Suspended degassing device

A suspension type and gas device technology, applied in the field of suspension type degassing device, can solve the problems of poor structure stability of degasser, affecting refining effect, severe vibration, etc., to avoid molten aluminum shaking, good structural stability, and vibration amplitude. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

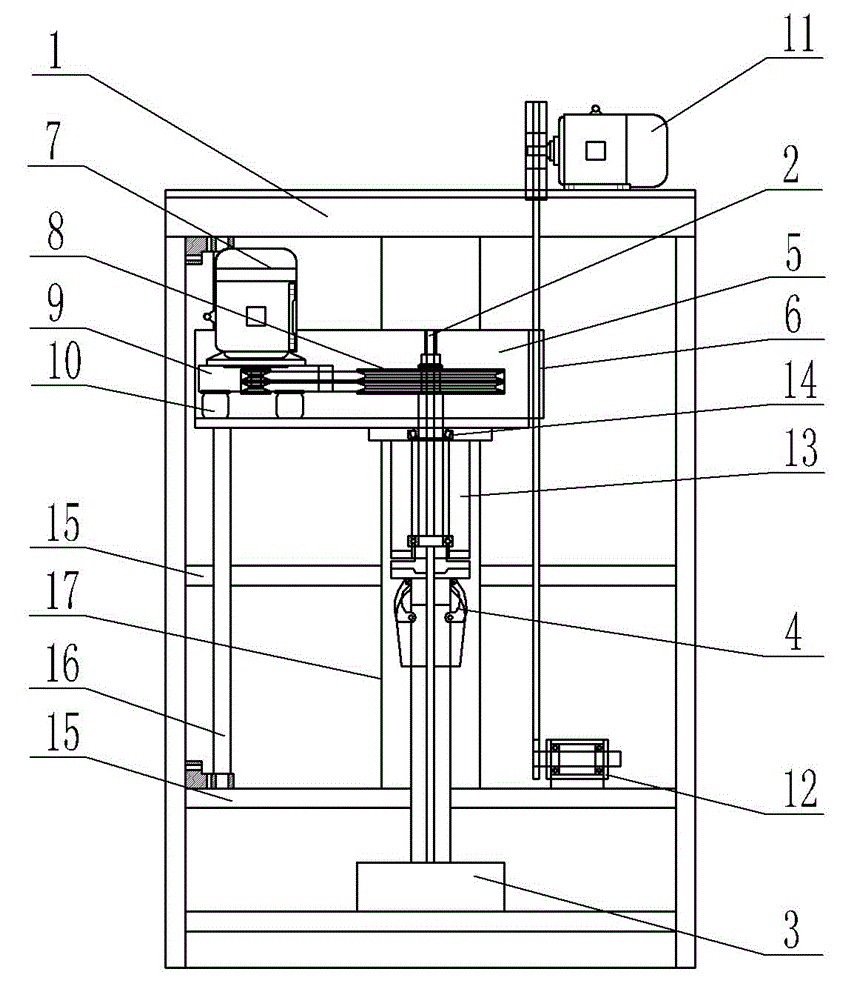

[0013] Such as figure 1 As shown, it includes a frame 1, a graphite rotor 3, a blowing pipe 2 and a rotor driving device, and the graphite rotor 3 and the blowing pipe 2 are connected through a connecting sleeve 4, which is characterized in that it also includes a guide rail 17, a lifting platform 5, and a guide post 16 And lifting driving device, frame 1 is provided with some crossbeams 15, and guide rail 17 is arranged in parallel with guide post 16, and is supported by crossbeam 15, and the two ends of lift table 5 are respectively connected with guide rail 17, guide post 16 slidingly, and lift table 5 The lower part is fixed with a bearing seat 13, and the blowing pipe 2 and the bearing seat 13 are installed together. The lifting platform 5 is provided with a driven wheel 6 and an elastic support 10. The driven wheel 6 cooperates with the lifting drive device, and the elastic support 10 is used to support the rotor drive. device.

[0014] The rotor driving device comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com