Device for treating pieces of a substrate at high pressure with a supercritical or near-critical treatment medium, piece by piece or in batches

A supercritical and near-critical technology, which is applied in the processing of textile materials, washing equipment, solvent processing, etc., can solve problems such as the limitation of the working range, the influence of faults and problems, and the effect of washing processing, and achieves low cost and simple design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

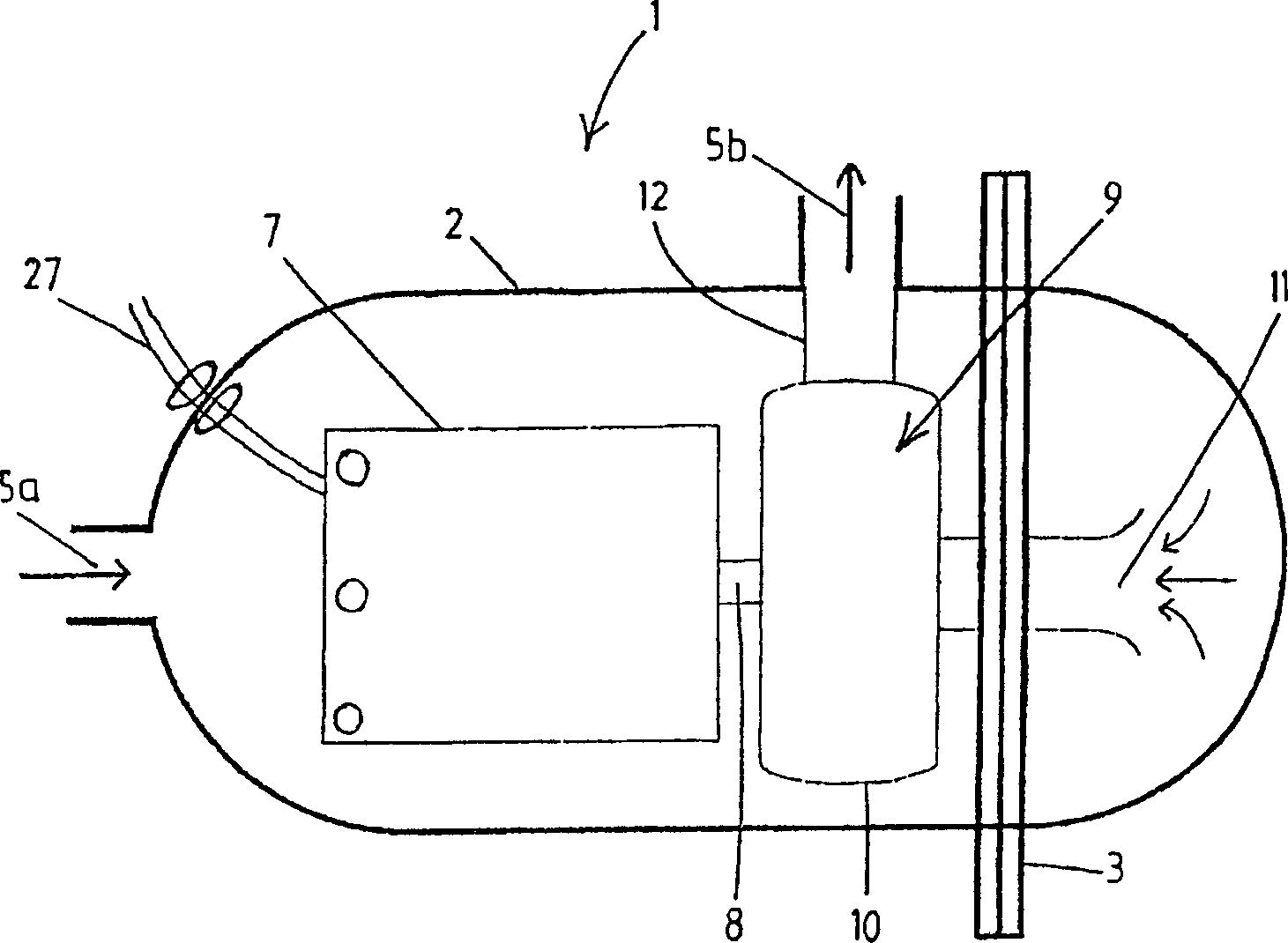

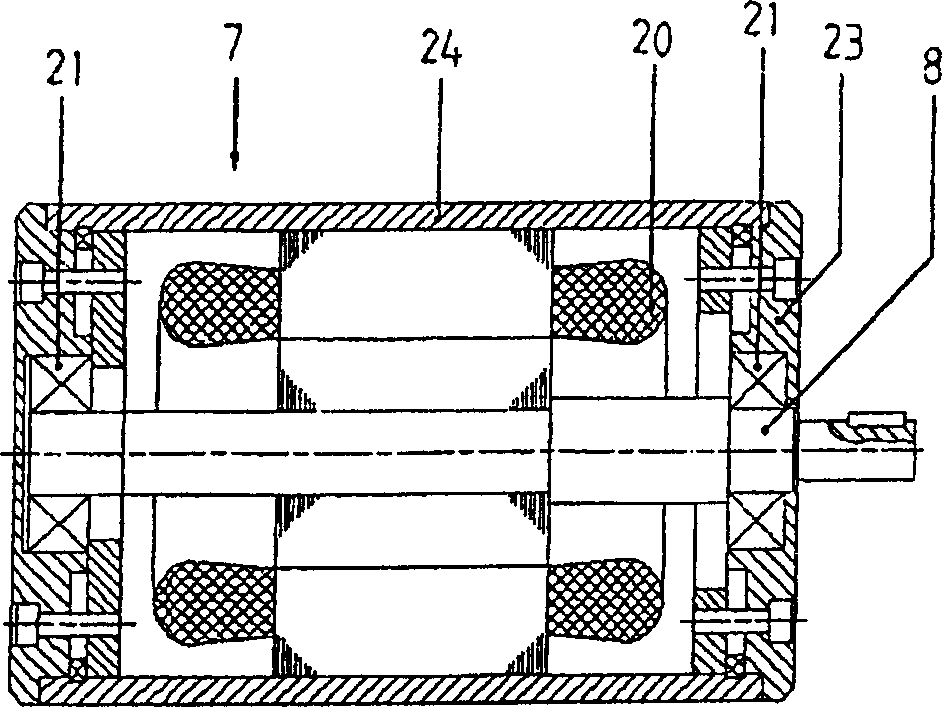

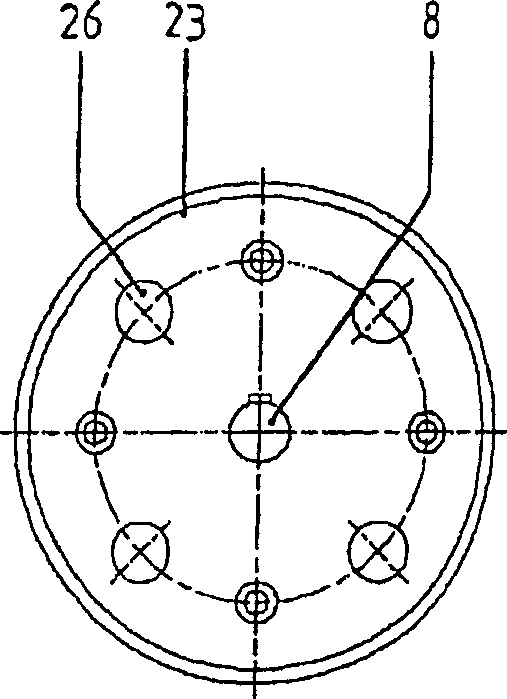

[0023] exist figure 1 In , the pressure chamber device as a whole is denoted by reference numeral 1 . The device 1 comprises a pressure chamber 2 , which in this case is formed by a pressure vessel, and has an opening, which can be closed by a cover 3 , for mounting an electric motor 7 with a pump 9 in the pressure vessel. There is also a pipe system 5 with an inlet 5a and an outlet 5b. The electric motor 7 is placed in the pressure chamber 2 . The pump 9 is mounted on the output shaft 8 of the motor 7 . The pump 9 , for example formed by a centrifugal pump with impellers, is in this case mounted directly on the motor shaft 8 . The pump 9 is housed in a pump housing 10 including an inlet 11 and an outlet 12 . The outlet 12 is connected to the outflow port 5b.

[0024] The shown pressure chamber arrangement can be used in a high-voltage circuit as a second pressure chamber in combination with a first pressure chamber for processing substrates.

[0025] Motor 7, which is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com