Threaded joint for forming telescopic flexible pipe fitting

A technology of threaded joints and pipe fittings, which is applied in the direction of pipe components, adjustable connections, pipes/pipe joints/pipe fittings, etc., can solve the problems of complex process, high material consumption and high cost of scalable flexible pipe fittings, and achieve saving stainless steel materials, The effect of strong competitiveness and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

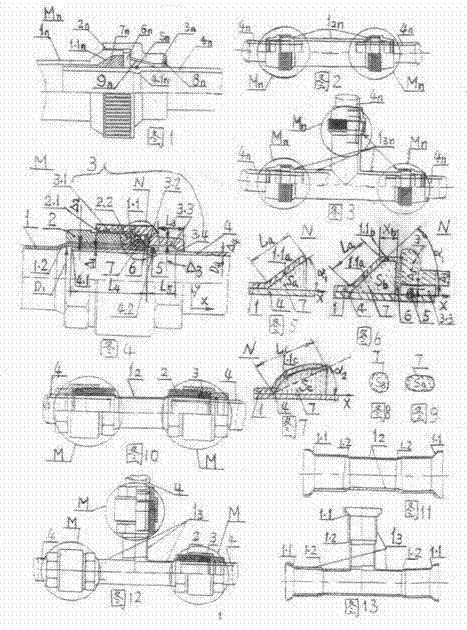

[0026] Threaded joints that make up telescopically flexible pipe fittings. For direct fittings. See Figure 4 -See Figure 9 , Figure 10 , Figure 11 .

[0027] 1) see Figure 4 , the pipe fitting is provided with a pipe fitting sleeve 1, and the outer circumference of the pipe fitting sleeve is covered with an externally threaded wire ring 2; the rear end of the wire ring 2 is provided with an inner bell mouth 2.2, which is used to expand the outer opening 1.1 of the pipe fitting sleeve. match. The outer thread 2.1 of the silk ring engages with the inner thread 3.1 of the lock nut to lock the threaded joint. 2) The X-Y shape of the above-mentioned flared longitudinal section can be one of the following three types: ① see Figure 5 , and the axis X has a hypotenuse 1.1a with an angle α1 of 50°, which is called single external expansion. The filling area of the sealing rubber ring is the area Sa of a right triangle. See Figure 8 , The circular cross-sectional are...

Embodiment 2

[0035] Threaded joints that make up telescopically flexible pipe fittings. For tee fittings. See Figure 4 -See Figure 9 , Figure 12 , Figure 13 . Present embodiment 2, except that following structure is different from embodiment 1, it is exactly the same: see Figure 12 , in this embodiment 2, the telescopic flexible threaded joint is used for the three-way pipe fittings, which are three joints, which are respectively connected according to the above-mentioned joints at the joints. Figure 4 The connected pipe 4 at the three ends is adorned with three sets of threaded joints. Figure 4 The pipe fitting sleeve 1 in the three-way pipe fitting is called the three-way pipe fitting sleeve 13 (three ports), see Figure 13 Draw the three-way pipe fitting sleeve pipe 13 one-piece figures among. When the working pressure of the pipeline is not greater than 2.5MPa, the pipe sleeve 13 is a thin-walled pipe with a wall thickness of ≤2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com