Permanent magnet direct current (DC) speed-reducing motor

A geared motor, permanent magnet DC technology, applied in the direction of DC commutator, electric components, electrical components, etc., can solve the problems of large core loss, large change in contact voltage drop, long magnetic flux path, etc., to achieve a power-to-mass ratio and Effects of high torque volume factor, low vibration and noise, and short flux paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention is described in detail below in conjunction with the embodiment shown in the accompanying drawings:

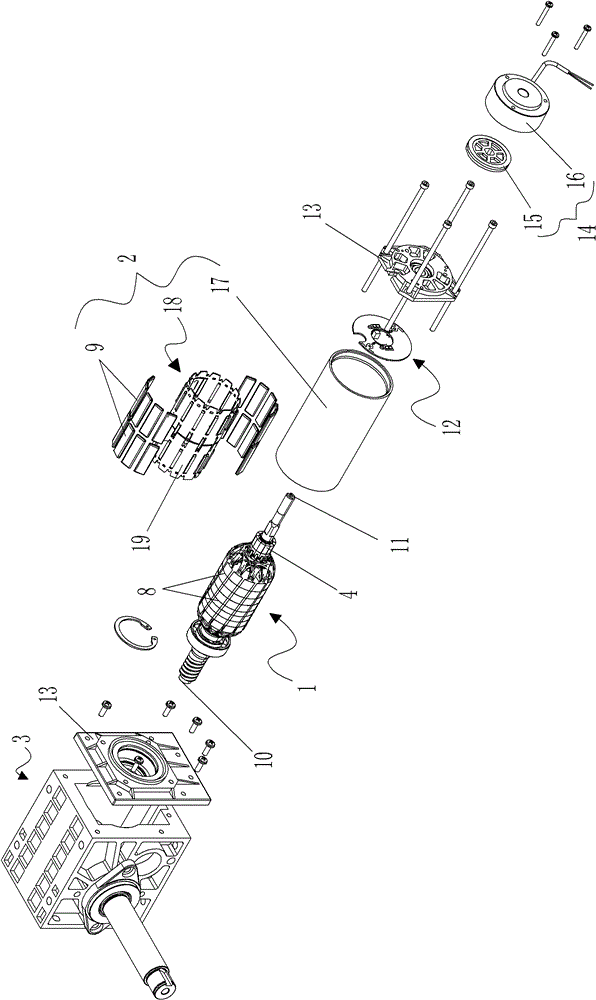

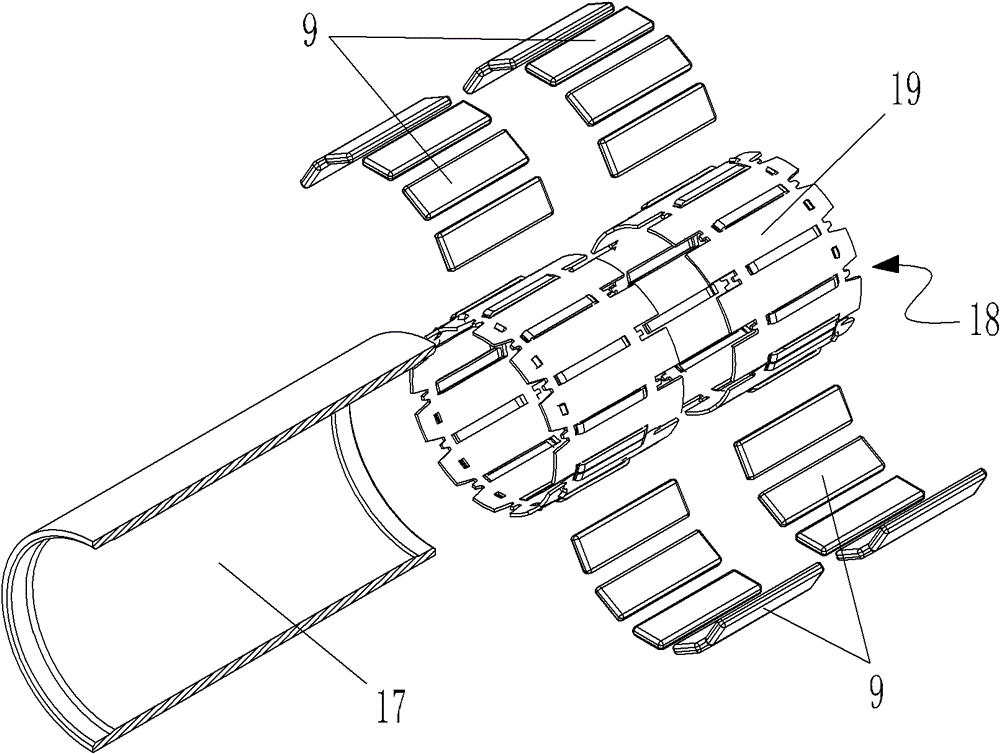

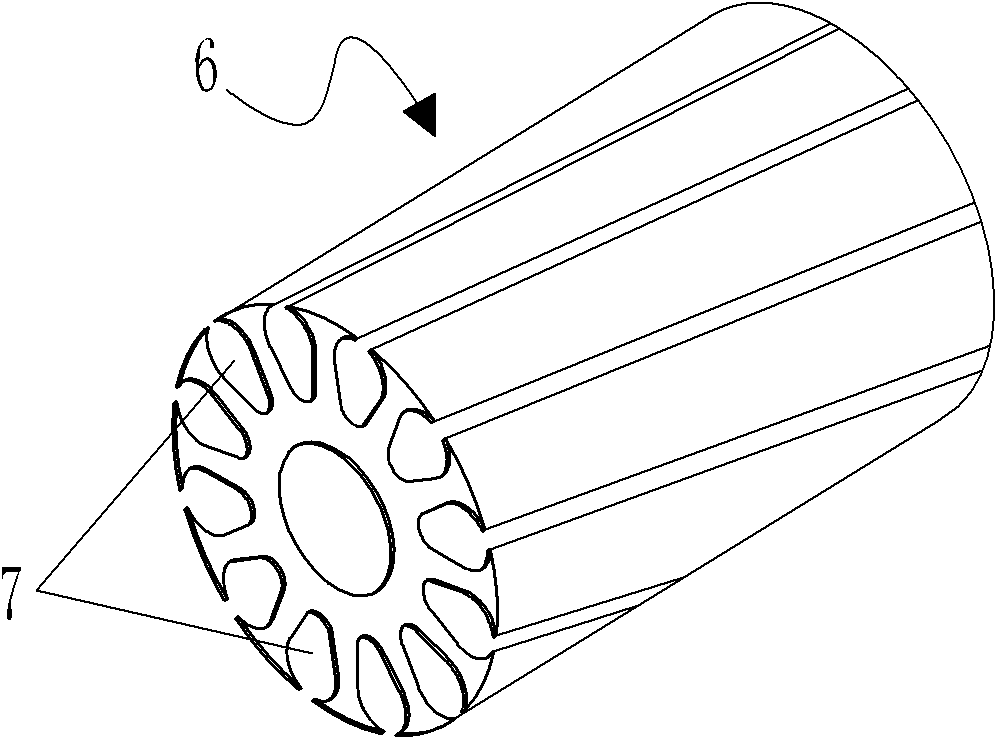

[0023] as attached figure 1 As shown, the permanent magnet DC geared motor of the present invention includes a rotor 1, a stator 2 arranged on the periphery of the rotor 1, a speed reducer 3 connected to the output end of the rotor 1, a commutator 4, and the rotor 1 includes a motor shaft 5 and is installed on The rotor core 6 on the motor main shaft 5, as attached image 3 and attached Figure 4 As shown, the outer peripheral wall of the rotor core 6 is provided with several grooves 7 distributed along its length direction, the outer circumference of the rotor core 6 is provided with windings 8, the stator 2 is provided with several permanent magnets 9, and the motor shaft 5 has a first end 10 and the second end 11, the commutator 4 is arranged on the second end 11, the commutator 4 is provided with a brush mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com