Conveyor roller and conveyor system with moisture protection

A technology of conveying equipment and conveying rollers, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of equipment control system rust, corrosion, influence, etc., and achieve the effect of ensuring trouble-free operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As an introduction, the first thing to note is that in the various embodiments described in different descriptions, the same components are provided with the same reference numerals or the same component names. Among them, the disclosure contained in all the descriptions can be used according to the meaning. To the same parts provided with the same reference signs or the same component names. Furthermore, the orientation descriptions selected in the description, such as up, down, side, etc., are all relative to the direct description and the drawings shown, and when the orientation changes, it can be transferred to a new orientation according to the meaning. . In addition, individual features or combinations of features from the different shown and described embodiments can also constitute an independent, inventive or inventive solution.

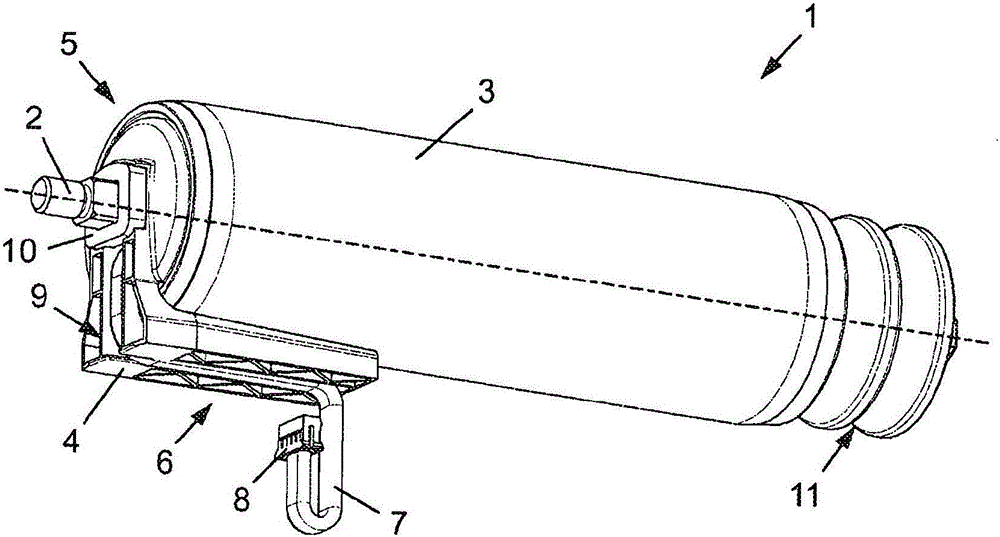

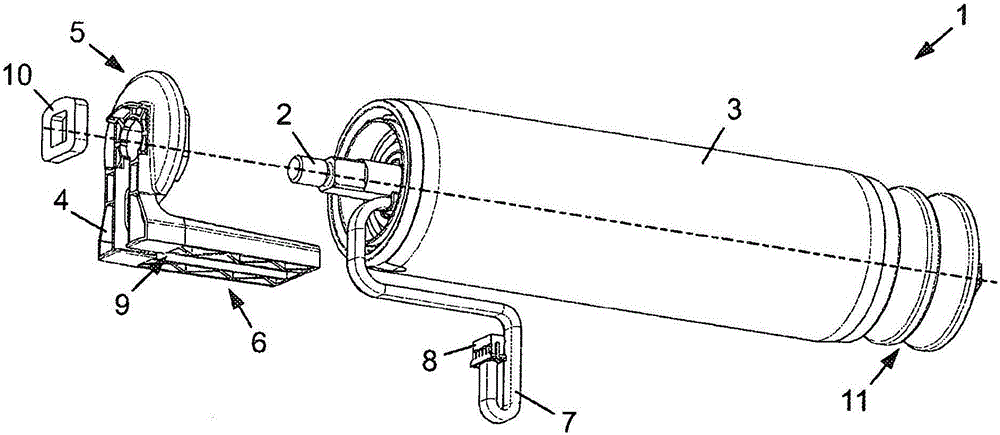

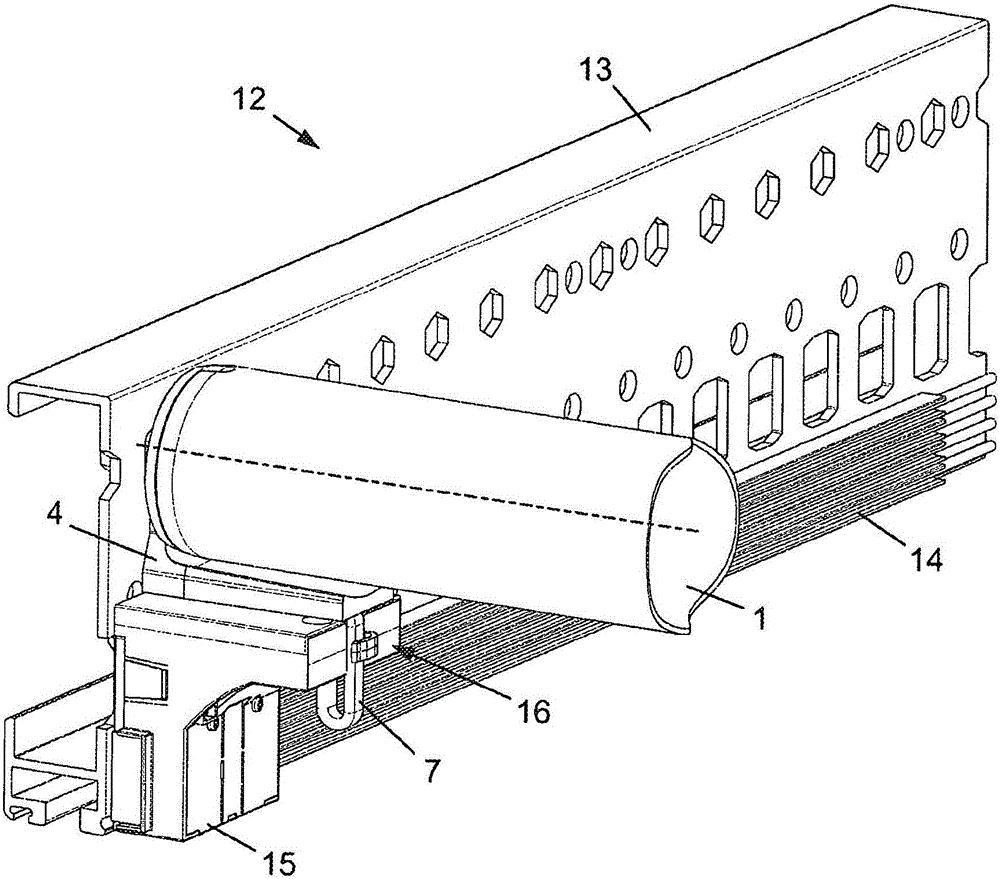

[0026] figure 1 with 2 Shown is an oblique view of an exemplary conveying roller 1 ( figure 1 ) And exploded view ( figure 2 ). in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com