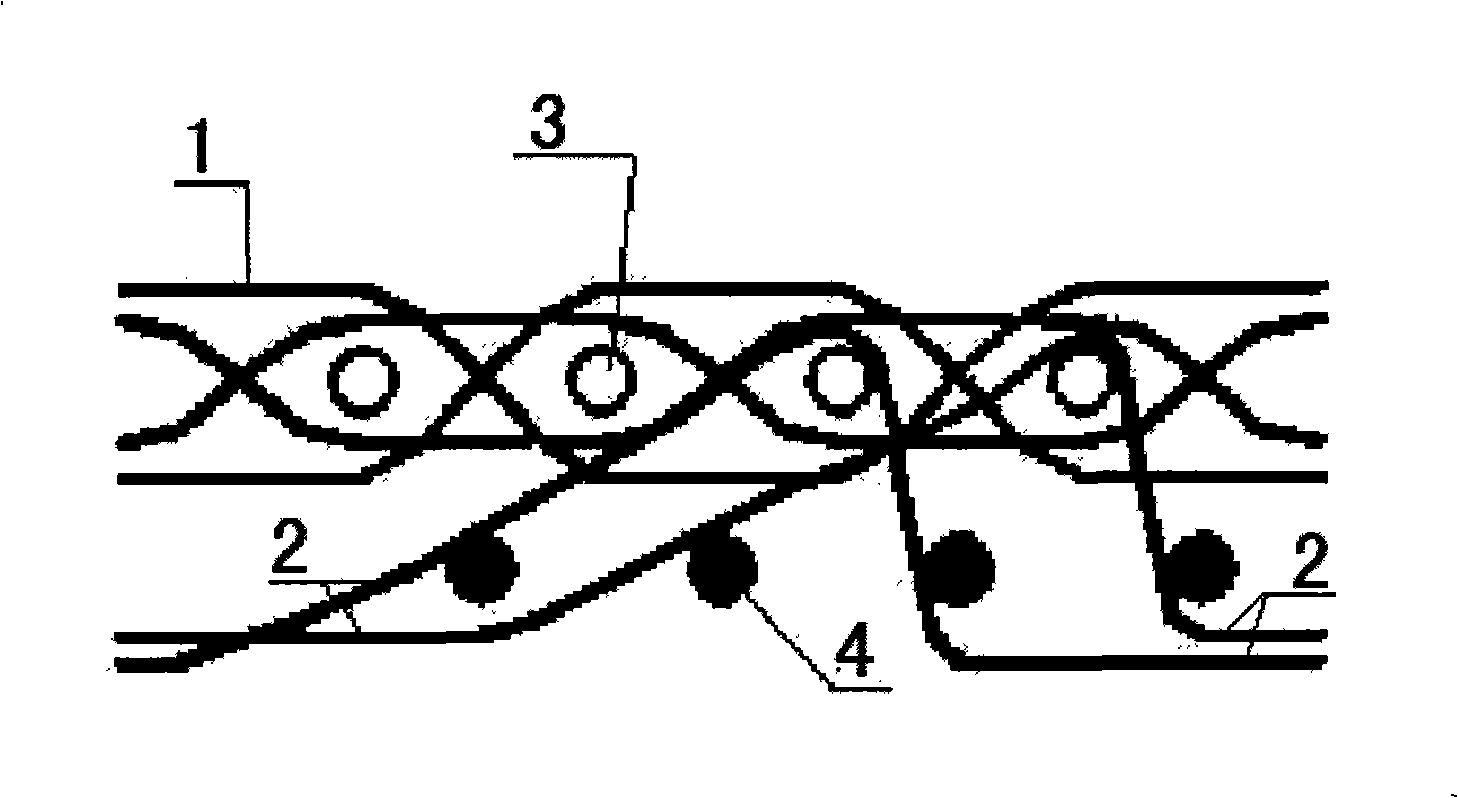

[0031] In the present embodiment, the structure of the ramie / polyester double-layer fabric used for curtain cloth is as follows: figure 1 As shown, it includes the surface layer and the inner layer, the surface layer is made of ramie yarn, and the inner layer is made of polyester yarn. Its technical specifications are shown in Table 1.

[0032] Table 1 Technical specifications of ramie / polyester double-layer fabric curtain fabric I

[0033]

[0034] Present embodiment weaves on the HZF758 type rapier loom, and technological process is as follows:

[0035] (1) Preparation process

[0036] The preparation process of warp yarn is fixed twist, winding, warping, sizing and drawing in, and the preparation process of weft yarn is fixed twist and winding.

[0037] Twist setting: The twist setting of polyester warp yarn, weft yarn and ramie warp yarn and weft yarn is carried...

Embodiment 2

[0045] Embodiment 2: ramie / polyester double-layer fabric curtain cloth II and manufacture method thereof

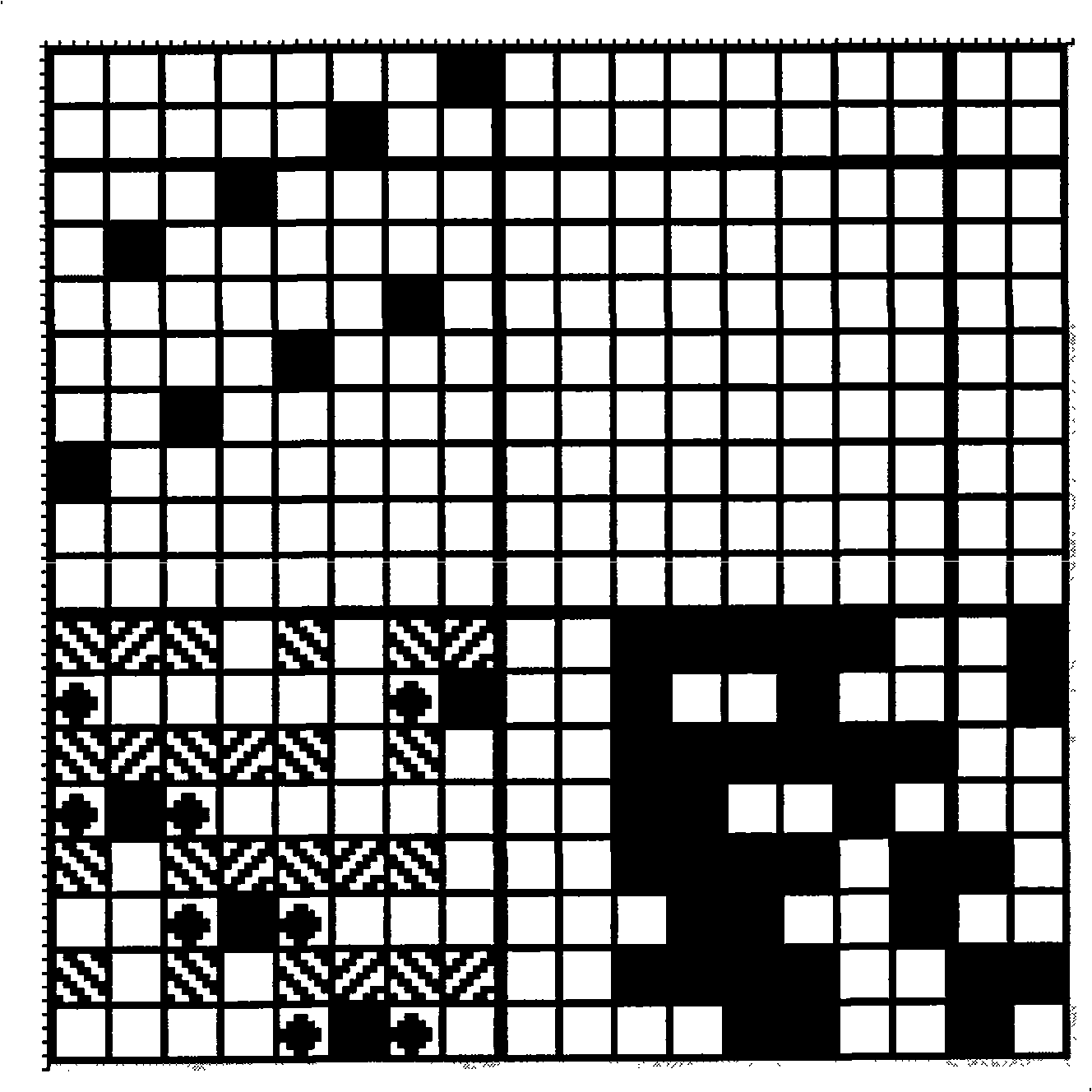

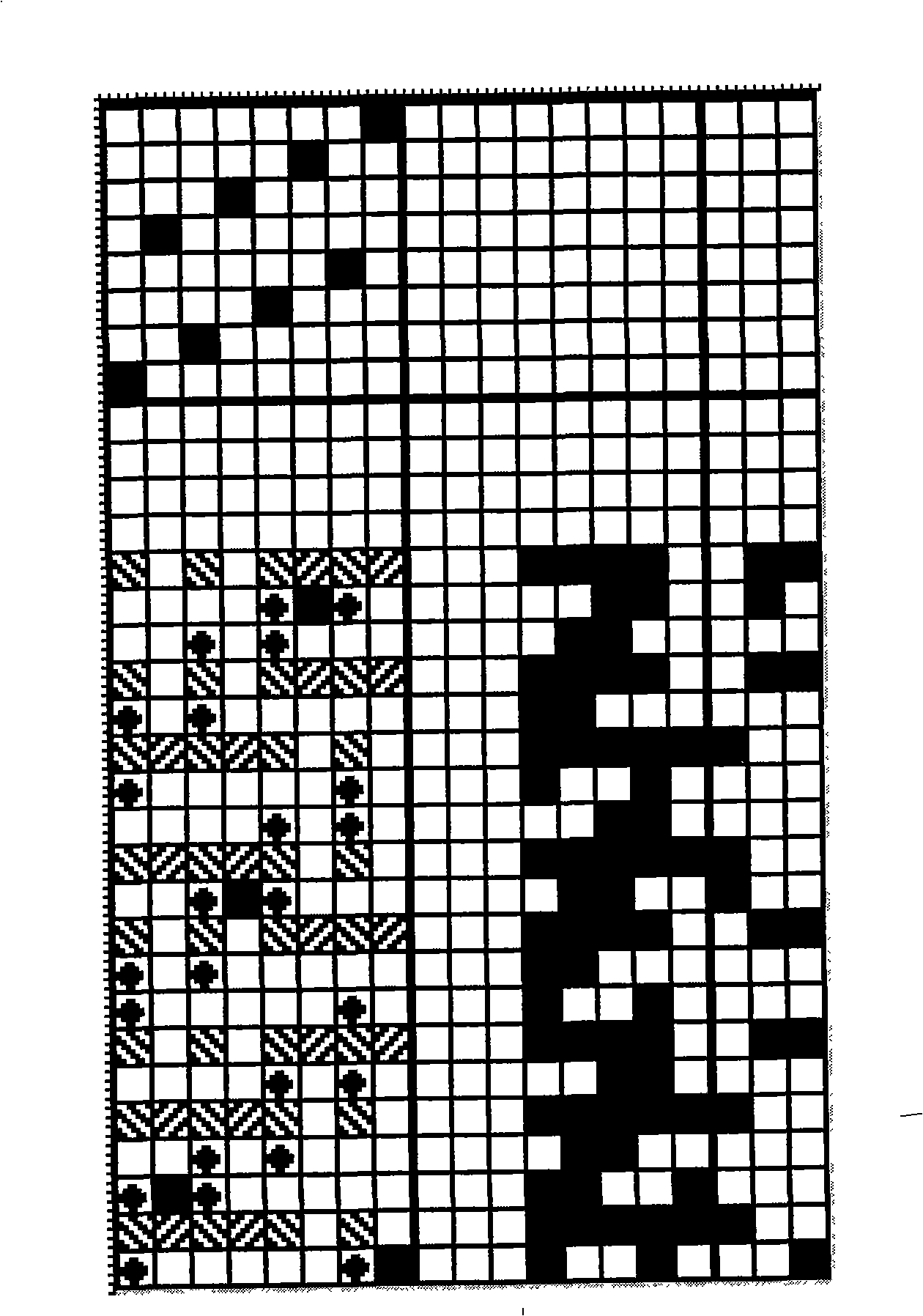

[0046] In this embodiment, the ramie / polyester double-layer fabric used for curtain cloth includes a surface layer and an inner layer. The surface layer is made of ramie yarn, and the inner layer is made of polyester yarn. One piece, the joints do not appear on the front and back of the fabric, see the organization diagram and the upper machine diagram image 3 , see Table 3 for technical specifications.

[0047] Present embodiment weaves on the HZF758 type rapier loom, and technological process is as follows:

[0048] (1) Preparation process

[0049] Twist fixation: The twist fixation of polyester warp yarns, weft yarns and ramie warp yarns and weft yarns is carried out in a ZDKX vacuum heat setting steamer at a temperature of about 100°C for about 70 minutes.

[0050] Warping: Firstly pre-warp the ramie yarn and polyester yarn according to the designed and calculated e...

Embodiment 3

[0059] Embodiment 3: ramie / polyester double-layer fabric wall covering and manufacture method thereof

[0060] In this embodiment, the ramie / polyester double-layer fabric used for wall coverings includes a surface layer and an inner layer, the surface is made of ramie yarn, and the inner layer is made of polyester yarn, and the surface layer and the inner layer are integrated by joints , the joints do not appear on the front and back of the fabric, and its tissue diagram and machine diagram are as follows Figure 4 As shown, the technical specifications are shown in Table 5.

[0061] Table 5 Technical specifications of ramie / polyester double-layer fabric wall covering

[0062]

[0063] The production process of the present embodiment is basically the same as that of Example 1, the difference being that the number of heddles used is 11 pages, of which 9 pages are ground healds and 2 pages are side healds;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com