Non-contact precision measuring instrument

A non-contact, precision measurement technology, applied in the field of measuring instruments, can solve the problems of easily damaged product surface, affect the quality, low precision, etc., achieve the effect of convenient operation, ensure measurement accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

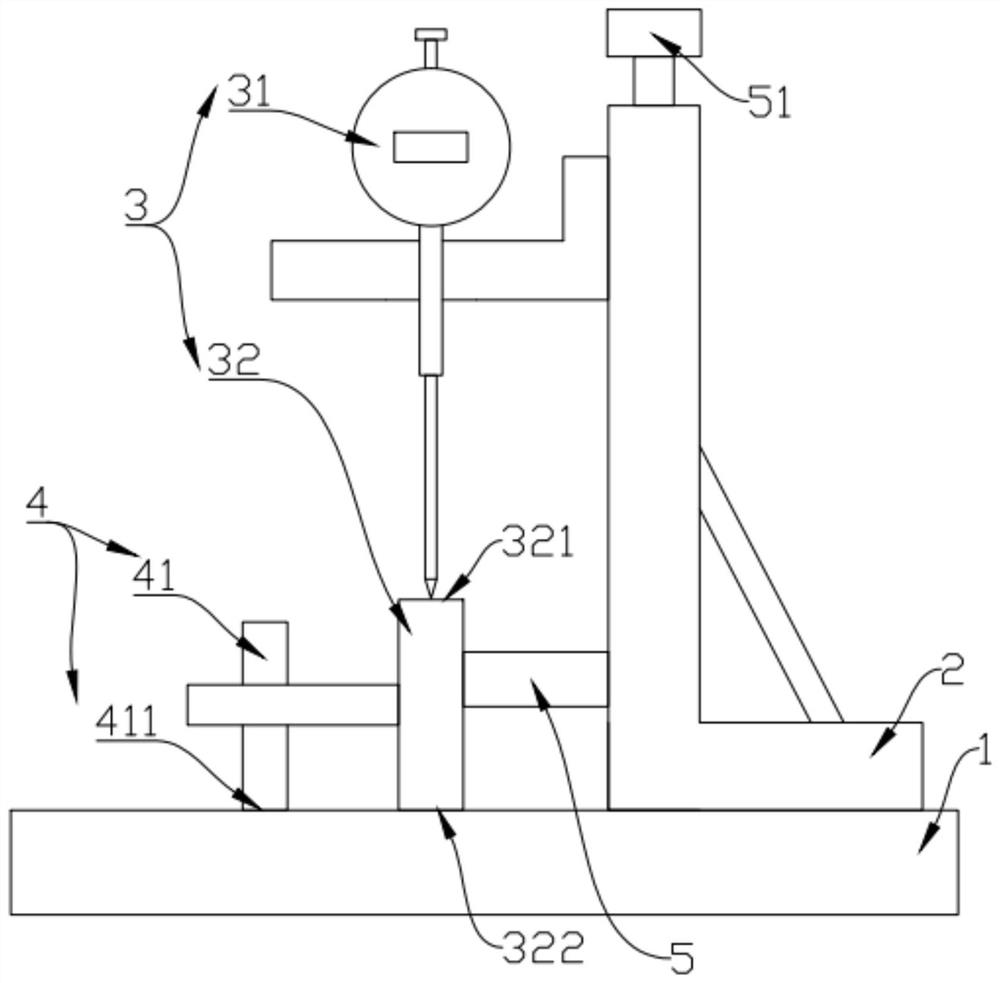

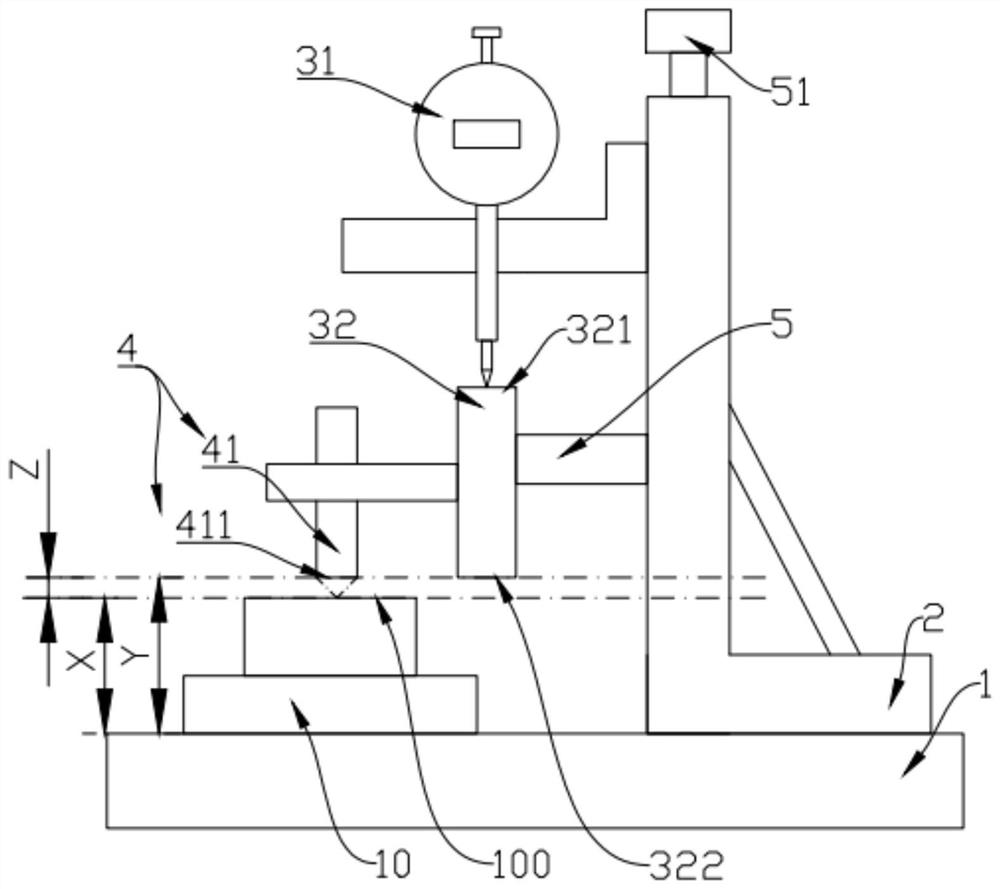

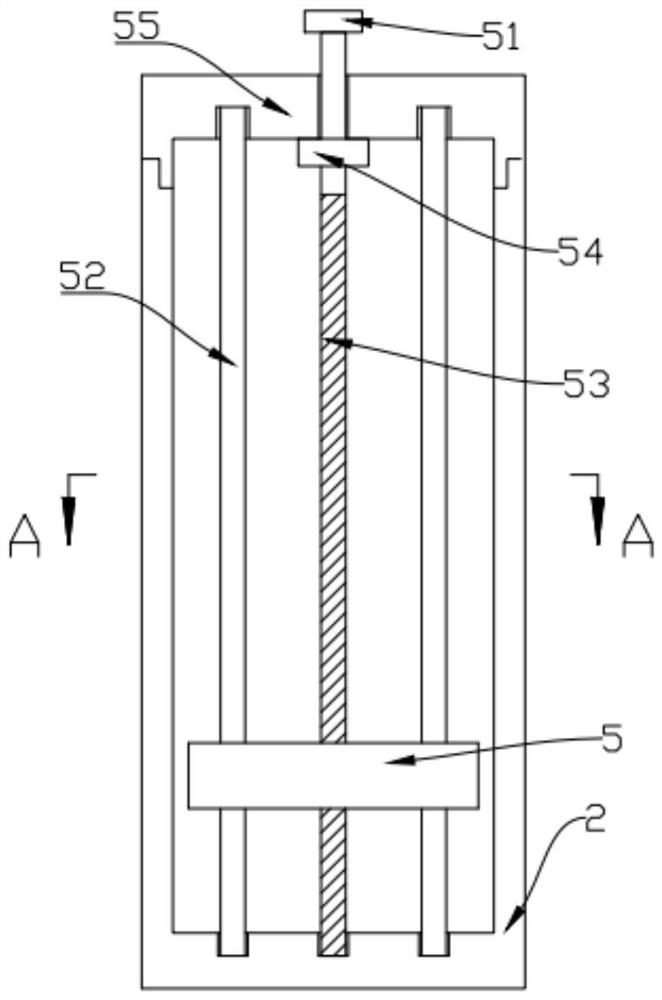

[0020] like figure 1 As shown, the technical solution of the present invention is a non-contact precision measuring instrument, including a measuring platform 1 for placing a test piece 10 and a measuring tool. The measuring tool includes a column 2 placed on the measuring platform 1 and a series connection on the column 2. Coarse gauge 3 and fine gauge 4. The rough measuring tool 3 includes a lifting block 32 and a dial indicator 31 placed on the top of the lifting block 32. When the bottom surface 322 of the lifting block 32 is placed on the measuring platform 1, the thimble of the dial indicator 31 contacts the top surface 321 of the lifting block 32. and display a reading of zero. The precision measuring tool 4 includes a non-contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com