Method, forming and injection tool for manufacturing aperture surrounding frame for aircraft fuselage, and the frame obtained thereof

A technology for aircraft fuselage and enclosure, applied in the direction of fuselage, aircraft accessories, home appliances, etc., can solve the problems of time-consuming, unsatisfactory, and NFC solutions do not provide fibers, etc., to simplify the manufacturing method and ensure continuity. , the effect of avoiding weaknesses and other shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

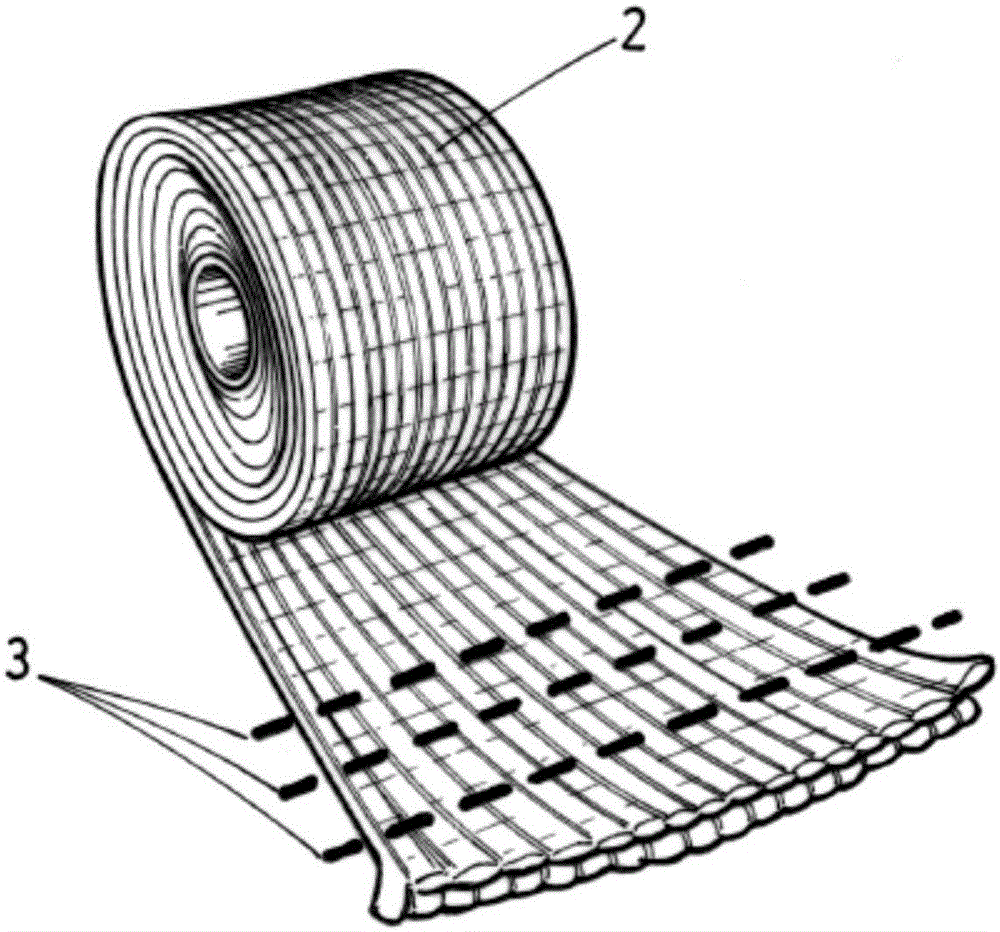

[0042] image 3 A roll 2 of woven material is shown. According to the invention, the perimeter of the roll of woven material is equal to the perimeter of the perforated enclosure to be produced. Therefore, the framework will have no discontinuities that could affect its coherence.

[0043] Then, along the image 3The cutting lines shown cut across the roll 2 of braided material to obtain sheets 3 of braided material. Due to the tubular condition of the braided material 2, each piece of braided material 3 has an annular shape. As noted above, this annular shape provides continuity and uniformity to the potential aperture enclosure while enhancing its strength by avoiding weakening of the joint area.

[0044] Once the endless woven material sheet 3 is obtained, said material sheet 3 is laminated around the inner mold 4 . Figure 4 A sheet of braided material 3 , an inner mold 4 and the sheet of braided material 3 laminated around the inner mold 4 are shown.

[0045] The la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com