Processing method for rapidly rehydrating dried osmunds

A processing method and a technology for dried kelp, which is applied in the field of fast rehydration of dried cabbage, can solve the problems of easy damage to the tissue structure, quality decline, rot, etc., achieve control of quality and commerciality, save production costs, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

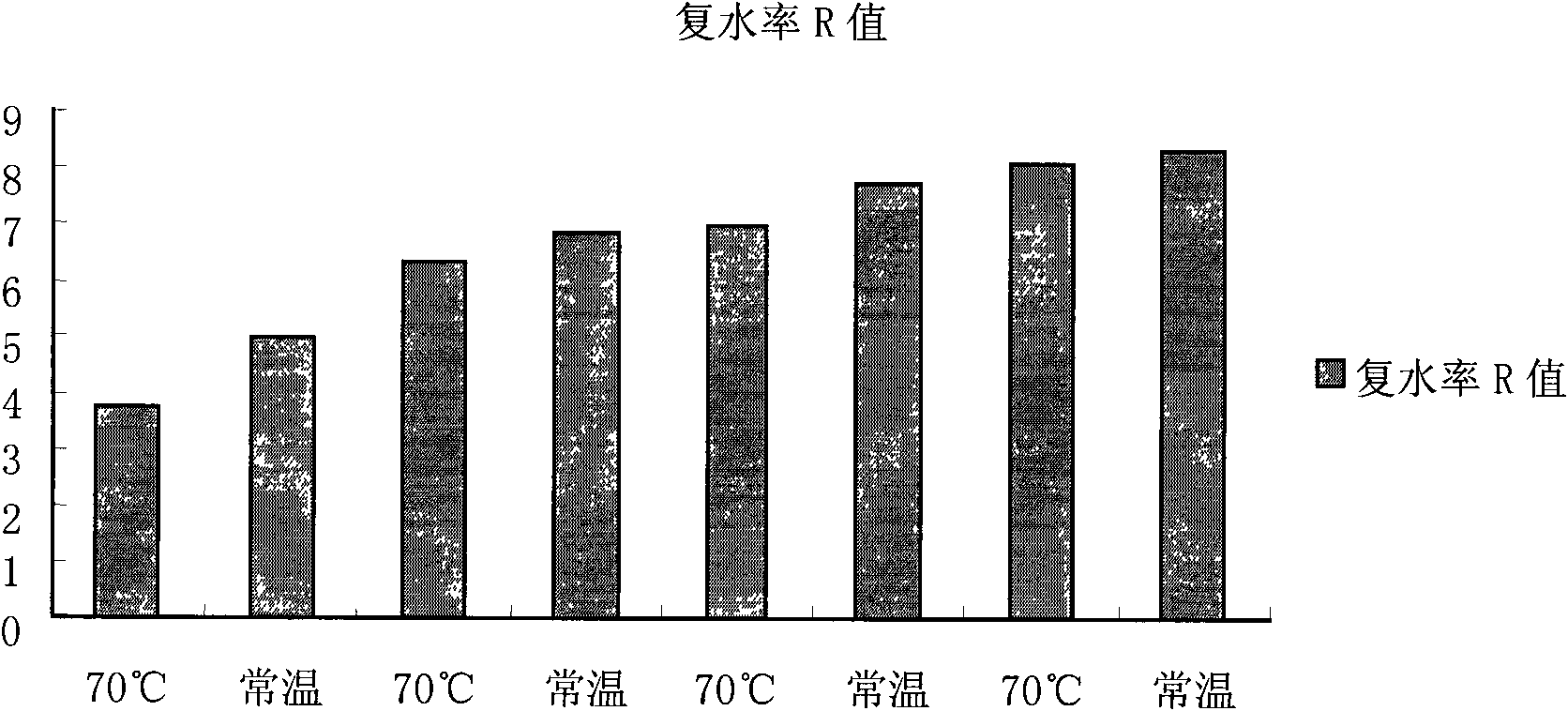

[0022] This example is mainly to test the effect of soaking temperature on the rehydration effect of dried weed

[0023] Pick a dry sample of Osmanthus vinaigrette with uniform size and color from the raw materials, weigh 3 g each time, soak for a fixed time of 12 hours, and soak at a ratio of 1:20, and place them in 40°C, 50°C, and 60°C respectively , 70°C, and 80°C constant temperature water baths, and after soaking, the texture changes of Dried Osmanthus after rehydration were measured. The test structure is shown in Table 1.

[0024] Table 1 Analysis of dry hardness of vetch at different temperatures

[0025]

[0026]

[0027] It can be seen from Table 1 that the hardness in the temperature range of 60-80 °C meets the requirements, and the quality is the best at 70 °C.

Embodiment 2

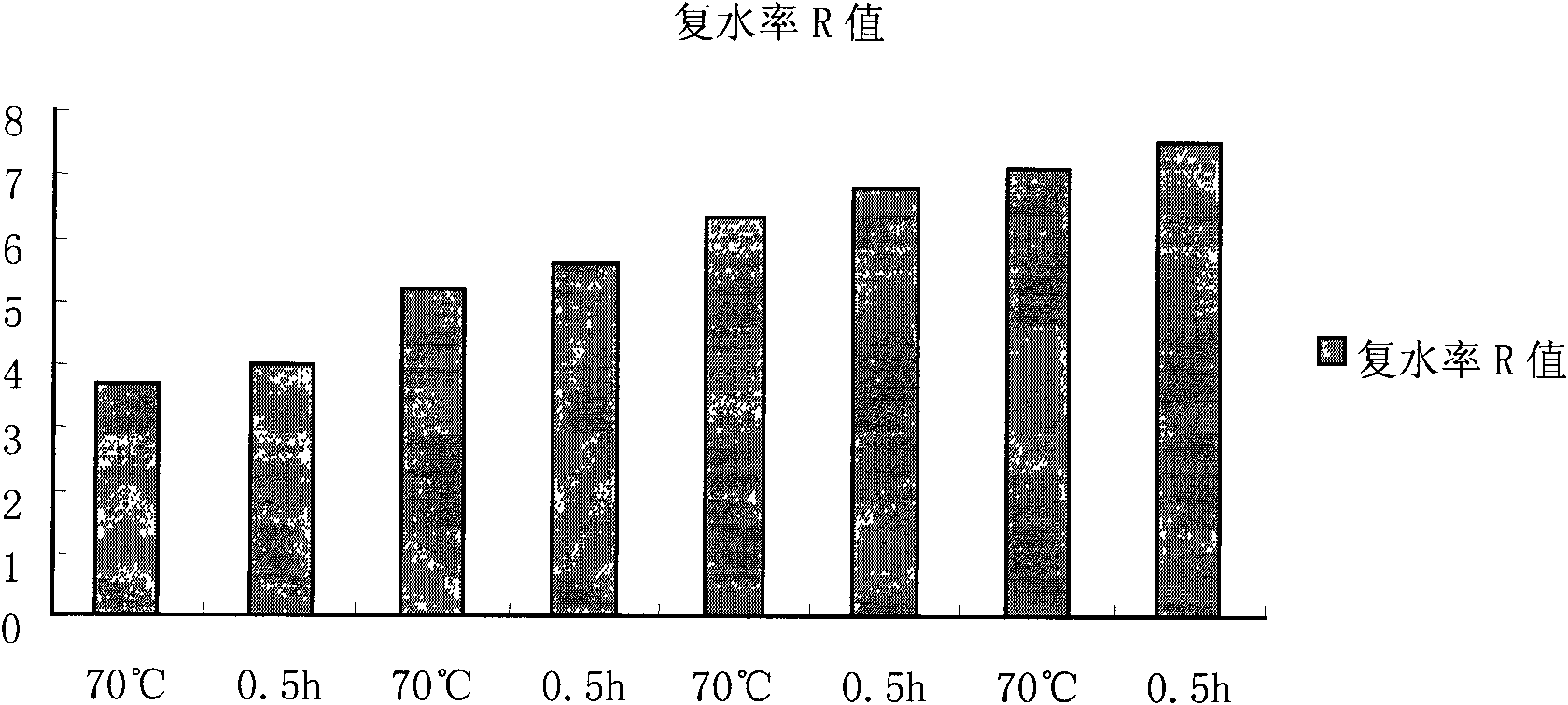

[0029] This example is mainly to test the influence of soaking time on the rehydration effect of dried welt

[0030] Pick dry samples of Osmanthus vetense with uniform size and color from the raw materials, weigh 3 g of each dried sample of Osmanthus vetense, fix the soaking temperature at 70°C, and soak at a ratio of 1:20, put them in a constant temperature water bath for 4 hours, After 6h, 8h, 10h, and 12h, the texture changes of Dried Osmanthus after rehydration were measured, and the data are shown in Table 2.

[0031] Table 2 Analysis of the dry hardness of vetch under different soaking times

[0032]

[0033] As can be seen from Table 2, the effect of soaking time in 6-10 hours is better, especially 10h is the best.

Embodiment 3

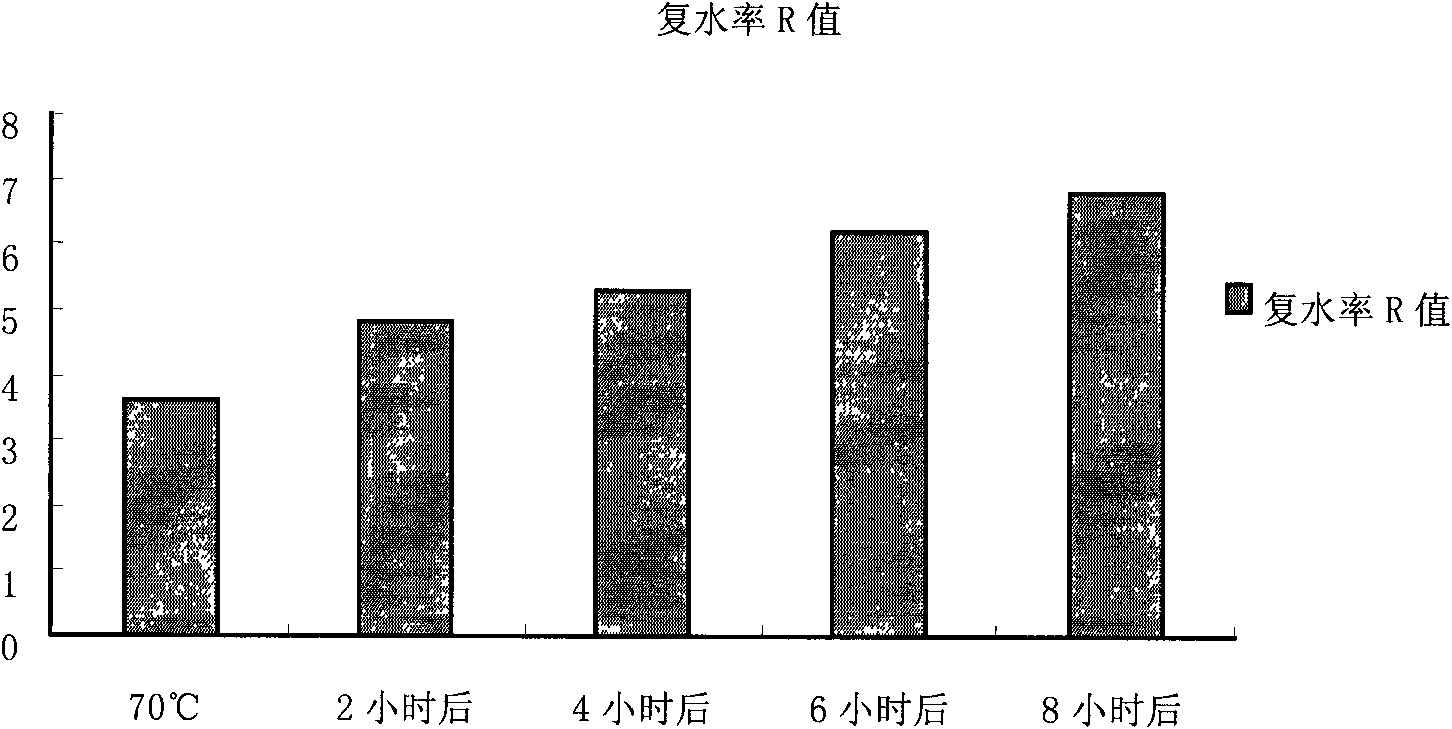

[0035] This example is mainly to test the influence of the soaking ratio on the rehydration effect of dried weed

[0036] Pick dry samples of Osmanthus spinach with uniform size and uniform color from the raw materials, weigh 3 g of Dried Osmanthus spinach each time, fix the soaking temperature at 70°C, soaking time for 10 hours, and the soaking ratios are 1:20, 1:30, 1:40, 1:50, and 1:60 were soaked in a constant temperature water bath to measure the texture changes of dried welt. The test structure is shown in Table 3.

[0037] Table 3 Analysis of dry hardness of weed cabbage under different soaking ratios

[0038]

[0039] It can be seen from Table 3 that the ratio of material to liquid has a great influence on the texture, but the change is small. It can be 1:20-40, preferably 1:30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com