Device and method for automatically removing sprue

A gate and automatic technology, which is applied in the field of automatic gate removal devices, can solve problems affecting machining processes, large gate residues, high noise from electric saws, etc., and achieve high work efficiency and safety. High consistency, the effect of realizing the whole process of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

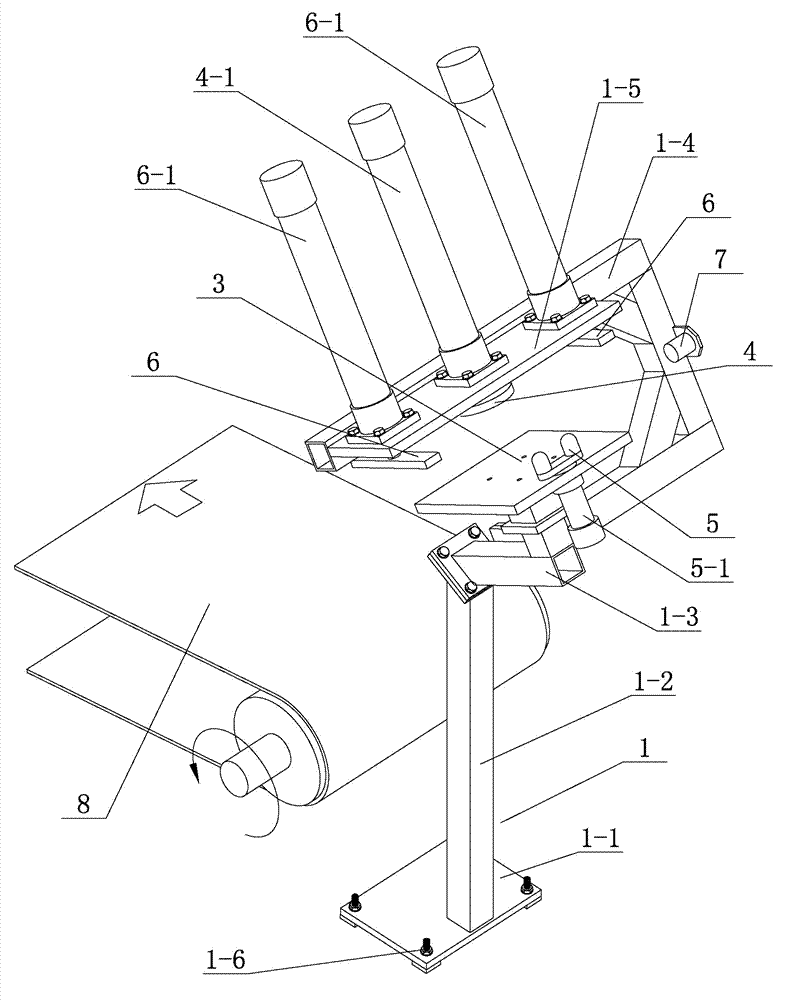

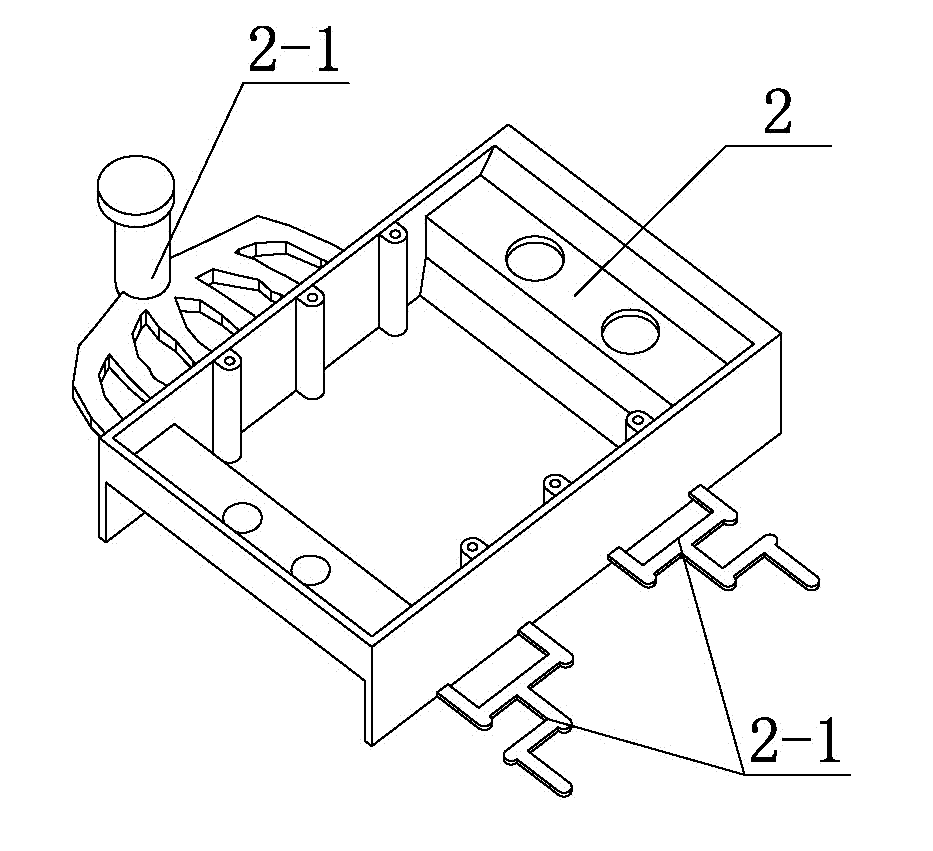

[0018] Such as figure 1 , figure 2 , a device for automatically removing the gate, removes the gate of the workpiece during casting on the automatic production line, including a frame 1, a workbench 3 for placing the workpiece 2, a workpiece chuck 4, a positioning head 5, a punch 6, Grating sensor 7; It is characterized in that, described frame supports a described workbench with inclination; The described positioning head that is used to locate workpiece is installed on the workbench; Described workpiece clamping head is positioned at the workbench top, workpiece clamp The head can move along the direction perpendicular to the table top to press the workpiece on the work table; the hammer is located above the side of the table, and the hammer can face the gate of the workpiece on the outside of the work table in the direction perpendicular to the table top The position of the grating sensor is installed on the frame, and the installation height of the grating sensor is equa...

Embodiment 2

[0031] A method for automatically removing gates, said method is based on the method for removing gates of the device for automatically removing gates in Embodiment 1.

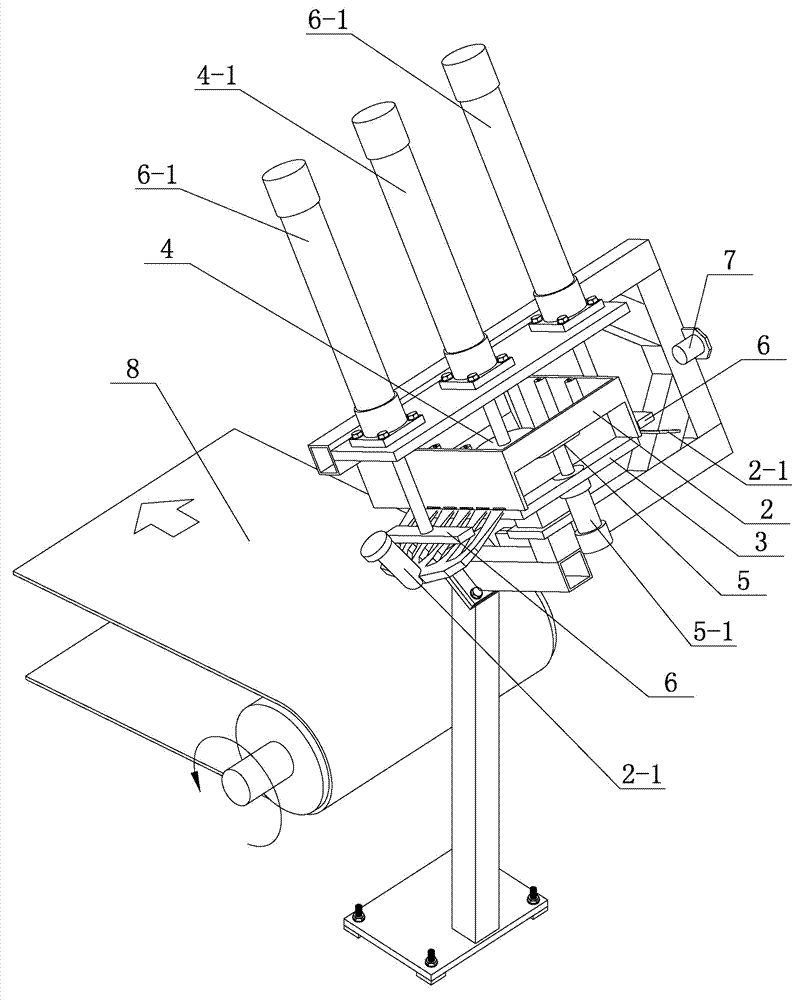

[0032] Such as image 3 , when the grating sensor 7 detects that there is no workpiece on the workbench 3, the robot operates a manipulator (not shown in the figure) to place a workpiece 2 on the workbench, and the positioning cylinder 5-1 pushes the positioning The head 5 protrudes upward from the workbench surface to position the workpiece, the chuck cylinder 4-1 pushes the workpiece chuck 4 to move downward to press the workpiece on the workbench, the manipulator returns to a safe position, and the robot operates two Support the hammer cylinder 6-1 to push the two hammers 6 to stamp and remove the workpiece gate 2-1 on the outside of the workbench along the direction perpendicular to the workbench surface; Figure 4 After the gate of the workpiece is removed, the hammer cylinder drives the hammer to reset,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com