Anti-overturning jacking mechanism for power transmission line tower

A technology for transmission line towers and jacking mechanisms, which is applied to towers, building structures, infrastructure engineering, etc., and can solve the problems that transmission line towers cannot be dynamically compensated or adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

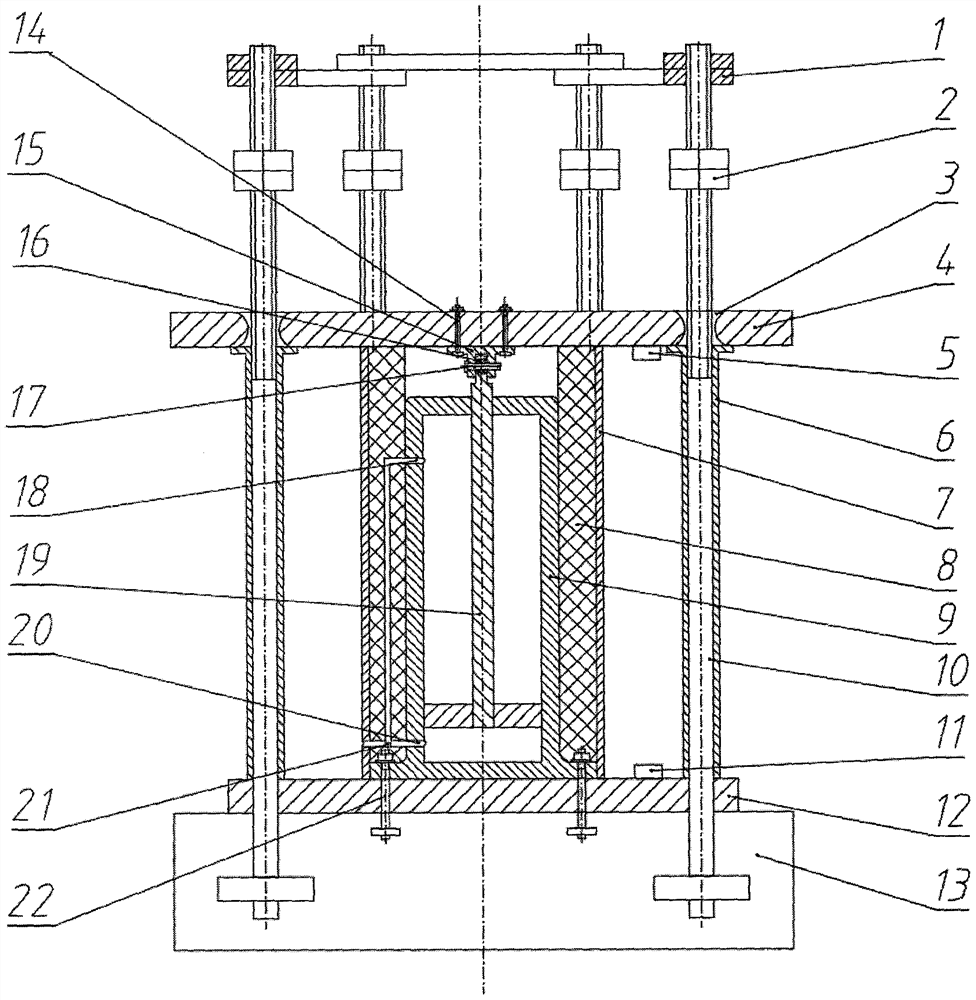

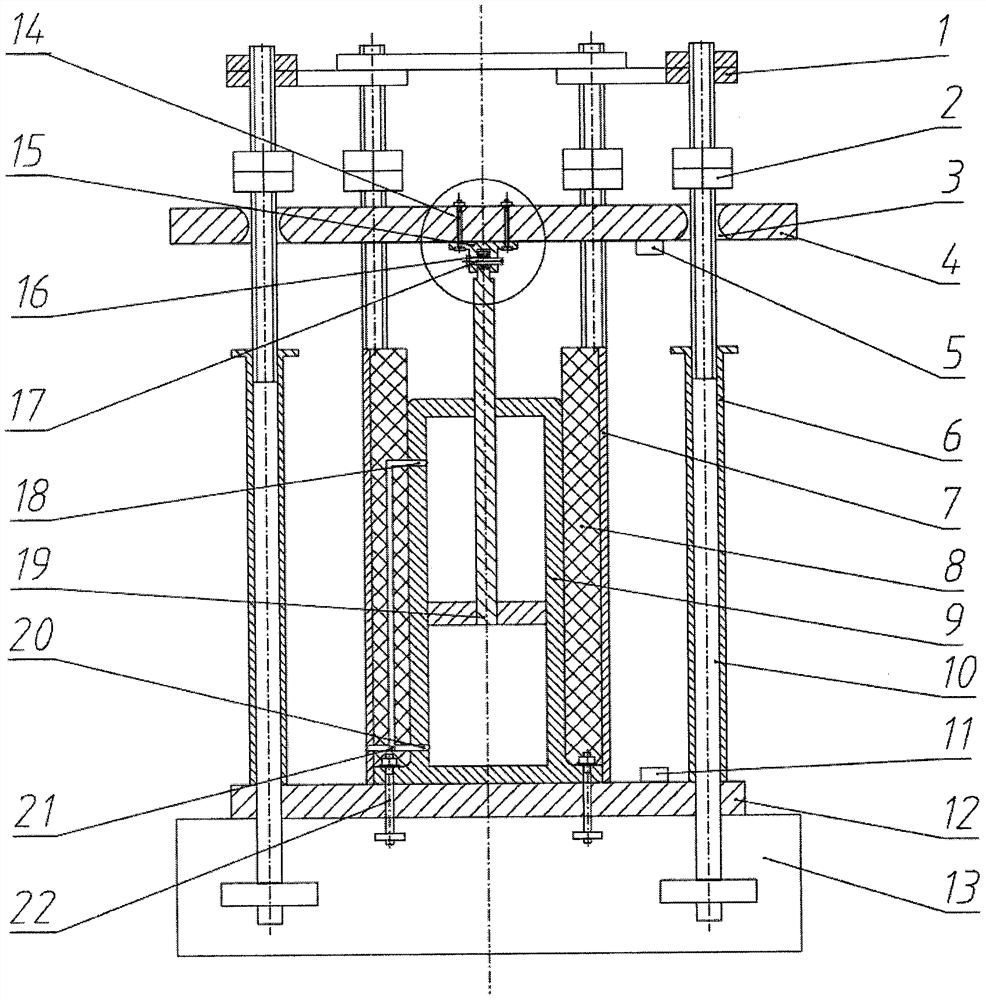

[0024] After the mechanism is installed, such as figure 1 shown. At this time, the jacking plate 4 needs to be raised to the working position, the electric control device sends out a signal, the oil delivery hole 20 starts to enter the oil, the piston rod 19 moves upwards, and the head of the piston rod 19 makes the U-shaped latch plate 15 and the jacking plate 15 and the jacking plate through the pin 17. Lifting plate 4 moves upwards, and when reaching the predetermined working position (judged by the position sensor), if figure 2 As shown, the electric control device controls the hydraulic lock 21 to lock the oil circuit to reach the working state.

[0025] When the monitoring device detects that the transmission line tower is tilted, the monitoring device calculates the displacement required for the jacking mechanism of each leg based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com