Die for building materials products and preparation method thereof

A technology for molds and products, applied in the field of molds for building materials and their preparation, can solve the problems of large amount of silica gel, environmental pollution, increase in manufacturing processes and costs, etc., and achieve the effects of speeding up mold turnover, reducing production costs, and simplifying production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

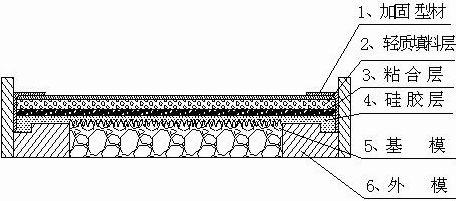

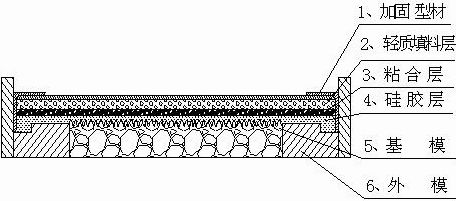

[0020] The mold for building material products of the present invention is composed of a surface layer of non-stick material, an adhesive layer and a hard base material.

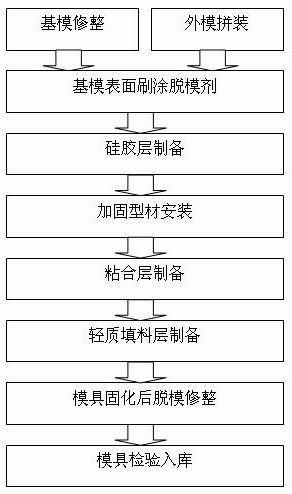

[0021] Specific steps are as follows:

[0022] 1) Use an air pump to clean the surface of the master mold, then evenly brush the release agent and let it stand for 10 minutes;

[0023] 2) Use a spatula to evenly spread the silicone surface layer on the surface of the master mold; after vacuum treatment, place two 25 angle irons in the length and width directions of the mold, and let it stand for 30 minutes;

[0024] 3) After the silicone surface layer is gelled, use a spatula to lay a silicone adhesive layer with a thickness of 2mm and vulcanize at room temperature for 10 minutes; lay a layer of gauze and let it stand for 60 minutes to wait for condensation;

[0025] 4) Lay the epoxy resin adhesive layer, that is, evenly lay a layer of epoxy resin gel coat on the gauze, then lay the glass fiber mesh cloth i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com