Energy-saving ball mill

A technology of ball mills and hydrostatic bearings, applied in grain processing, etc., can solve the problems of high energy consumption, high maintenance costs, and low operational reliability, and achieve low energy consumption, low maintenance costs, high operational reliability, Good centering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

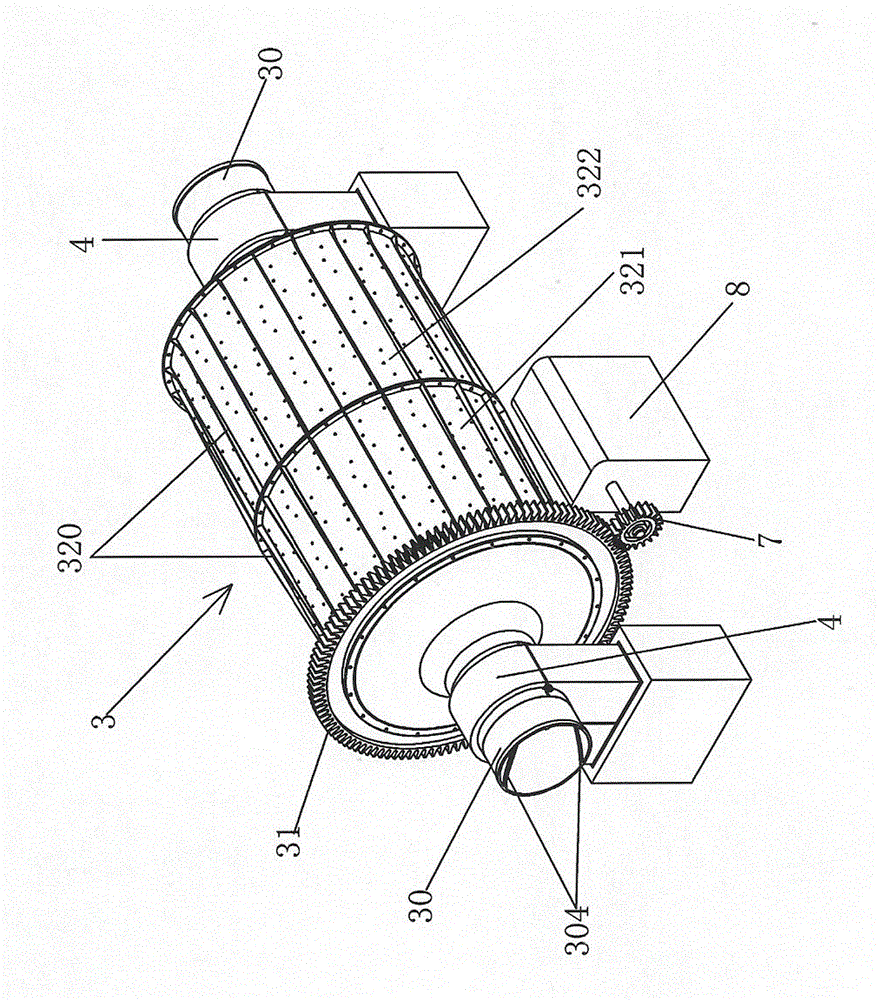

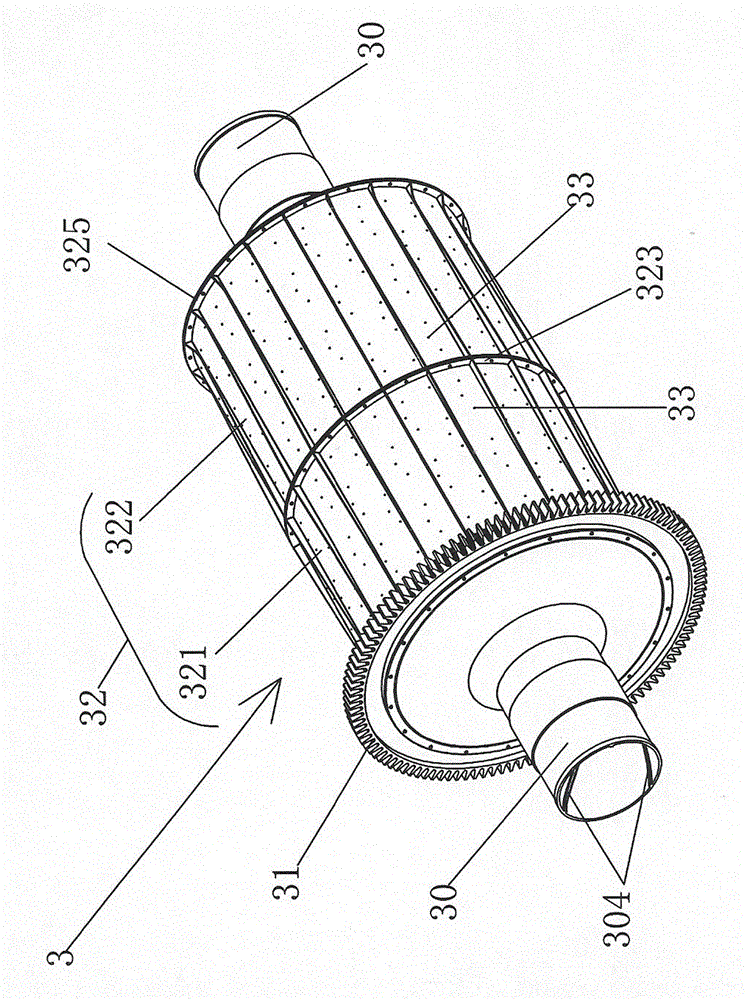

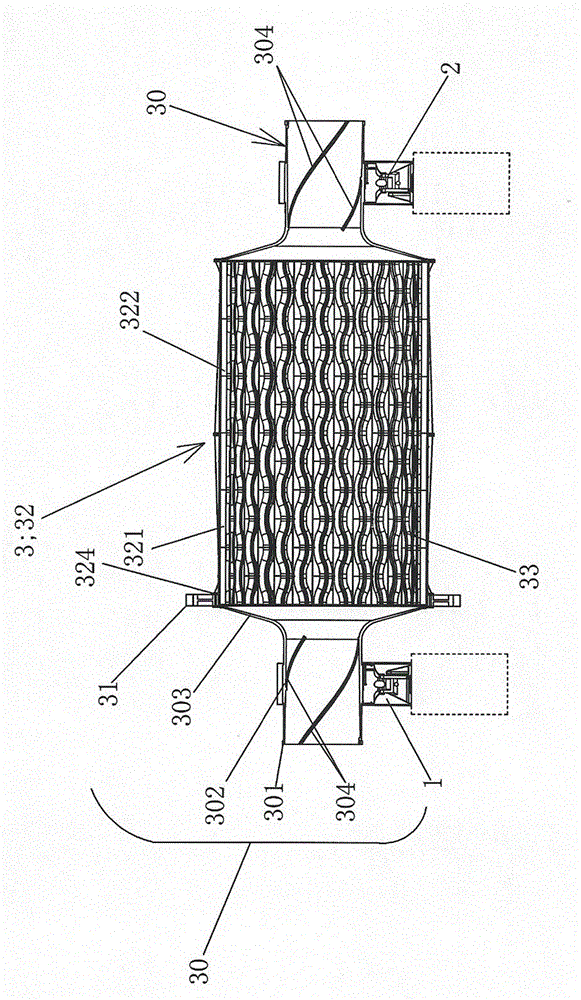

[0051] see figure 1 , figure 2 and image 3 Shown, the present invention is made up of first hydrostatic bearing 1, second hydrostatic bearing 2, revolving body 3, two hydrostatic bearing sealing covers 4, first partial dust collector 5, second partial dust collector 6, pinion 7 and a transmission system 8; the journals 302 of the hollow shaft 301 at both ends of the rotary body 3 are respectively placed on the first hydrostatic bearing 1 and the second hydrostatic bearing 2, and are respectively covered with two hydrostatic bearing sealing covers 4 The pinion 7 is connected with the output shaft of the transmission system 8, the left end of the barrel 32 is pierced with a large gear 31, and the pinion 7 meshes with the large gear 31;

[0052] see Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the first hydrostatic bearing 1 is composed of a bearing body 10, a bearing seat 11, a first axial positioning plate 12, a second axial posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com