Material conveying mechanism

A material and transportation line technology, applied in the field of machinery, can solve the problems of reducing the life of the drive motor, affecting the normal operation of the production line, and increasing the failure rate, so as to reduce the failure rate, increase reliability and accuracy, and reduce the failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

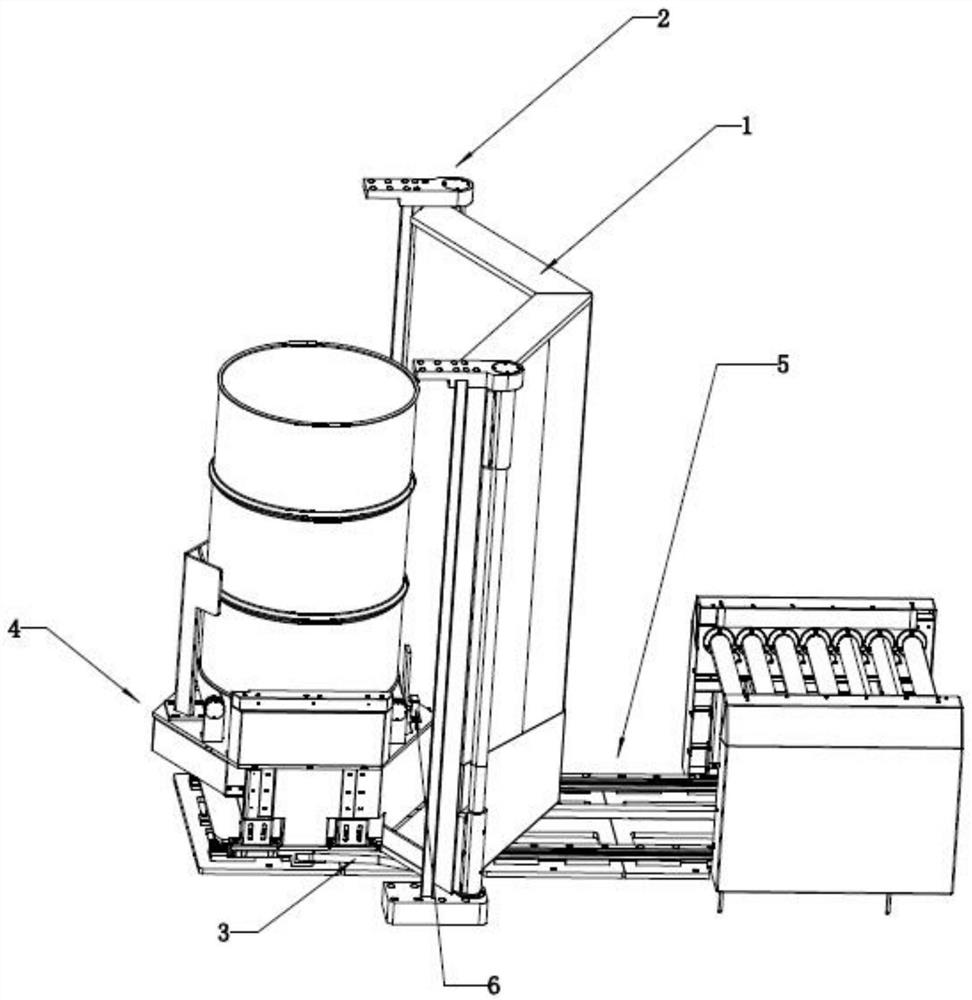

[0040] Such as figure 1 As shown, the present invention provides a material transportation mechanism, including a linkage door opening and closing mechanism, a transportation line and an automatic stop mechanism 6; the material carrier 4 of the linkage opening and closing mechanism moves out of the opening and closing door 1 and then docks with the transportation line to The material is transferred to the transport mechanism; the automatic stop mechanism 6 is set on the material carrier 4 and / or the transport line to prevent or allow the transport of the material.

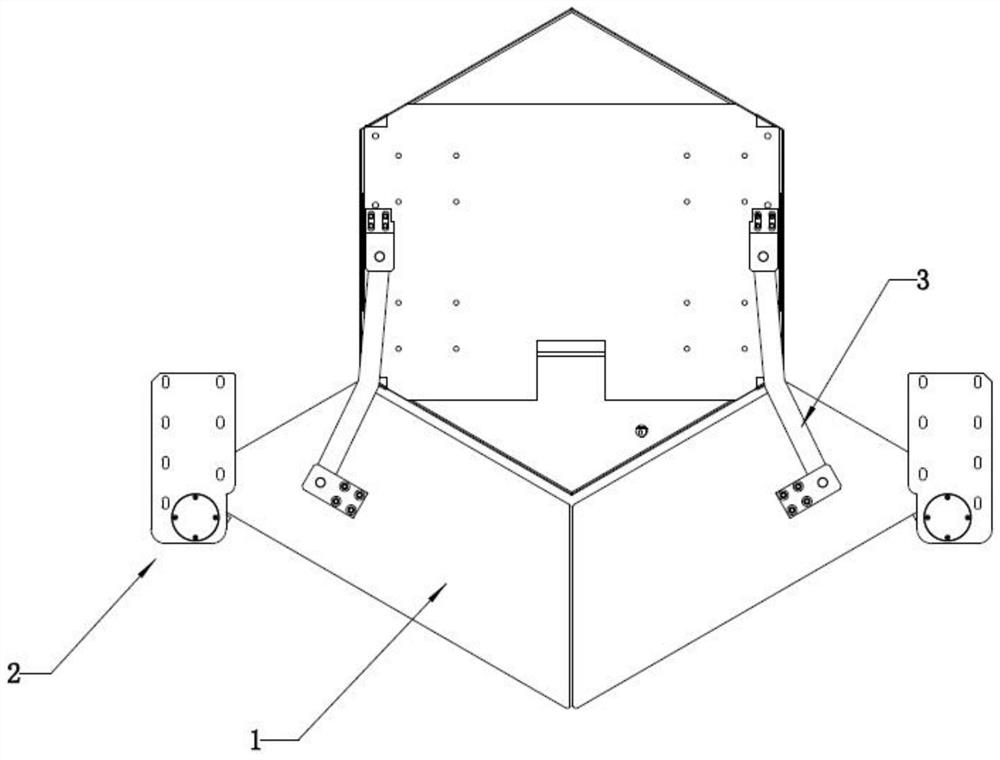

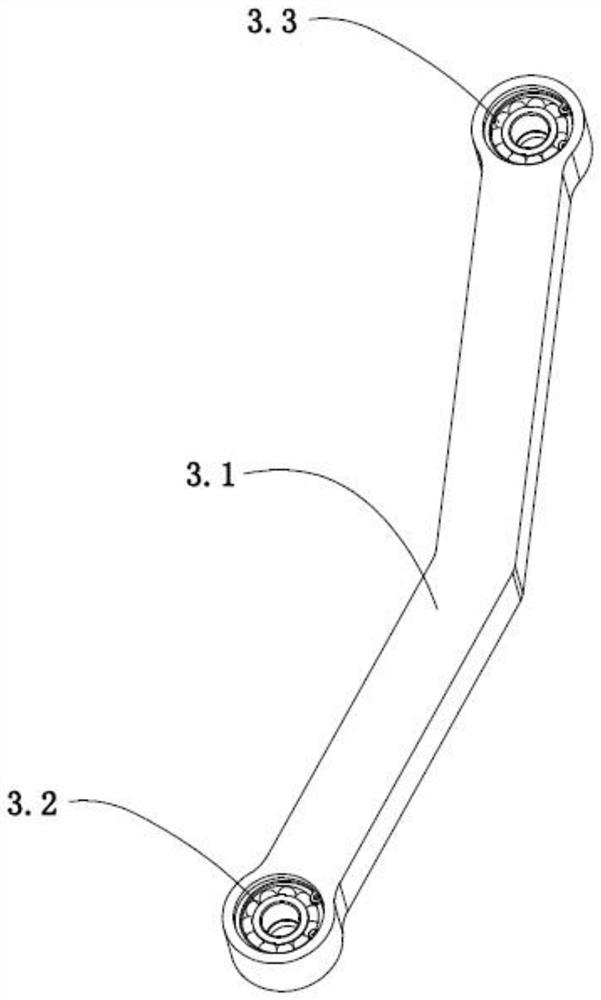

[0041] Such as figure 2 As shown, the linkage opening and closing mechanism includes a switch door 1, a rotating shaft part 2, a material carrier 4 and a connecting rod part 3; the opening and closing door 1 is installed through the rotating shaft part 2 and can rotate around the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com