Patents

Literature

47results about How to "Run without trouble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

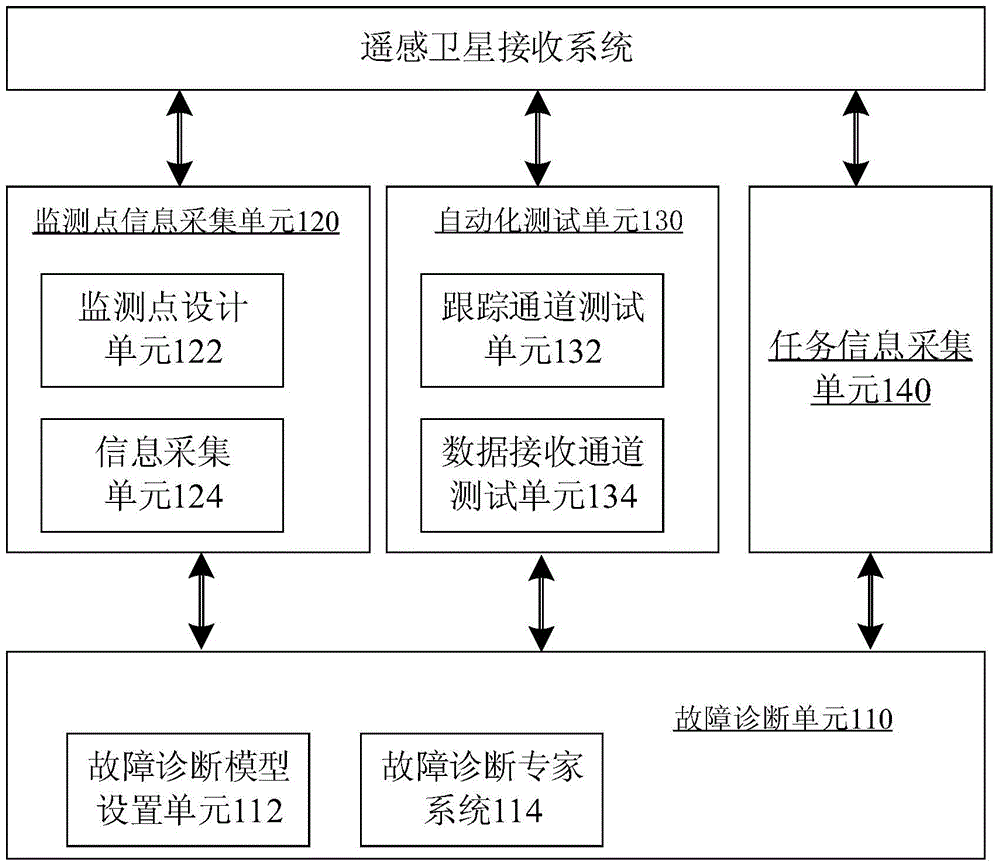

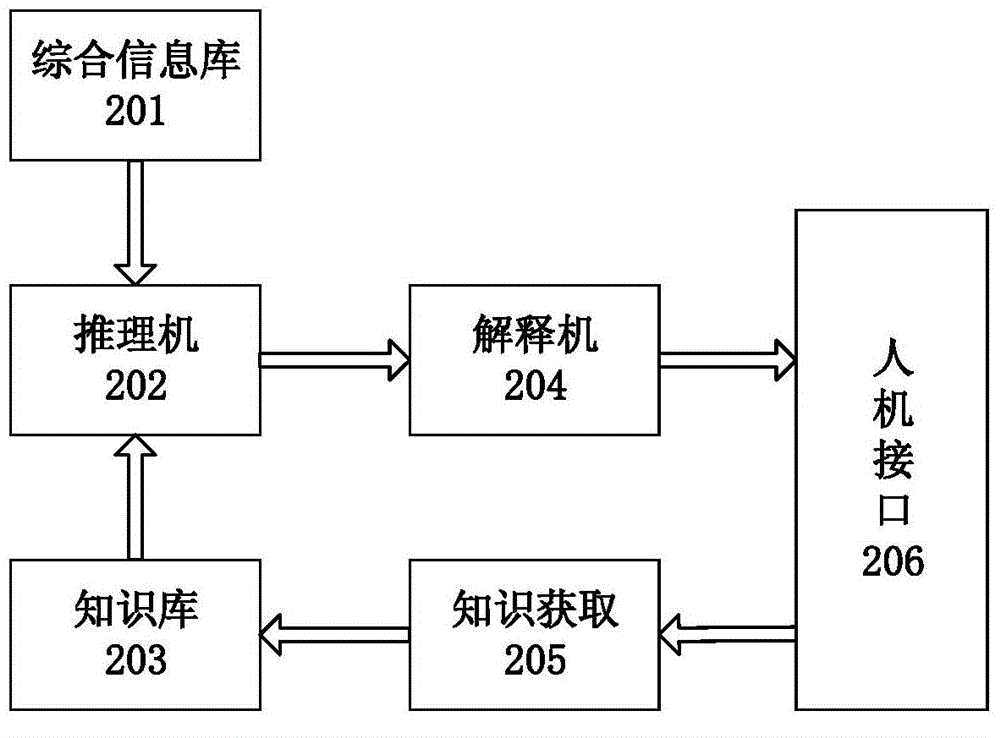

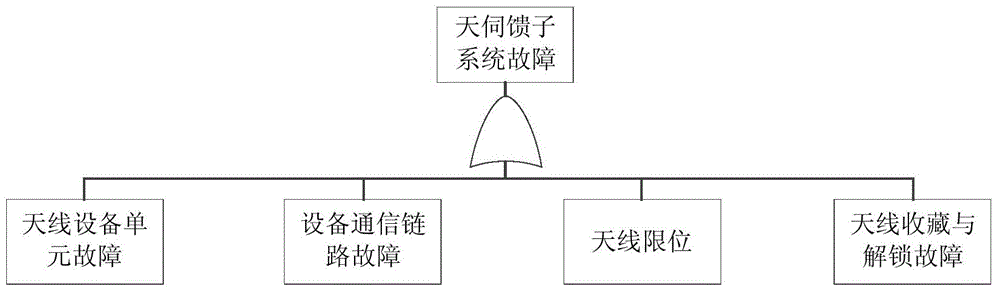

Fault diagnosis device and method for remote sensing satellite receiving system

ActiveCN104460650AImplement fault diagnosisRun without troubleElectric testing/monitoringEngineeringFault model

The invention provides a fault diagnosis device and method for a remote sensing satellite receiving system. The method includes the steps that state information of preset monitoring points in devices of the remote sensing satellite receiving system is acquired; parameters of the devices in a servo system, a tracking channel and a data receiving channel of the remote sensing satellite receiving system are set according to a test type, and then an automatic test is finished; various kinds of task information recorded through the remote sensing satellite receiving system in real time in the data receiving task execution process is acquired; according to the acquired state information of the monitoring points, the automatic test information and the various kinds of task information, fault diagnosis of the remote sensing satellite receiving system is finished by establishing a fault diagnosis model and a fault diagnosis expert system. By the adoption of the device and method, fault information in the system can be acquired, found and reported instantaneously, the system fault model is established, and quick and automatic fault diagnosis of the remote sensing satellite receiving system is achieved.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

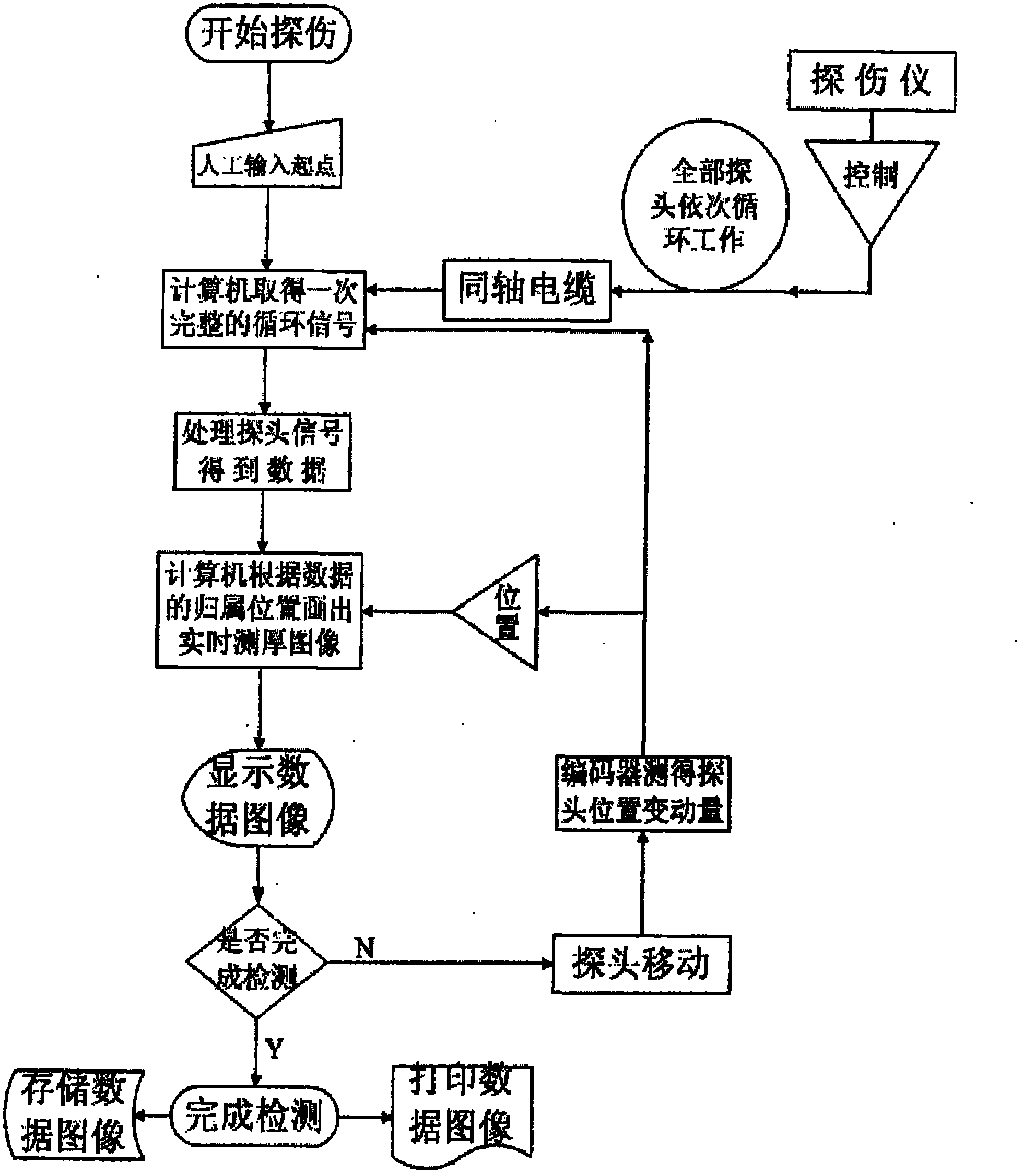

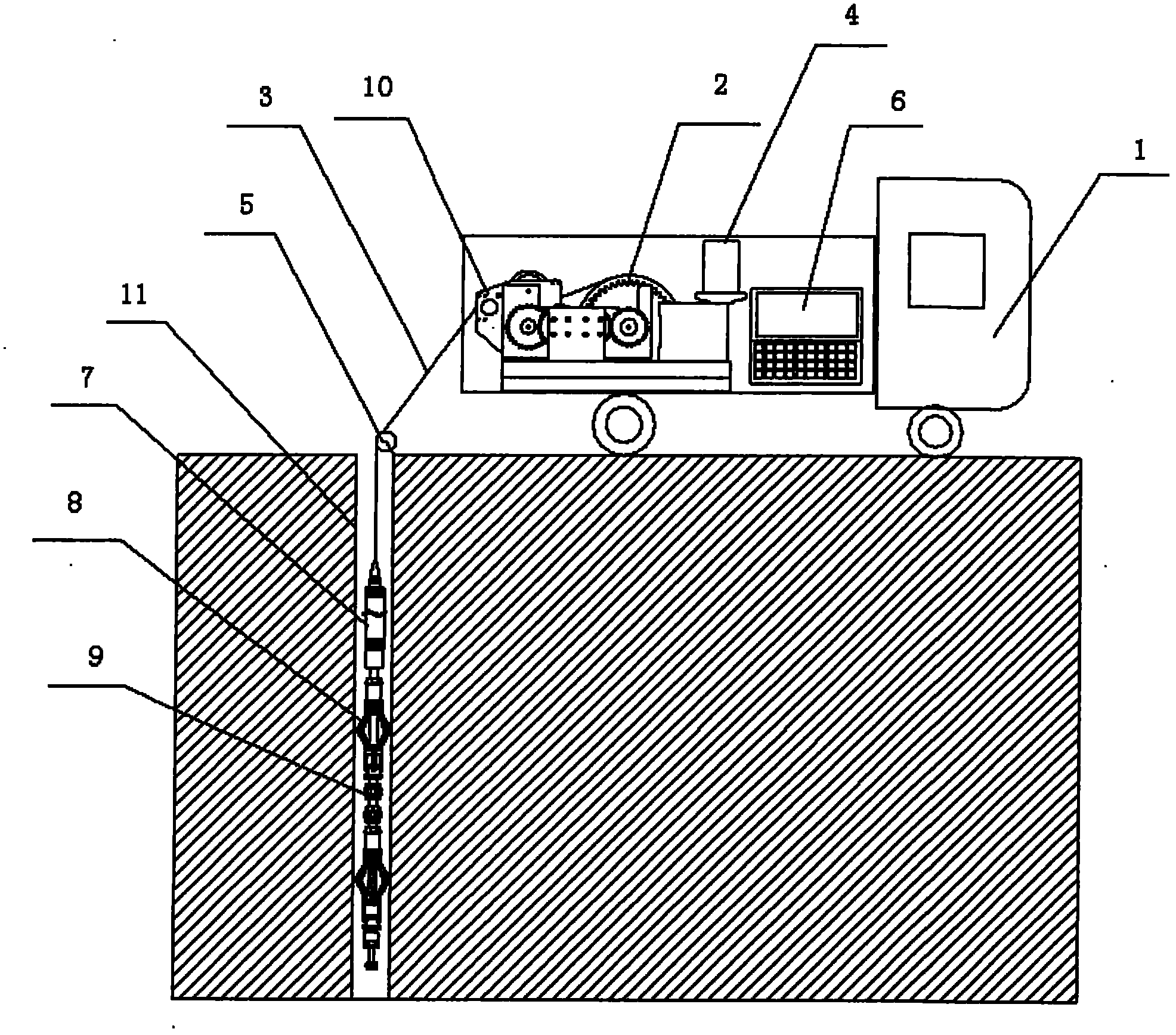

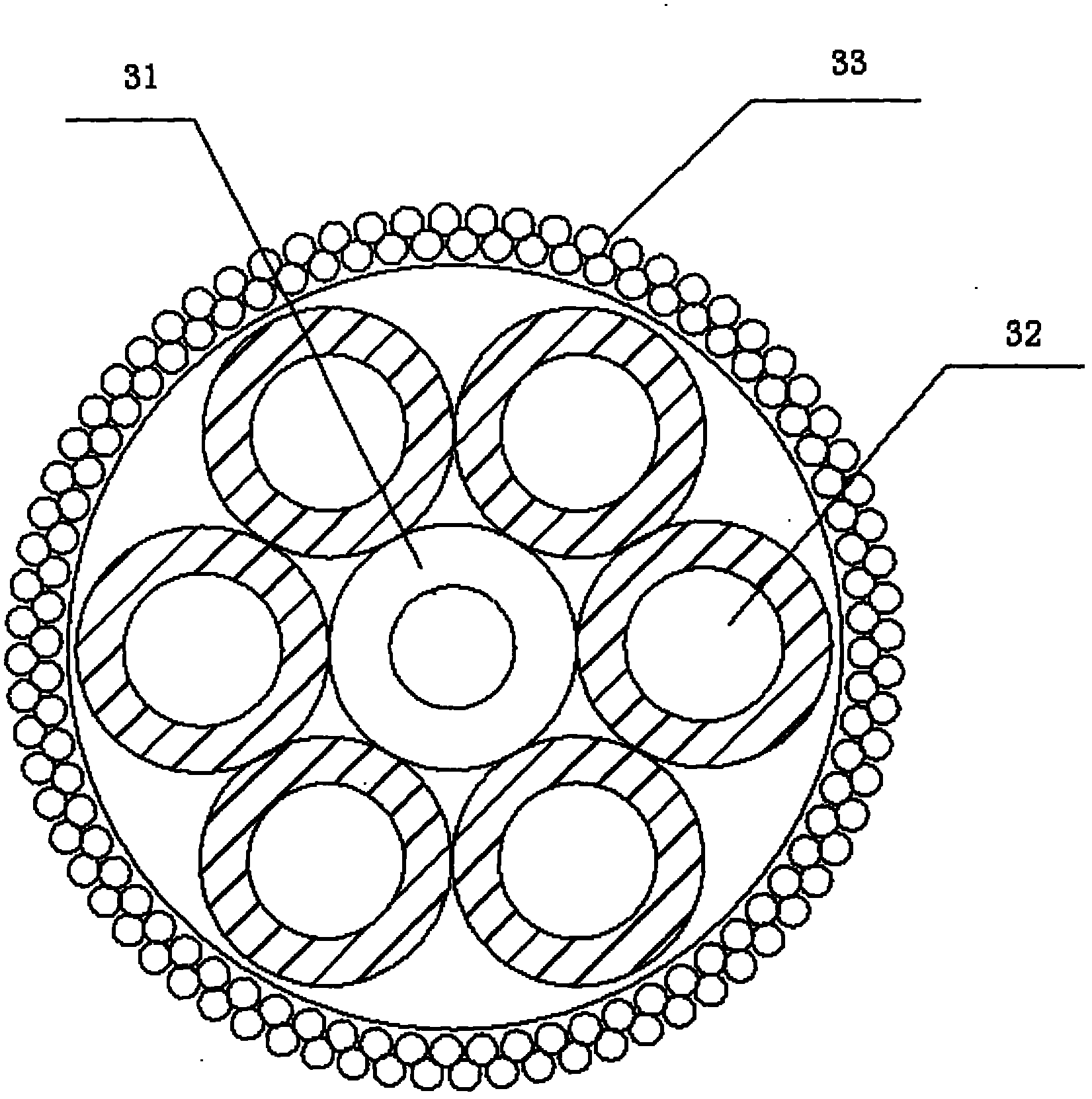

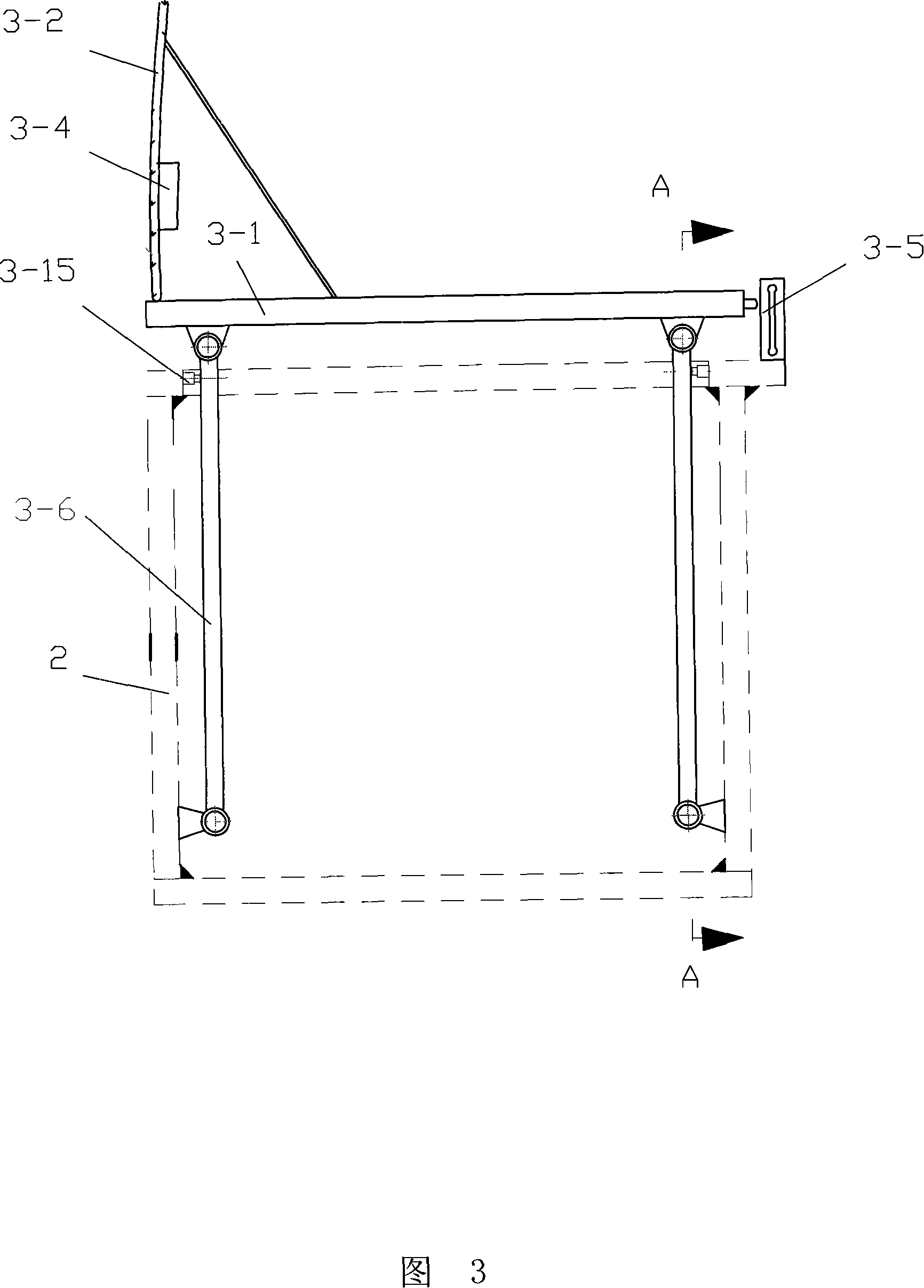

Improved system and method for detecting wall thickness and corrosion of well casing of gas storage well

InactiveCN102072714ALift freelyFirmly connectedWeather/light/corrosion resistanceUsing subsonic/sonic/ultrasonic vibration meansWater immersionEngineering

The invention discloses an improved system and method for detecting wall thickness and corrosion of a well casing of a gas storage well. The system comprises an overground signal processing part and an underground signal receiving and transmitting part arranged inside the gas storage well, wherein the overground part is provided with a mobile detection device connected with the underground part through an armored composite wire, and the detection device is provided with a dragging part and a control terminal; a coaxial cable in the armored composite wire inputs a plurality of collected analog probe signals into a computer, and the computer finishes digital conversion of analog signals and processing of data signals; the signal processing part moves up and down on the inner wall of the well casing through a centralizer; an annular water immersion analog probe array is also arranged; and the armored composite wire is manufactured by winding the coaxial cable for signal transmission with an underground instrument power cord layer by layer and winding a steel wire at the outermost layer, and the coaxial cable and the power cord share one multi-core waterproof seal joint. An encoder is directly installed at the wire swinging part in front of a roller, and the joint of encoder and the computer are in fixed connection. The system disclosed by the invention has stronger reliability and better vibration resistance, and can operate for a long time without faults.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

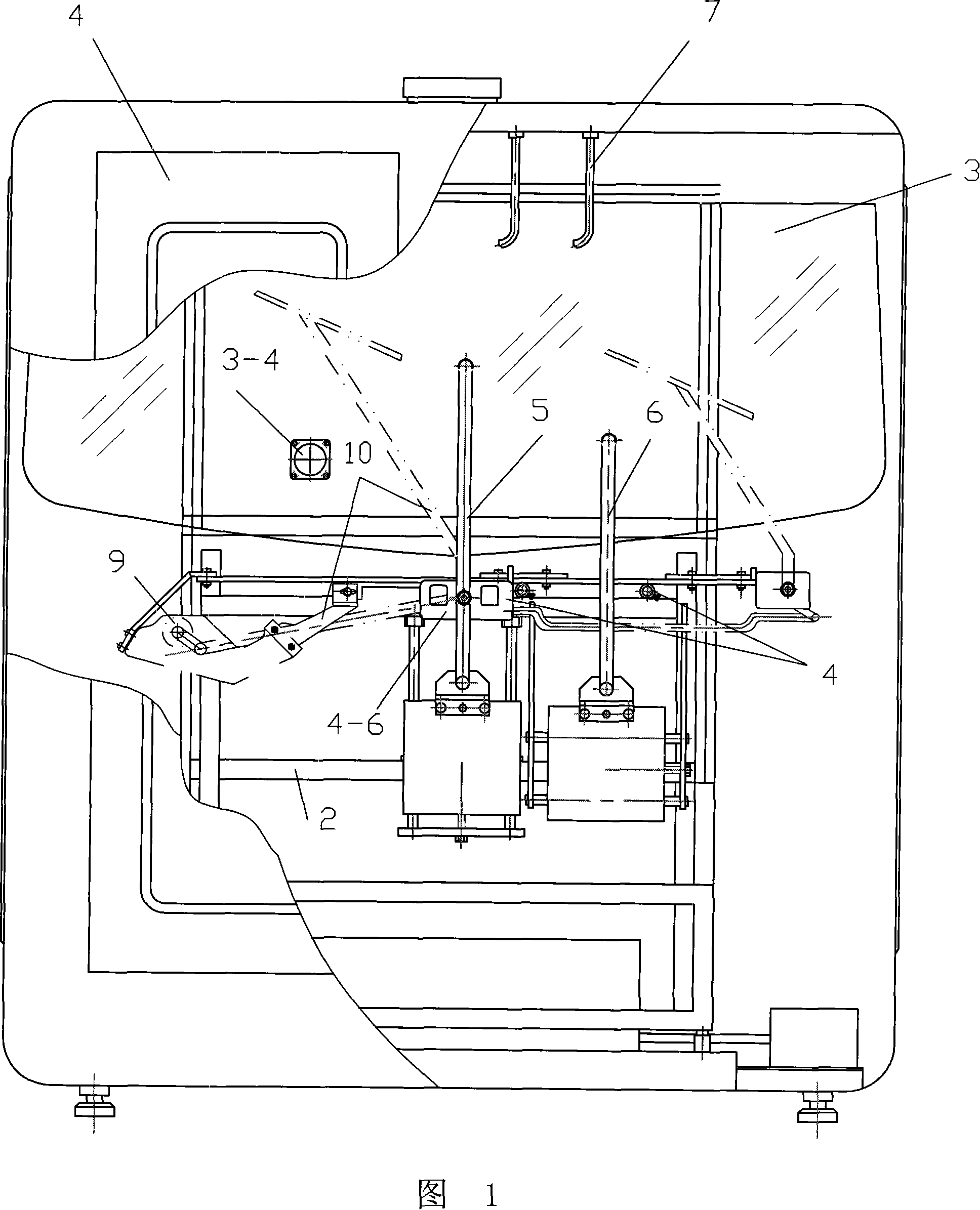

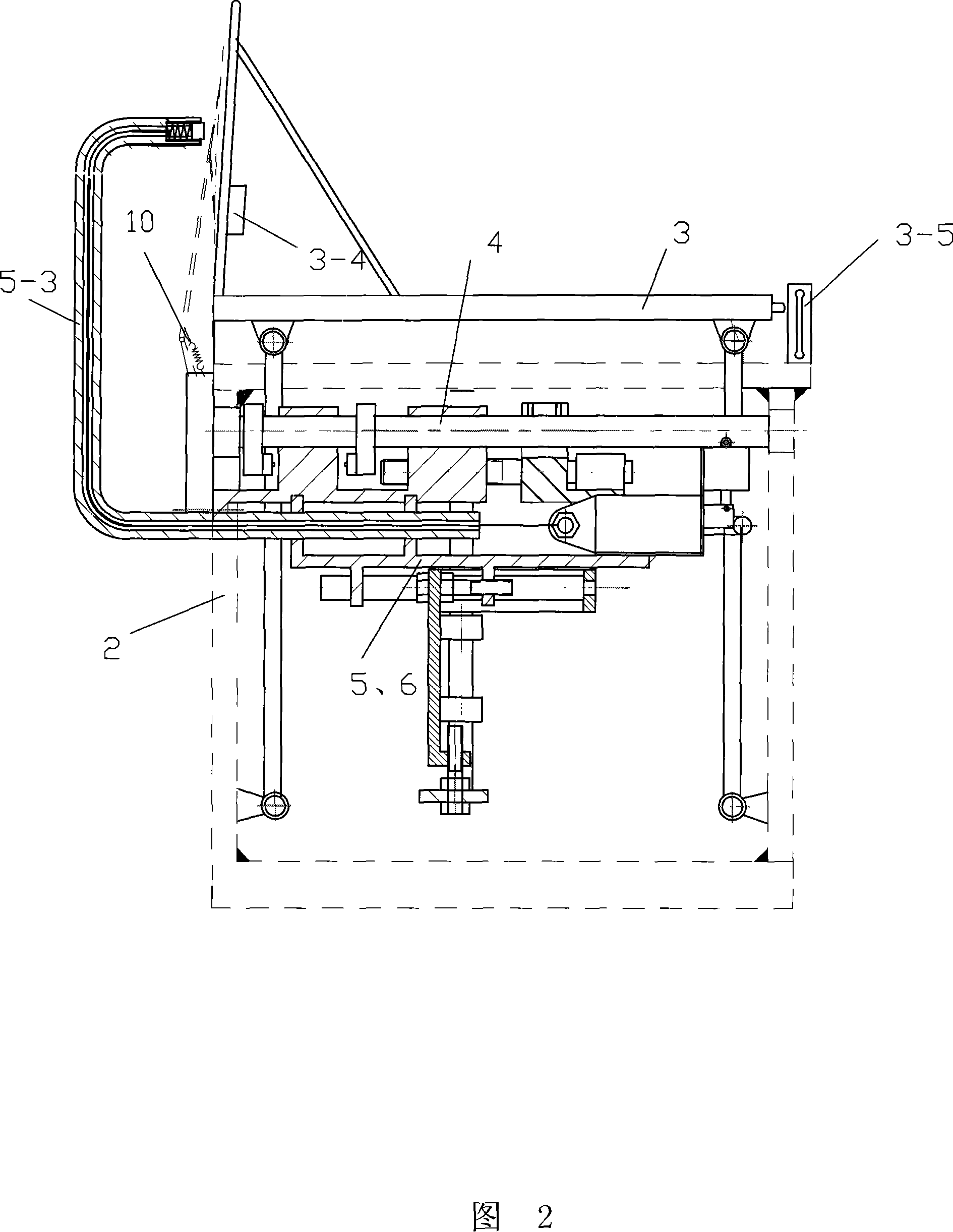

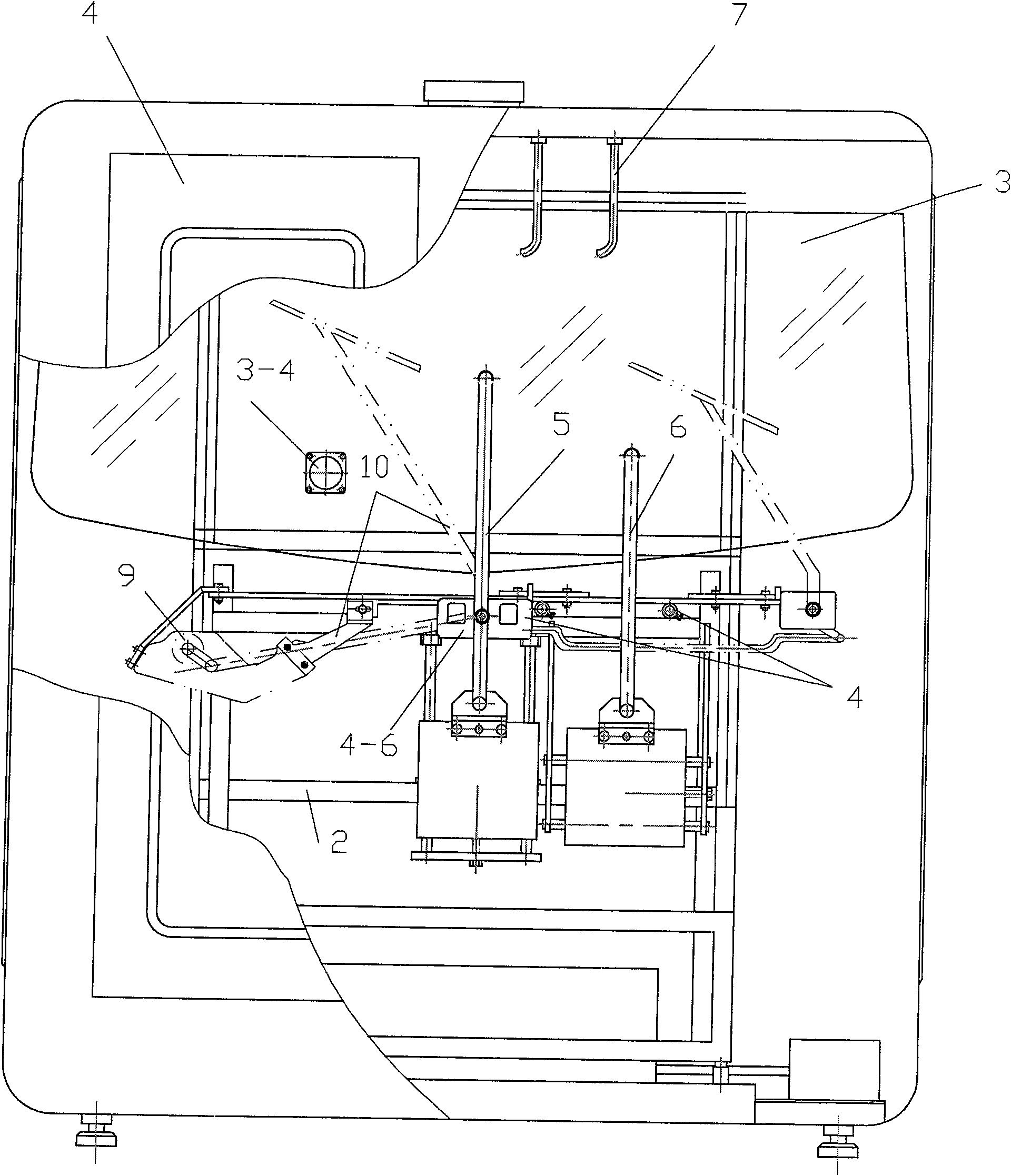

Test centre for performance of vehicle wind screen wiper assembly

InactiveCN101089586AGuaranteed detection accuracyGuaranteed continuityStructural/machines measurementPressure transmissionElectrical control

A test center of wiper assembly on automobile consists of pressure transmission unit and pressing-force regulation unit for detecting and regulating press-force of wiper on window glass, brake unit for repeatedly stopping operation of wiper in transient way, rain unit for providing rain environment in test cabin and control unit of using industrial control computer to make control and data treatment. It is featured as setting said computer and control unit in electric control table and placing all the other said units in closed test cabin with front and back doors.

Owner:CHANGZHOU TEXTILE GARMENT INST

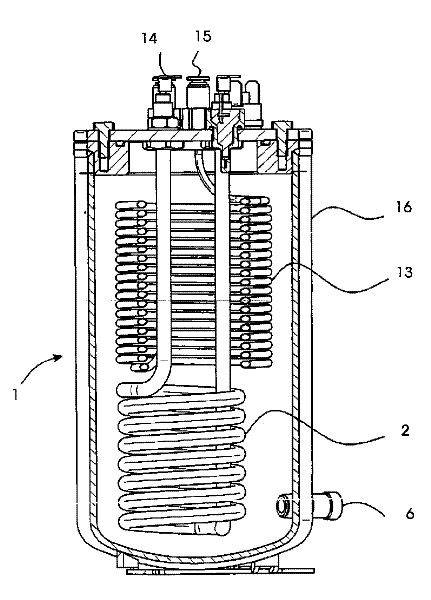

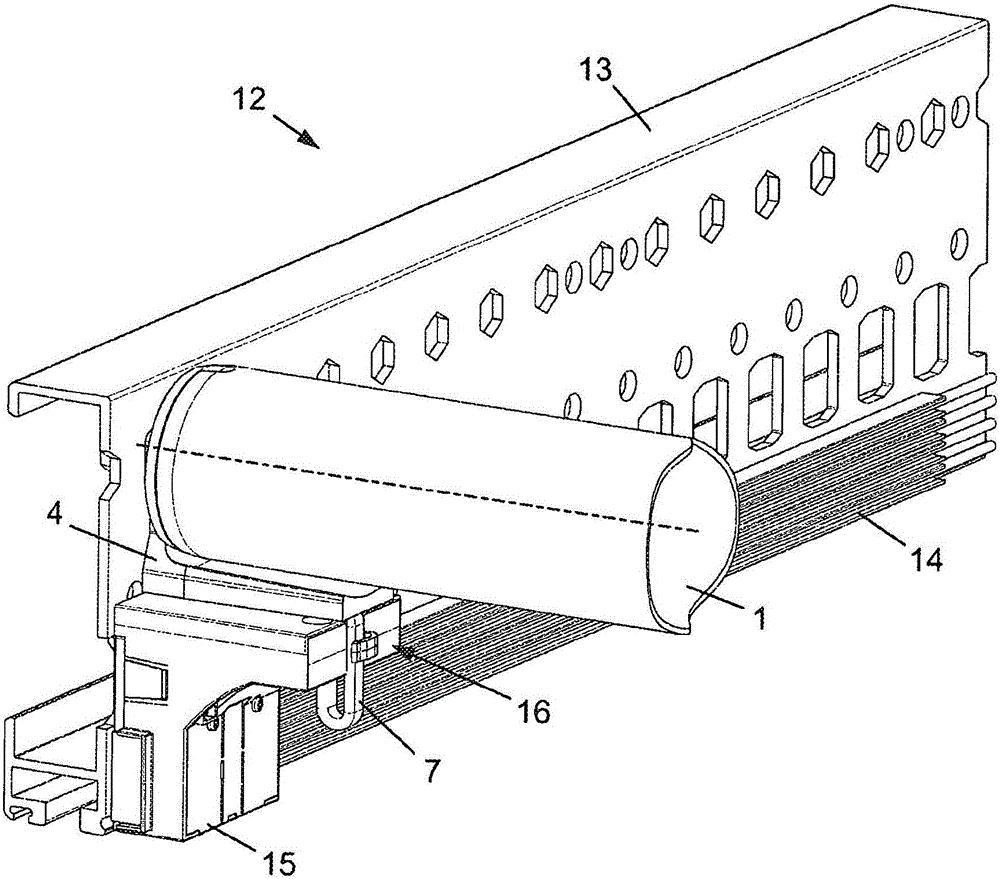

Coffee machine

ActiveCN102245067ARun without troubleSimplify the installation processBeverage vesselsRinse waterCoiled tubing

The invention relates to a coffee machine comprising a boiler (1) for producing hot water and steam for the preparation of coffee or coffee-containing beverages. A coiled tubing (13) is located in the boiler for producing hot milk or milk froth. Thus, no separate heating element is required for producing the hot milk or milk froth, as the milk or milk froth is heated by the water heated in the boiler for preparing the coffee. The coiled tubing (13) is connected alternately to a milk container (8) and a rinsing water source (25), so that potential milk residue is flushed out from the coiled tubing (13) after each milk heating process. A predetermined amount of milk or rinsing water is fed to the coiled tubing (13) by a pump (10). Thus the milk and rinsing water usage is optimized and the energy consumption is reduced.

Owner:STEINER WEGGIS AG

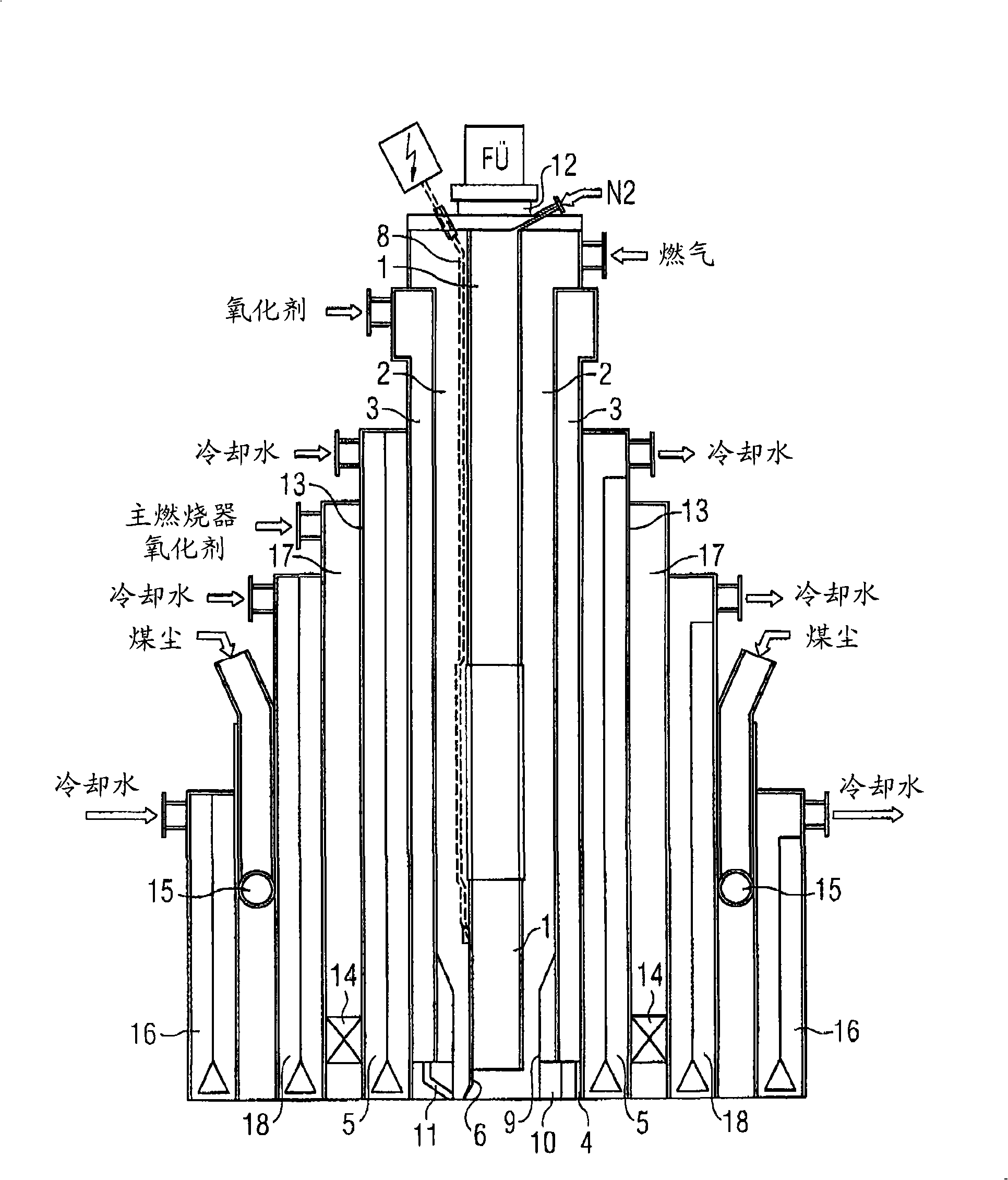

Combined pulverized coal burner comprising an integrated pilot burner

ActiveCN101403496AReliable functionRun without troubleBurner ignition devicsPulverulent fuel combustion burnersCombustorDust explosion

The invention comprises a combination burner for the gasification of pulverized fuels with an oxidation means containing free oxygen at ambient or higher pressures, as well as temperatures between 800-1800 DEG C., with the ignition device of the pilot burner with flame monitoring and the pulverized fuel burner being integrated as a combination burner and all operating channels being routed separately from each other up to the mouth of the burner and the media carried by the channels only being mixed at the mouth of the burner. When the pilot burner is dismantled the eddy bodies 14 attached to its sleeve in the main burner oxidation means supply 17 can be exchanged quickly and easily and thus the main burner flame adapted in the optimum way to the reaction chamber contour of the reactor.

Owner:西门子能源全球两合公司

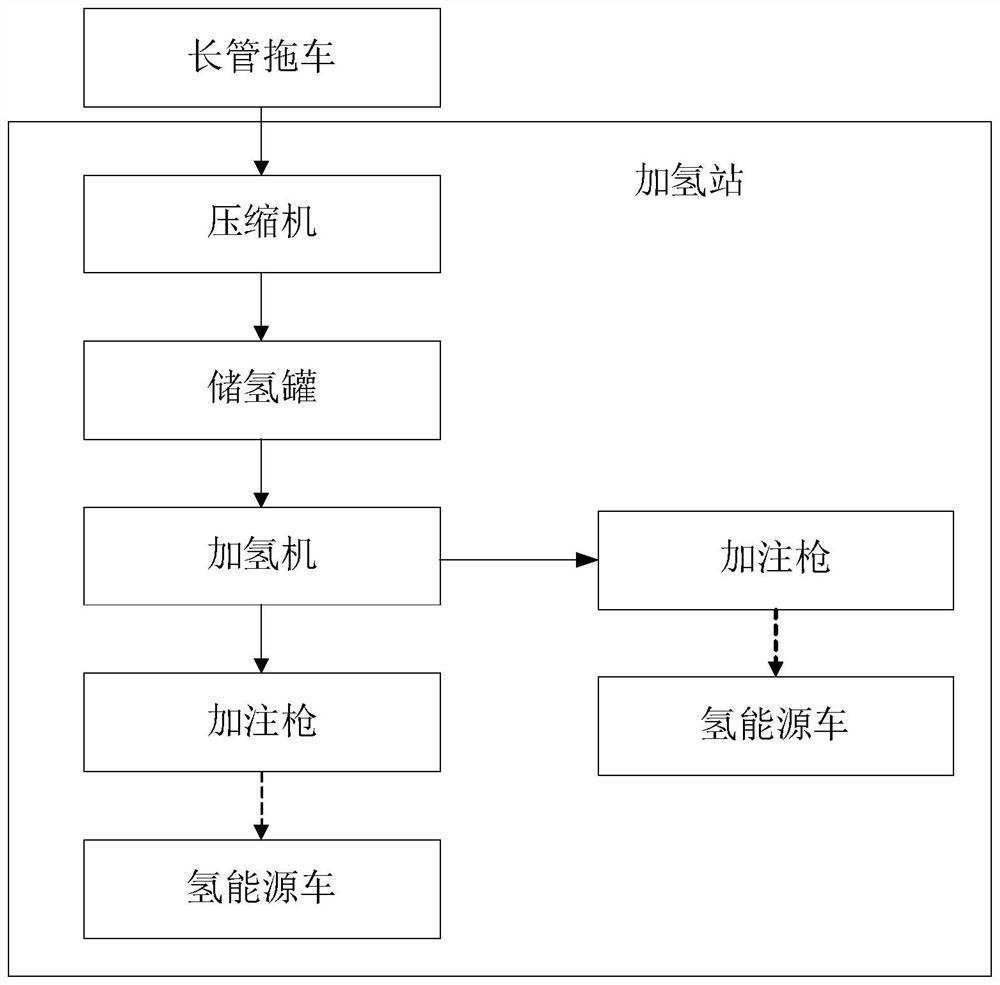

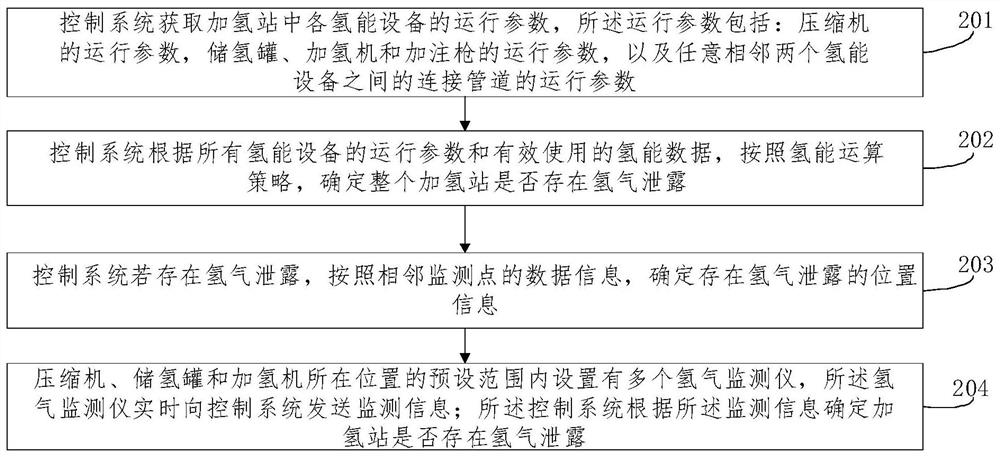

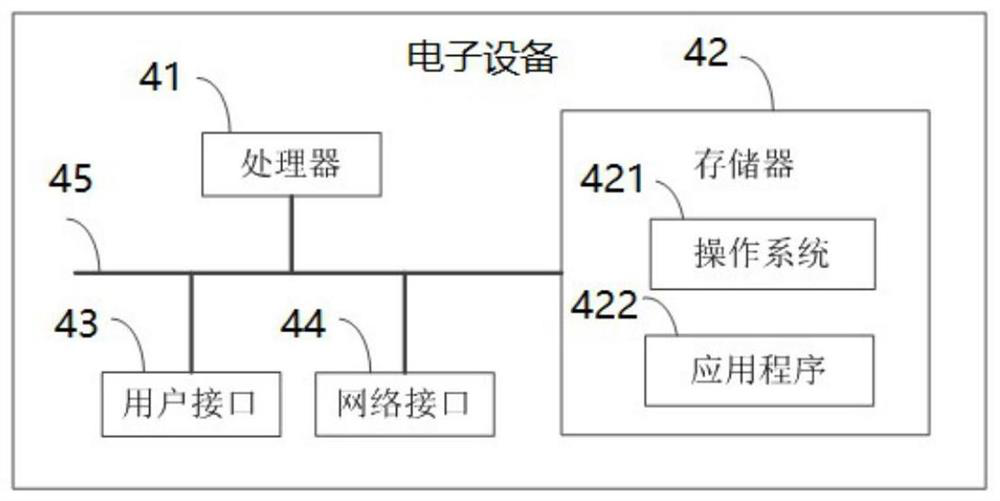

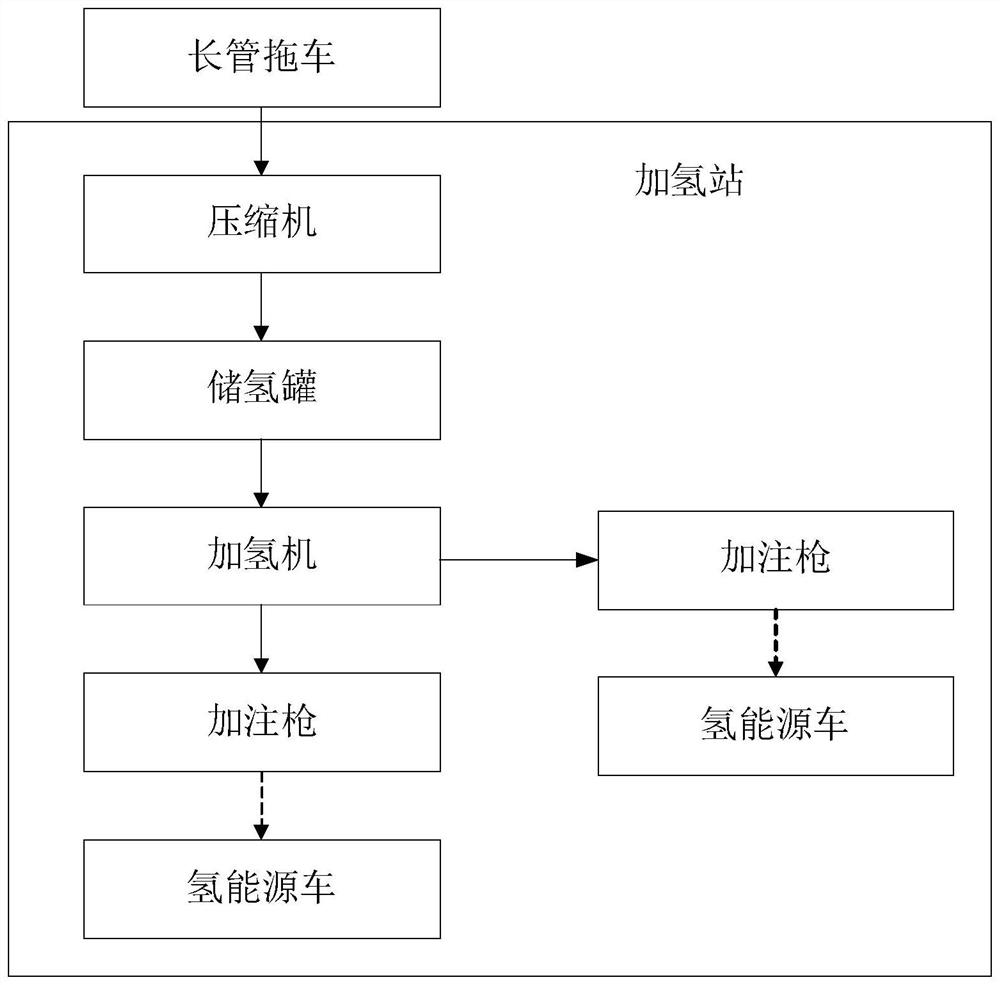

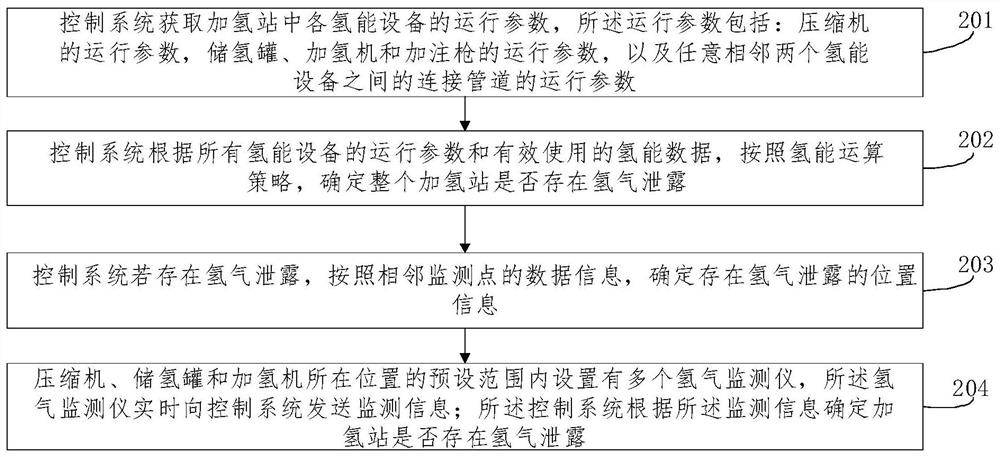

Risk evaluation method for hydrogen energy equipment in hydrogen refueling station

ActiveCN112819097AEasy to useRun without troubleContainer filling methodsCharacter and pattern recognitionThermodynamicsEnergy facilities

The invention relates to a risk evaluation method for hydrogen energy equipment in a hydrogen refueling station, and the method comprises the steps: a control system obtains the operation parameters of each hydrogen energy equipment in the hydrogen refueling station, and the operation parameters comprise the operation parameters of a compressor, the operation parameters of a hydrogen storage tank, the operation parameters of a hydrogen refueling machine, the operation parameters of a filling gun, and the operating parameters of a connecting pipeline between any two pieces of adjacent hydrogen energy equipment; the control system determines whether hydrogen leakage exists in the whole hydrogen refueling station or not according to the operation parameters of all hydrogen energy equipment and effectively used hydrogen energy data and a hydrogen energy operation strategy; and if the hydrogen leakage exists, the control system determines the position information of the hydrogen leakage according to the data information of the adjacent monitoring points. According to the method, the availability and the reliability are fully considered, and the safety and the reliability of the hydrogen energy facility are guaranteed.

Owner:ZHEJIANG UNIV CITY COLLEGE

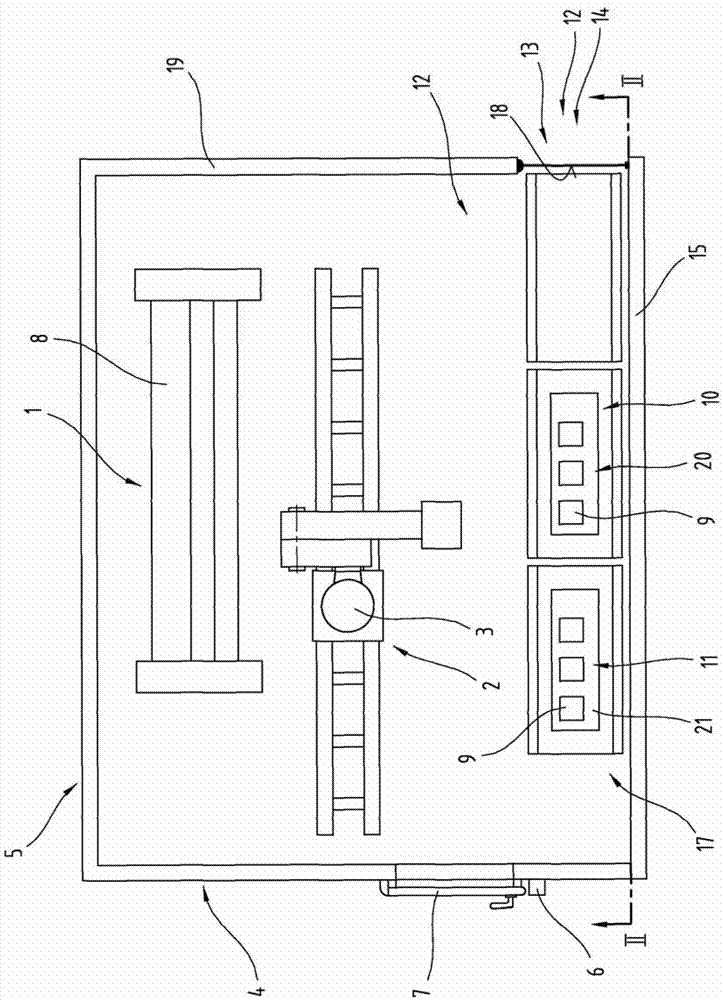

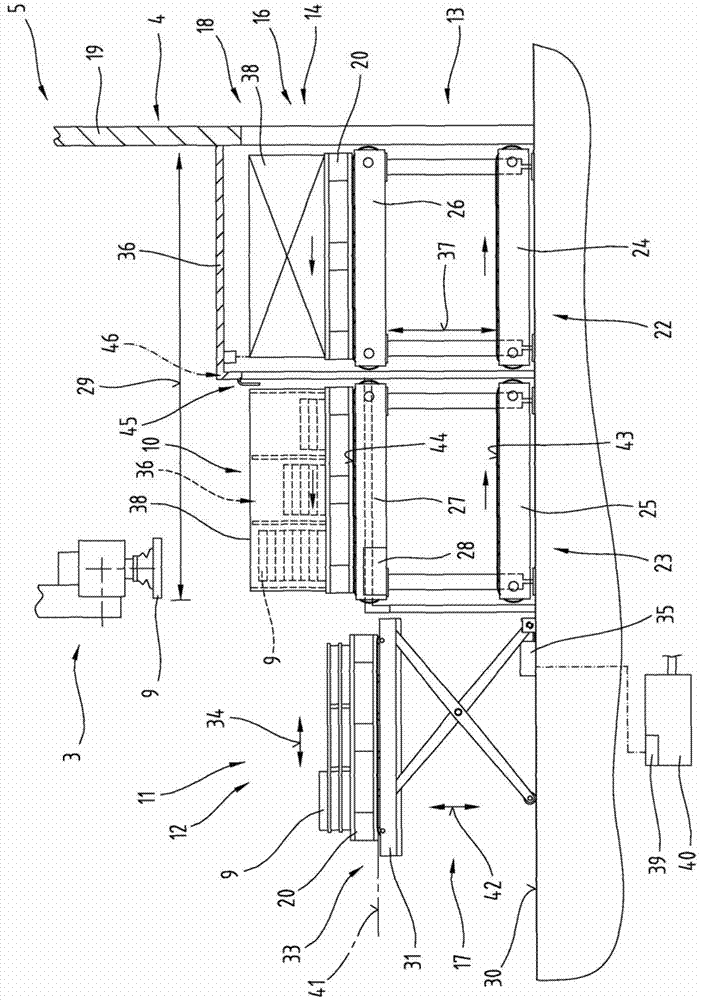

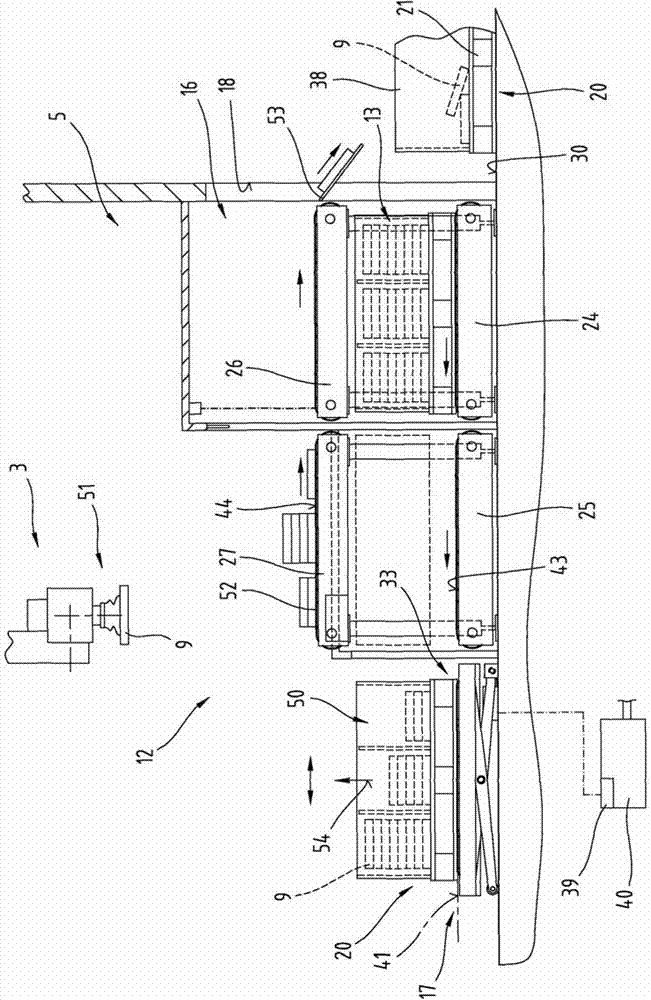

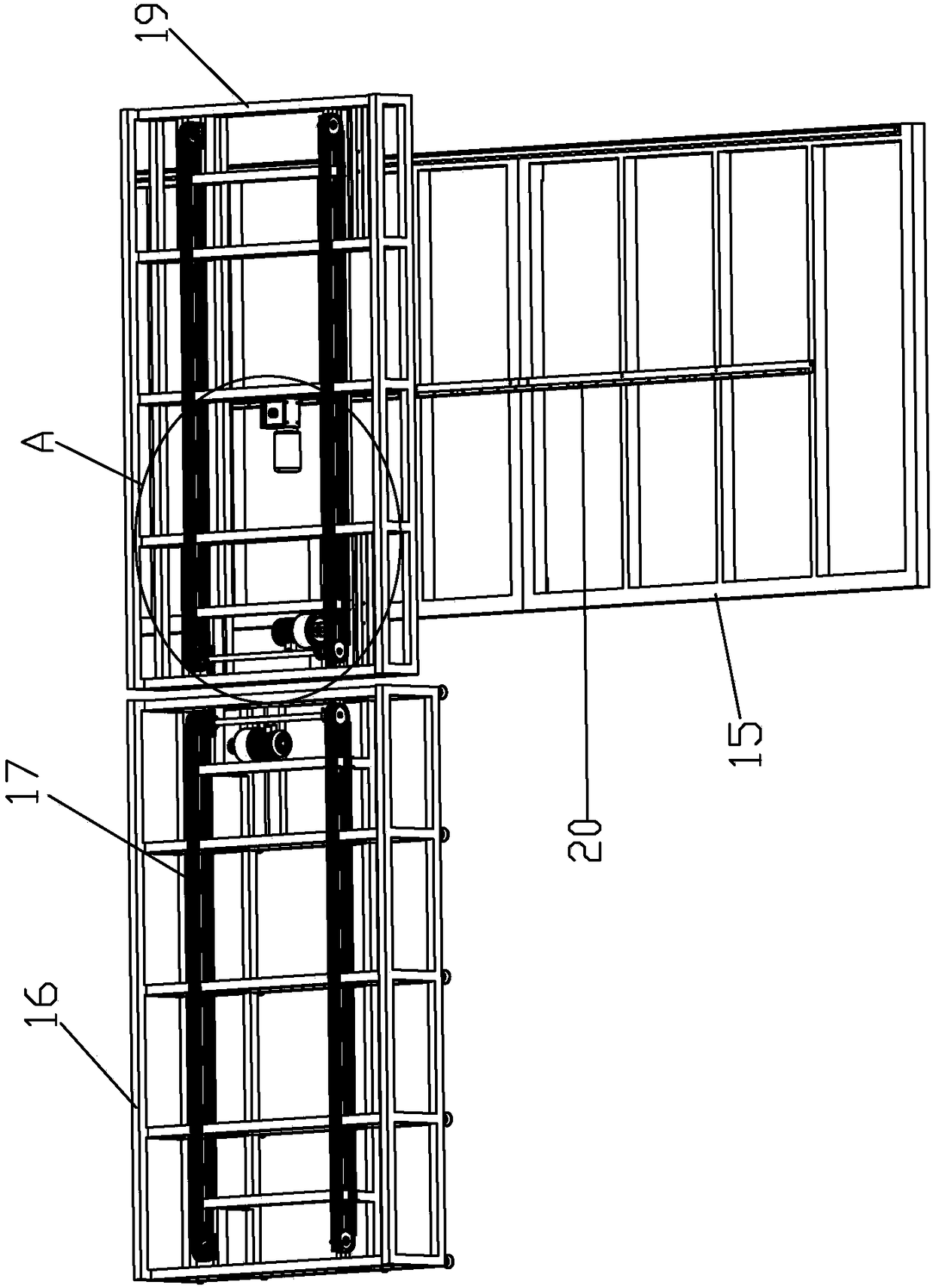

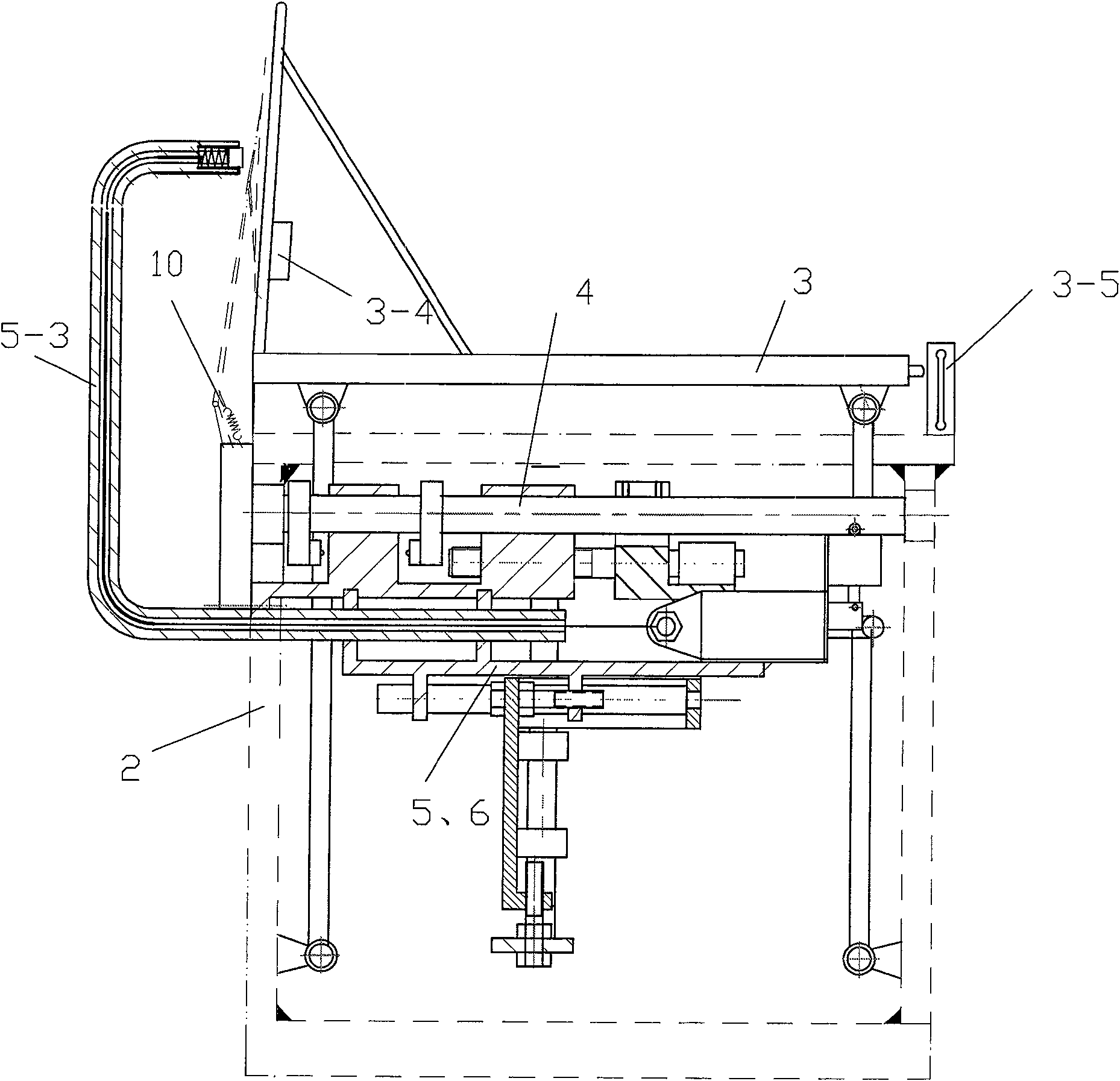

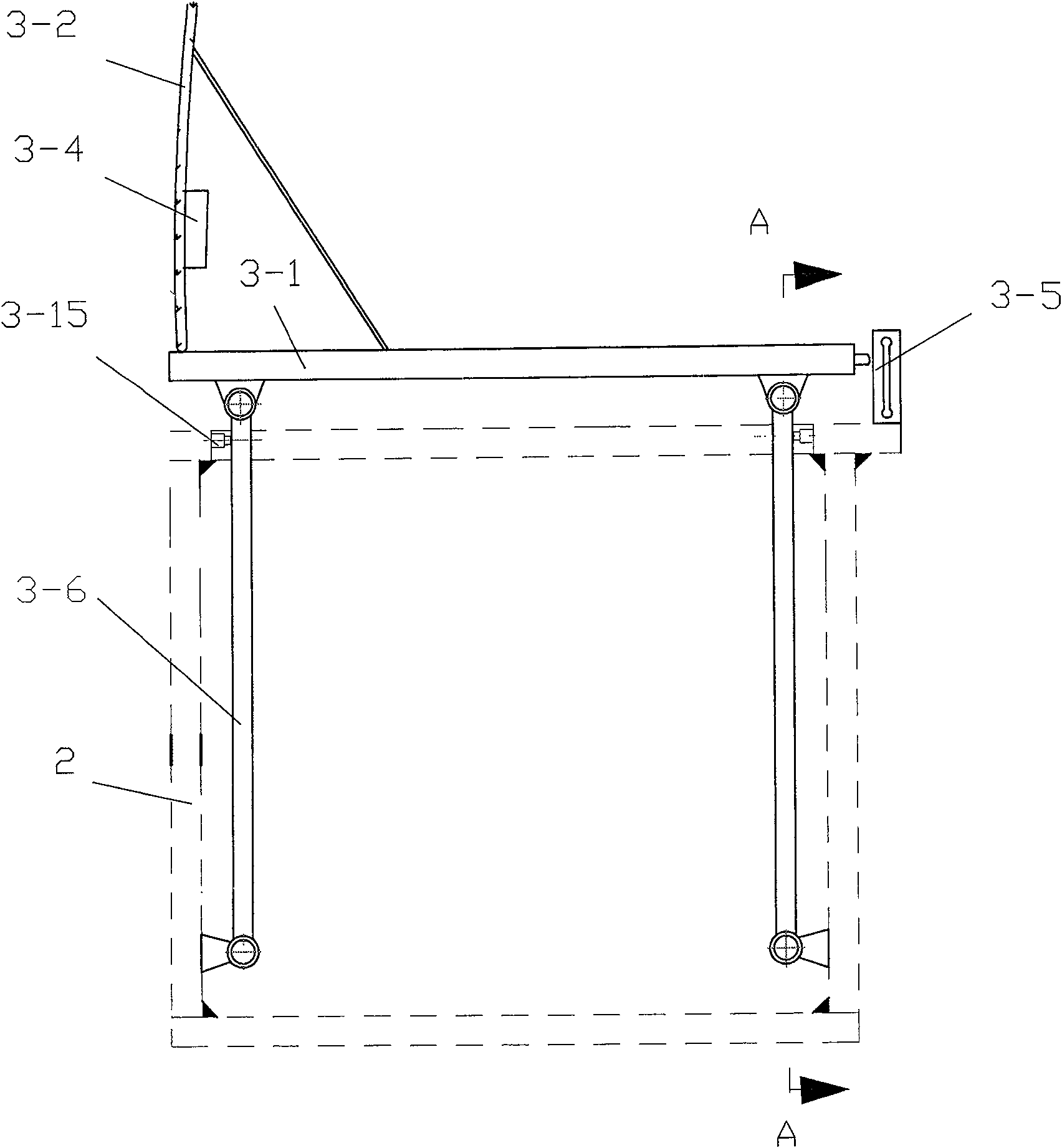

Production cell with a workpiece transfer device, and transport device for workpieces and part carriers

ActiveCN103201068ASmall space requirementReduce auxiliary timeMetal working apparatusMechanical conveyorsEngineeringManufacturing cell

The invention relates to a production cell (5) for automated processing of workpieces (9) having a protective fence (4) and, arranged therein, at least one production device (1), for example a bending press (8), and at least one handling device (2). A workpiece transfer device (12) for part carriers (20) or workpieces (9) is arranged in the production cell (5), which workpiece transfer device (12) forms a supply position (10) and a delivery position (11). Here, a delivery device (16) of the workpiece transfer device (12) forms a first delivery path (13) and a second delivery path (14) which extends parallel to the former, wherein, furthermore, a conveyor (33) for optional transfer of a part carrier (20) between the delivery paths (13, 14) is provided on an actuating device (17).

Owner:TRUMPF MASCHEN AUSTRIA

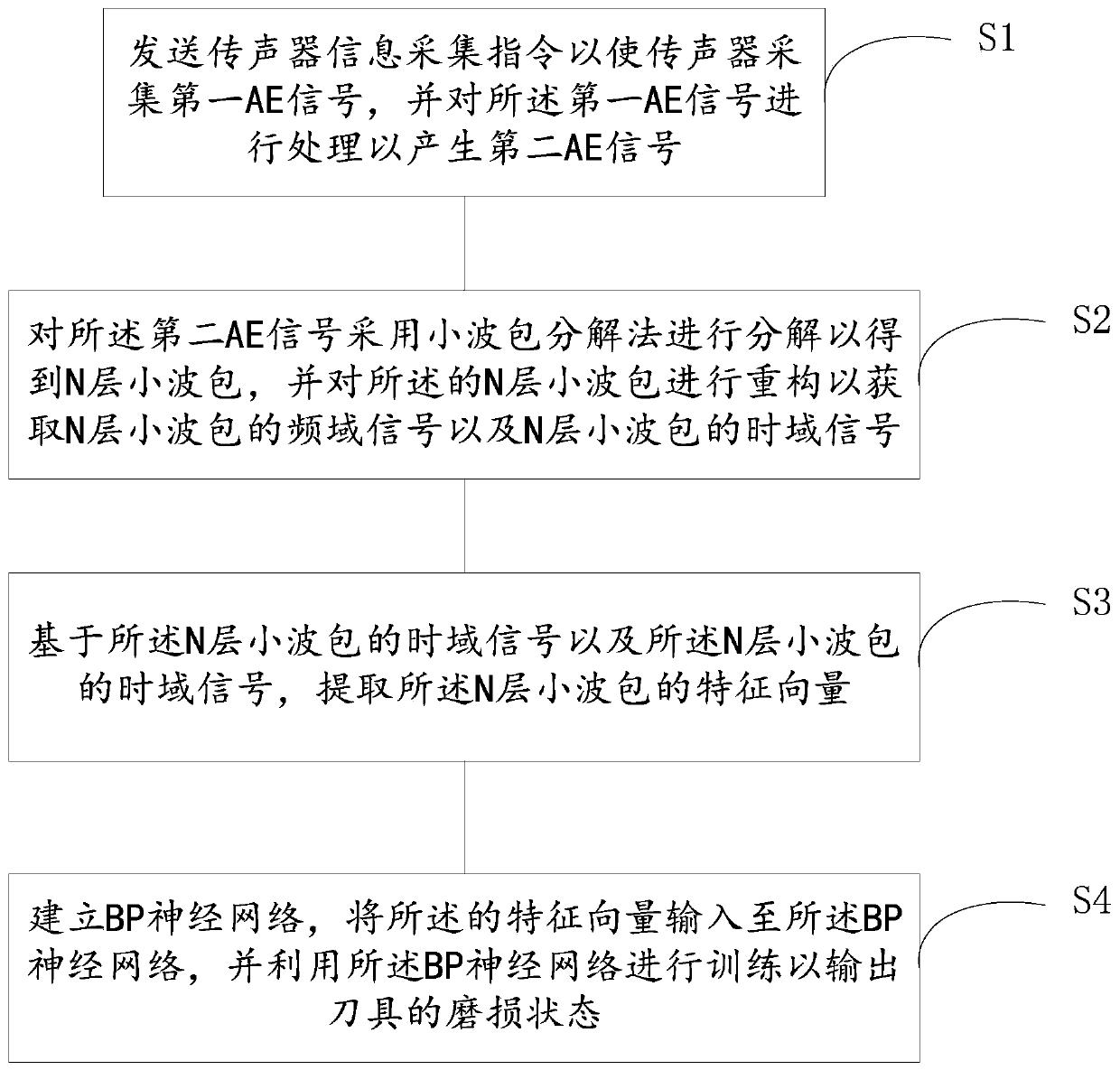

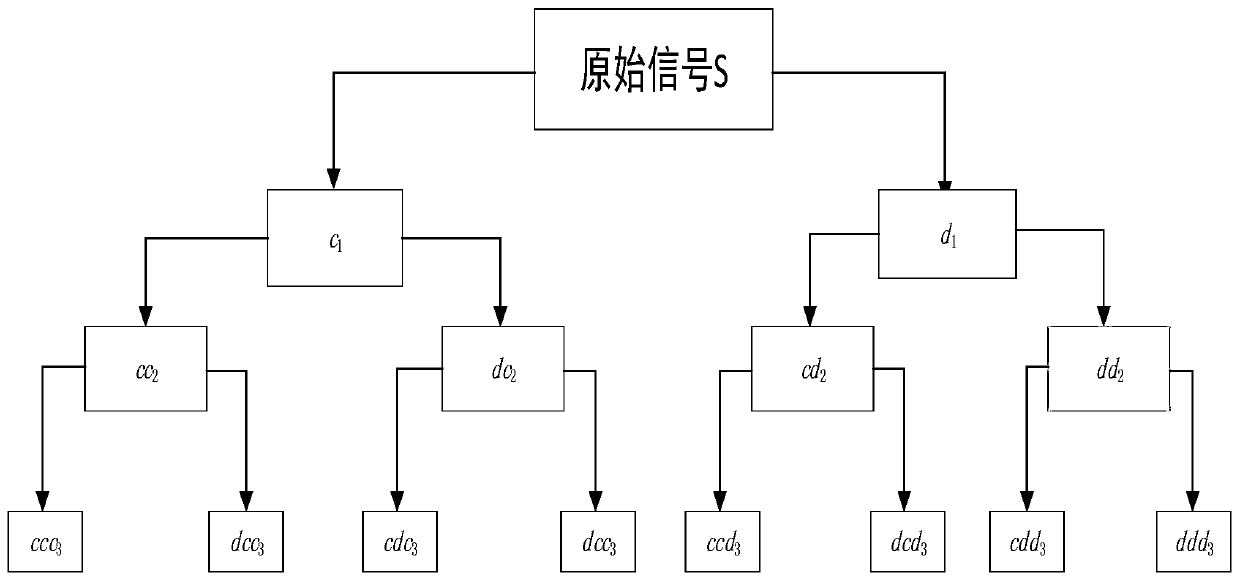

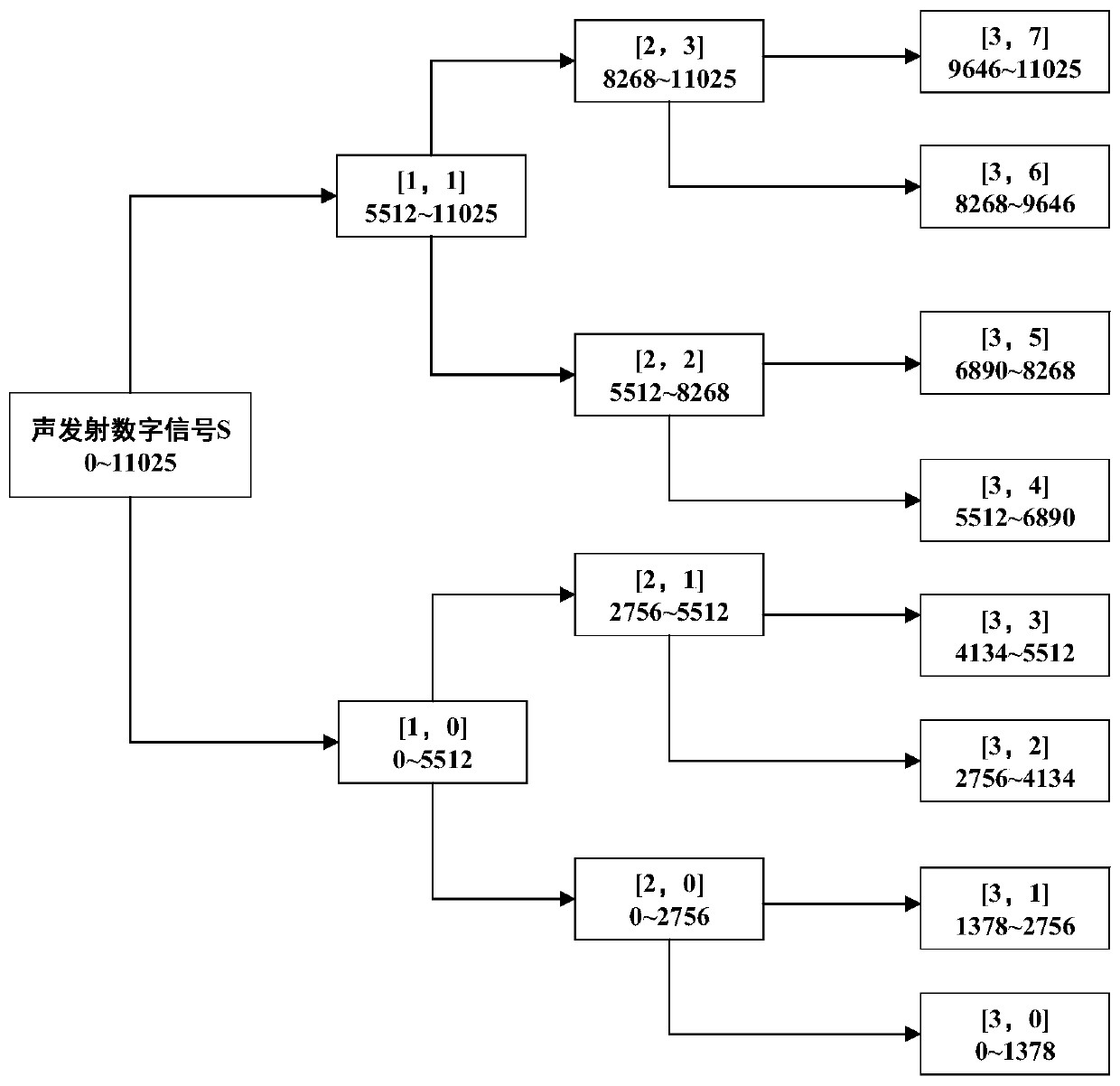

Method and device for monitoring abrasion state of tool based on energy analysis of wavelet packets

InactiveCN111331429AWear condition monitoringQuality assuranceMeasurement/indication equipmentsTime domainMonitoring methods

The invention provides a method and device for monitoring an abrasion state of a tool based on energy analysis of wavelet packets, and relates to the technical field of tool abrasion detection. The method comprises the steps that a microphone information collection instruction is sent to enable a microphone to collect a first AE signal, and the first AE signal is processed to generate a second AEsignal; the second AE signal is decomposed through a wavelet packet decomposition method to obtain the N layers of wavelet packets, and the N layers of wavelet packets are reconstructed to obtain frequency domain signals and time domain signals of the N layers of wavelet packets; based on the frequency domain signals and the time domain signals of the N layers of wavelet packets, characteristic vectors of the N layers of wavelet packets are extracted; and a BP neural network is established, the characteristic vectors are input into the BP neural network, and training is conducted through the BP neural network so as to output the abrasion state of the tool. By utilizing the method and device provided by the invention, the abrasion state of the composite material tool can be effectively monitored, and thus the quality of aircraft composite material machined parts is guaranteed.

Owner:CIVIL AVIATION UNIV OF CHINA

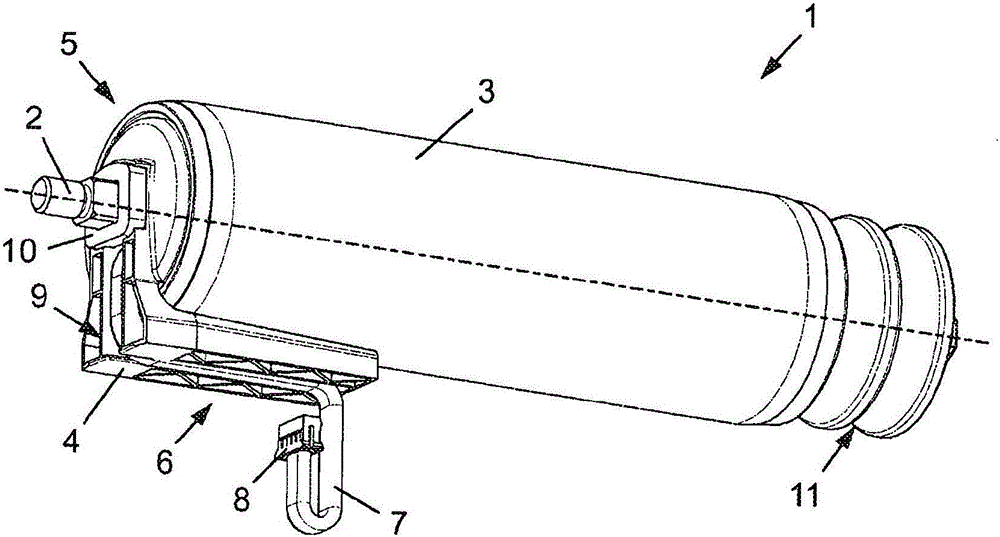

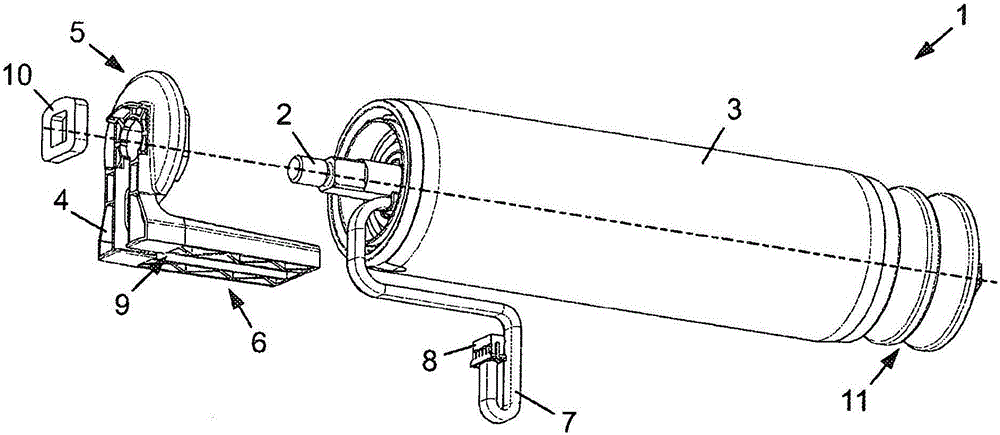

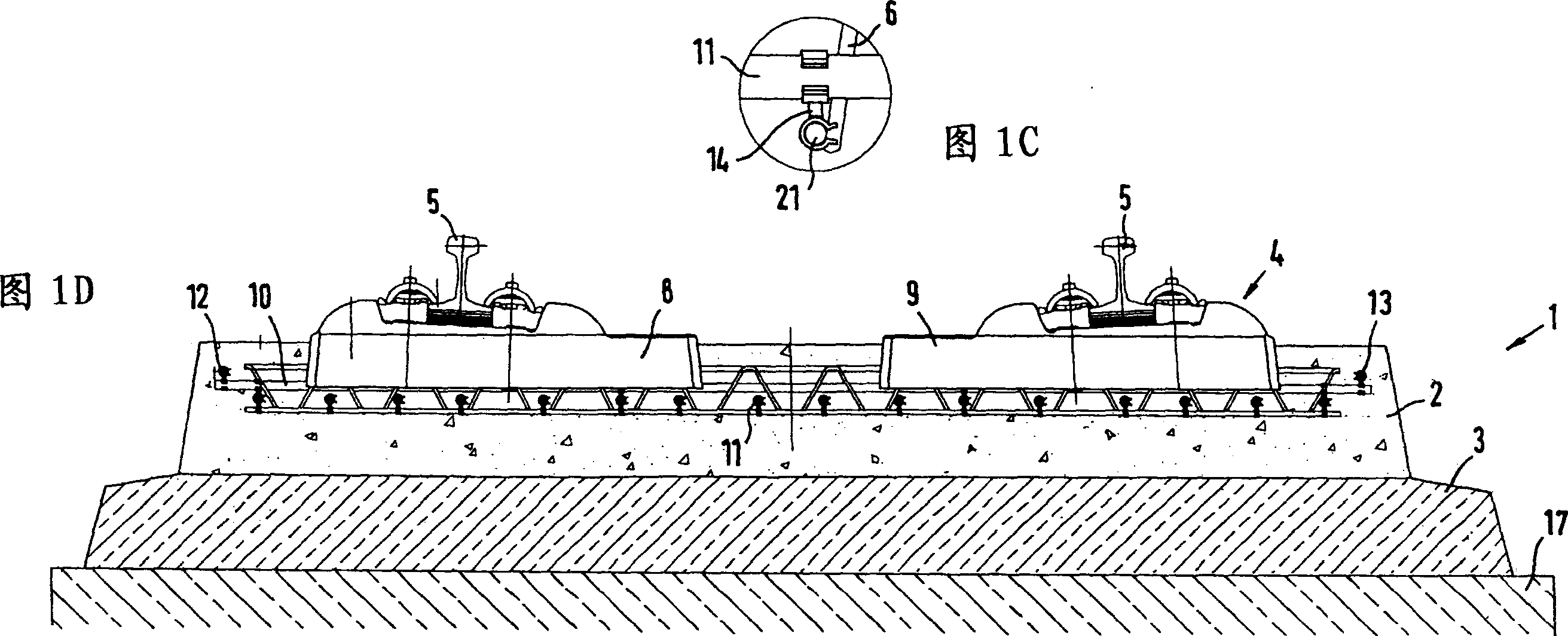

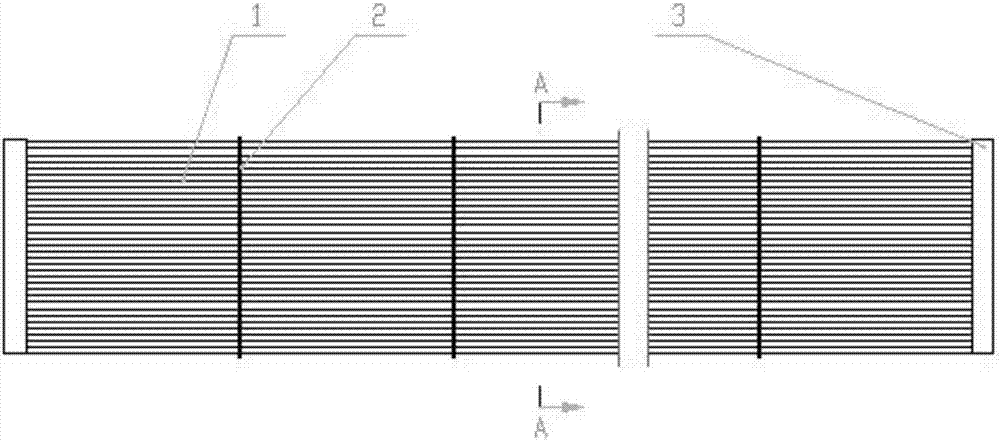

Conveyor roller and conveyor system with moisture protection

ActiveCN105793173AImprove protectionGuaranteed trouble-free operationConveyorsRollersEngineeringMoisture

Disclosed is a conveyor roller (1) which comprises a shaft (2), a roller body (3) which is mounted to be rotatable about the shaft (2), and a protective cap (4). The protective cap (4) has a disc-shaped first section (5) for covering the interior of the roller body (3), which first section (5) is arranged fixedly with respect to the shaft (2) and is oriented normally with respect thereto, and a channel-like or roof-like second section (6) which is arranged obliquely with respect to the shaft (2) and runs over a part length of the roller body (3) so as to be spaced apart radially from the latter. Furthermore, a conveyor system with a conveyor roller (1) is disclosed, in which conveyor system a connector cable (7) of the conveyor roller (1) is guided in a curve or a loop to an electrical interface (8, 17) with a connector box of the conveyor system, wherein the lowest point of the curve / the loop is located below said interface (8).

Owner:TGW MECHANICS GMBH

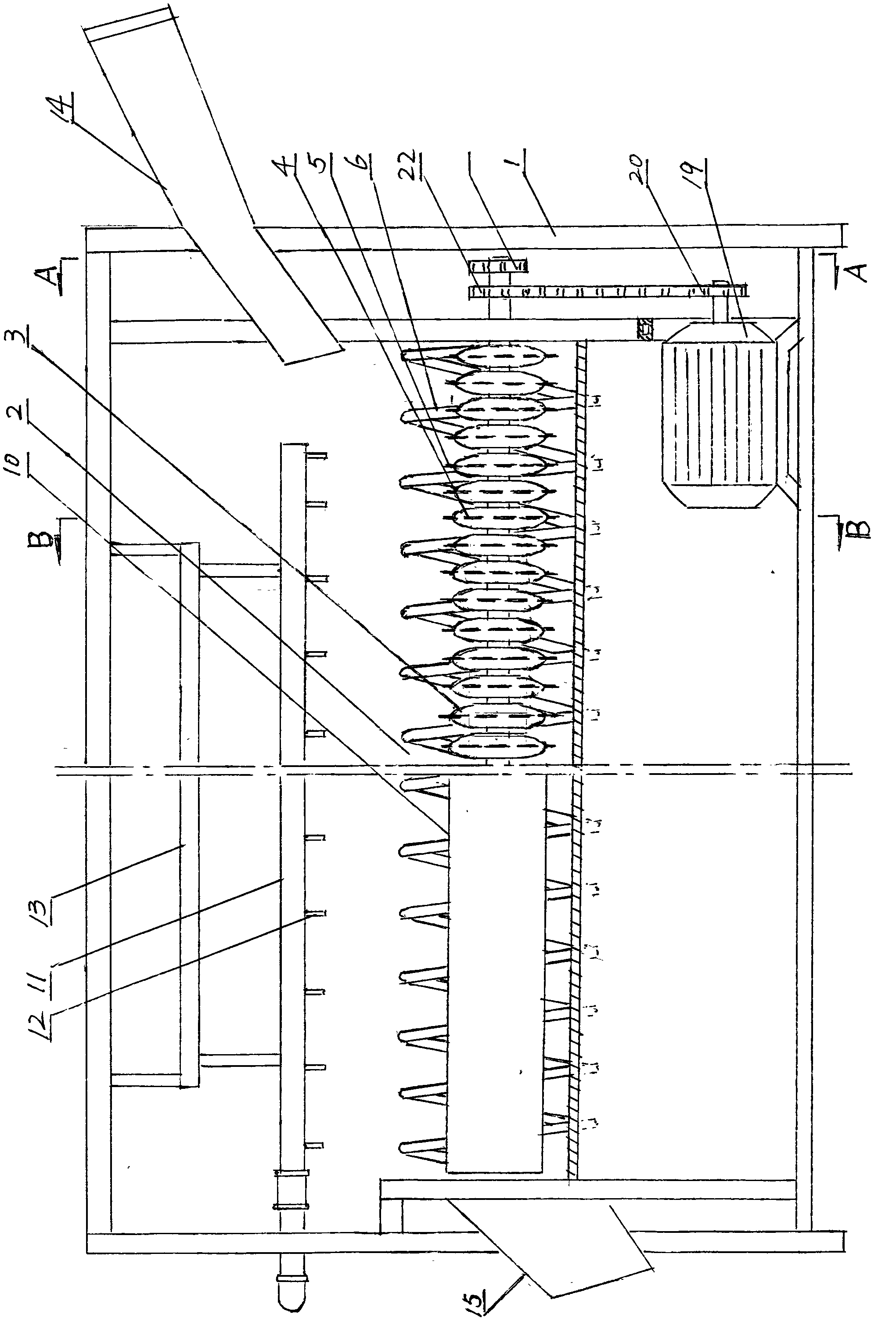

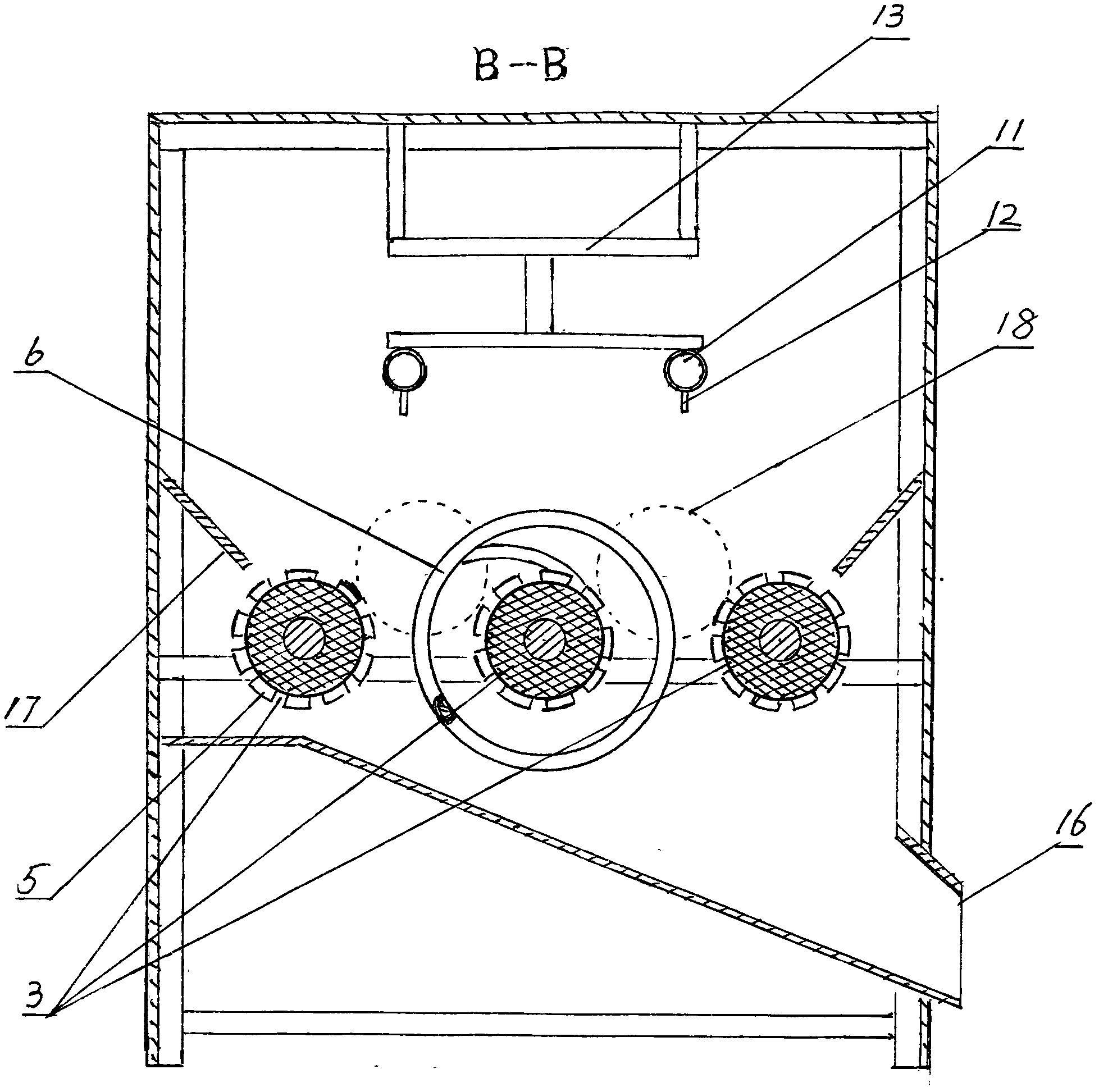

Onion peeler

The invention provides an onion peeler, relating to the onion peeler of vegetable processing machineries. The onion peeler comprises a frame, three peeling rollers which are arranged in parallel and a high pressure gas spraying pipe which is arranged above the peeling rollers; the middle peeling roller is provided with a screw 6; the three peeling rollers are formed by a front section and a back section, respectively; the peeling roller 3 at the front section consists of parallel assembling a plurality of cake shaped circular disc wheels 4; the peripheral edges of the cake shaped circular disc wheels are provided with skin scratching blades; and the peeling roller 10 at the back section is a plain cylindrical stick. The machine has the advantages of innovating design on the basis of the prior art, simplifying structure, and finishing the skin-scratching and peeling once without fault in operation. Compared with the prior art, the production efficiency is increased by 3-5 times; the peeling quality is good, and the requirements of export and deep-processing enterprises are completely satisfied. The machine has low manufacturing cost, which is only 1 / 5 of that of the original machine.

Owner:QINGDAO WEIMA MACHINERY

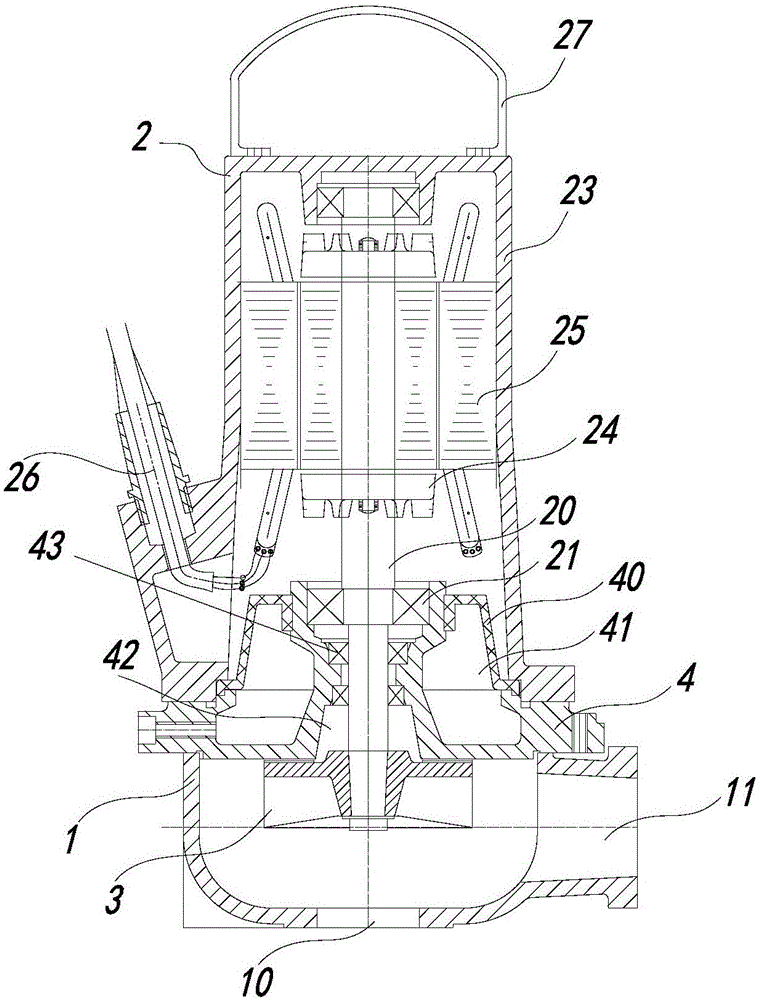

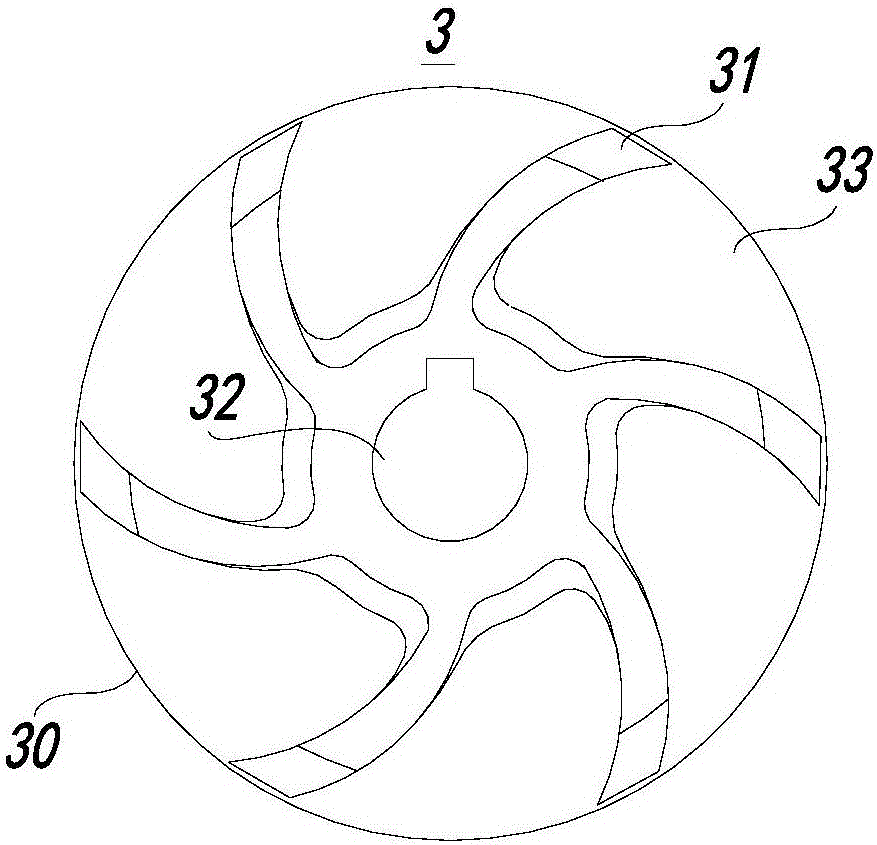

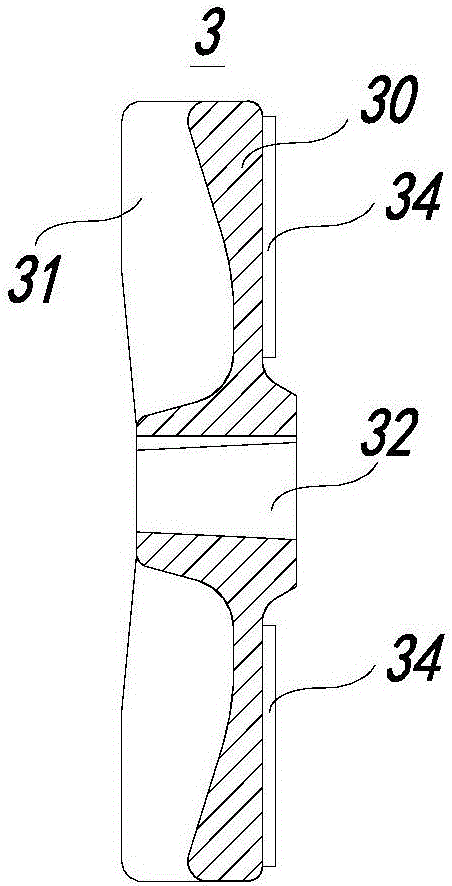

Non-clogging sewage pump

PendingCN106122040ARealize non-blockingLarge runner spaceSpecific fluid pumpsPump componentsFiberImpeller

The invention discloses a non-clogging sewage pump. The non-clogging sewage pump comprises a pump body, a motor and an impeller, wherein a water suction opening and a water draining opening are formed in the pump body. The non-clogging sewage pump further comprises a sealing seat and an oil chamber, wherein the sealing seat is arranged between the pump body and the motor, the oil chamber is arranged on the sealing seat in a sleeving manner in the circumferential direction, an annular oil storage chamber is formed between the oil chamber and the sealing seat, a containing hole for the rotary shaft of the motor to penetrate through is formed in the middle of the sealing seat, the lower bearing of the motor is installed above the containing hole, and a mechanical seal is arranged below the lower bearing and between the rotary shaft and the containing hole. According to the non-clogging sewage pump, the impeller is driven by the motor to rotate at a high speed so that eddy currents can be generated to achieve medium conveying, and furthermore, because of the open type impeller and an ample pass way designed in a volute casing, various solid particles, even fiber sundries prone to intertwining, in mediums all can be sent out without obstruction as long as the particles or sundries can enter the water suction opening of the volute casing, and the effect of no clogging is really achieved.

Owner:SHANGHAI GUANMIN ENVIRONMENTAL TECH

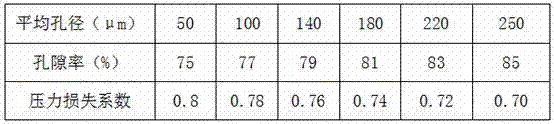

Foamed ceramic high-temperature gas filter pipe and manufacturing technology thereof

InactiveCN102775137AImprove permeabilitySmall pressure lossDispersed particle filtrationFiltration separationPorositySodium Bentonite

The invention relates to the technical field of a filter pipe, and in particular relates to a foamed ceramic high-temperature gas filter pipe and a manufacturing technology thereof. The foamed ceramic high-temperature gas filter pipe comprises 10-30 parts of Al2O3, 10-40 parts of SiO2, 10-30 parts of SiC, 1-3 parts of nano calcium carbonate, 5-10 parts of refractory clay, 1-2 parts of rectorite and 0.5-1.5 parts of sodium bentonite. According to the invention, the average aperture of the filter pipe is 20-250 mu m, the porosity can reach 75-85%, the gas permeability can be improved, and the pressure loss of the filter pipe in work is effectively reduced so that the energy consumption of a draught fan of a dust collector is reduced by 20-30% and the effect of saving energy is achieved; and the manufacturing technology comprises the steps of mixing materials, forming, firing and the like, wherein the firing process is performed under normal pressure, the requirements on equipment and the like are low, the energy consumption is low.

Owner:GUANGDONG SOUTHCHINA INST OF INDAL DESIGN

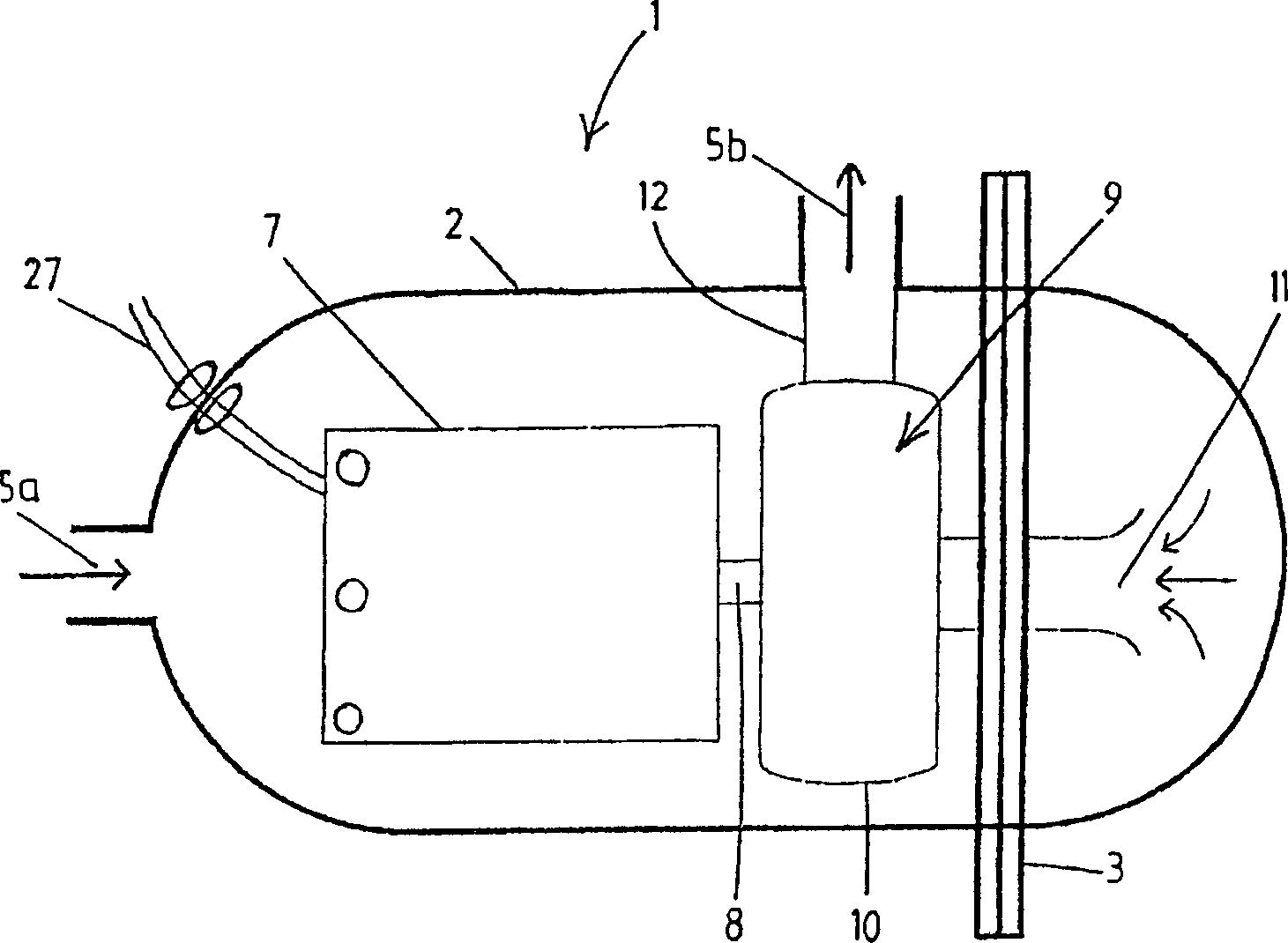

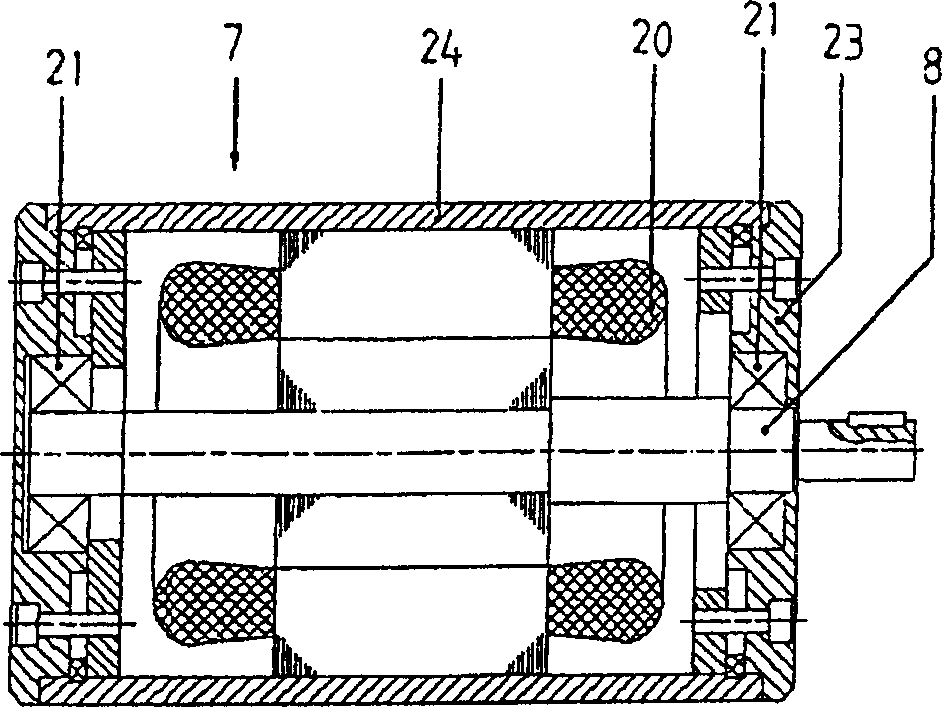

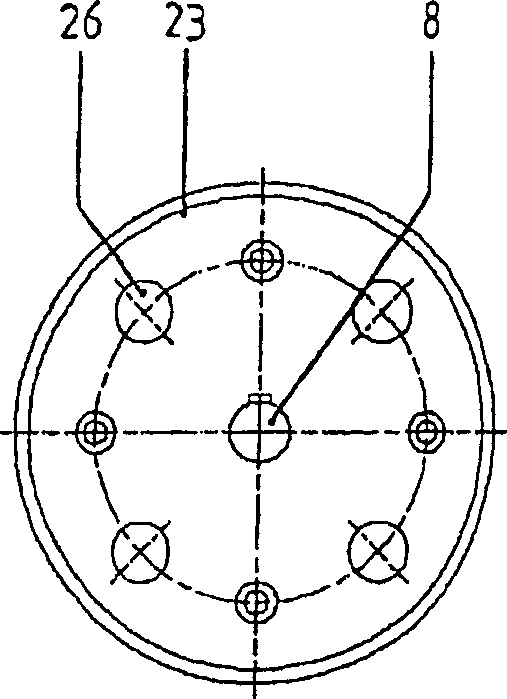

Device for treating pieces of a substrate at high pressure with a supercritical or near-critical treatment medium, piece by piece or in batches

A device for treating pieces of a substrate at high pressure, piece by piece or in batches, with a treatment medium in the supercritical or near-critical state, comprising a first pressure chamber (2), a pipe system (5) for supplying and discharging the treatment medium, to and from the pressure chamber (2) under high pressure and an electric motor (7), which is fixed to the housing in the first pressure chamber or in a second pressure chamber coupled to the first pressure chamber under the high pressure, for driving an actuator to carry out a mechanical action in the treatment medium. The electric motor (7) is in this case open to the treatment medium and is disposed and designed to be accessible to the treatment medium, in such a manner that during the treatment of a substrate the treatment medium flows through and around the electric motor (7).

Owner:STORK BRADANT BV

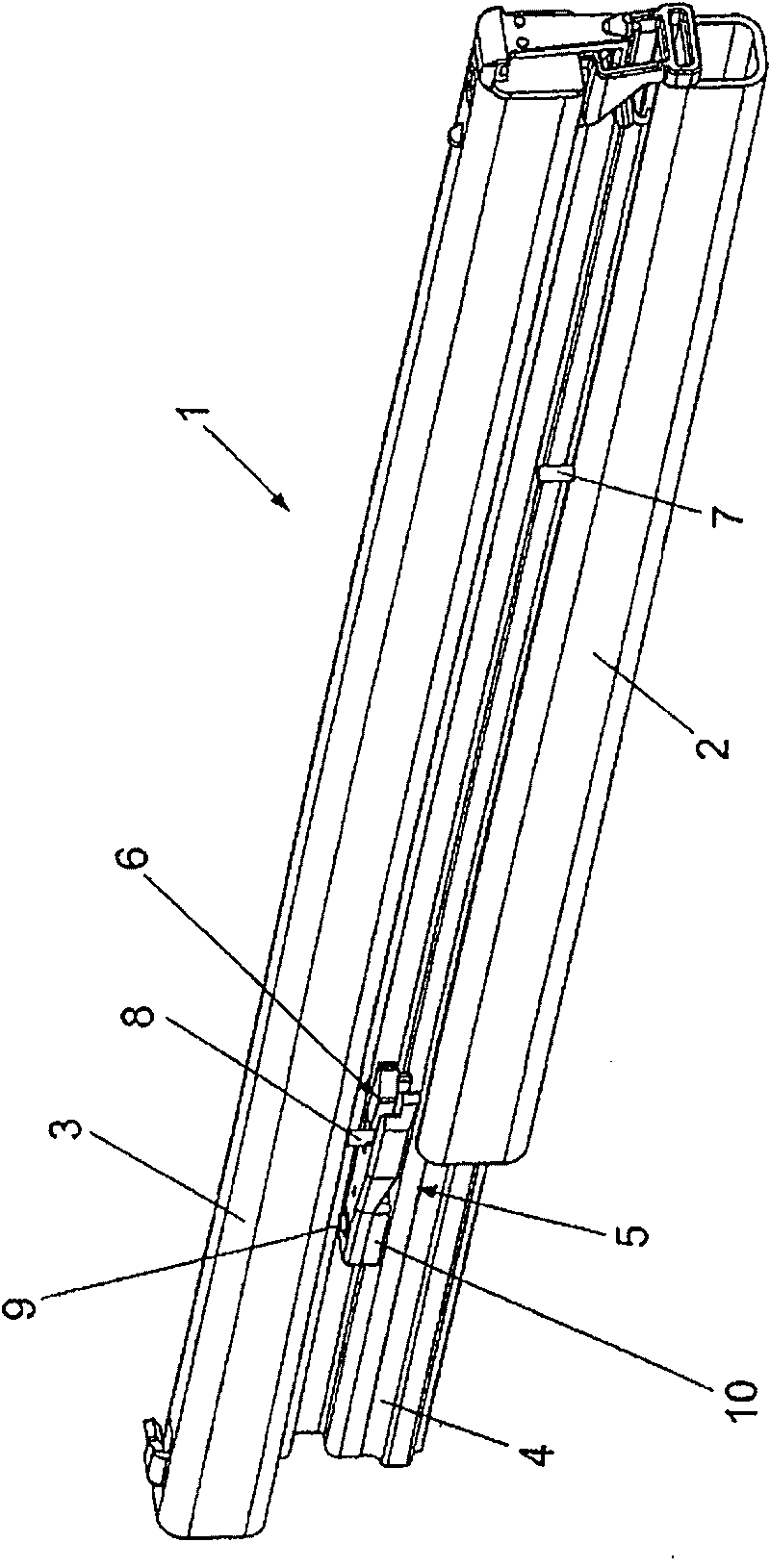

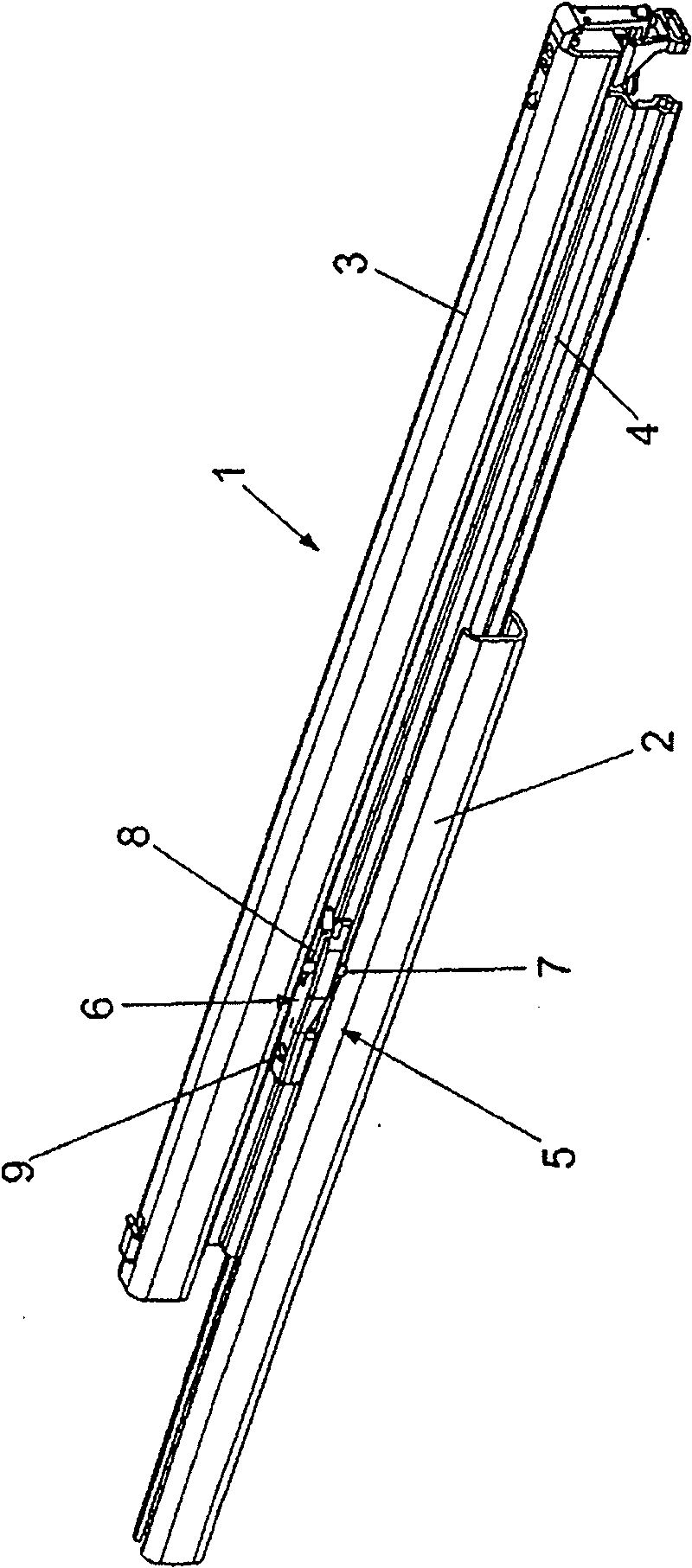

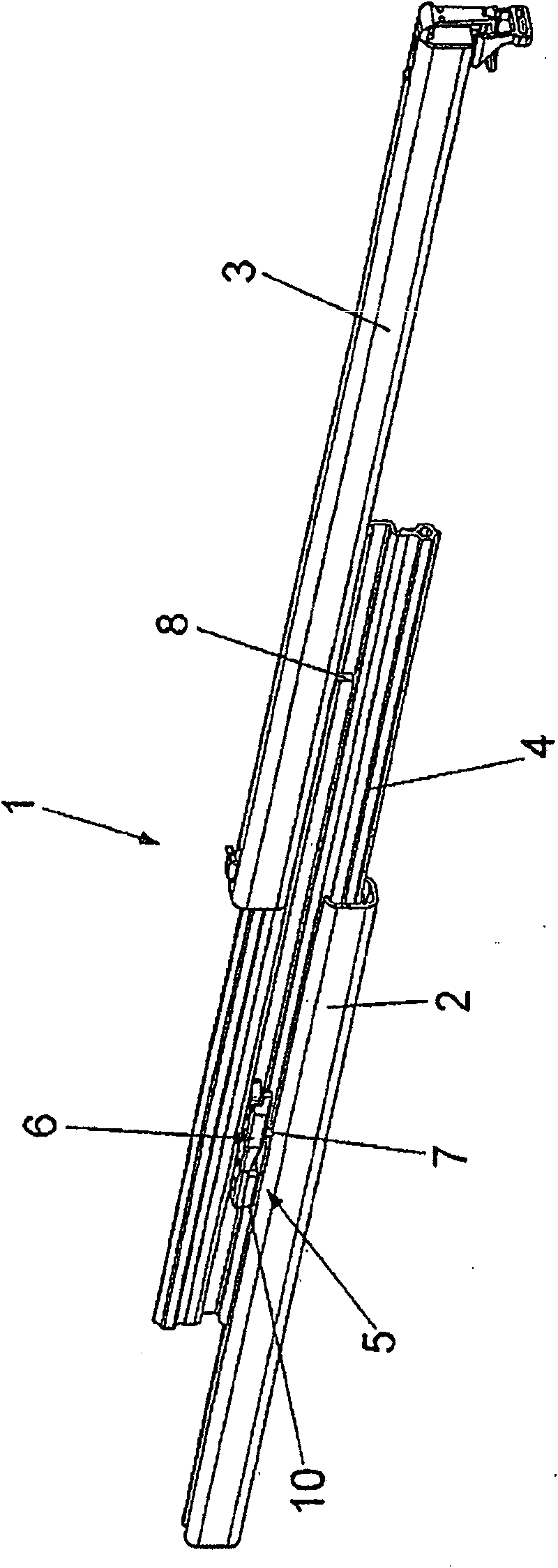

Telescopic guide rail

InactiveCN101720192AAdverse effect on carrying capacityCarrying capacity impactDrawersMechanical engineeringProcess control

Disclosed is a telescopic guide rail (1) for extractable furniture parts such as drawers or the like, comprising a body rail (2) that can be mounted on a furniture part, a drawer rail (3) that can be connected to an extractable furniture part, a central rail (4) which is disposed between the body rail (2) and the drawer rail (3) and increases the pull-out length, and a control appliance (5) by means of which the drawer rail (3) is coupled to the central rail (4) during pull-out from the closing position until the central rail (4) is deployed to the maximum pulled-out position and is blocked in said position with respect to the body rail (4) while the drawer rail (3) is simultaneously decoupled from the central rail (4), the central rail (4) being displaced in the closing direction with respect to the body rail (2) only when the drawer rail (3) is maximally displaced in the direction of insertion in relation to the initially blocked central rail (4), thereby being coupled again to the central rail (4). The control appliance (5) is composed of a coupling member (6), which is provided with two sliding guides (6a, 6b) extending in an mirror-inverted manner to one another, a first slide (7) fixed to the body rail (2) and associated to a first sliding guide (6a), and a second slide (8) fixed to the drawer rail (3) and associated to the second sliding guide (6b), wherein the coupling member (6) is pivotably mounted about an axis (9) that extends perpendicular to the plane of displacement of the telescopic guide rail (1) and the sliding guides (6a, 6b) extend in a V-shape by expanding one in relation to the other in such a manner that during the entry of the first slide (7) into the first sliding guide (6a) associated therewith a switching of the coupling member (6) and thus a release of the second slide (8) from the second sliding guide (6b) associated therewith is caused and vice versa.

Owner:PAUL HETTICH

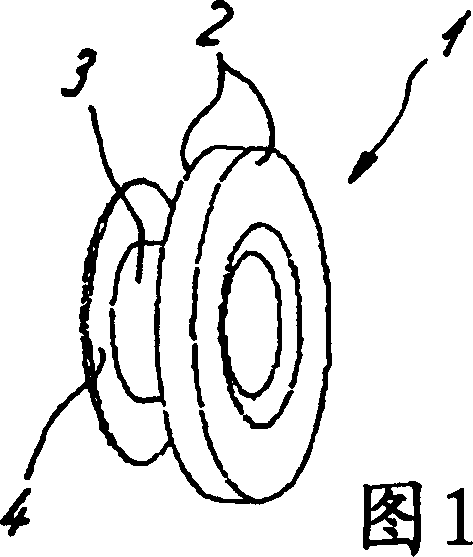

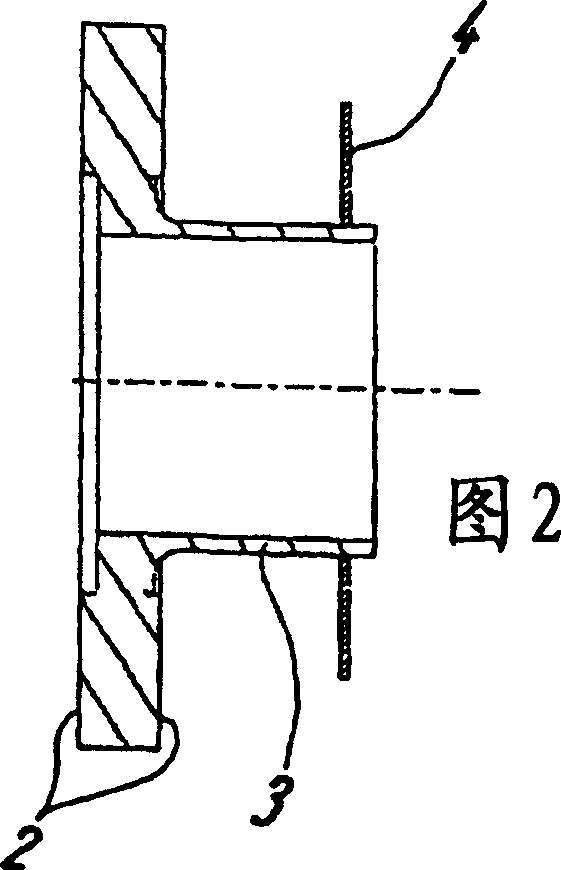

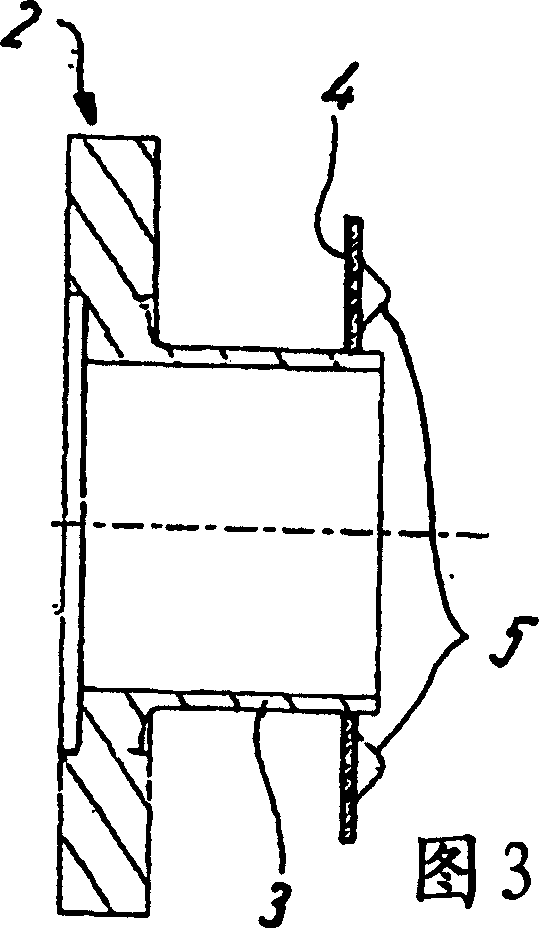

Brake disk that can be fixed to a wheel hub

InactiveCN1856666ASimple structureCheap manufacturingBraking discsPulp and paper industryCommercial vehicle

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

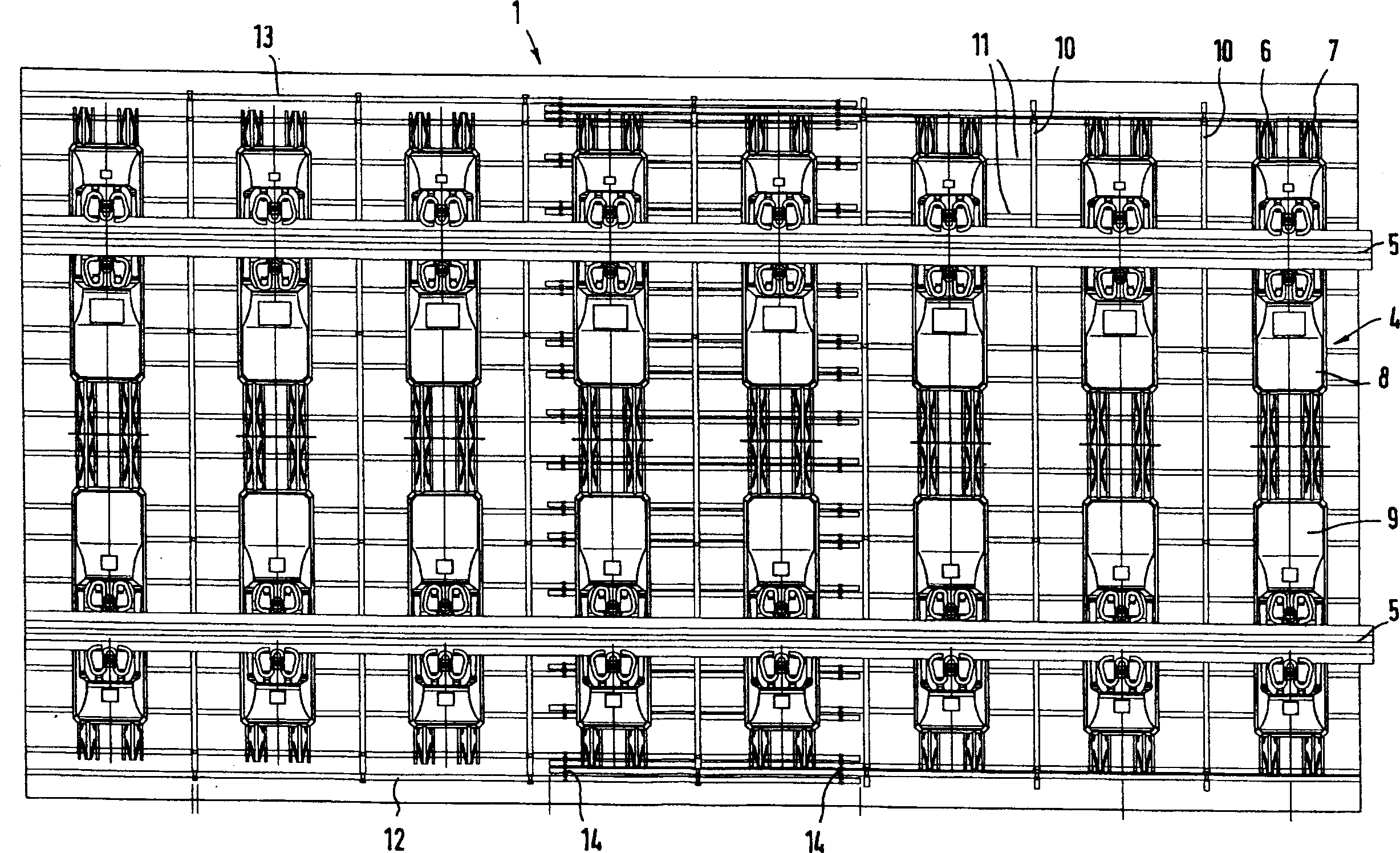

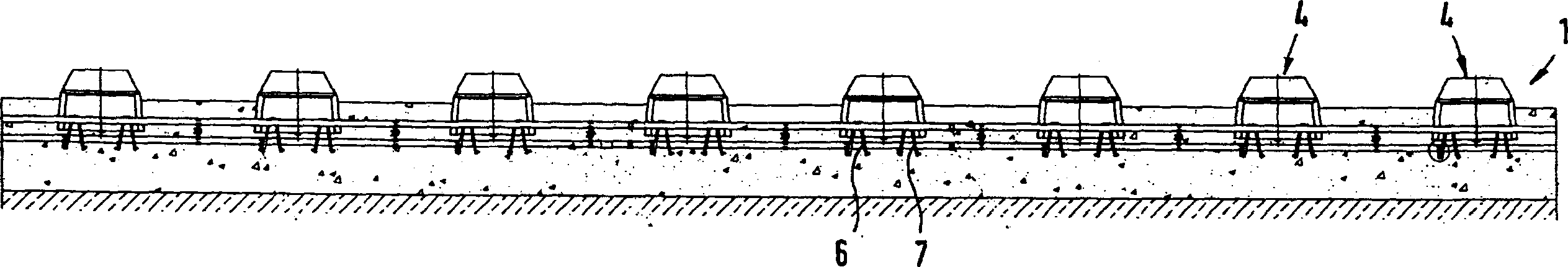

Fixed carriageway for rail vehicles and method of manufacturing the same

Owner:RAIL ONE GMBH

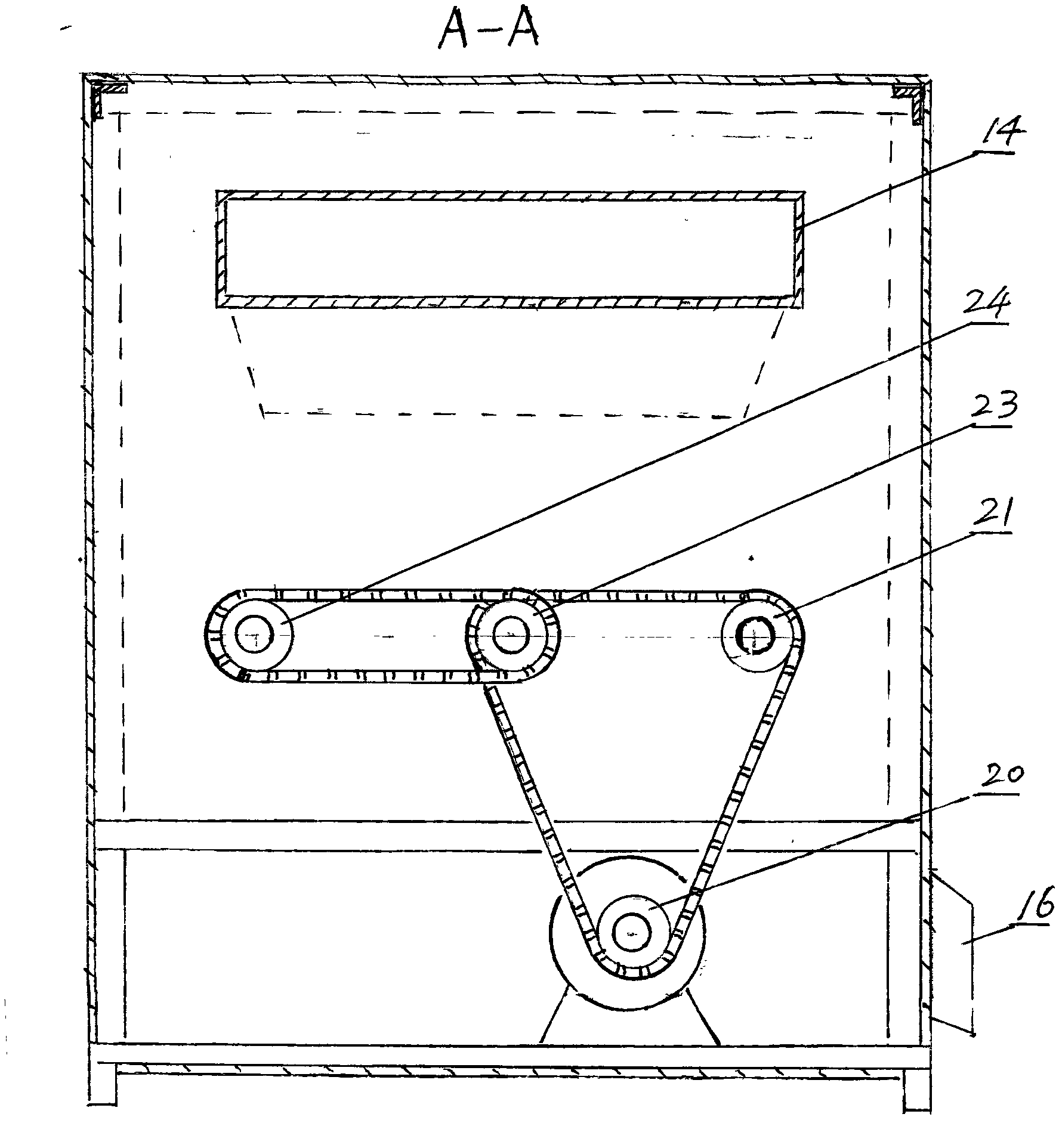

Method for grinding spring ends and spring-end grinding machine

ActiveCN105722640AAvoid overheatingNo need for cooling measuresGrinding feed controlPlane surface grinding machinesTemperature measurementAirflow

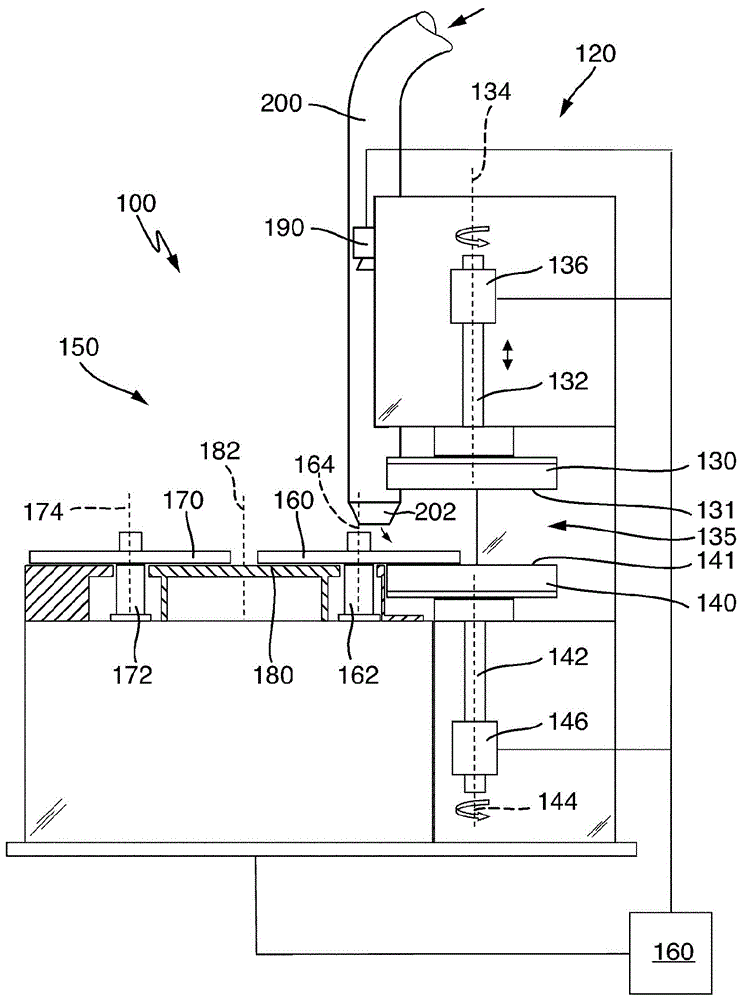

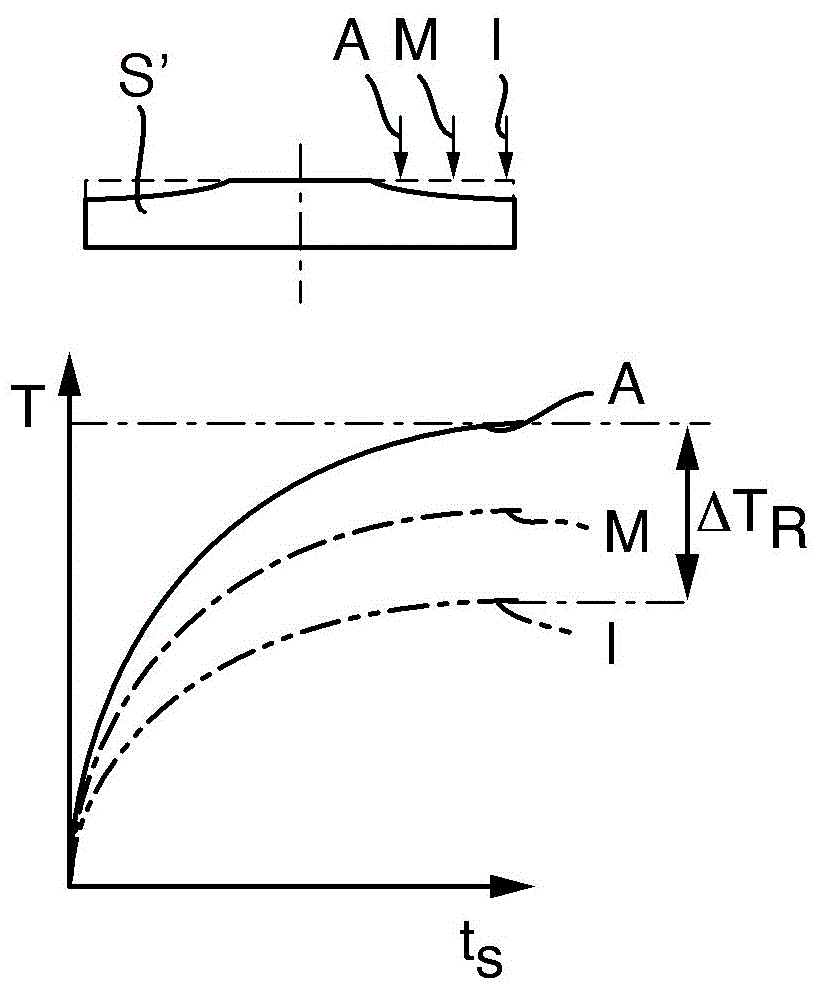

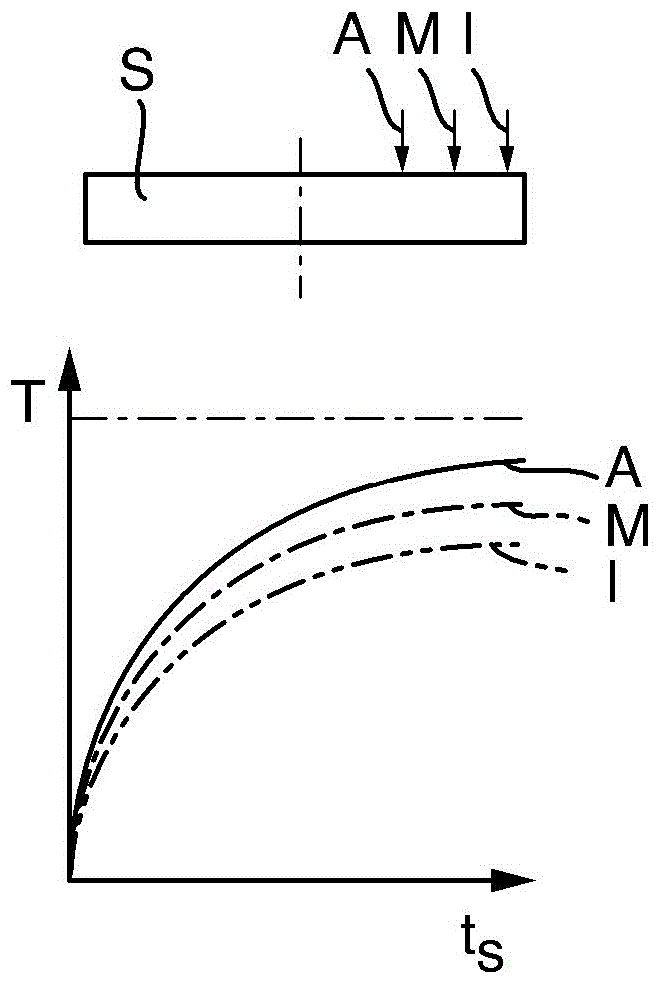

The invention relates to a method for grinding spring ends of helical compression springs using a numerically controlled spring-end grinding machine (100) having a grinding unit (120), a loading unit (150) and a control unit (160) for controlling the loading unit (150) and the grinding unit (120). The grinding unit (120) has a grinding disc pair with two rotatable grinding discs (130, 140), between which a grinding space (135) is formed. The loading unit (150) has at least one loading plate (160, 170), which is rotatable substantially axially parallel to the grinding discs (130, 140) and has a plurality of off-axial spring receptacles (166), each for receiving a respective helical compression spring (F). During a grinding operation, helical compression springs (F) received in spring receptacles (166) are successively transported through the grinding space between the rotating grinding discs (130, 140) by rotation of the loading plate (160, 170) and in the process both spring ends of the helical compression springs (F) located in the grinding space are simultaneously machined by grinding. The method is characterized in that a temperature signal representing the temperature is determined on at least one of the helical compression springs (F) by a temperature measurement during the grinding operation. The spring-end grinding machine (100) is preferably controlled on the basis of the temperature signal. In one embodiment, the temperature is measured using a thermal imaging camera (190). The temperature measuring device (190) is arranged in a cooling air supply duct (200) belonging to a cooling device and / or in a cooling air stream generated by the supply duct (200).

Owner:WAFIOS AKTIENGES

Waterproof GRC shower tray production line and production method thereof

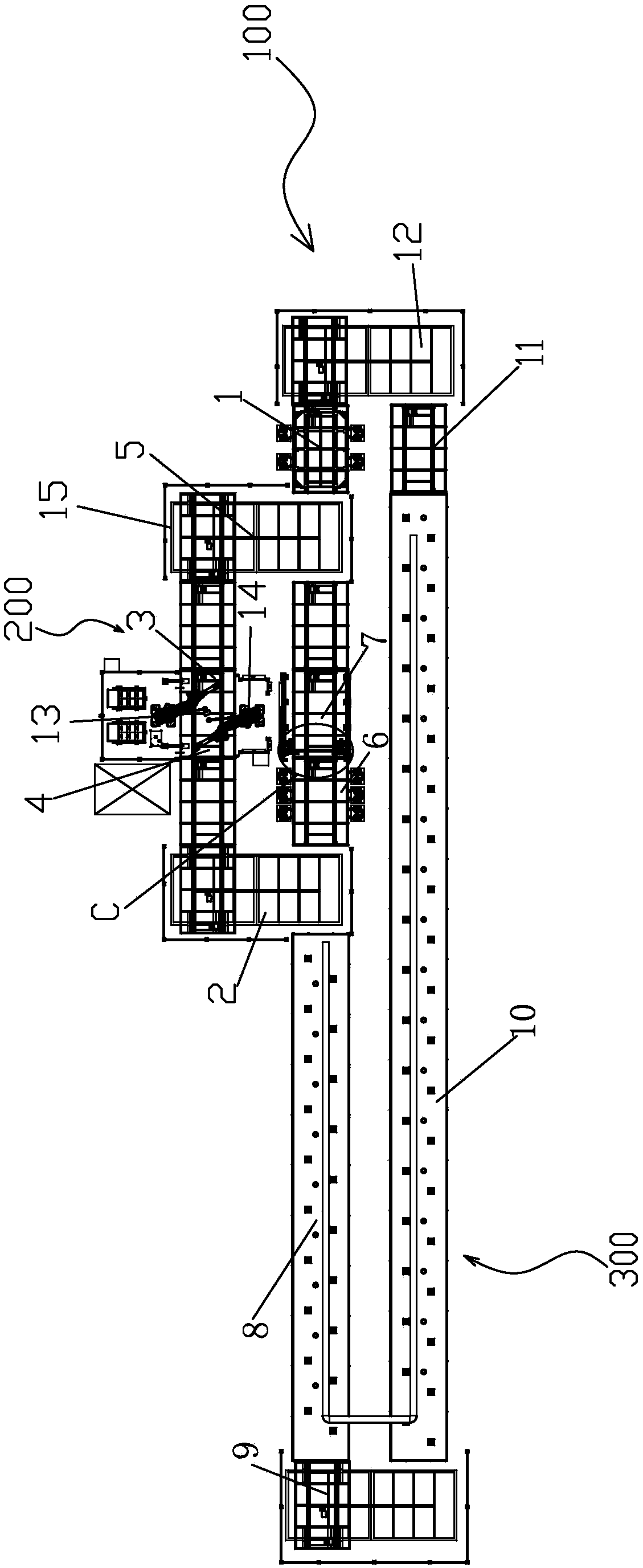

The invention discloses a waterproof GRC shower tray production line and a production method thereof. According to the key point of the technical scheme, the waterproof GRC shower tray production linecomprises an automatic conveying line; a feeding and discharging station is arranged on the automatic conveying line; an inner circulating station and a warm box curing station connected with the output end of the inner circulating station are arranged at the output end of the feeding and discharging station; the inner circulating station comprises a brick placement station, a slurry spray station, a side plugging station and a slurry rolling station which are connected in sequence; the slurry rolling station is connected with the slurry spray station; a brick placement robot is arranged on the brick placement station; a slurry spray robot is arranged on the slurry spray station; and the feeding and discharging station is arranged at the output end of the warm box curing station. According to the waterproof GRC shower tray production line, multiple times of slurry spraying and slurry rolling are achieved through the inner circulating station, then slurry is fast cured within short time through the warm box curing station, the production efficiency can be greatly improved, and the labor intensity of workers can be relieved.

Owner:ZHONGSHAN SALLY SHOWER EQUIP

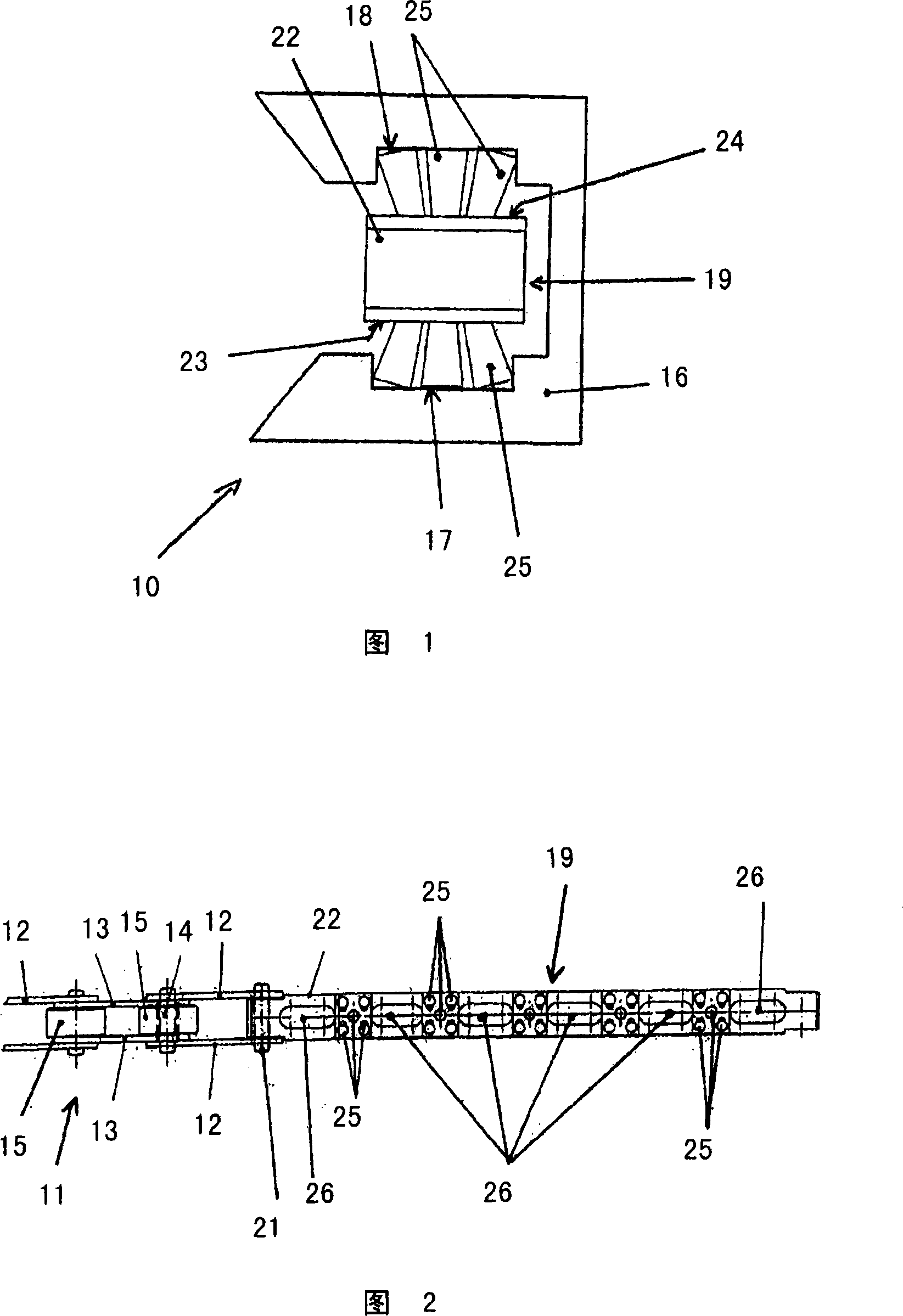

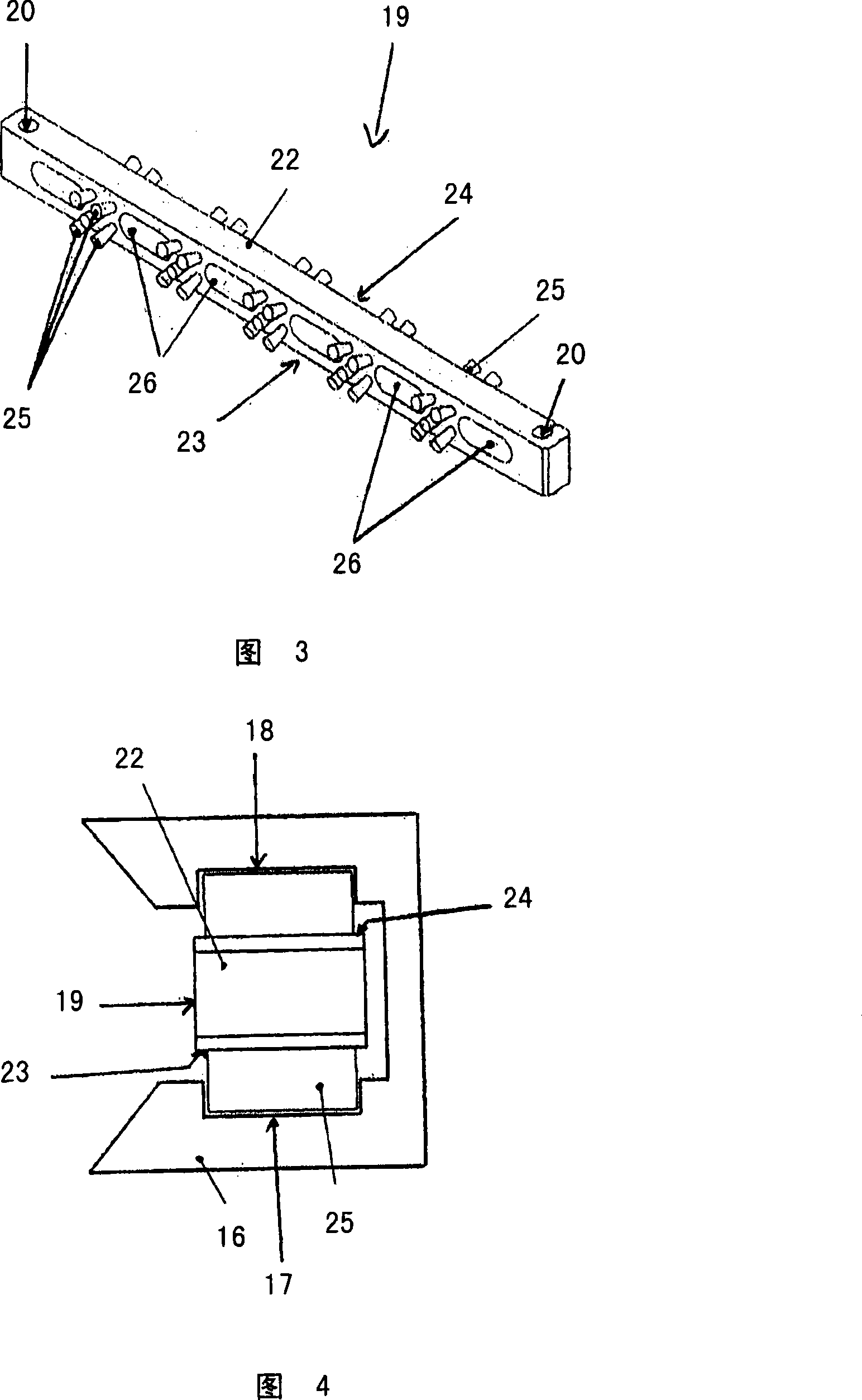

Apparatus and method for cleaning a webbing-up device in a printing press

InactiveCN101239524ARun without troubleReliable removalRotary pressesWebs handlingPrinting pressMechanical engineering

The invention relates to a pull-in device for pulling a printed material web into a printing press, that is to say into a rotary printing press, with a limited conveyor chain (11) consisting of several Connected chain rail segments are formed and guided in the chain guide rail. According to the invention, at least one end of the limited conveyor chain (11) is assigned a cleaning device (19), which is detachably connected to the conveyor chain (11).

Owner:MANROLANAD AG

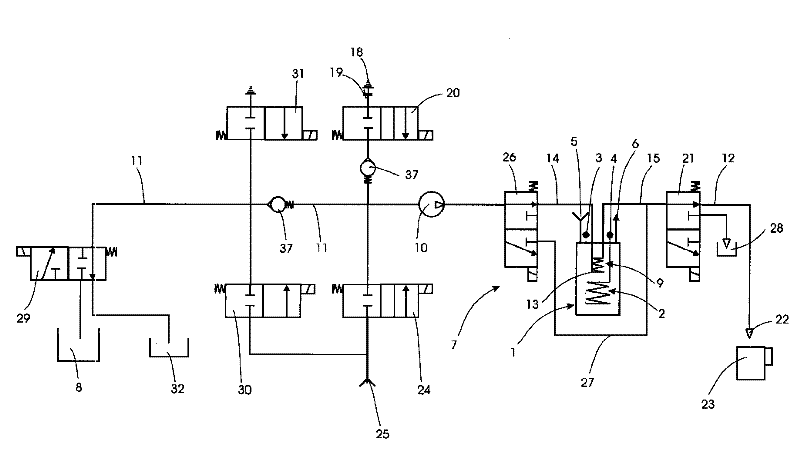

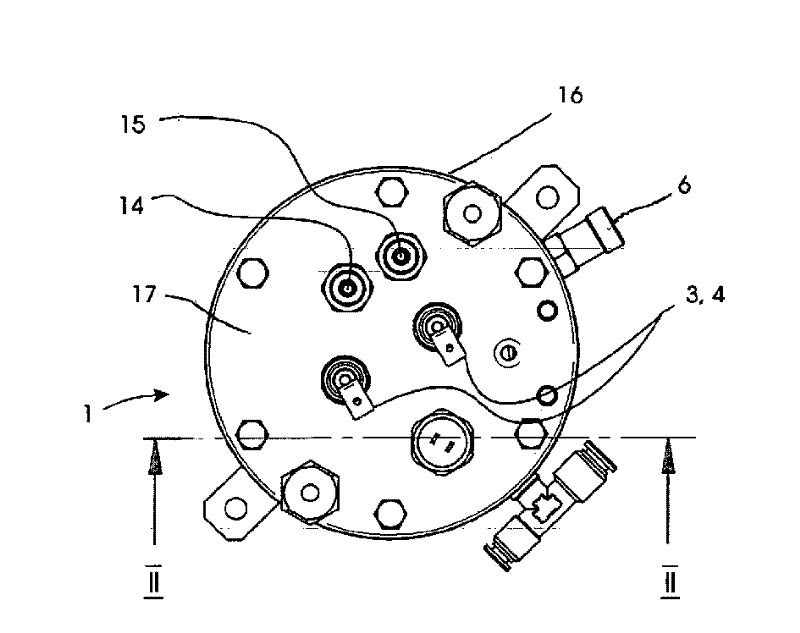

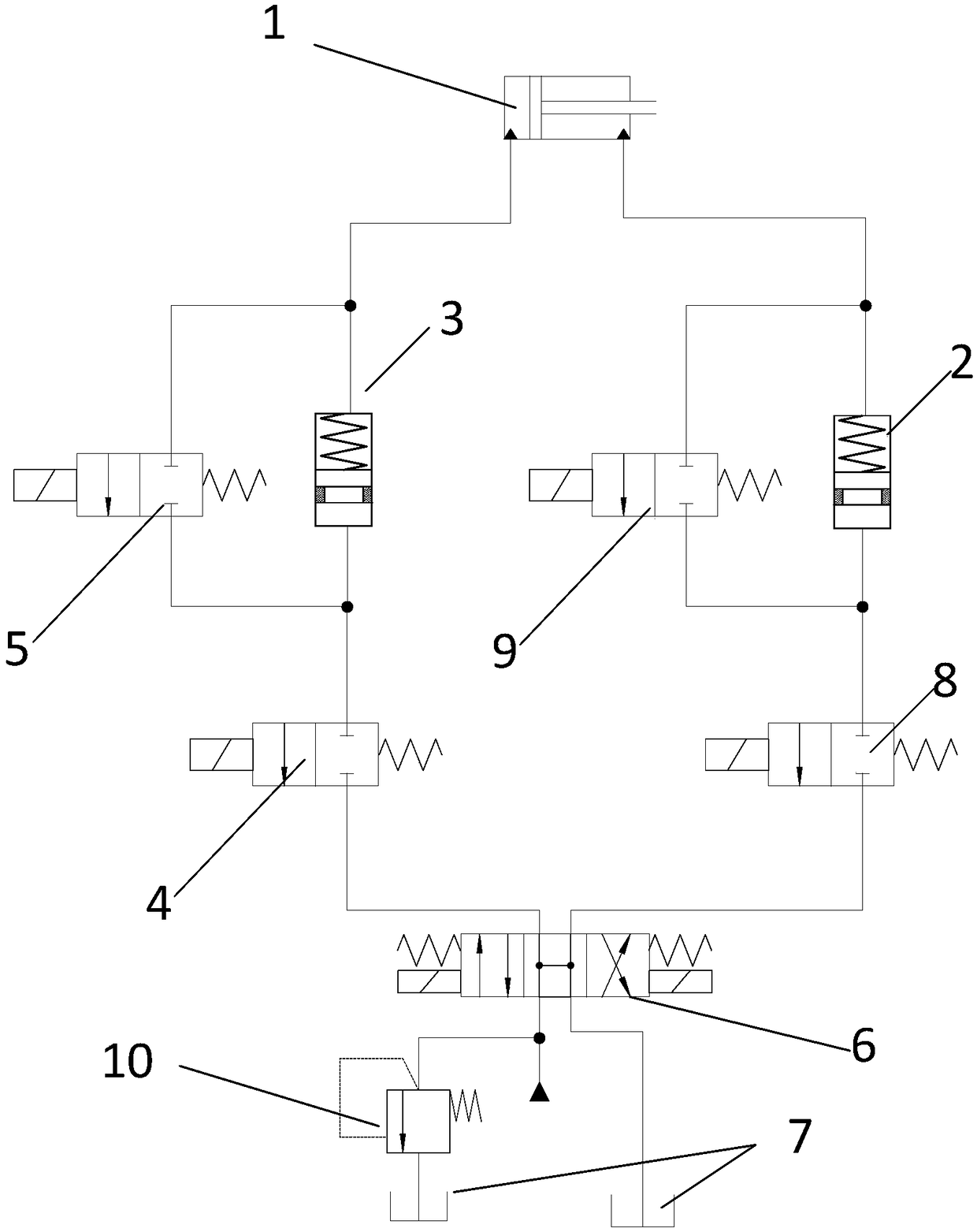

Position control system of hydraulic stepping driver and control method applying same

PendingCN109372829ALow costEasy maintenanceServomotor componentsFluid-pressure actuator componentsFuel tankEngineering

The invention discloses a position control system of a hydraulic stepping driver and a control method applying the same. The position control system comprises a main cylinder, a first driven cylinder,a second driven cylinder, a first switching valve, a second switching valve, a third switching valve, a fourth switching valve and a three-position four-way valve, wherein the interiors of the firstdriven cylinder and the second driven cylinder each are composed of a driven piston with a sealing piece and a reset spring, two through holes in one end of the three-position four-way valve are correspondingly connected with a hydraulic source and an oil tank, through holes in another two ends of the three-position four-way valve are correspondingly connected with the other end of the first switching valve and the other end of the third switching valve, the other end of the first switching valve is correspondingly connected with one end of the second switching valve and a spring-free cavity of the first driven cylinder, the other end of the second switching valve and a spring cavity of the first driven cylinder are connected in parallel and then are connected with a rodless cavity of themain cylinder, a rod cavity of the main cylinder is connected to one end of the fourth switching valve and a spring cavity of the second driven cylinder, and the other end of the fourth switching valve is connected with a spring-free cavity of the driven cylinder in parallel and then is connected with one end of the third switching valve. According to the position control system of the hydraulic stepping driver and the control method applying the same, accurate hydraulic cylinder stepping motion can be realized without a position sensor, and the system is low in cost and has strong oil-pollution resistance.

Owner:FUJIAN UNIV OF TECH

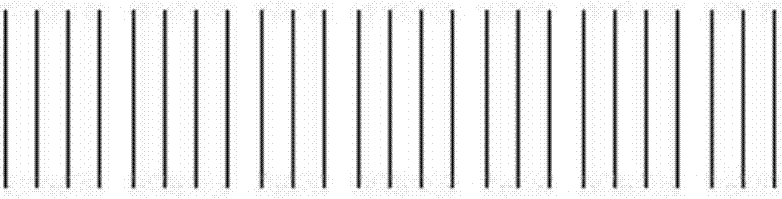

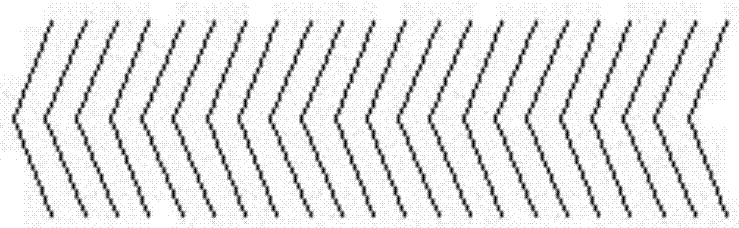

Efficient combining integration module

The invention provides an improvement on electric precipitator polar plate and polar line design and relates to an efficient combining integration module which is applied to a device for collecting electrical charge smoke particles in an electric precipitator. The efficient combining integration module is characterized by being different from various airstream shield type dust collecting polar plates formed by rolling metal plates in the past. The efficient combining integration module has high airflow permeability and can provide enough sedimentation area for electrical charge smoke particles, and especially has a high ability to adsorb the submicron-order electrical charge smoke particles. The electric precipitator adopting the efficient combining integration module has high strength and high stability, and can greatly increase the wind speed of an electric field, shorten the length of a sedimentation channel in the electric field and effectively reduce secondary flying dust, equipment transportation, installation and adjustment are easy and convenient, operation is efficient, the investment and operation cost of the electric precipitator is reduced substantially, and the emission concentration technical performance index is lower than that of a bag type dust collector.

Owner:中电国核(北京)节能环保科技有限公司

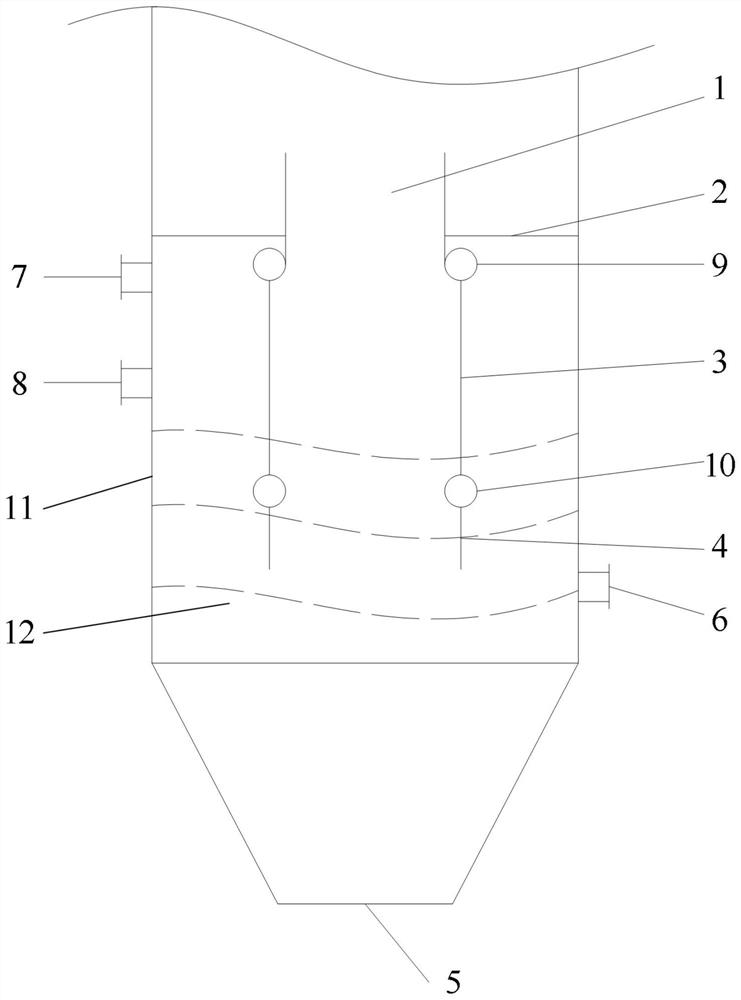

High-temperature coal gas chilling chamber

The invention discloses a high-temperature coal gas chilling chamber. A chilling chamber is formed in a chilling shell; a water-cooled wall descending cylinder is arranged in an inner cavity of the chilling shell; a high-temperature coal gas inlet for allowing high-temperature coal gas and gasified ash to enter is formed in the upper part of the water-cooled wall descending cylinder; the lower part of the water-cooled wall descending cylinder extends into a chilling water bath of the chilling chamber; a slag discharging port is formed in the bottom of the chilling chamber, a coal gas outlet isformed in the side wall of the upper portion of the chilling shell, an ash water outlet is formed in the side wall of the lower portion of the chilling shell, an annular gap between the water coolingwall descending cylinder and the chilling shell is a chilling chamber annular gap, and a water cooling wall of the water cooling wall descending cylinder is cooled through desalted water. The high-temperature coal gas chilling chamber has the effects that chilling water of a gasification furnace directly enters the chilling chamber through the pipeline, high-temperature coal gas and ash slag arecooled and washed in the chilling chamber, then coal gas containing part of fine ash enters a subsequent procedure to be treated, coarse slag enters a slag discharging system to be treated, and ash water containing fine ash enters the subsequent procedure to be treated.

Owner:BEIJING QING CHUANG JIN HUA TECH CO LTD

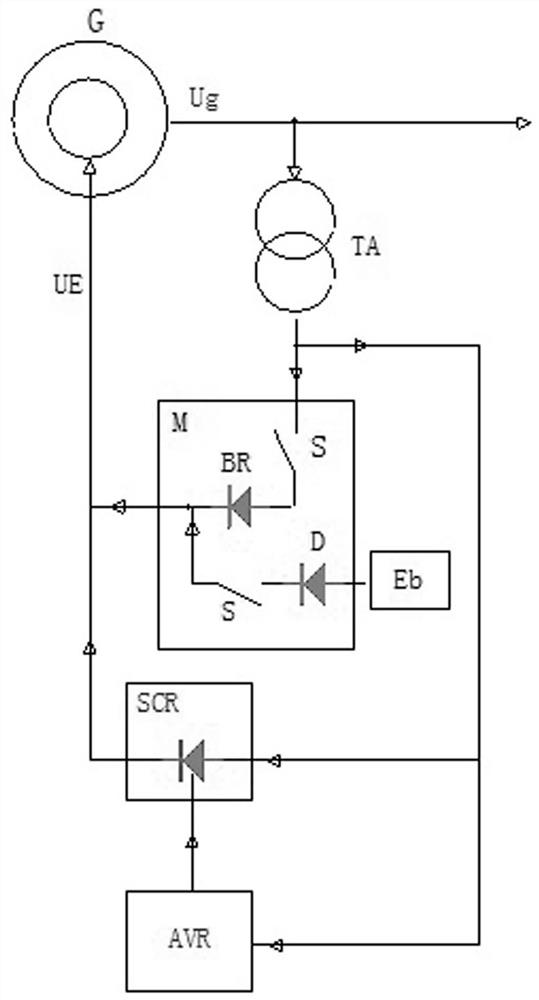

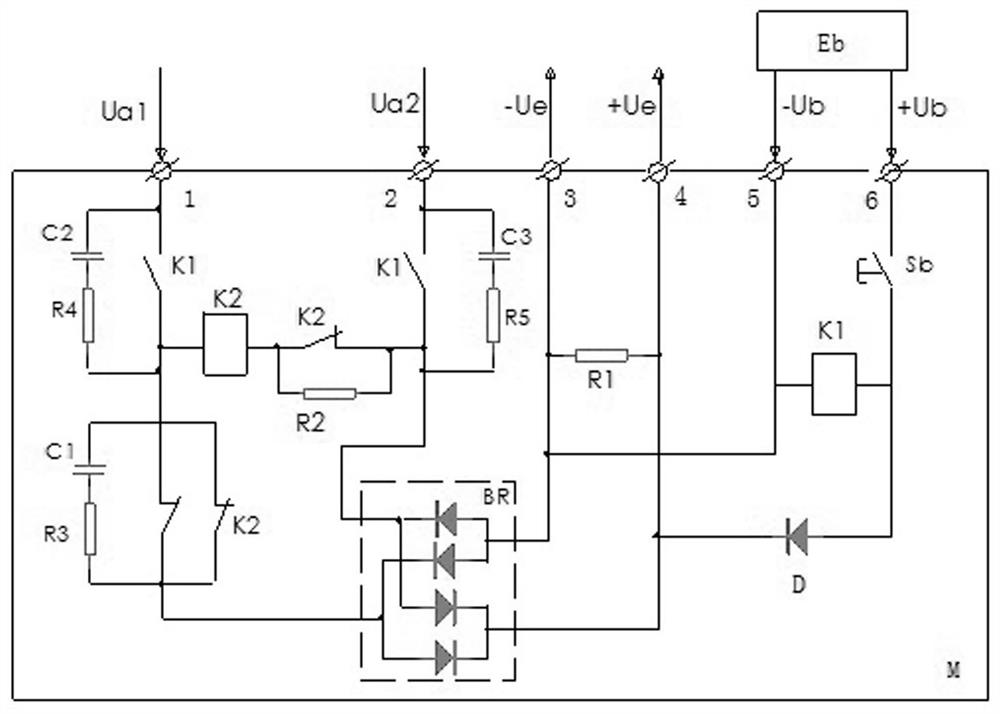

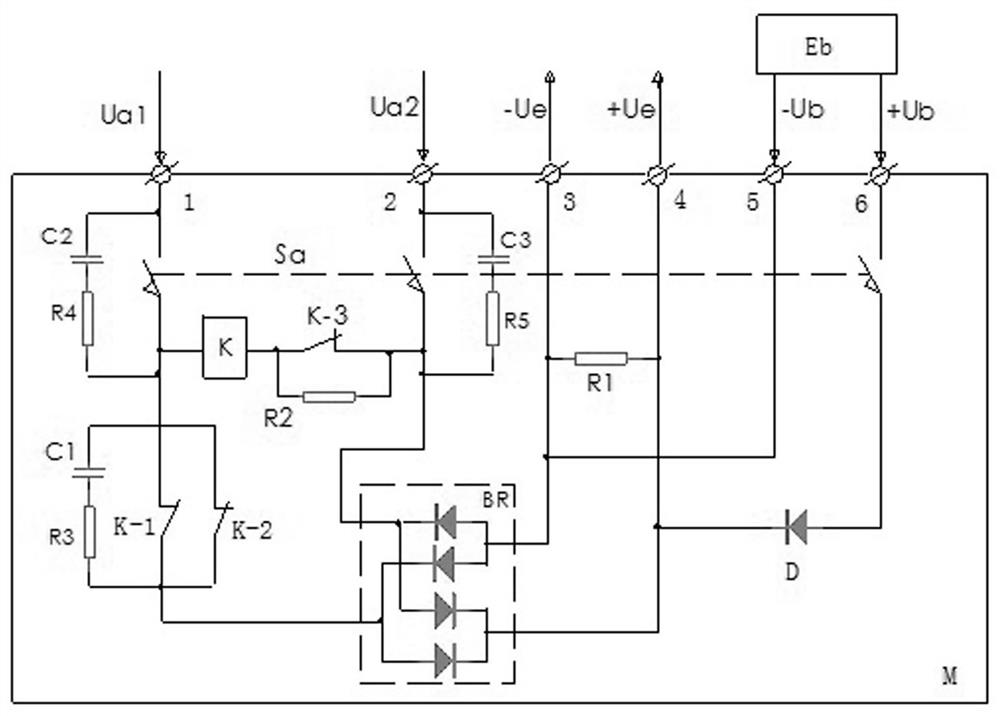

An excitation circuit and device for a synchronous generator

ActiveCN109150041BSolve the problem of only relying on bulky DC power cabinetsEasy to useGenerator control by field variationTerminal voltageExcitation current

Owner:邓光辉

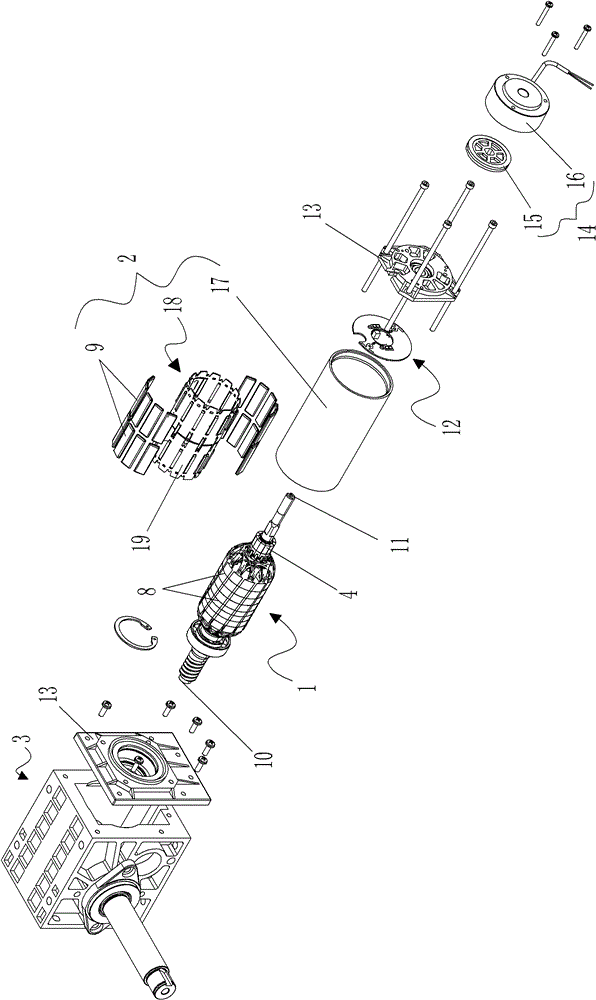

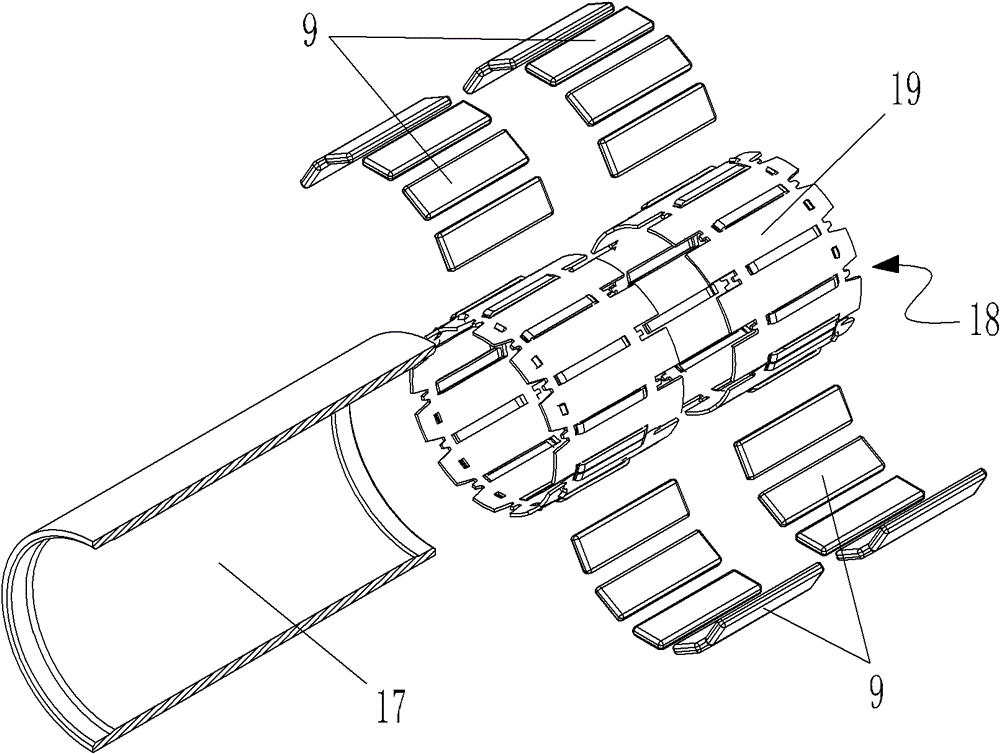

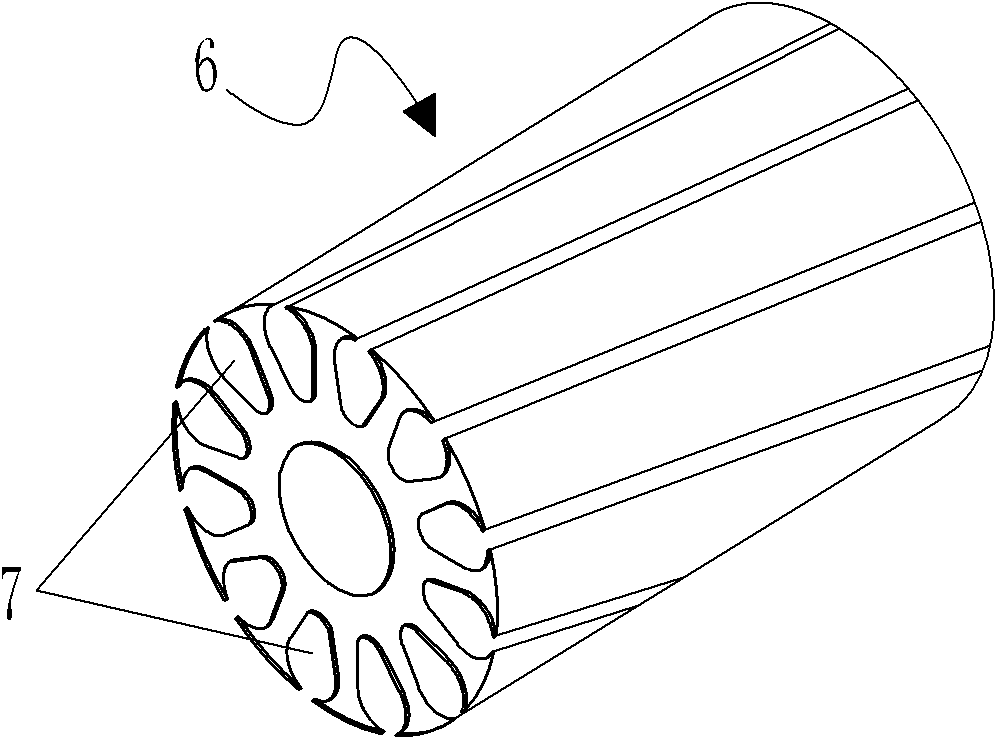

Permanent magnet direct current (DC) speed-reducing motor

ActiveCN102185450BSimple structureCompact structureMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineReduction drive

The invention discloses a permanent magnet direct current (DC) speed-reducing motor, which comprises a rotor, a stator arranged at the periphery of the rotor, a speed reducer connected to an output end of the rotor, and a commutator, wherein the rotor comprises a motor spindle and a rotor core which is arranged on the motor spindle; a plurality of grooves which are distributed along the length direction of the rotor core are formed on a peripheral wall of the rotor core; a winding is arranged at the periphery of the stator; a plurality of permanent magnets are arranged on the stator; the motor spindle is provided with a first end and a second end; the commutator is arranged at the second end; an electric brush mechanism is arranged on the commutator; and both ends of the stator are provided with an end cover which is fixed with the stator. Due to the integrated design of transmission, speed reduction, brake and manually fine tuning of the spindle of the permanent magnet DC speed-reducing motor, the motor can be better matched with equipment; due to the self-pressing design of the electric brush mechanism in the permanent magnet DC speed-reducing motor, commutation is guaranteed, and the motor operates without any fault for a long time; and the motor is compact in structure, small in volume, low in vibration and noise and suitable for popularization in industries.

Owner:久久艳阳福祉科技秦皇岛有限公司

A risk assessment method for hydrogen energy equipment in a hydrogen refueling station

ActiveCN112819097BEasy to useRun without troubleContainer filling methodsCharacter and pattern recognitionMonitoring siteEnergy facilities

The invention relates to a risk assessment method for hydrogen energy equipment in a hydrogen refueling station. The method includes: a control system obtains operating parameters of each hydrogen energy equipment in a hydrogen refueling station, and the operating parameters include: operating parameters of a compressor, a hydrogen storage tank , the operating parameters of the hydrogen refueling machine and the filling gun, as well as the operating parameters of the connecting pipeline between any two adjacent hydrogen energy equipment; the control system is based on the operating parameters of all hydrogen energy equipment and the effectively used hydrogen energy data, According to the hydrogen energy calculation strategy, it is determined whether there is hydrogen leakage in the entire hydrogen refueling station; if there is hydrogen leakage in the control system, the location information of the hydrogen leakage is determined according to the data information of adjacent monitoring points. The method of the invention fully considers availability and reliability, and ensures the safety and reliability of hydrogen energy facilities.

Owner:ZHEJIANG UNIV CITY COLLEGE

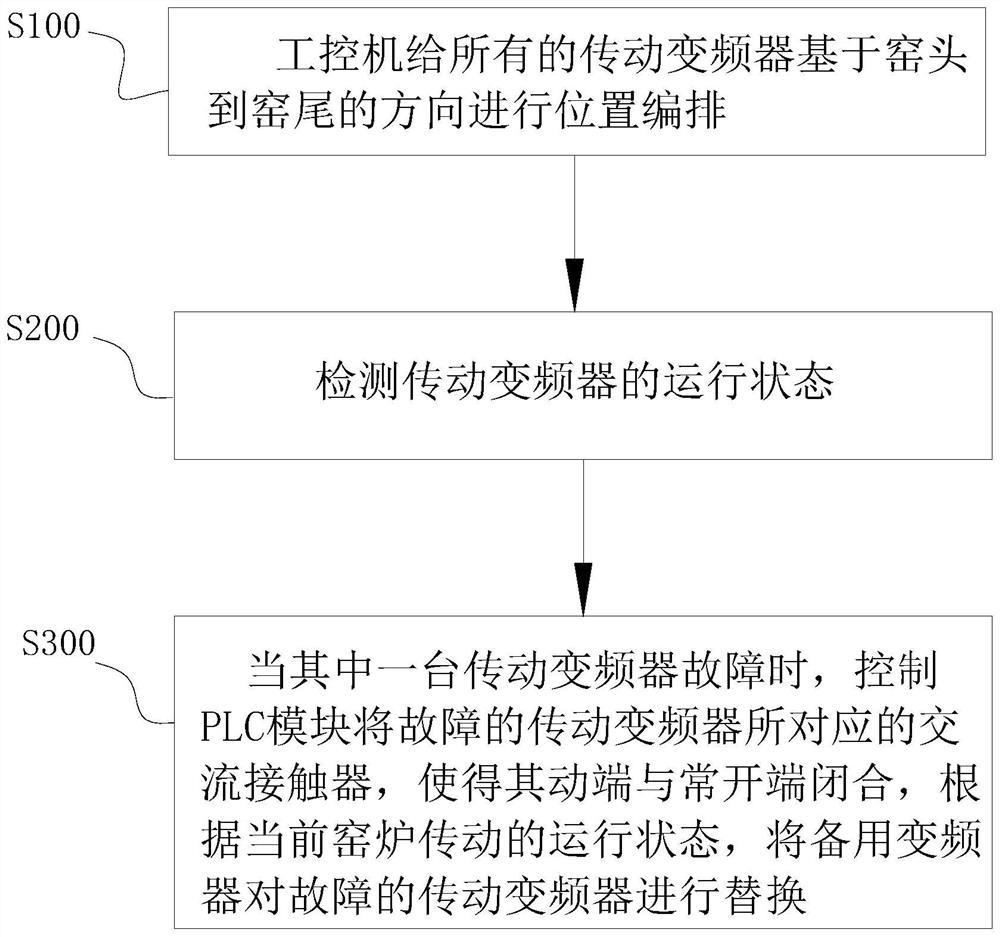

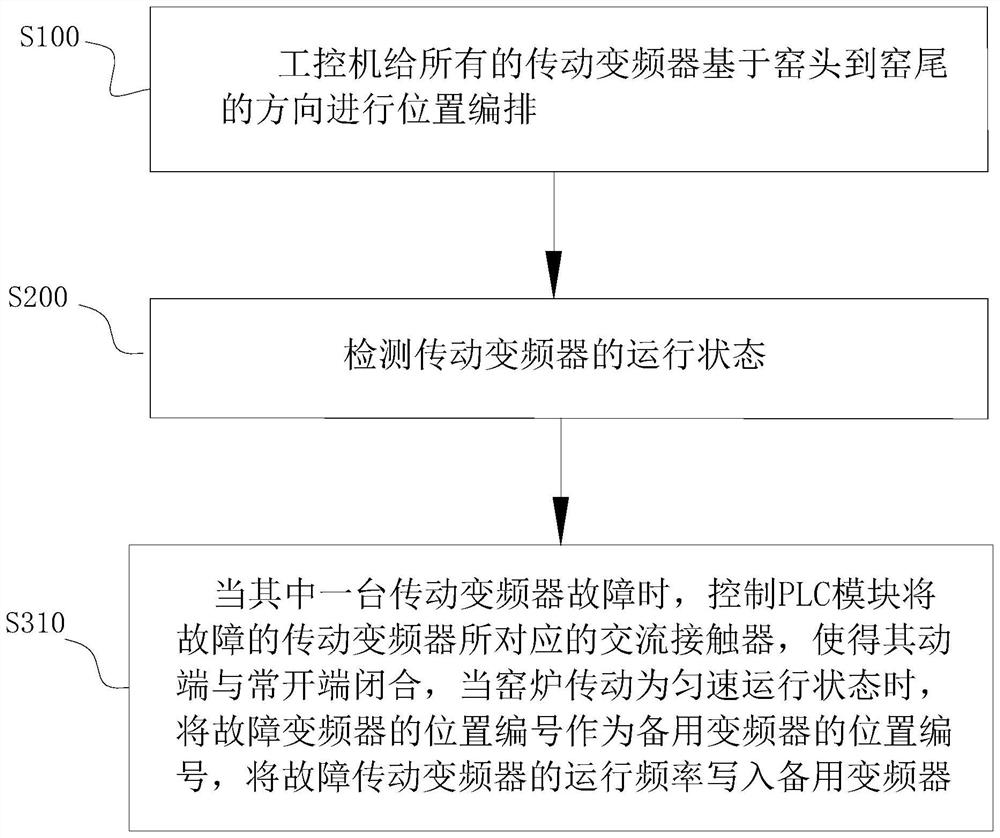

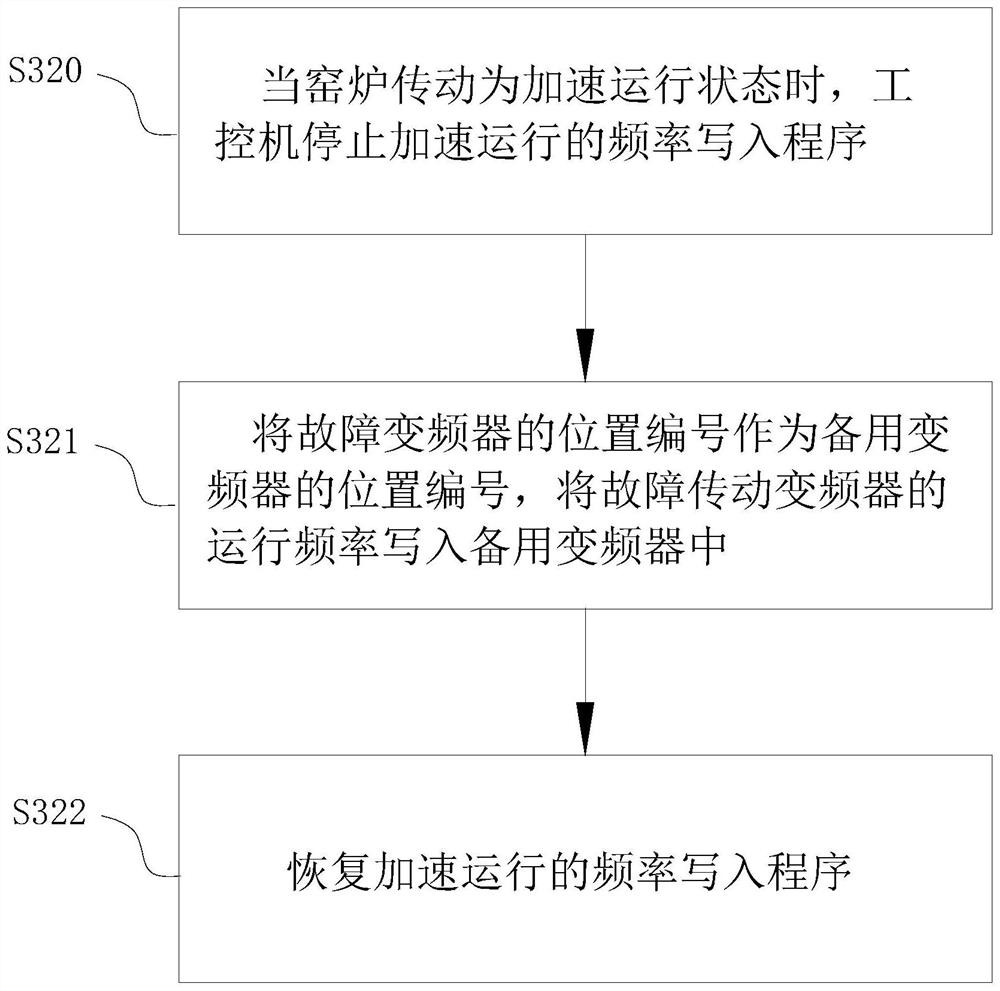

Automatic and efficient switching method of kiln transmission standby frequency converter

PendingCN114374353ASwitching is fully automatic and efficientRealize functionAC motor controlPower network operation systems integrationFrequency changerConverters

The invention discloses an automatic and efficient switching method of a kiln transmission standby frequency converter, which is applied to a standby frequency converter switching system and comprises the following steps that: an industrial personal computer carries out position arrangement on all transmission frequency converters based on the direction from a kiln head to a kiln tail, so that each transmission frequency converter has a respective position number; detecting the operation state of the transmission frequency converter; when one transmission frequency converter breaks down, the PLC module is controlled to close the moving end and the normally-open end of the alternating current contactor corresponding to the transmission frequency converter which breaks down, and the standby frequency converter is used for replacing the transmission frequency converter which breaks down according to the running state of current kiln transmission. According to the method, the faulted transmission frequency converter can be automatically and efficiently switched, so that the standby frequency converter replaces the faulted transmission frequency converter to work, and the switching method can still switch the faulted frequency converter in the operation state of acceleration, deceleration and segmented swinging of kiln transmission.

Owner:DLT TECH CO LTD

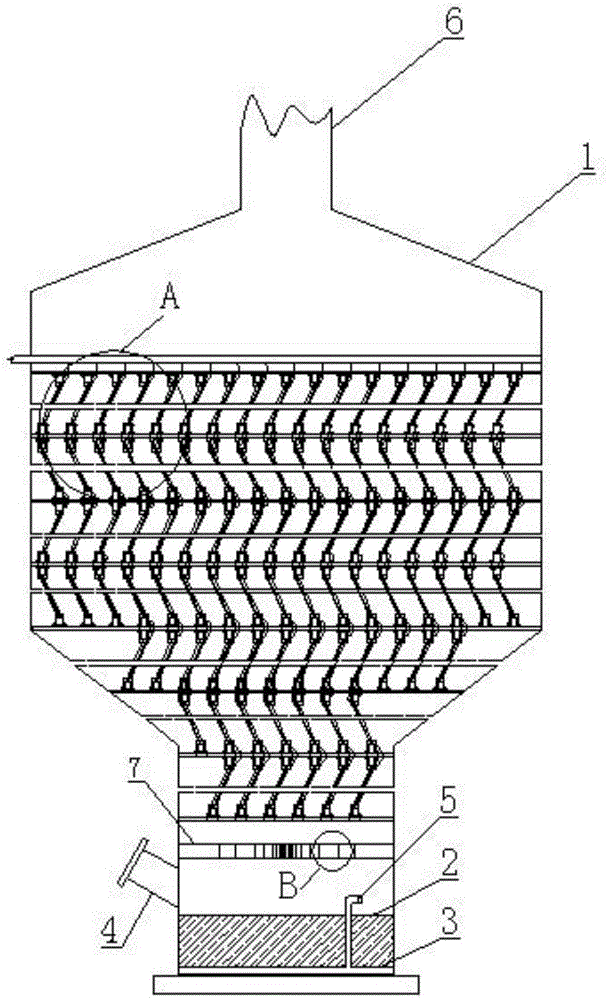

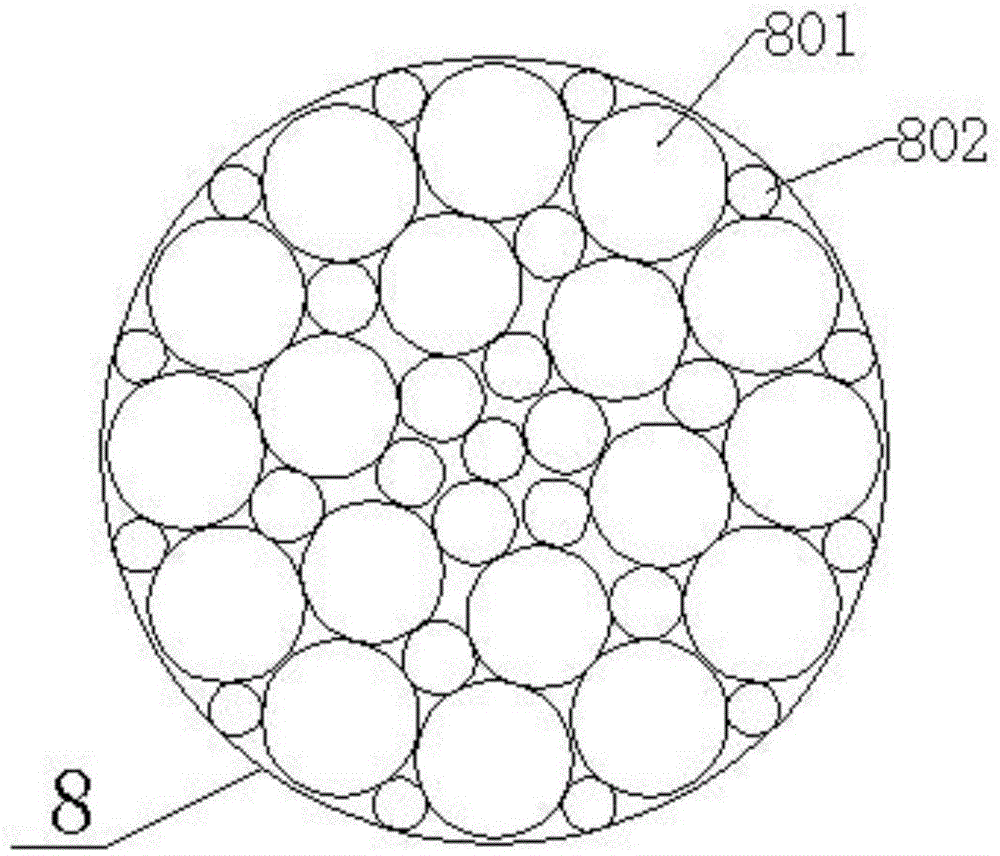

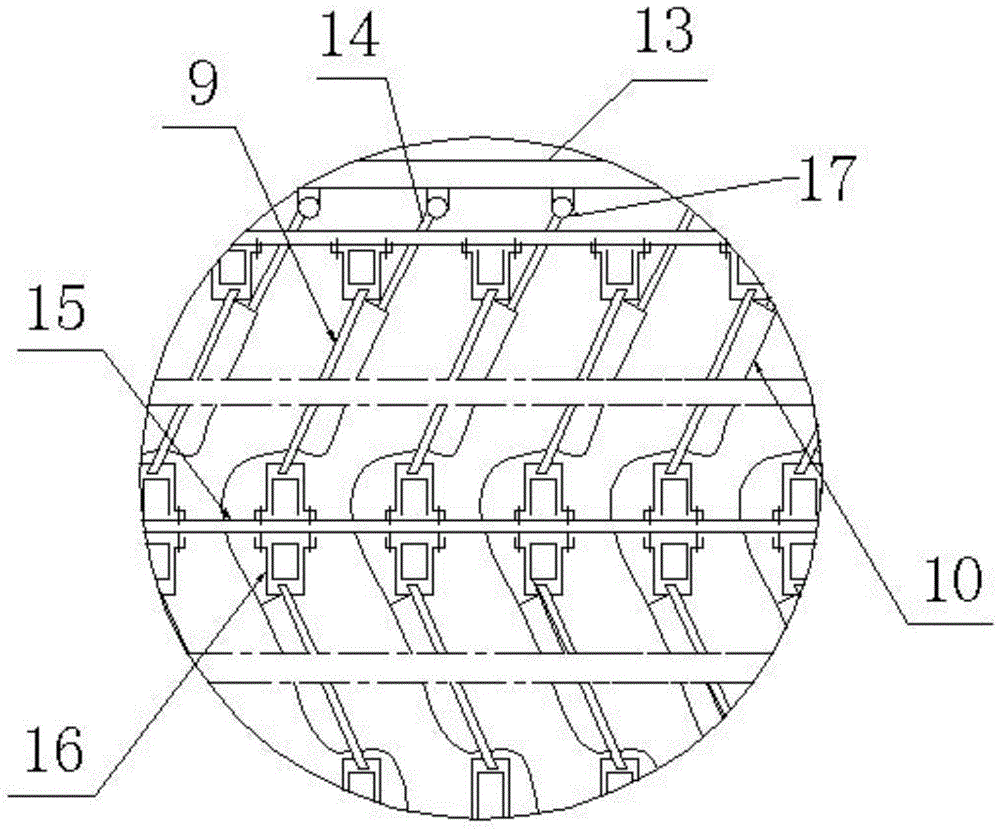

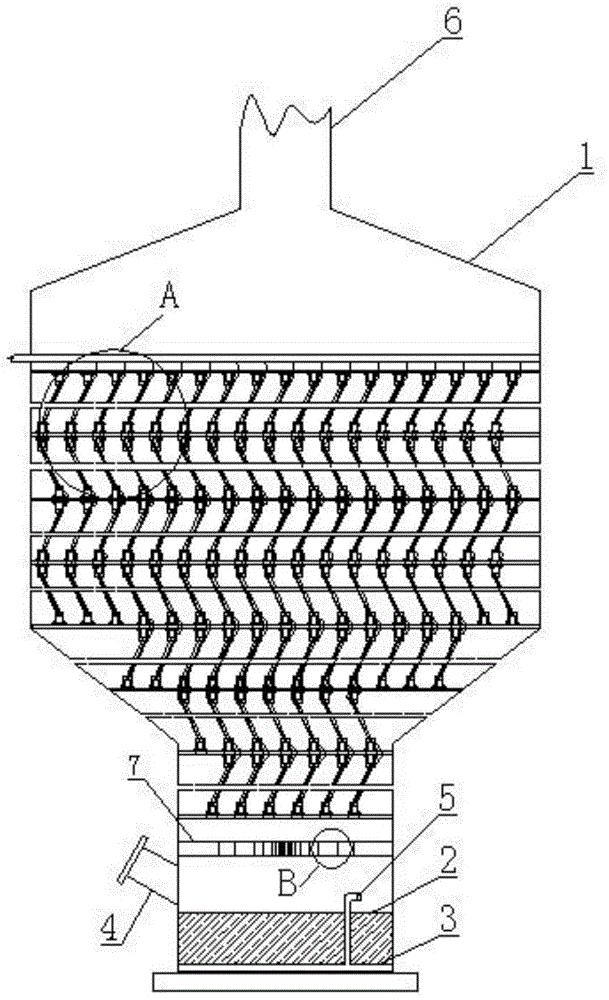

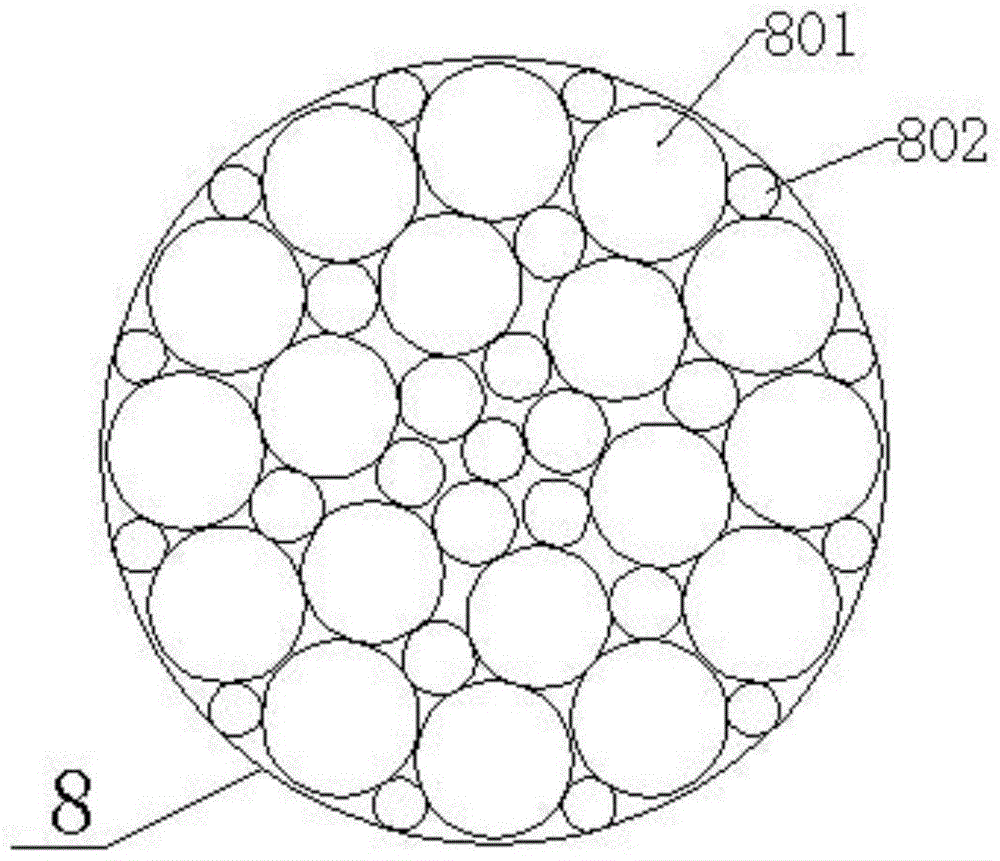

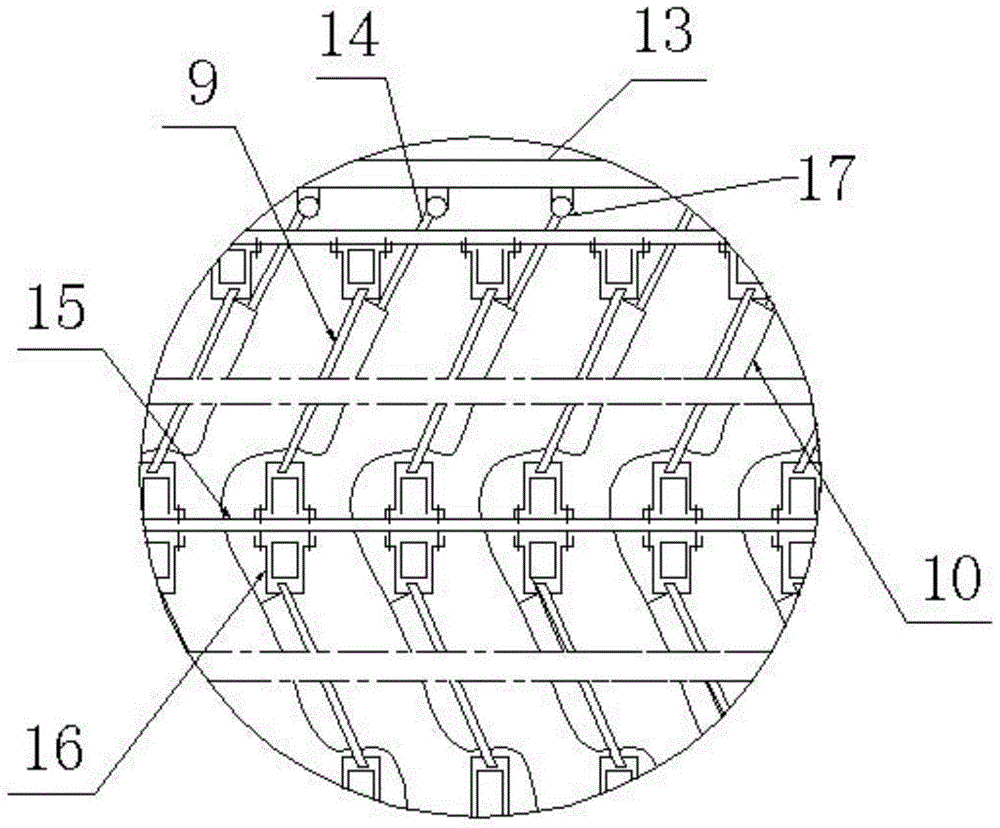

High-performance integrated absorption tower for dust removal and desulfuration via physical method

InactiveCN104857837ATo achieve the purpose of equalizationSolve the problem of outflowUsing liquid separation agentContact timeSlurry

The invention relates to a high-performance integrated absorption tower for dust removal and desulfuration via a physical method, of which the contact time of alkaline serous fluid and smoke is long, the contact area is large, the reaction is sufficient, the desulfuration effect is good, the sulphur content in the discharged smoke is extremely low, and the smoke containing quantity is low, the high-performance integrated absorption tower for the dust removal and desulfuration via the physical method comprises a tower body, and is characterized in that: a smoke current equalizer is arranged above a smoke inlet in the tower body, the upper part of the tower body is provided with plate shelves which are arranged in a layered manner up and down, each layer of plate shelf is composed of multiple rows of inclined plate shelf groups in parallel, each group of plate shelf is composed of multiple plate shelves which are arranged in parallel and passes through the tower body, the back surfaces of the plate shelves arranged up and down are provided with antiseptic water sac cloth bags with openings at the upper ends, multiple strip-shaped water sacs arranged in parallel are arranged in the water sac cloth bags, each water sac is corresponding to a water nozzle, a water pipe is arranged above the plate shelf on the tower body, multiple water nozzles are installed on the water pipe, and the water outlets of the water nozzles are positioned in the upper end openings of the water sacs of the corresponding water sac cloth bags.

Owner:张凯 +1

High-performance physical dust removal and desulfurization integrated absorption tower

InactiveCN104857837BTo achieve the purpose of equalizationSolve the problem of outflowUsing liquid separation agentLow physical performanceFlue gas

An alkaline slurry and flue gas contact time is long, the contact area is large, the reaction is sufficient, the desulfurization effect is good, the sulfur content in the discharged flue gas is extremely low, and the dust content is low. The high-performance physical dust removal and desulfurization integrated absorption tower, Including the tower body, the special feature is that a flue gas flow equalizer is installed above the flue gas inlet in the tower body, and a plate frame arranged up and down in layers is arranged on the upper part of the tower body. and each group of panels is composed of multiple panels arranged side by side and penetrating through the tower body. On the back of the panels arranged up and down, there is an anti-corrosion water bag with an open upper end. There are multiple strip-shaped water bags arranged side by side, and each water bag corresponds to a water nozzle. On the tower body, a water pipe is arranged above the plate frame, and a plurality of water nozzles are installed on the water pipe. The water outlet of the water nozzle It is located in the upper port of the water bladder of the corresponding water bladder cloth bag.

Owner:张凯 +1

Test centre for performance of vehicle wind screen wiper assembly

InactiveCN100545621CGuaranteed detection accuracyGuaranteed continuityStructural/machines measurementPressure transmissionElectrical control

The invention relates to an automobile windshield wiper assembly performance testing center. It includes a pressure transmission device and a pressure adjustment device that detects and adjusts the pressing force of the wiper on the windshield, a wiper braking device that can repeatedly act on the wiper to make it stop working instantaneously, and build a test chamber The rain shower system in the rain shower environment and the electrical control device using industrial control computer for control and data processing. Except that the industrial control computer and electrical control device are installed in the electrical console, all other devices are sealed in the test compartment with front and rear doors that can be opened. When the automobile windshield wiper assembly performance test center is working, it only needs to install the wiper assembly on the installation template and set the test parameters, and then it can carry out the automatic detection program test of the whole process, through the display screen Monitor the test status and various dynamic data, and automatically print out the test report after the test is completed.

Owner:CHANGZHOU TEXTILE GARMENT INST

Threaded joint for forming telescopic flexible pipe fitting

ActiveCN102996946BRich materialSave materialPipeline expansion-compensationAdjustable jointsGlass fiberPipe fitting

The invention relates to a threaded joint for forming a telescopic flexible pipe fitting. The pipe fitting consists of a pipe fitting sleeve and an external-thread screw ring outside the pipe fitting sleeve. A locknut, a rubber sealing ring, a gasket, a snap ring and a snap ring groove are arranged outside a connected pipe which is inserted into the pipe fitting sleeve, wherein the locknut is provided with internal threads which are engaged with external threads, the rubber sealing ring and the gasket are arranged in an external expansion port of the pipe fitting sleeve, and the rear end of the connected pipe is provided with the snap ring and the snap ring groove. The rear end of the locknut is provided with a circular-ring-shaped sliding chute and an anti-pull-out internal lug boss. A reasonable matching gap between the snap ring and the circular-ring-shaped sliding chute is selected, so that the situation that the snap ring moves and is difficultly subjected to radial slippage when the connected pipe is subjected to expansion caused by heat and contraction caused by cold is guaranteed, and the trouble-free operation is realized. A rubber compression amount and a matching gap which are appropriate are selected so as to enable the telescopic flexivity to be greater than or equal to + / -2.2. Without increasing the cost, the inserted length can be increased, and the reliability can be improved. The pipe fitting sleeve is made of a thin-walled pipe, so that the one-piece casting is not required, the materials are saved, and the cost is low. The threaded joint is arranged outside the external expansion port and isolated from a medium, thereby being applicable to any pipeline for conveying any medium, e.g. stainless steel, carbon steel, ductile cast iron, plastics, glass fiber reinforced plastics, and the like. Furthermore, the threaded joint is universal to pipeline interfaces with the same pipe diameter.

Owner:四川民生管业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com