Hot rolled steel plate five-roll straightening machine

A technology for hot-rolled steel plate and roll leveling, which is applied in the field of five-roll straightening machine for hot-rolled steel plate, can solve the problems of difficulty in manufacturing and maintenance, inconvenient control, insufficient adjustment accuracy of roll gap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

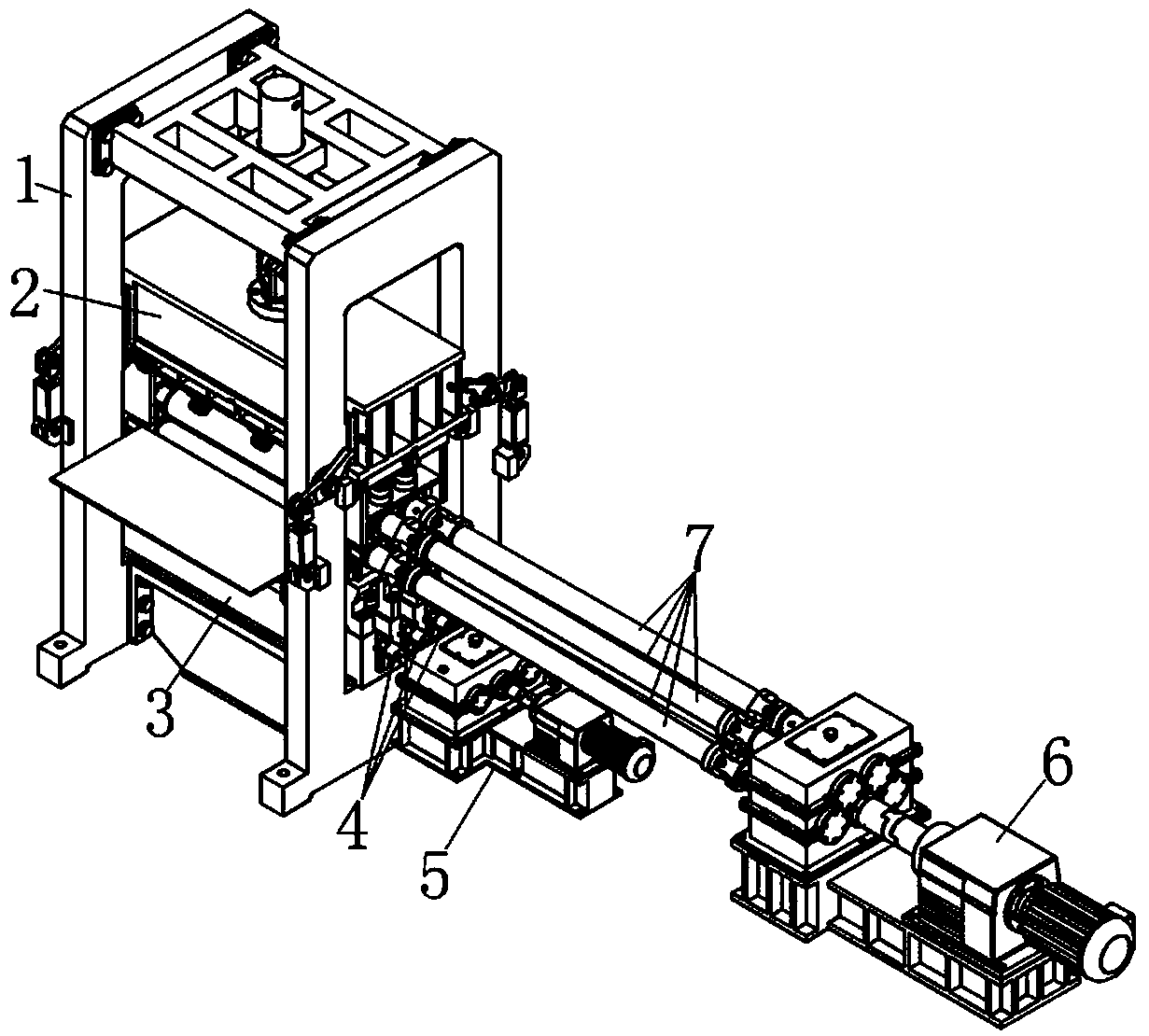

[0038] see figure 1 , the present invention is composed of a basic device 1, an upper roller device 2, a lower roller device 3, three Oldham couplings 4, a roll gap adjustment drive device 5, a straightening roller drive device 6, and five double universal joints The upper roller device 2 and the lower roller device 3 are arranged on the basic device 1, the roll gap adjustment driving device 5 is connected with the lower roller device 3 through three Oldham couplings 4, and the straightening roller driving device 6 It is connected with the upper roller device 2 through five double universal joints 7 .

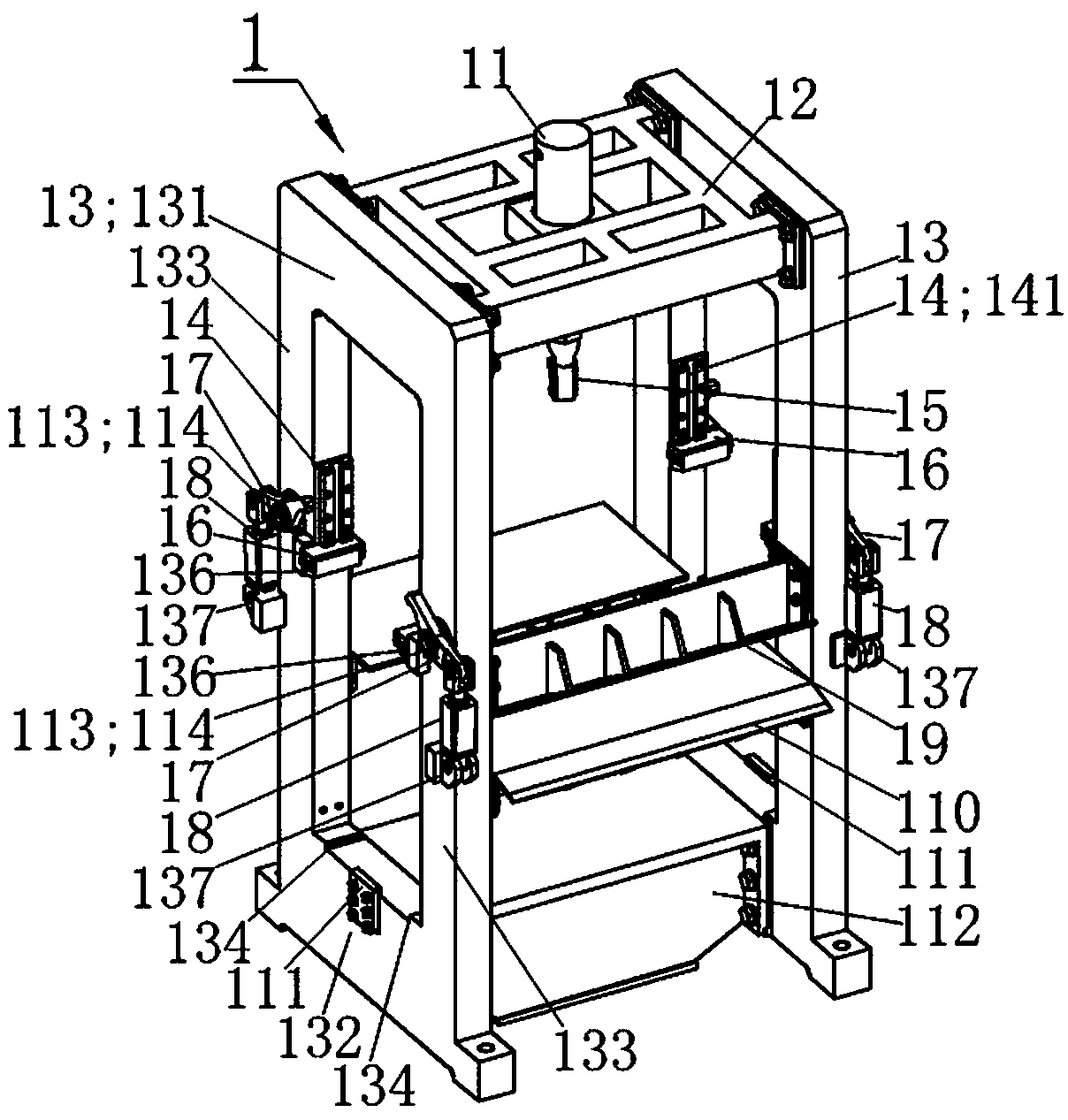

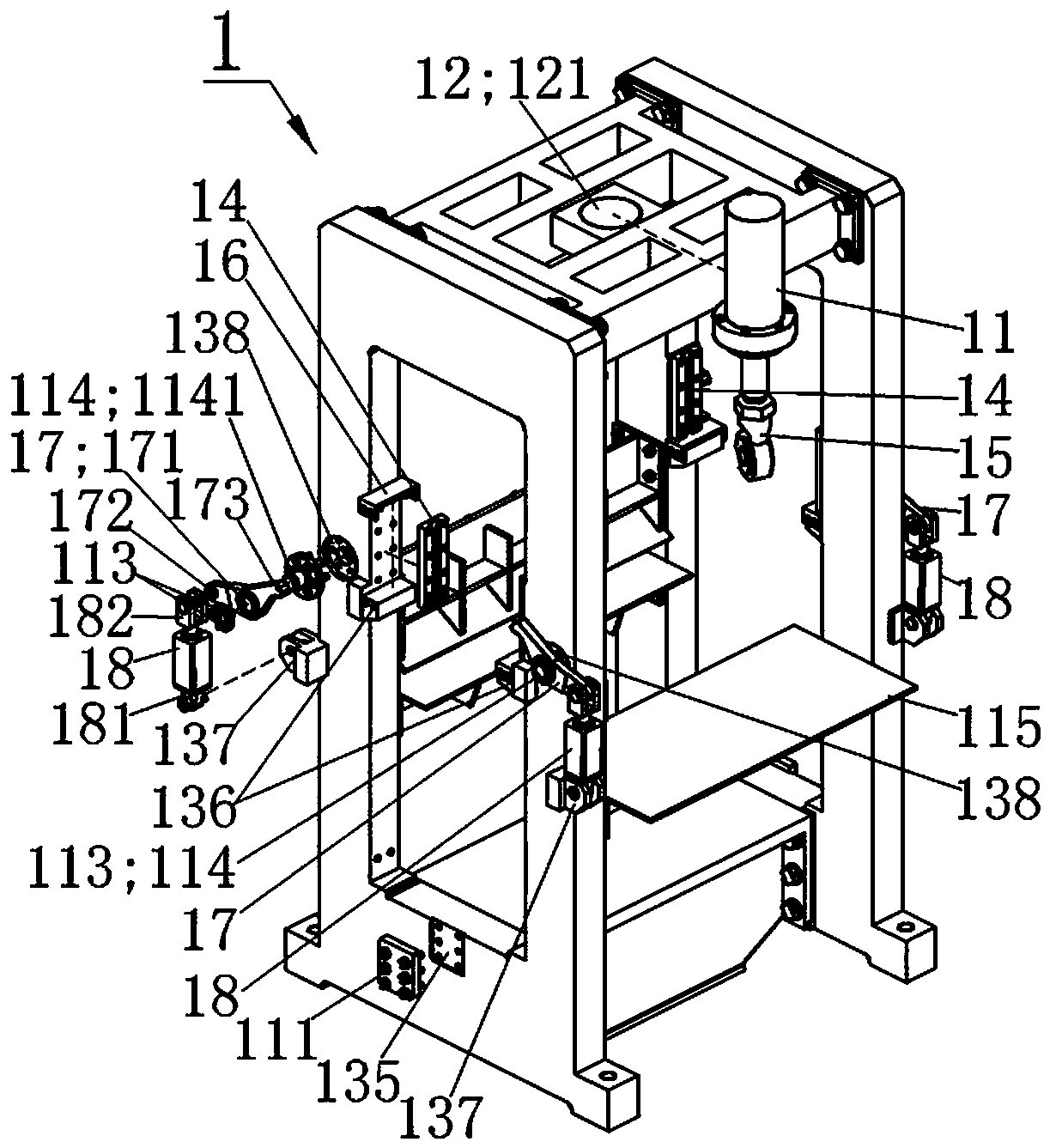

[0039] see figure 2 , image 3 As shown, the basic device 1 is composed of a lifting hydraulic cylinder 11, an upper connecting frame 12, two frames 13, four inner guide plates 14, joint bearing lugs 15, four backing plates 16, and four levers 17. , four clamping hydraulic cylinders 18, inlet upper guide plate 19, inlet lower guide plate 110, two thrust plates 111, lower conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com