Stirrer

A technology for mixers and mixing boxes, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of shortening the service life of mixer shafts, difficulty in replacing mixing blade blades, and easy bending and deformation of mixer shafts. The effect of making bricks, ensuring the degree of maturity of the mixing material, and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

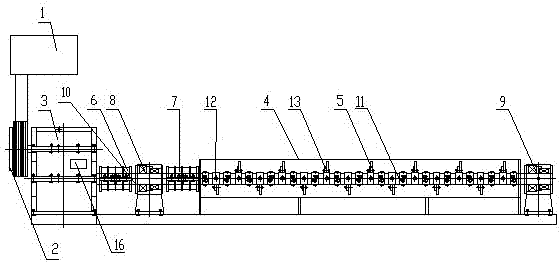

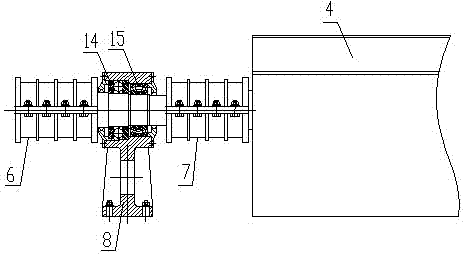

Embodiment 1

[0034] A mixer, including a motor 1, a clutch 2, a speed reducer 3, a mixing box 4, a stirring shaft, and a mixing knife blade 5, the motor 1 is connected to the speed reducer 3 through the clutch 2, the stirring shaft is driven by the motor 1, and a first clamping case is also included Coupling 6, the second clamshell coupling 7, front joint two bearing blocks 8, rear joint two bearing blocks 9, the stirring shaft is composed of the stirring short shaft 10 outside the stirring box 4 and the stirring shaft 10 inside the stirring box 4 Stirring long shaft 11 is formed, and one end of said stirring short shaft 10 is connected with the low-speed shaft of reducer 3 through the first shell coupling 6, and the other end is connected with the bearing inner hole of the second bearing seat 8 of the front coupling. One end of the shaft 11 is connected with the inner hole of the bearing of the second bearing seat 8 of the front coupling through the second shell coupling 7, and the other e...

Embodiment 2

[0037]A mixer, including a motor 1, a clutch 2, a speed reducer 3, a mixing box 4, a stirring shaft, and a mixing knife blade 5, the motor 1 is connected to the speed reducer 3 through the clutch 2, the stirring shaft is driven by the motor 1, and a first clamping case is also included Coupling 6, the second clamshell coupling 7, front joint two bearing blocks 8, rear joint two bearing blocks 9, the stirring shaft is composed of the stirring short shaft 10 outside the stirring box 4 and the stirring shaft 10 inside the stirring box 4 Stirring long shaft 11 is formed, and one end of said stirring short shaft 10 is connected with the low-speed shaft of reducer 3 through the first shell coupling 6, and the other end is connected with the bearing inner hole of the second bearing seat 8 of the front coupling. One end of the shaft 11 is connected with the inner hole of the bearing of the second bearing seat 8 of the front coupling through the second shell coupling 7, and the other en...

Embodiment 3

[0041] A mixer, including a motor 1, a clutch 2, a speed reducer 3, a mixing box 4, a stirring shaft, and a mixing knife blade 5, the motor 1 is connected to the speed reducer 3 through the clutch 2, the stirring shaft is driven by the motor 1, and a first clamping case is also included Coupling 6, the second clamshell coupling 7, front joint two bearing blocks 8, rear joint two bearing blocks 9, the stirring shaft is composed of the stirring short shaft 10 outside the stirring box 4 and the stirring shaft 10 inside the stirring box 4 Stirring long shaft 11 is formed, and one end of said stirring short shaft 10 is connected with the low-speed shaft of reducer 3 through the first shell coupling 6, and the other end is connected with the bearing inner hole of the second bearing seat 8 of the front coupling. One end of the shaft 11 is connected with the inner hole of the bearing of the second bearing seat 8 of the front coupling through the second shell coupling 7, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com