Positioning and pressing device for gear shaft hole lining thin-walled sleeve

A press-fitting device and thin-wall sleeve technology, applied in the direction of workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of small size of reverse gear, poor manual press-fitting efficiency, high labor intensity, etc., to achieve integral Simple structure, convenient and efficient press-fitting, and high-precision press-fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

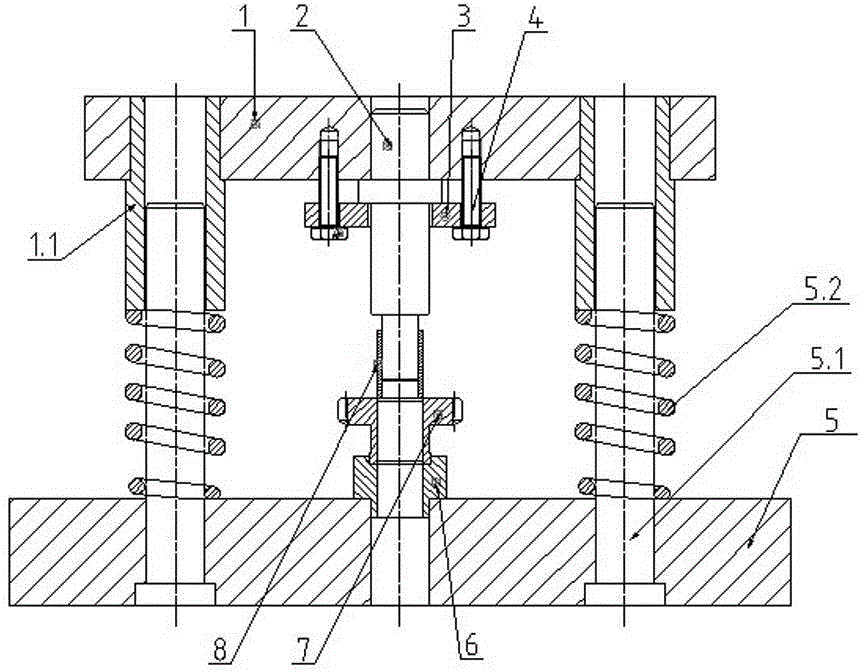

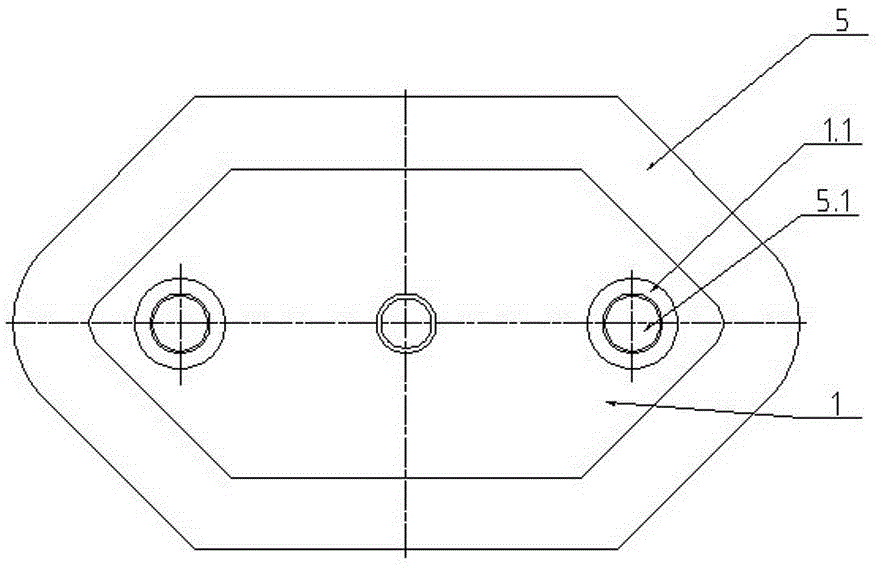

[0014] The gear shaft hole lining thin-wall sleeve positioning and pressing device shown in the accompanying drawings includes a template 1, a pressing rod 2, a pressing plate 3, a bolt 4, a mold base 5 and a positioning seat 6. The template 1 and the mold base 5 are both plate-shaped components, and the center of the plate surface is provided with a positioning hole, and 4 coaxial through holes are evenly distributed around the centered positioning hole on the template 1 and the mold base 5 plate surface. The sliding sleeve 1.1 protruding downward is installed in the axial through hole, and the guide rod 5.1 protruding upward is inserted in the static mold base 5 through the axial through hole, and the spring 5.2 is set on the guide rod 5.1 to match the template 1 The sliding sleeve 1.1 has a clearance fit, and the pressure spring is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com