Onion peeler

A peeling machine, onion technology, applied in application, food processing, food science and other directions, can solve the problems of high labor, high price and high operation requirements, and achieve the effect of improving production efficiency, low machine cost and good processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

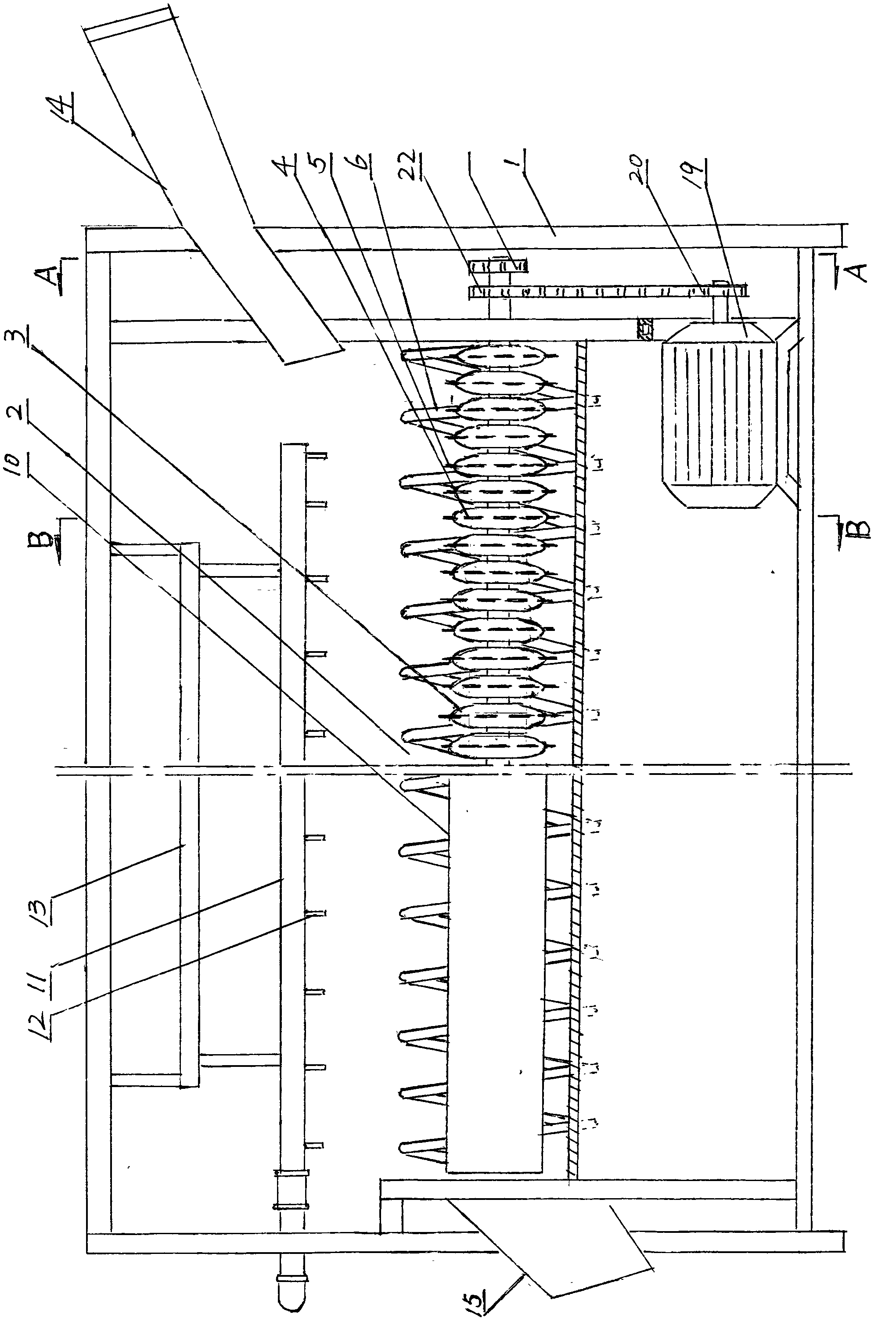

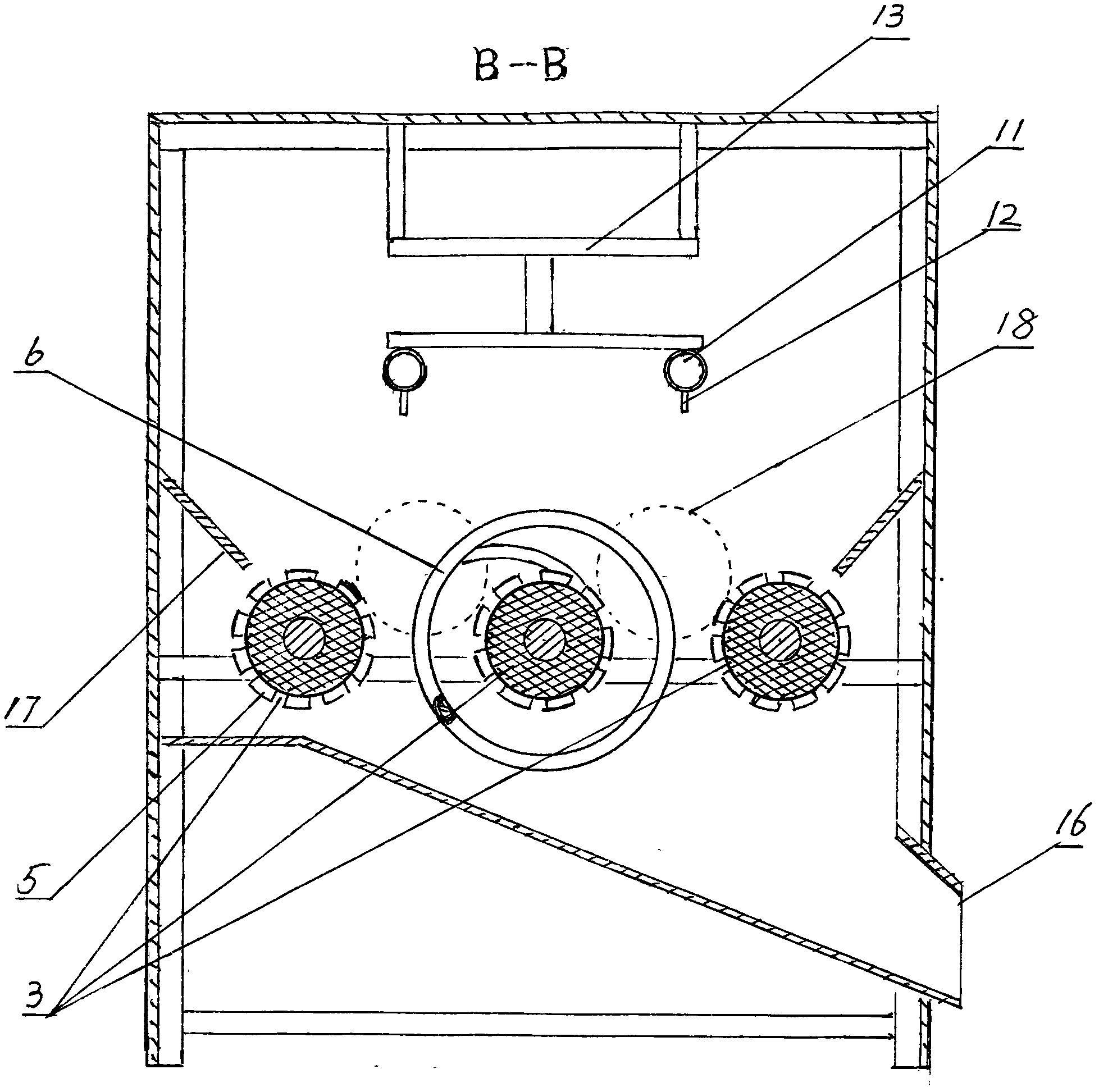

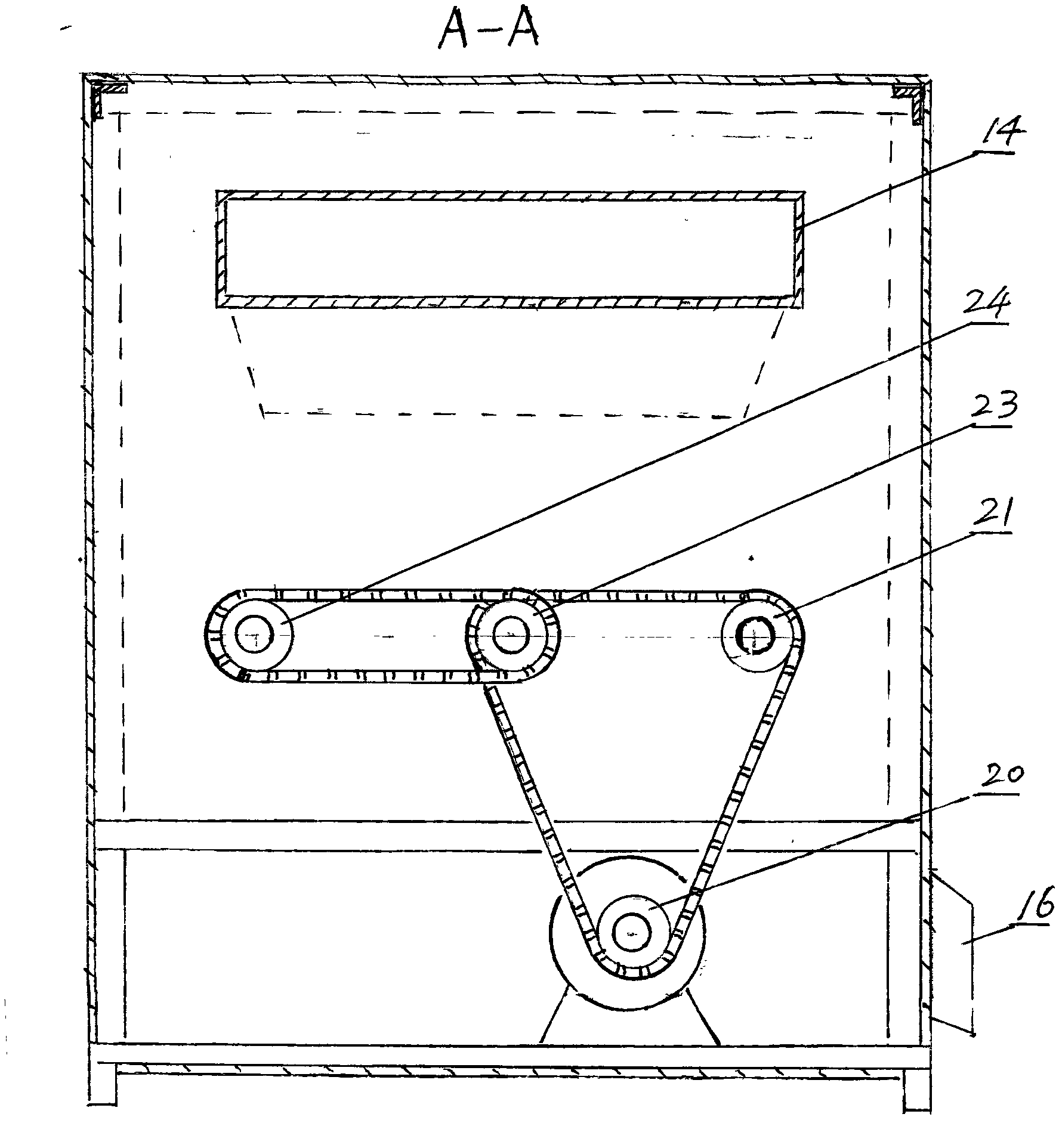

[0018] Below, combined with figure 1 , 2 , 3, and 4 provide a specific embodiment to further illustrate the structure of the present invention.

[0019] This peeling machine comprises frame 1, and three peeling rollers 2 are installed on the frame in parallel side by side, are respectively left peeling roller, right peeling roller and middle peeling roller 2 ' (see figure 2 shown), driven by the driving device, and rotate in the same direction. The intermediate skinning roller 2 ′ has a spiral 6 . The three peeling rollers are respectively formed by connecting front and rear sections, and the front section peeling roller 3 is assembled by a plurality of pie-shaped disc wheels 4, and the periphery of the disc wheels is provided with a skinning mechanism. The skinning mechanism is a plurality of rectangles evenly distributed along the periphery ( Figure 5 shown), or curved ( Figure 6 shown), or zigzag ( Figure 7 Shown) the peeling blade 5, height 2-6mm, the onion surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com