Open can type six-axis molten iron vehicle with load of 140 to 160t

A technology of molten iron car and loading capacity, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc. It can solve the problems of high equipment and site requirements, difficulty in increasing the overall load capacity, and large unsprung weight, so as to achieve maintenance Convenience, improved passing capacity, and large safety margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

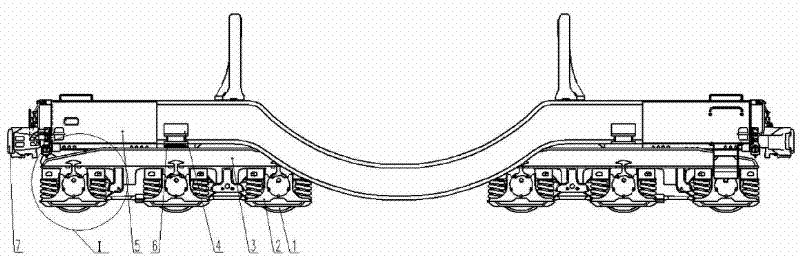

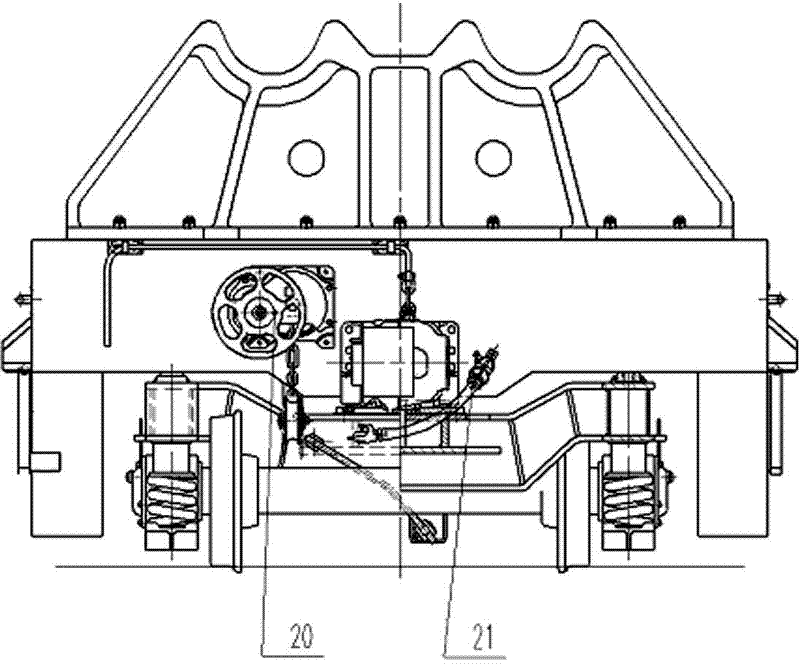

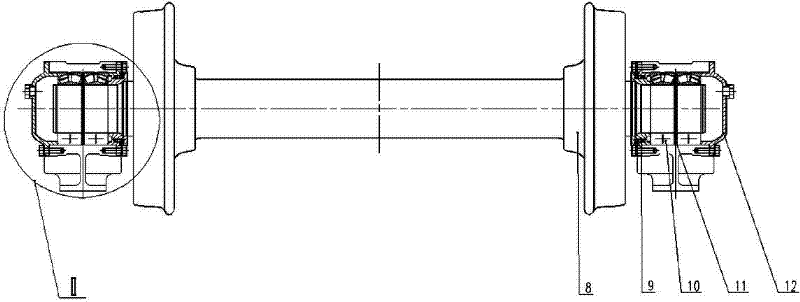

[0034]A six-axle open-top hot metal car with a loading capacity of 160 tons, which includes a bogie 3 and a car body 5. Coupler buffer devices 7 are arranged at both ends of the car body 5. The bogie 3 is an integral welded frame type bogie. The wheel set installed on the frame 3 is the special wheel set 1 for the molten iron car. The special wheel set 1 is connected by the axle box spring device 2 at both ends of the axle 16 and the integral welded frame 15 of the integrally welded frame bogie. The axle box spring device 2 is made up of axle box 13 and inner and outer spring group 14, and axle box 13 and inner and outer spring group 14 are a series of suspensions. The braking device on the car body 5 is a wind brake device 21 and a hand brake device 20, and the connecting hub 6 between the car body 5 and the bogie 3 has a diameter of 550 mm. Two double self-aligning bearings 10 are installed side by side in the axle box 13 of the axle box spring device 2, and an annular beari...

Embodiment 2

[0036] A six-axle open-top hot metal car with a loading capacity of 140 tons, which includes a bogie 3 and a car body 5. Coupler buffer devices 7 are arranged at both ends of the car body 5. The bogie 3 is an integral welded frame type bogie. The wheel pair 1 installed on the frame 3 is the special wheel pair 1 for the molten iron car. The special wheel pair 1 is connected with the integral welded frame 15 by the axle box spring device 2 at both ends of the axle 16. The axle box spring device 2 is composed of the axle box 13 and The composition of inner and outer spring group 14, axle box 13 and inner and outer spring group 14 are a series suspension. The braking device on the car body 5 is a wind brake device 21 and a hand brake device 20, and the connecting hub 6 between the car body 5 and the bogie 3 has a diameter of 300mm. Two double self-aligning bearings 10 are installed side by side in the axle box 13 of the axle box spring device 2, and an annular bearing spacer 11 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com