High-temperature coal gas chilling chamber

A technology of chilling chamber and high temperature, which is applied in the fields of high-temperature gas chilling chamber, high-temperature gas containing carbon materials and gasification ash and slag. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

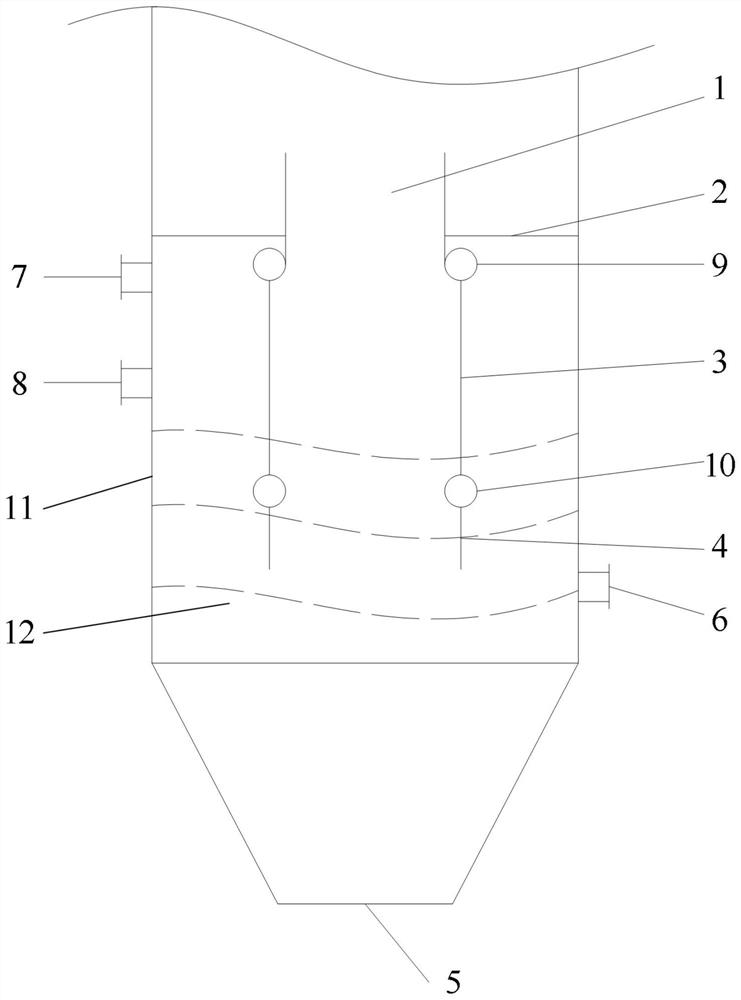

[0032] like figure 1 As shown, a high-temperature gas quenching chamber in this embodiment includes a quenching shell 11 and a water-cooled wall descending cylinder 3. A quenching chamber 12 is formed in the quenching shell 11, and the water-cooled wall descending cylinder 3 is arranged on the quenching shell. In the inner cavity of 11, the upper part of the water-cooled wall descending cylinder 3 is provided with a high-temperature gas inlet 1 for entering high-temperature gas and gasified ash, and the lower part of the water-cooled wall descending cylinder 3 extends into the quenching water bath of the quenching chamber 12, The bottom of the quenching chamber 12 is provided with a slag outlet 5, the upper side wall of the quenching shell is provided with a gas outlet 7, the lower side wall of the quenching chamber 12 is provided with a gray water outlet 6, and the water wall descending tube The annular space between 3 and the quenching shell 11 is the annular space of the qu...

Embodiment 2

[0035] like figure 1 As shown, a high-temperature gas quenching chamber in this embodiment includes all the technical features in Embodiment 1. In addition, it also includes a quenching water inlet 8, which is arranged on the upper part of the quenching shell On the side wall, the chilled water inlet 8 is located below the gas outlet 7.

[0036]A high-temperature gas quenching chamber in this embodiment, high-temperature gas and ash enter the water-cooled wall descending cylinder 3 from the high-temperature gas inlet 1, and enter the water bath at the lower part of the quenching chamber 12 under the protection of the water-cooled wall descending cylinder 3. In the water bath at the lower part of the water wall, the quenching and washing of high-temperature gas is completed, and the temperature of the gas after quenching and washing drops below 300°C, and the gas outlet 7 on the upper part of the quenching chamber 12 goes to the rear section; the quenching water is imported thr...

Embodiment 3

[0039] like figure 1 As shown, a high-temperature gas quenching chamber in this embodiment includes all the technical features in Embodiment 1. In addition, the water-cooled wall descending tube 3 is a vertical tube water-cooled wall or a spiral coil water-cooled wall; the water-cooled The boiler tubes of the wall drop tube 3 are connected by fins or directly connected; it also includes a flow guide tube 4, and the bottom of the water-cooled wall drop tube 3 is connected with a flow guide tube 4; There is a partition 2 between the combustion chamber of the gasifier, the partition 2 is located on the upper part of the annulus of the quenching chamber 12, and the partition 2 is located above the gas outlet 7; the cross section of the water-cooled wall descending tube 3 is circular or polygonal .

[0040] In some optional embodiments, the upper diameter of the water-cooled wall descending tube 3 is not equal to the lower diameter of the water-cooled wall descending tube 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com