Apparatus and method for cleaning a webbing-up device in a printing press

A technology for printing presses and substrates, applied in the field of pull-in devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

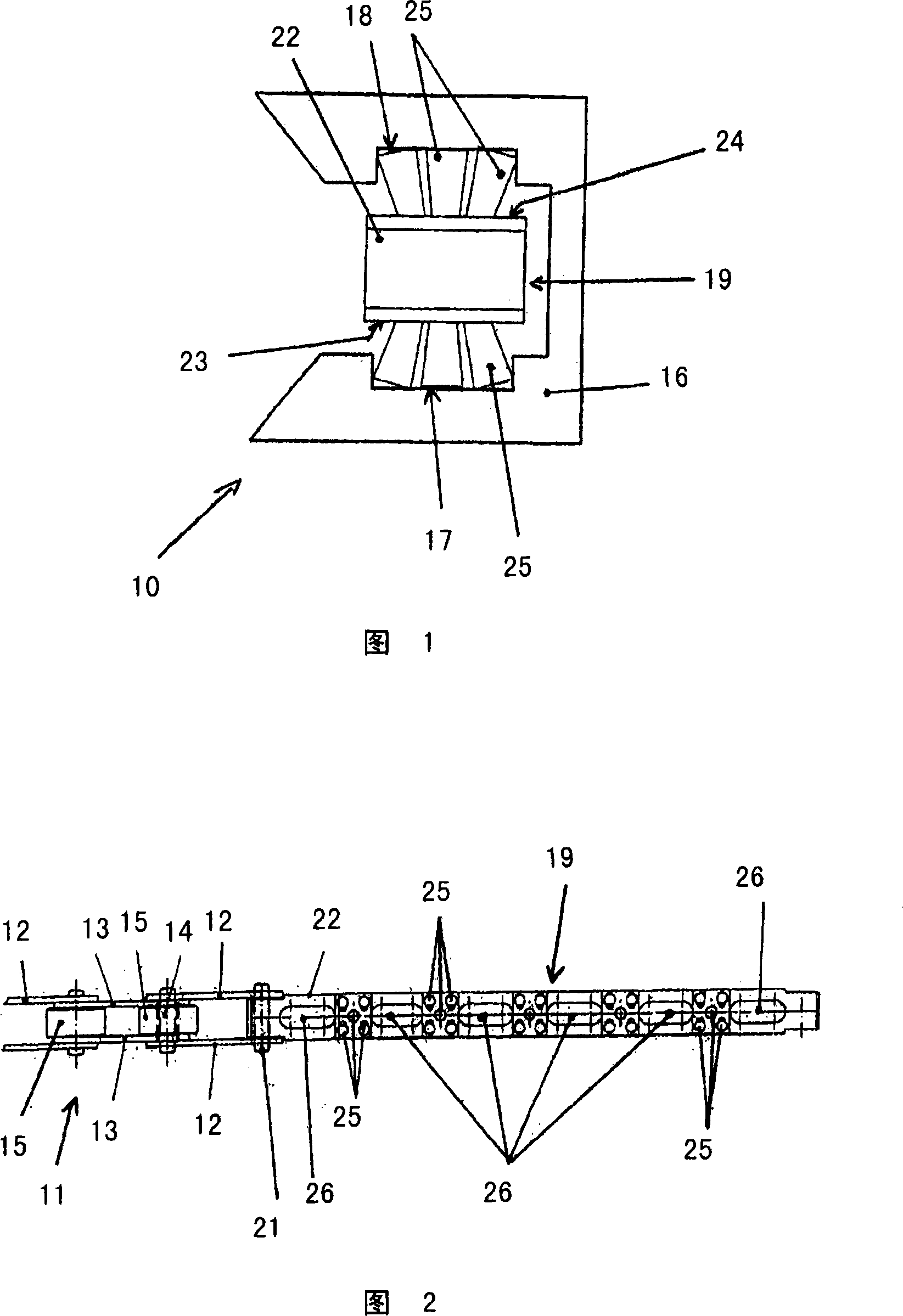

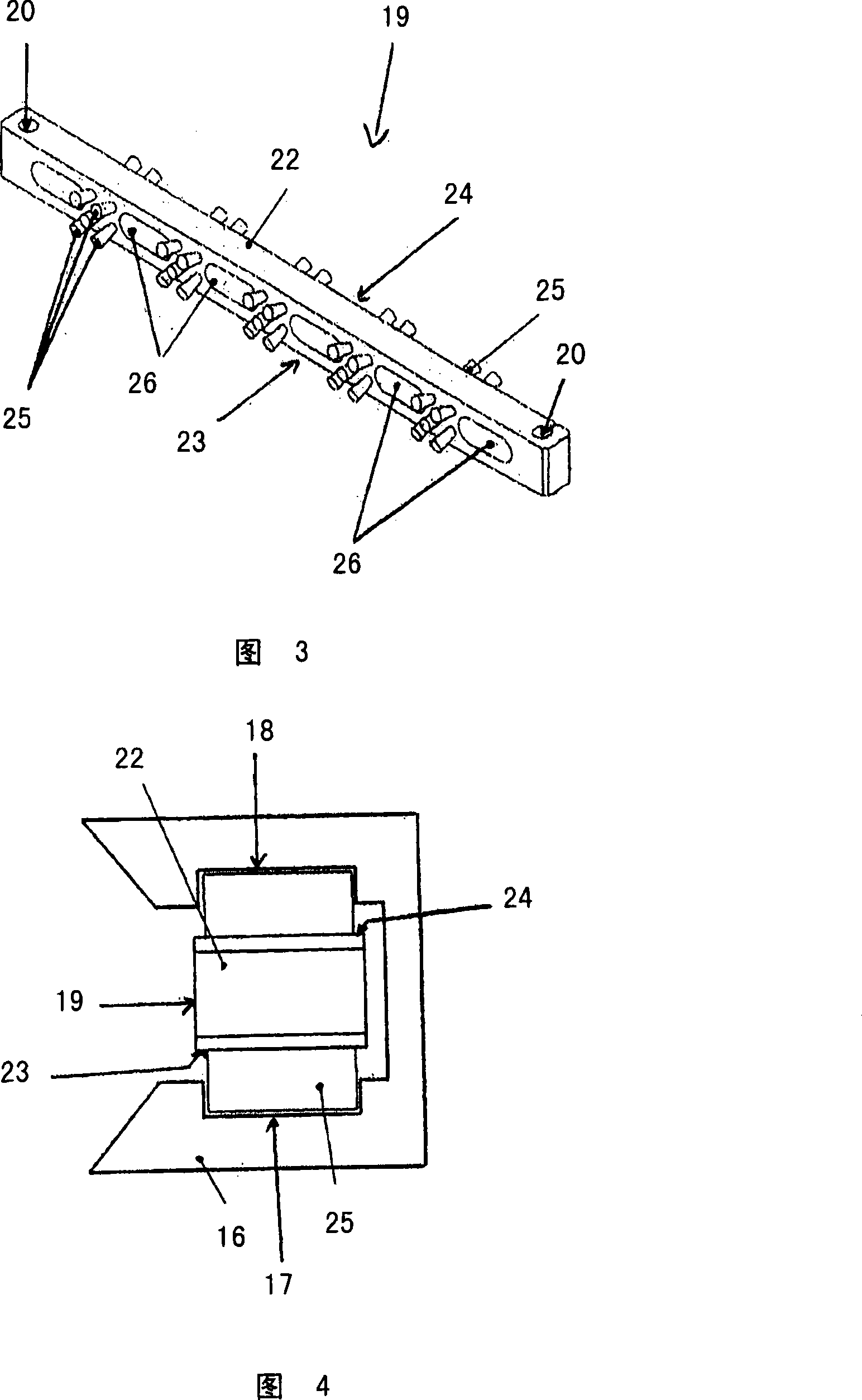

[0012] 1 to 3 show a preferred embodiment of an infeed device 10 according to the invention for drawing a printing material web into a rotary printing press, wherein the infeed device 10 according to the invention is included in FIG. 2 Partially shown limited conveyor chain 11 . The conveyor chain 11 consists of a plurality of chain rail links connected to one another in an articulated manner. The chain rail links are composed of alternately arranged outer chain links 12 and inner chain links 13, wherein the inner chain links 13 and the outer chain links 12 are hingedly connected by hinges. Each hinge comprises a chain track pin 14 extending through the overlapping ends of the outer 12 and inner 13 links and through the pulley 15 of the conveyor chain 11 . Only the two mentioned pulleys 15 of the conveyor chain 11 are shown in FIG. 2 .

[0013] The conveyor chain 11 of the intake device 10 is guided in a chain guide 16 , which is C-shaped in the exemplary embodiment shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com