Differential reducer

A split reducer and reducer technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., to achieve the effects of small friction coefficient, compensation of coaxiality error, and relaxation of load impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

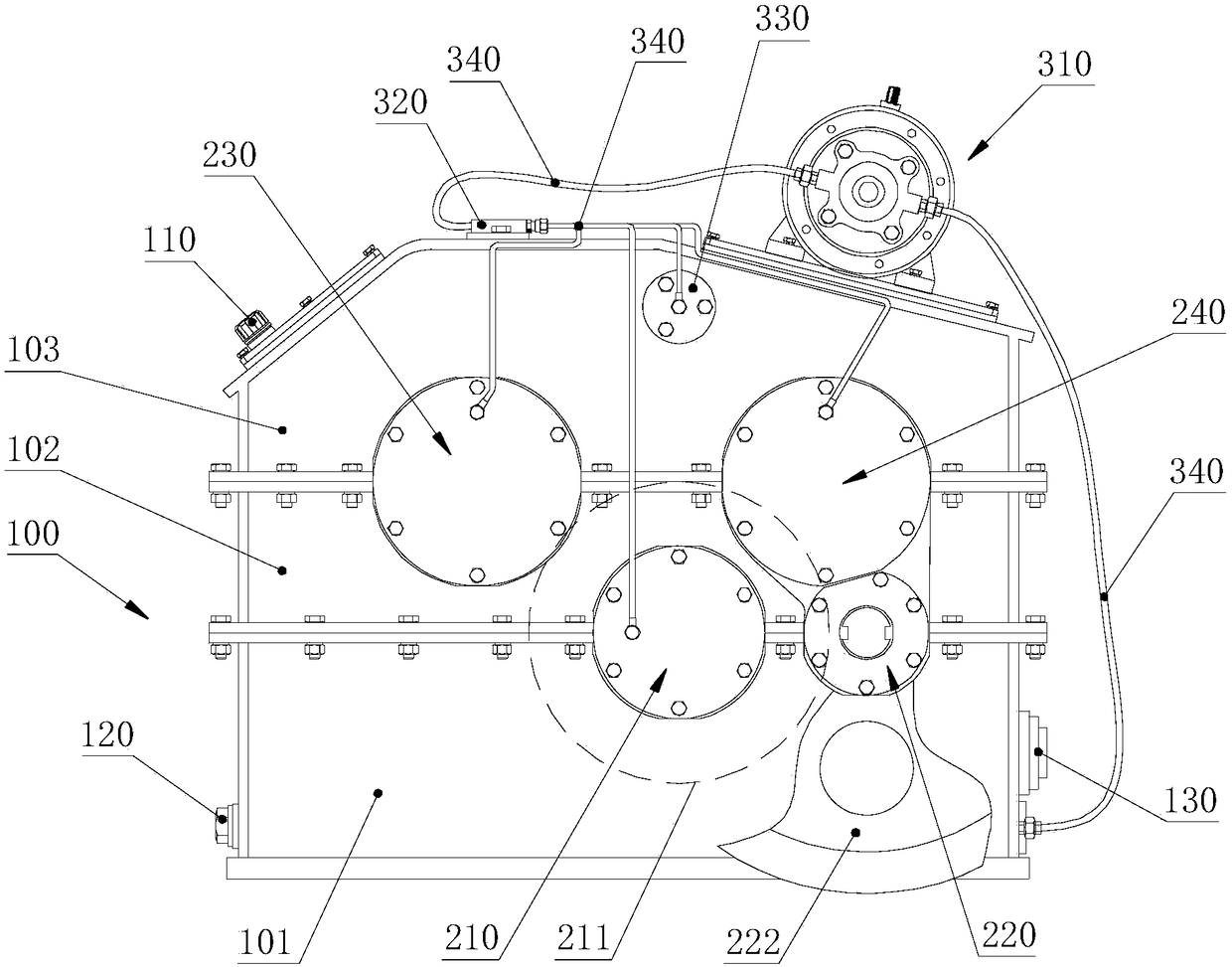

[0040] Please refer to figure 1, a transfer reducer, including: a sealed box 100, a reduction system and a lubrication system. The box body 100 includes a lower box body 101, a middle box body 102 and an upper box body 103 from bottom to top. The middle box body 102 is connected with the lower box body 101 and the upper box body 103 by bolts, and the connection positions are sealed. The bottom of the box 100 , that is, the lower box 101 has lubricating oil, the bottom side wall of the lower box 101 is provided with an oil drain plug 120 , and the middle side wall of the lower box 101 is provided with a cursor 130 . The side wall of the upper box body 103 is provided with a valve-type ventilation cap 110 .

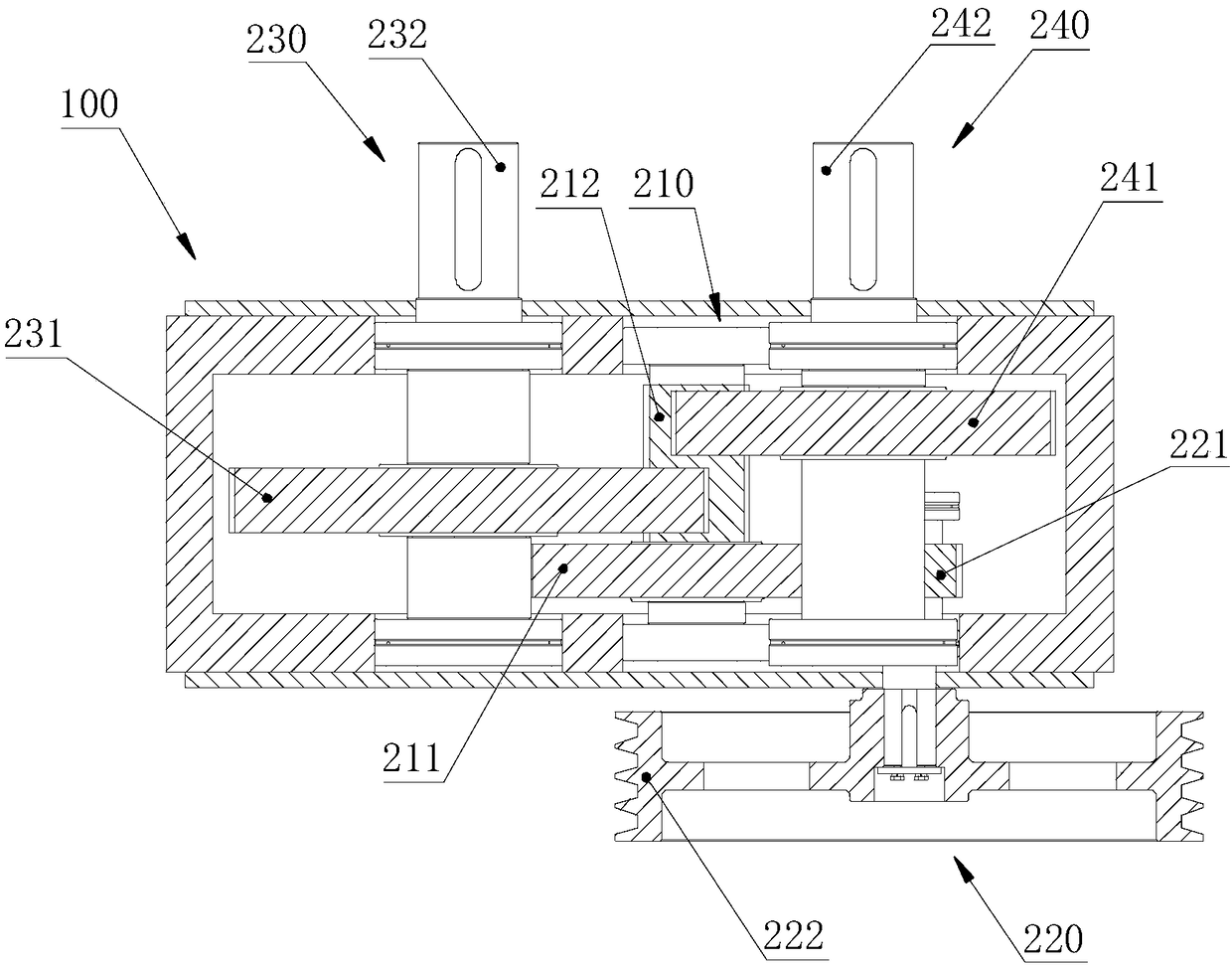

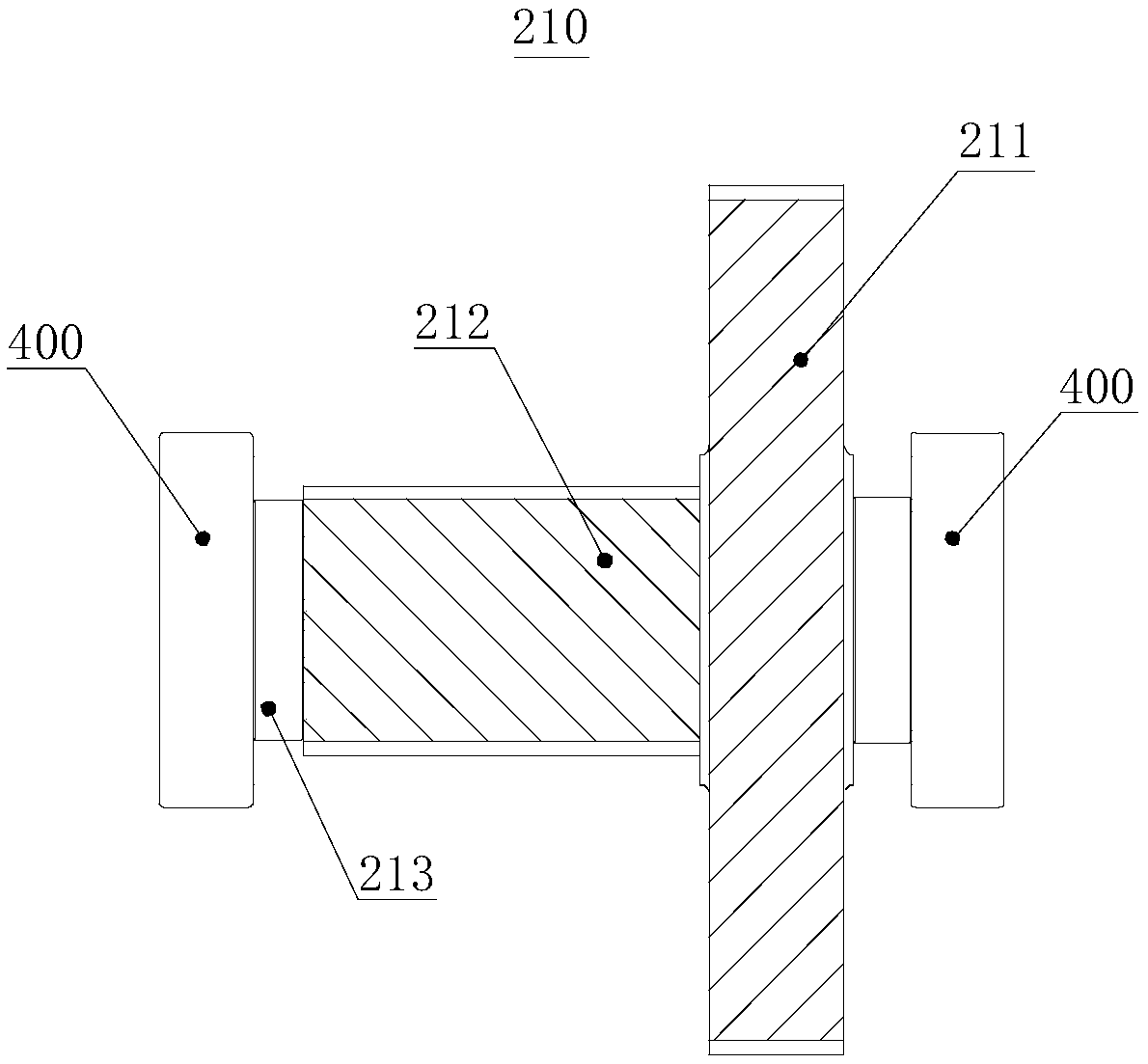

[0041] Please refer to Figure 1 to Figure 6 , the reduction system includes an intermediate shaft assembly 210, an input shaft assembly 220, a low-speed output shaft assembly 230, and a high-speed output shaft assembly 240. The intermediate shaft assembly 210 and the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com