Method for preparing Sialon hollow ball

A technology of hollow balls and sialon, applied in the field of materials, can solve the problems of not being effectively used, and achieve the effect of abundant raw materials, low cost of raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, Henan Fengyuan Industrial Co., Ltd. > 77 μm fly ash microbeads are used, and its main chemical composition is as follows:

[0023] Al 2 o 3

SiO 2

Fe 2 o 3

CaO

MgO

Duck River Microbeads

28.76%

60.80%

2.30%

2.20%

0.91%

[0024] (1) Select Fengyuan Industrial fly ash hollow microspheres (particle size > 77 μm) as raw material, mix the fly ash hollow microspheres with carbon powder (activated carbon or carbon black) in a weight ratio of 74:26, sieve;

[0025] (2) When the flow rate is 0.05-0.2L / min high-purity nitrogen (N 2 >99.999%) atmosphere, heat up to 1500°C, keep warm for 6 hours, and cool with the furnace to obtain powder;

[0026] (3) Heat the prepared powder in an oxidation furnace at 800° C. for 4-5 hours to remove residual carbon to obtain β-sialon hollow spheres.

Embodiment 2

[0028] Henan Yuzhou Power Plant > 43μm fly ash microbeads are used, and its main chemical composition is as follows:

[0029] al 2 o 3

SiO 2

Fe 2 o 3

CaO

MgO

Yuzhou Microbeads

26.61%

58.47%

4.45%

4.40%

1.28%

[0030] (1) Select Henan Yuzhou Power Plant > 43 μm as raw material, mix fly ash hollow microspheres and carbon powder (activated carbon or carbon black) in a ratio of 74:26 (100 parts in total), and sieve;

[0031] (2) When the flow rate is 0.05-0.2L / min high-purity nitrogen (N 2 >99.999%) atmosphere, heat up to 1450°C, keep warm for 6 hours, and cool with the furnace to obtain powder;

[0032] (3) Heat the prepared powder in an oxidation furnace at 800° C. for 4 to 5 hours to remove residual carbon, and then obtain hollow spheres whose main components are 0′-sialon and β-sialon.

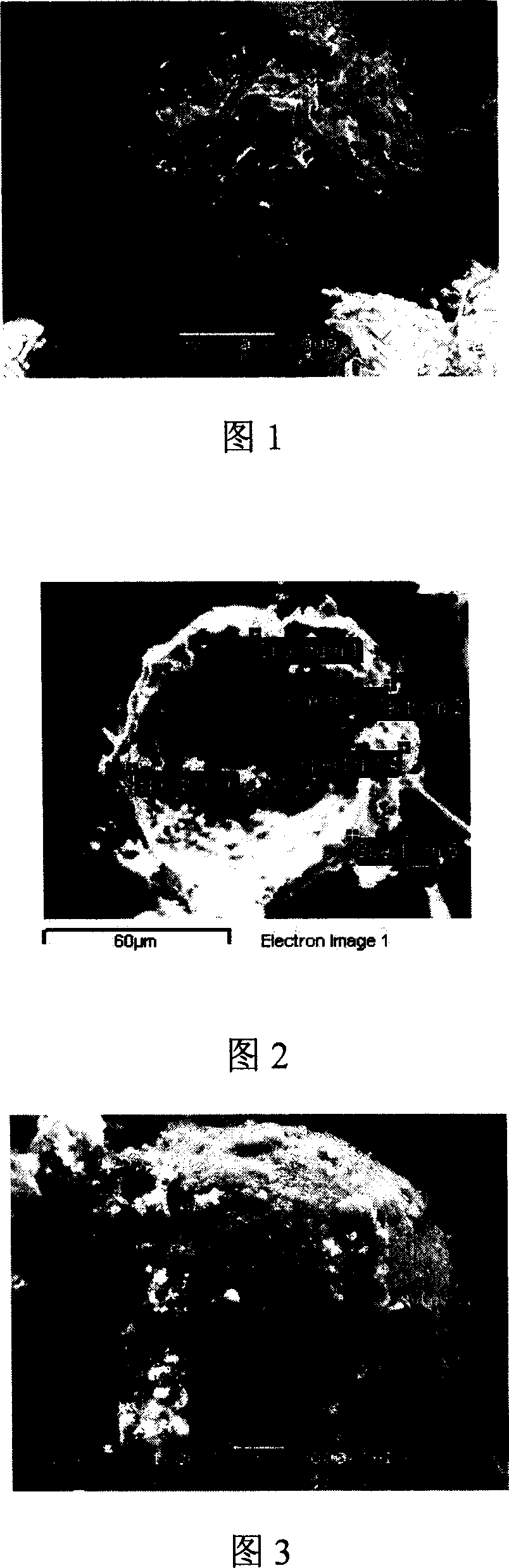

[0033] It can be seen from Fig. 1 that the surface of the sialon spheres formed after carbothermal reduction and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com