Concrete core cement soil stirring pile machine and its construction technological method

A technology of cement-soil mixing piles and concrete cores, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

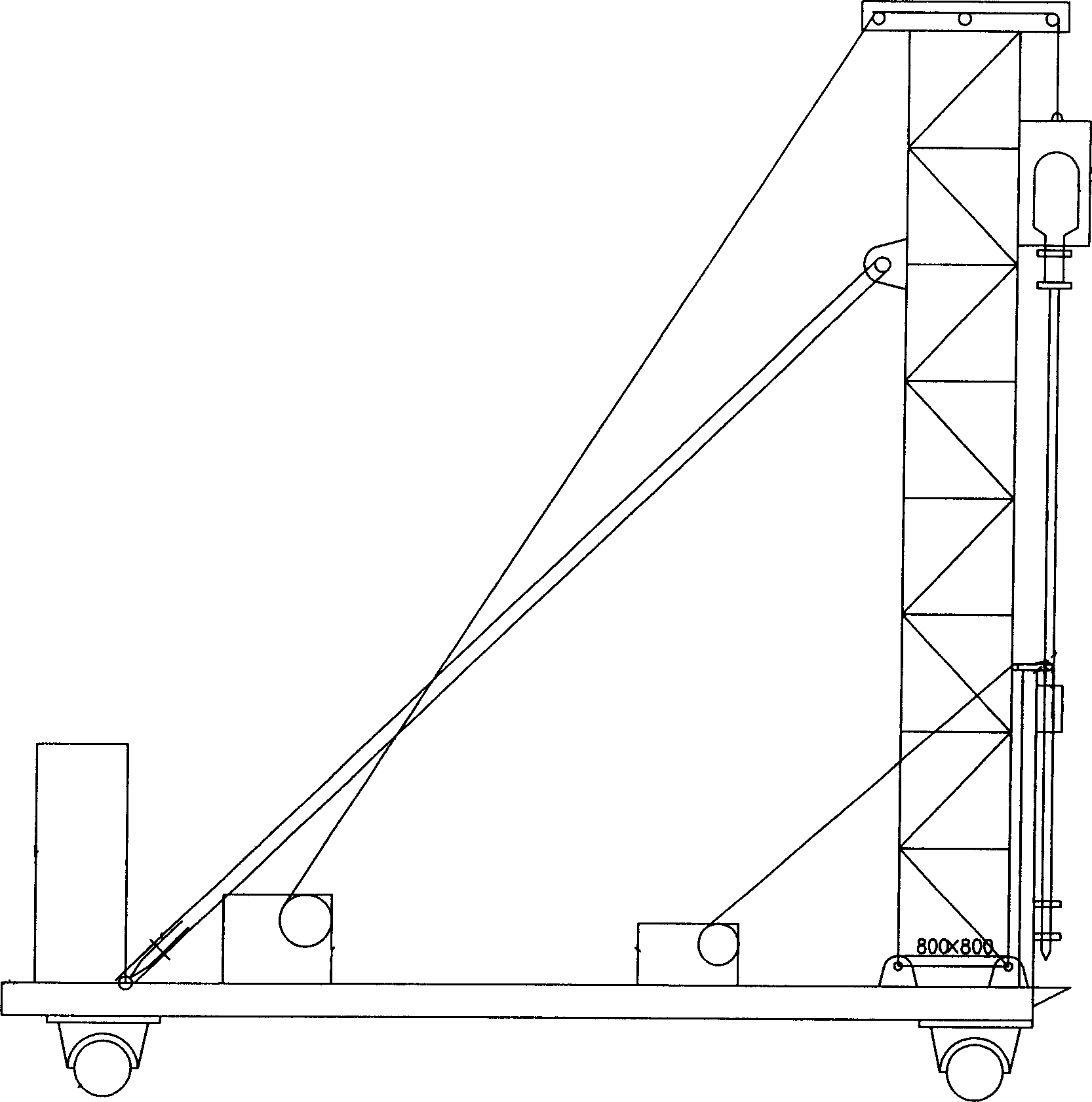

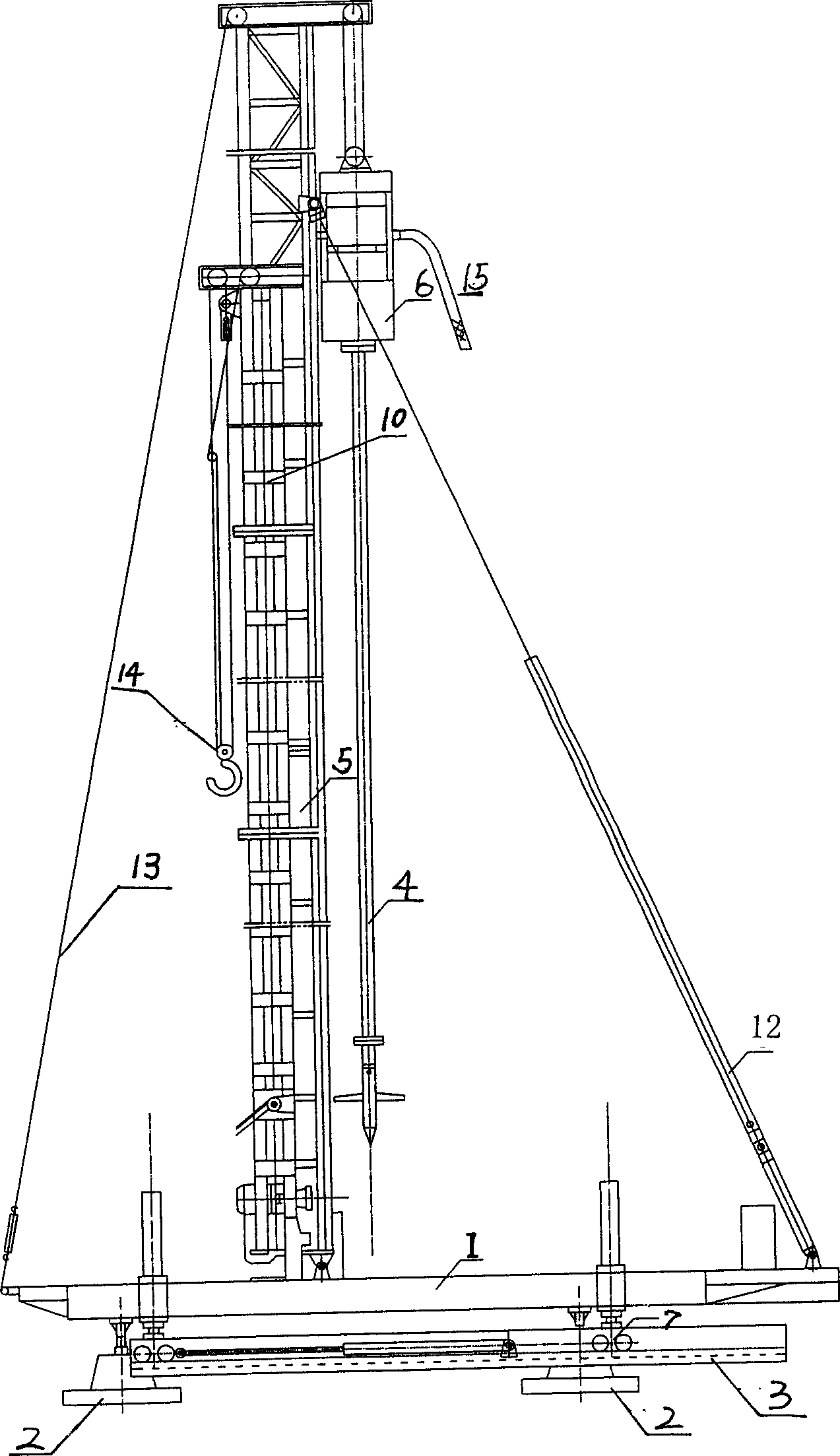

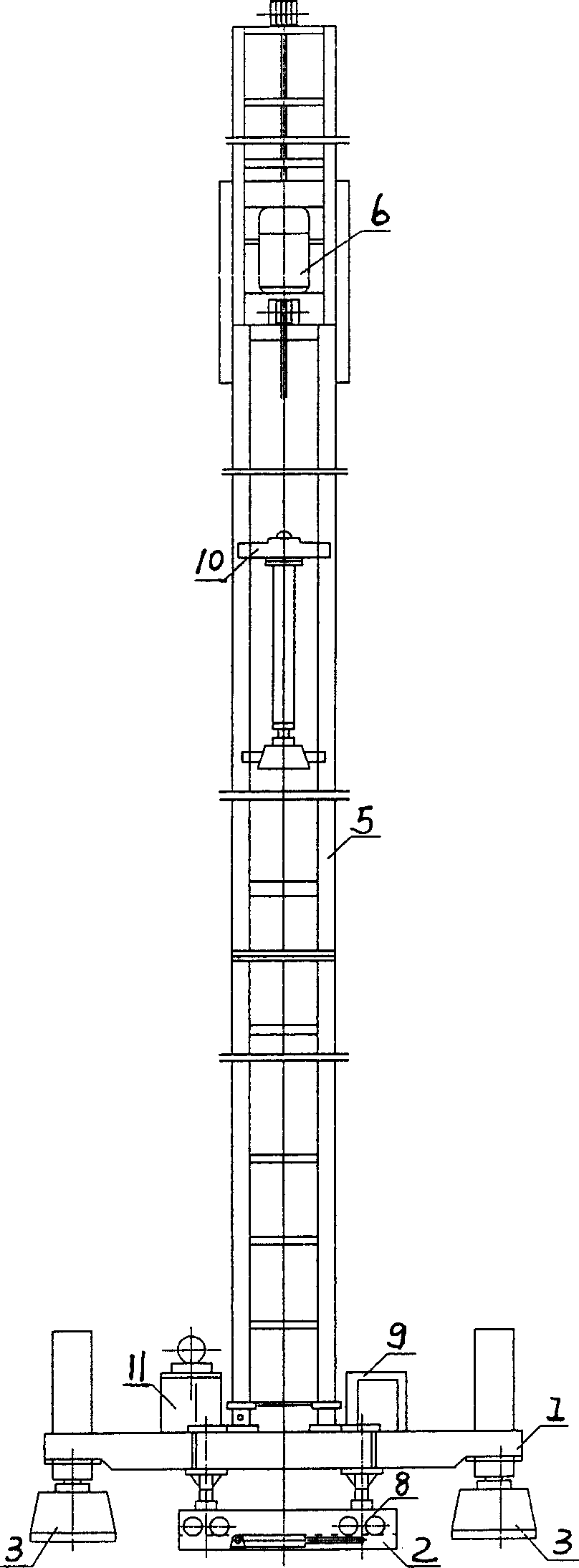

[0020] refer to Figure 2-A and Figure 2-B Can basically see the whole picture of the present invention-concrete core cement-soil mixing pile machine. The bottom of the pile driver is a hydraulic walking system, including a hydraulic pump station (11), a base and a leg beam (1), a traverse beam (2), a longitudinal beam (3), a longitudinal roller bracket (7) and a horizontal roller The bracket (8), the base and the outrigger beam (1) rest on the vertical and horizontal brackets (7, 8), and the roller brackets (7, 8) are respectively placed on the vertical moving beam (3) and the horizontal moving beam (2) Above, the hydraulic pump station (11) is fixed on the base and the support beam (1), and controls the longitudinal and lateral movement of the base; the frame (5) is welded on the slideable guide rail in the center of the base (1), and the guide rail can The guide groove slides, so that after the construction of the deep cement-soil mixing pile is completed, the central ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com