Bread automatic making machine, bread ingredient box and bread rapid making method

A raw material box and making machine technology, which is applied in the directions of toasting devices, baking, household appliances, etc., can solve the problems of inability to solve the batching process, the increase of learning costs, and the failure of bread, and achieve simplified operation, reduced failure rate, and simplified steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

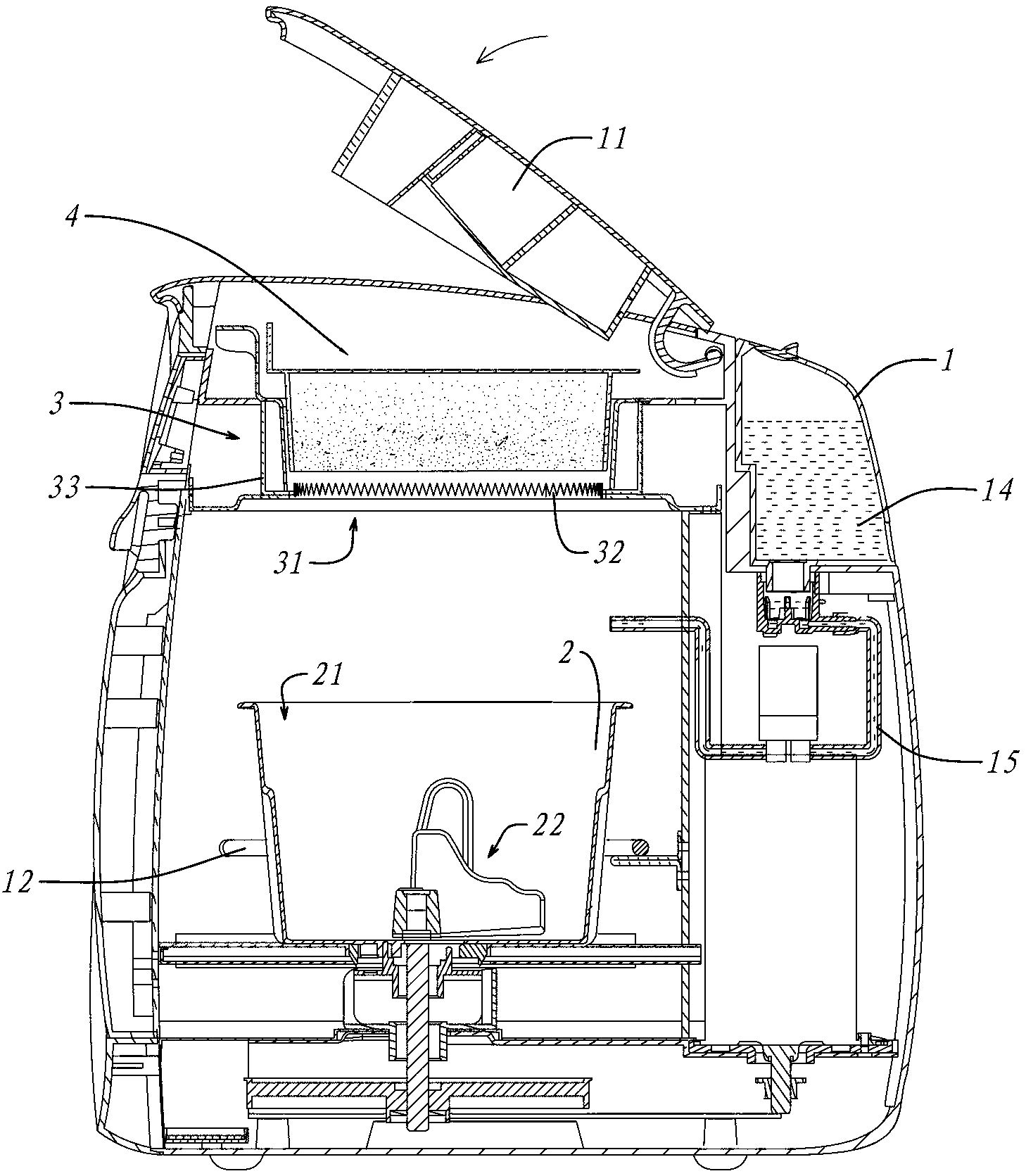

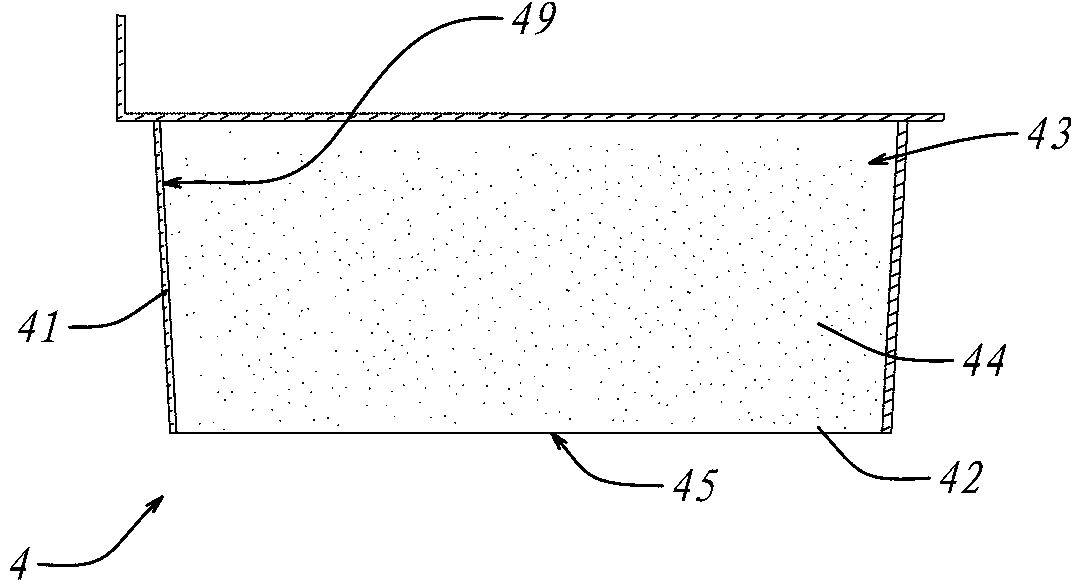

[0069] Embodiment one of the present invention, see Figure 1 to Figure 5 , including a complete bread raw material box 4, a complete automatic bread making machine;

[0070] Such as figure 1 , which is a cross-sectional view of a bread raw material box 4 loaded on an automatic bread making machine; the automatic bread making machine includes a shell 1, which has an inner container 2 inside, and this inner container 2 has a stirrer 22, and its outside also has Electric heating tube 12, so the inner container 2 and its accessories have the conventional functions of stirring and heating bread raw materials.

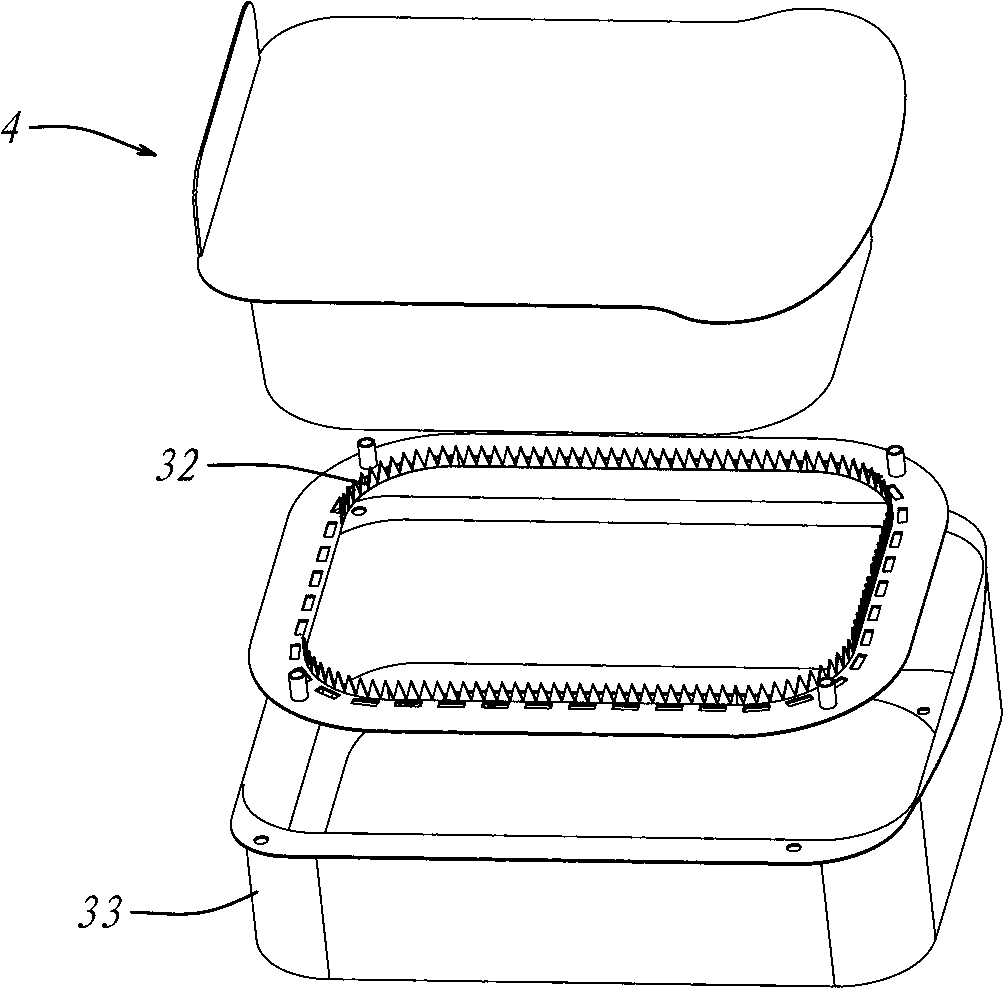

[0071] The inner container 2 has an upward inlet 21; in the shell 1, there is a hanger 3 above the inlet 21 of the inner container 2, and this hanger 3 can place the bread raw material box 4 so that it is positioned inside; and, the hanger Also have sawtooth bar 32 and the drop opening 31 below sawtooth bar 32 on the 3. It can be seen that the sawtooth bar 32 is located ...

Embodiment 2

[0087] Such as Figure 6-Figure 8 , are schematic diagrams of Embodiment 2 of the present invention:

[0088] Figure 6It is a sectional view of the second embodiment, with a bread raw material box and an automatic bread making machine; the bread raw material box 4 of this embodiment two has two accommodation spaces, and the hanger principle of the automatic bread making machine 3 is also the same as that of the first embodiment different. Cooperate Figure 7 , there is a blanking electromagnet 17 in the hanger 3, and the blanking electromagnet 17 controls a double-headed lever 172 through a push-pull rod 171. Article 32 Overall activities. The sawtooth bar 32 is movable up and down on the outside of the receiving groove 33 through the guide post assembly 175 with a return spring. According to the double-space structure of the bread raw material box 4, its accommodating groove 33 and the sawtooth bar 32 correspond to the two accommodating spaces one by one.

[0089] Fi...

Embodiment 3

[0095] Such as Figure 9-Figure 14 Shown, embodiment three of the present invention:

[0096] Figure 9 The sectional view of the third embodiment of the present invention has a bread raw material box and an automatic bread making machine; similar to the foregoing embodiments, the structure of the shell 1, the upper cover 11, and the inner container 2 are equivalent. The bread raw material box 4 of the third embodiment is the same as that of the second embodiment, and adopts the form of two independent accommodation spaces, and also has an ingredient mark 46 .

[0097] In the hanger 3 of this embodiment, there is a tray 37 and a bin 34 corresponding to the bread raw material box 4 . see you at the same time Figure 10 , the three-dimensional schematic diagram of the bread raw material box 4 and part of the hanger 3 accessories; the tray 37 can limit the bread raw material box 4 in the horizontal direction, and the tray 37 is a structure that can move up and down relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com