Brake disk that can be fixed to a wheel hub

A technology of brake discs and hubs, applied in the direction of brake discs, brake types, brake components, etc., can solve problems such as pollution, performance and reliability limitations of the durability of sliding guide devices, and achieve low-cost manufacturing, improved operating safety, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

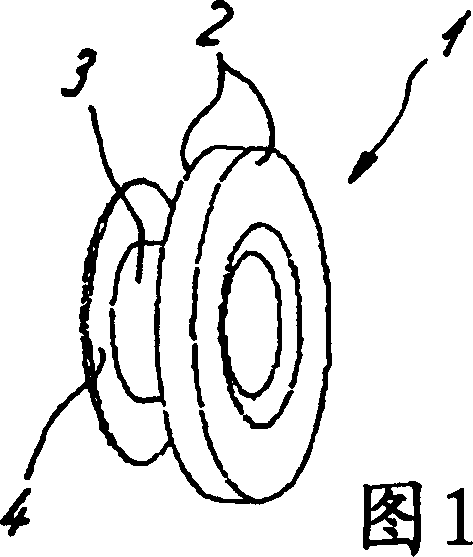

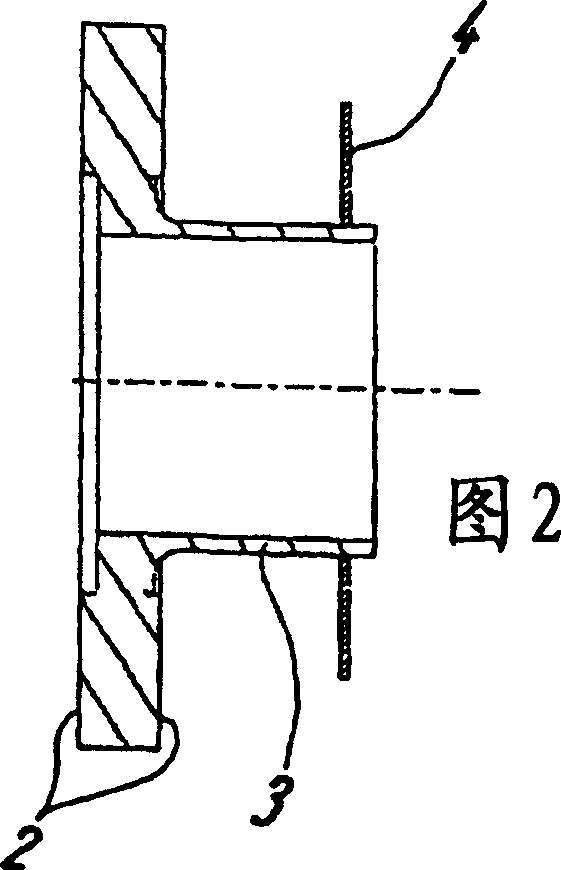

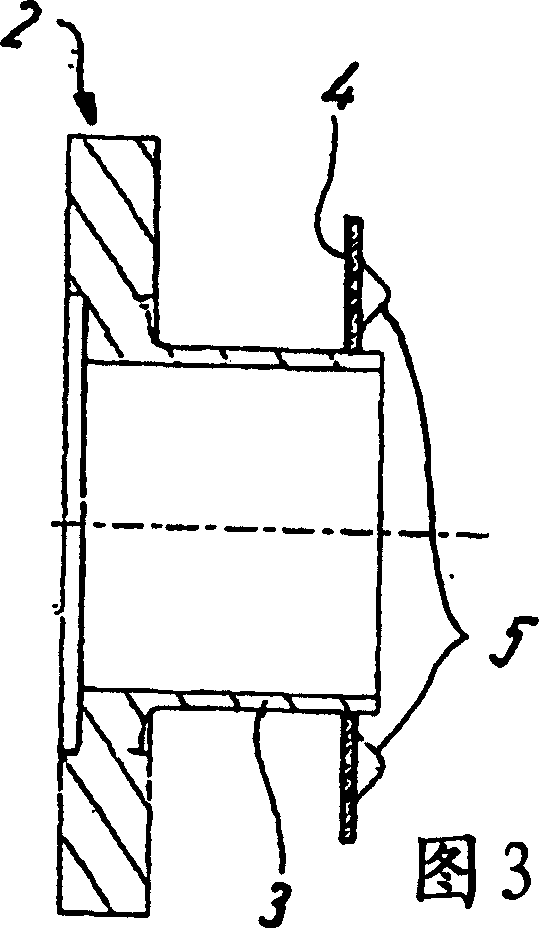

[0030] 1-12 show a brake disc 1 for a disc brake, which can be fastened on the hub of a commercial vehicle, in particular, with two concentric friction rings 2, which are formed for The friction surface of a not shown, compressible brake pad of the disc brake and is provided with a friction lining.

[0031] Furthermore, the brake disc 1 has a coaxial brake disc neck 3 into which a wheel axle of the motor vehicle can be inserted.

[0032] A connecting piece in the form of an annular spring element 4 is firmly connected in the region of the free end facing away from the friction ring 2 and is fastened to a hub or axle.

[0033] The elastic element 4 is axially elastically deformable relative to the friction ring 2 and has dimensions determined by the working stroke.

[0034] In addition, a spring element 4 arranged parallel to the friction ring 2 is preferably positively connected to the brake disk neck 3 . However, a force-fit or material-fit connection is also conceivable. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com