Patents

Literature

145 results about "Terete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terete is a term used in botany to describe a cross section that is circular, or like a distorted circle, with a single surface wrapping around it. This is usually contrasted with cross-sections that are flattened, with a distinct upper surface that is different from the lower surface. The cross-section of a branch in a tree is somewhat round, so the branch is terete. The cross section of a normal leaf has an upper surface, and a lower surface, so the leaf is not terete. However, the fleshy leaves of succulents are sometimes terete. Fruticose lichens are terete, with a roughly circular cross section and a single wrap-around skin-like surface called the cortex, compared to foliose lichens and crustose lichens, which have a flattened cross section with an upper surface that is distinct from the lower surface.

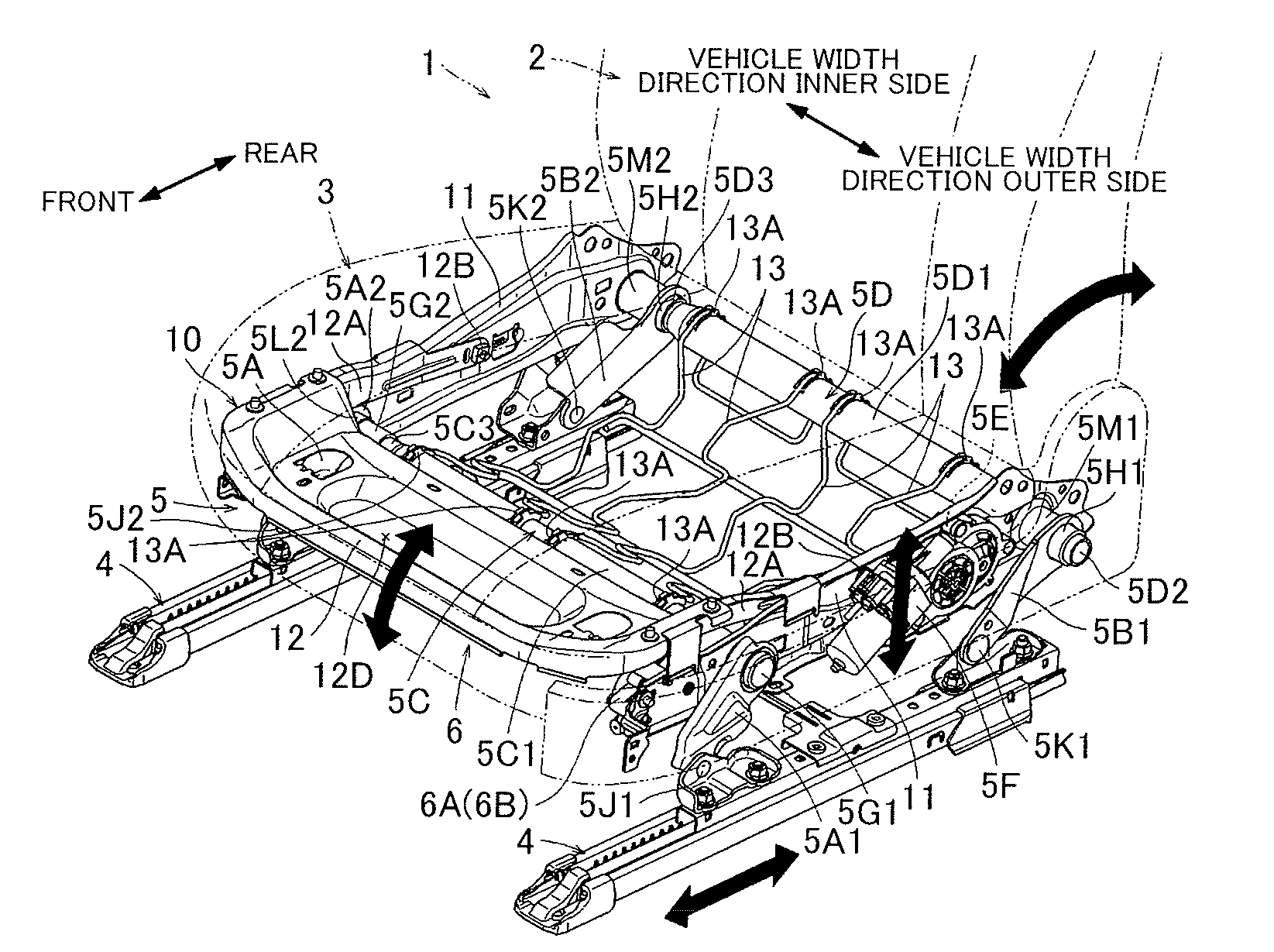

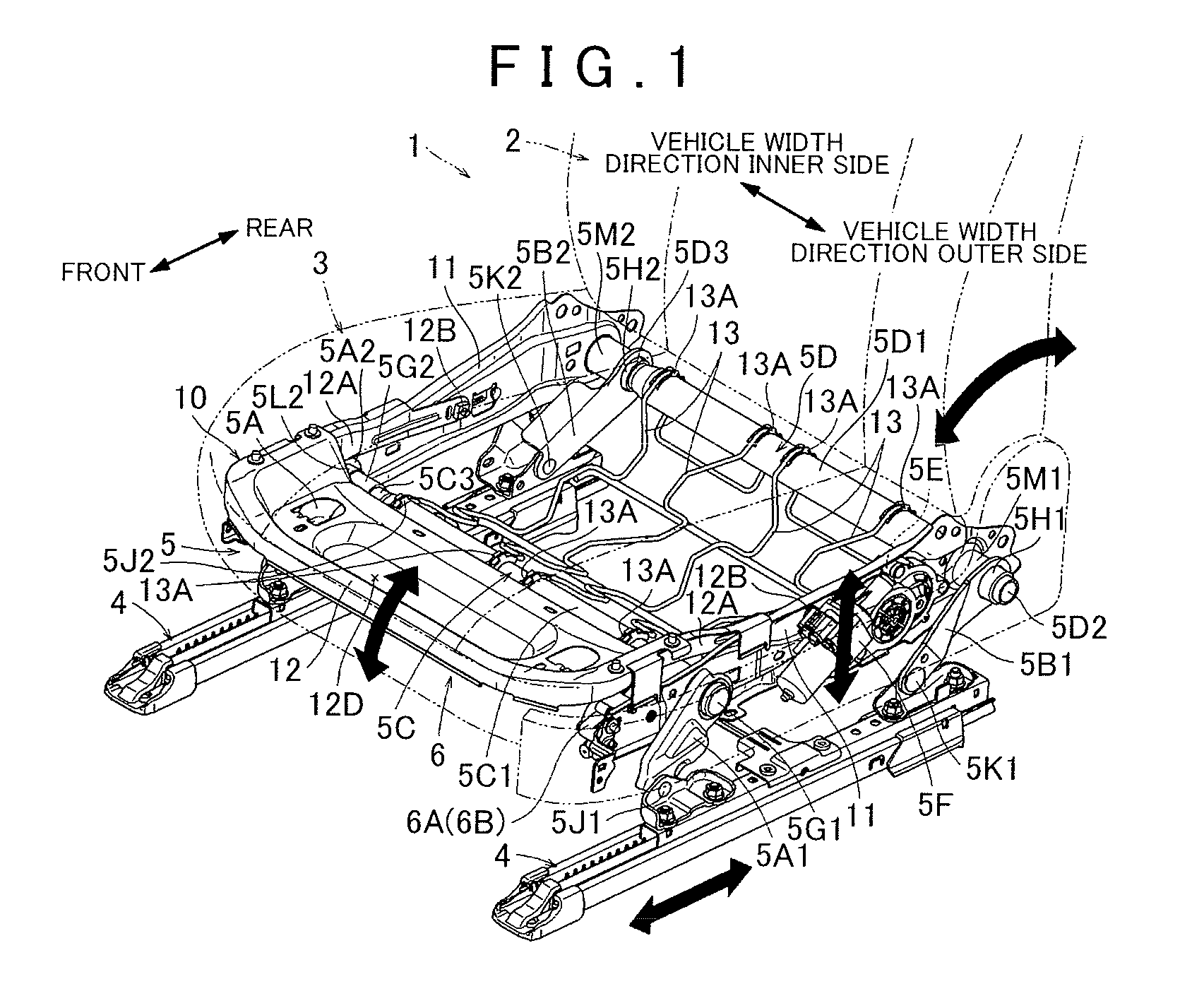

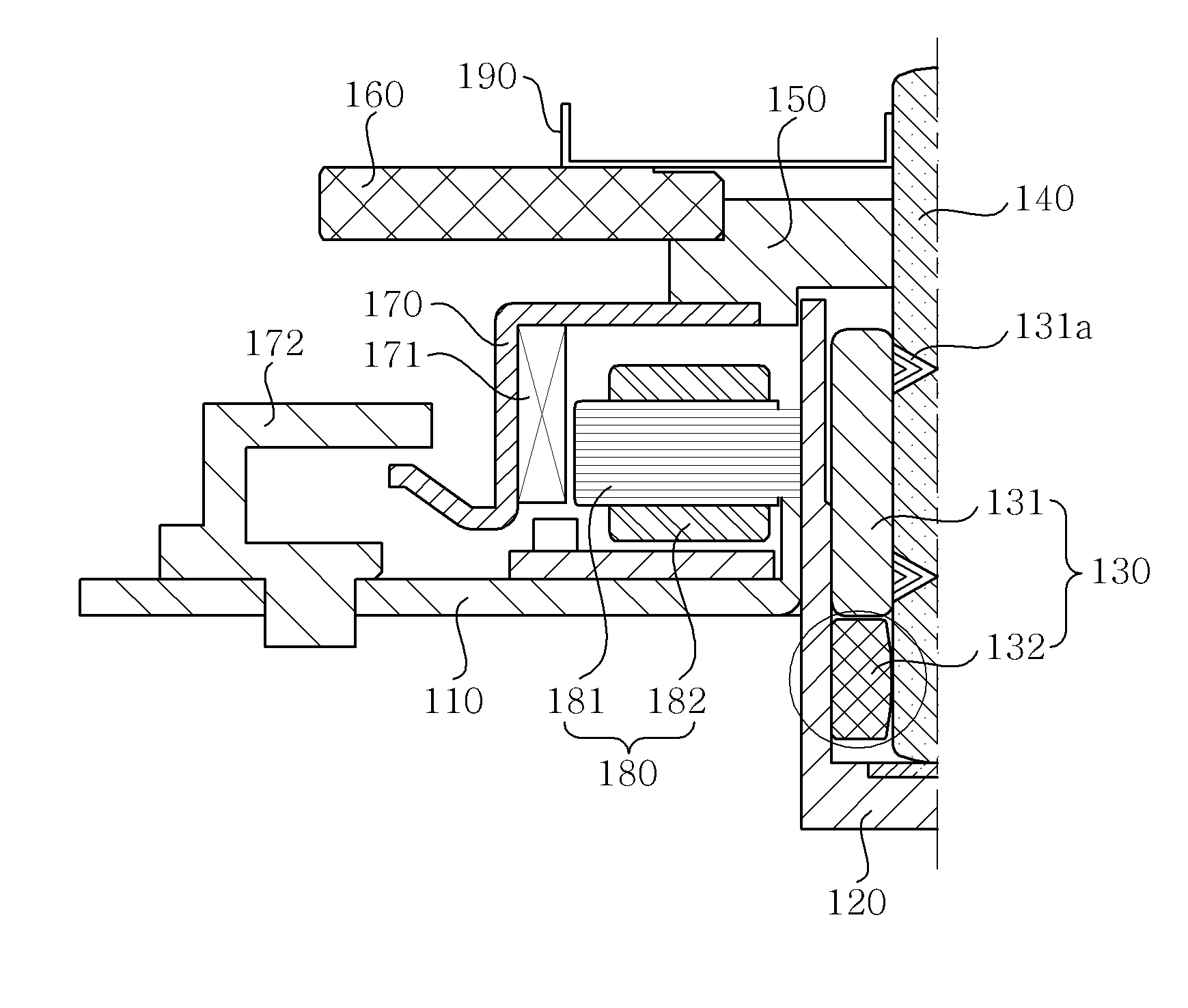

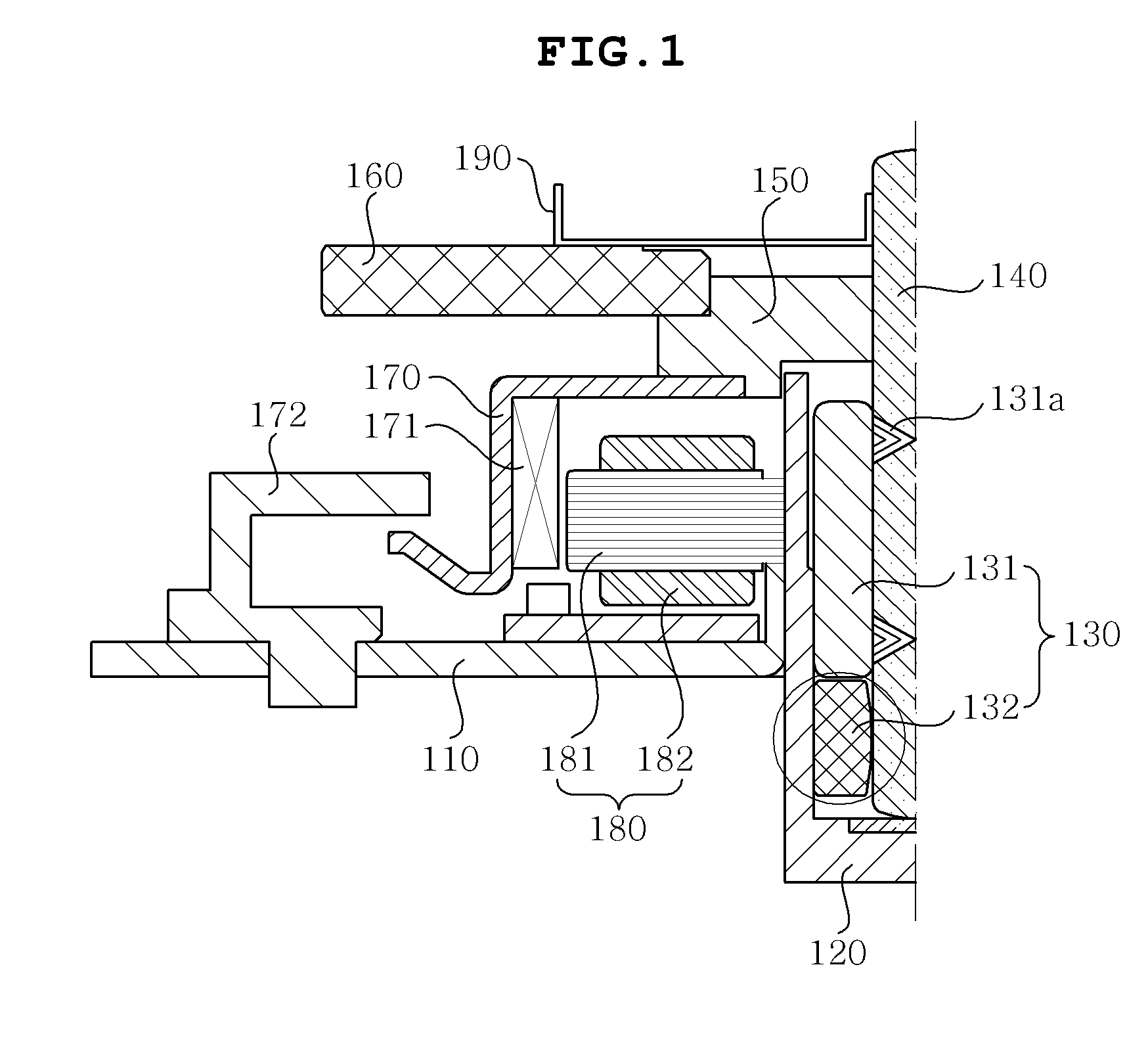

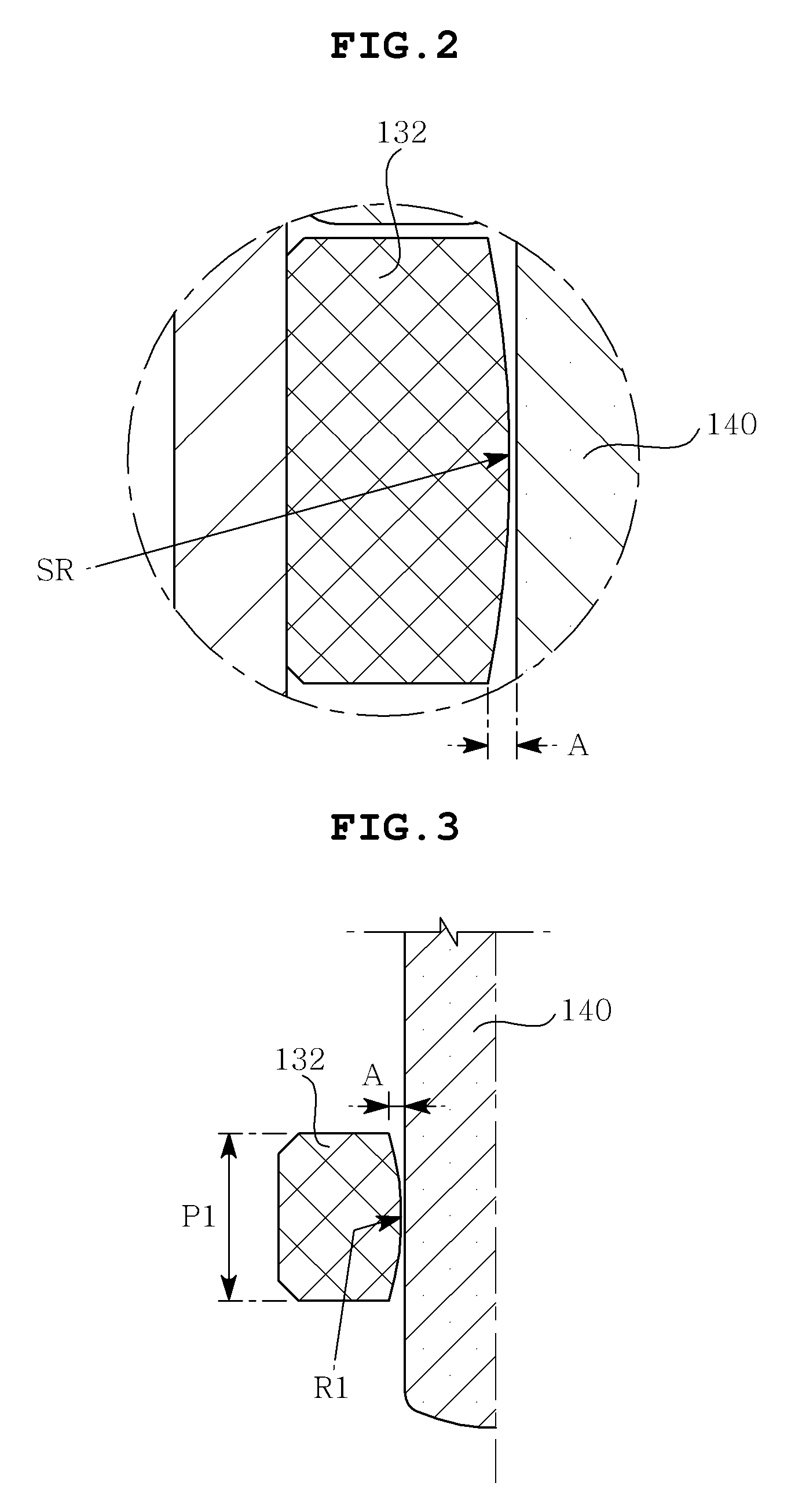

Vehicle seat

ActiveUS20150336477A1Improve structural strengthPosture can be firmlySeat framesStoolsEngineeringMechanical engineering

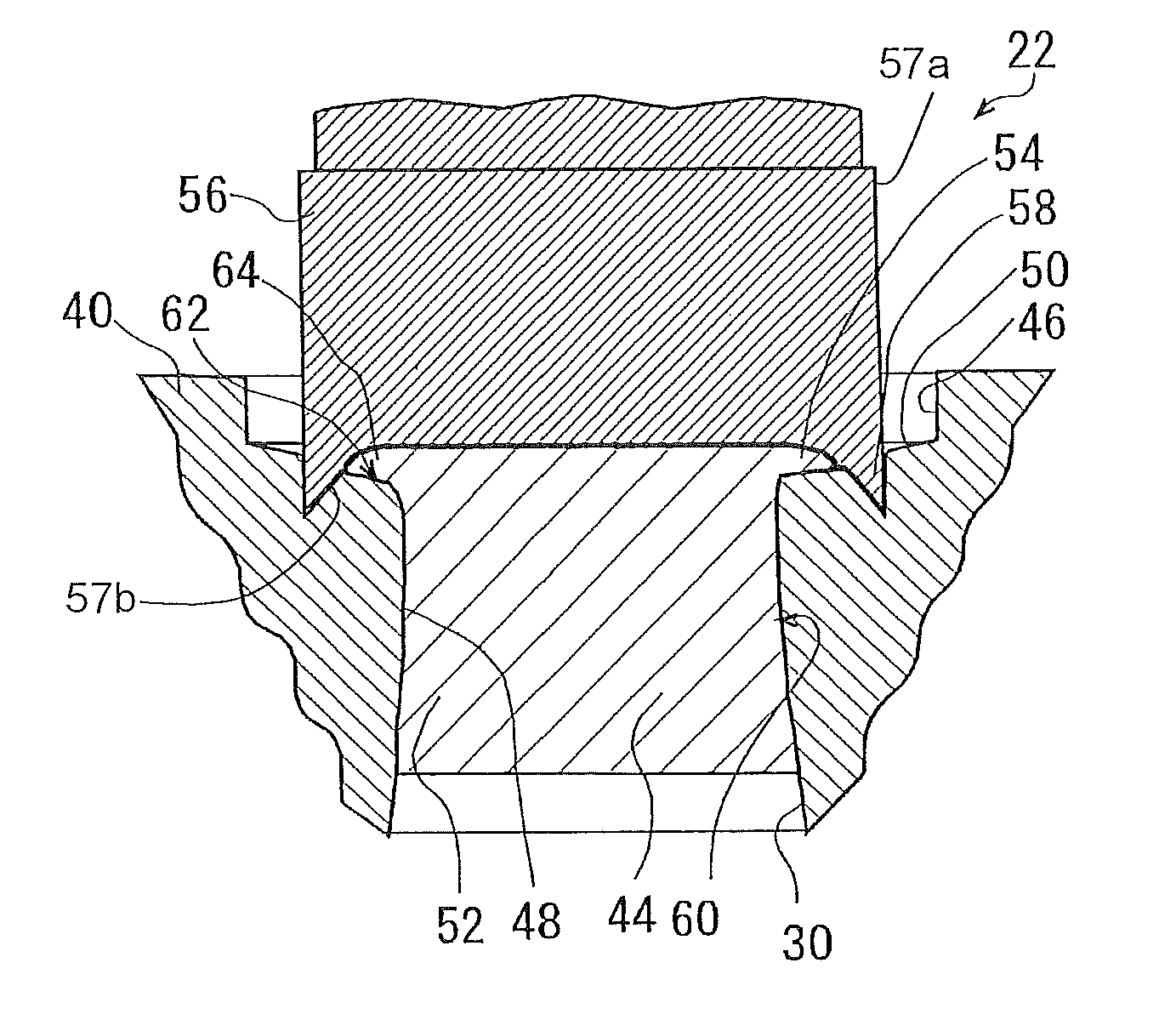

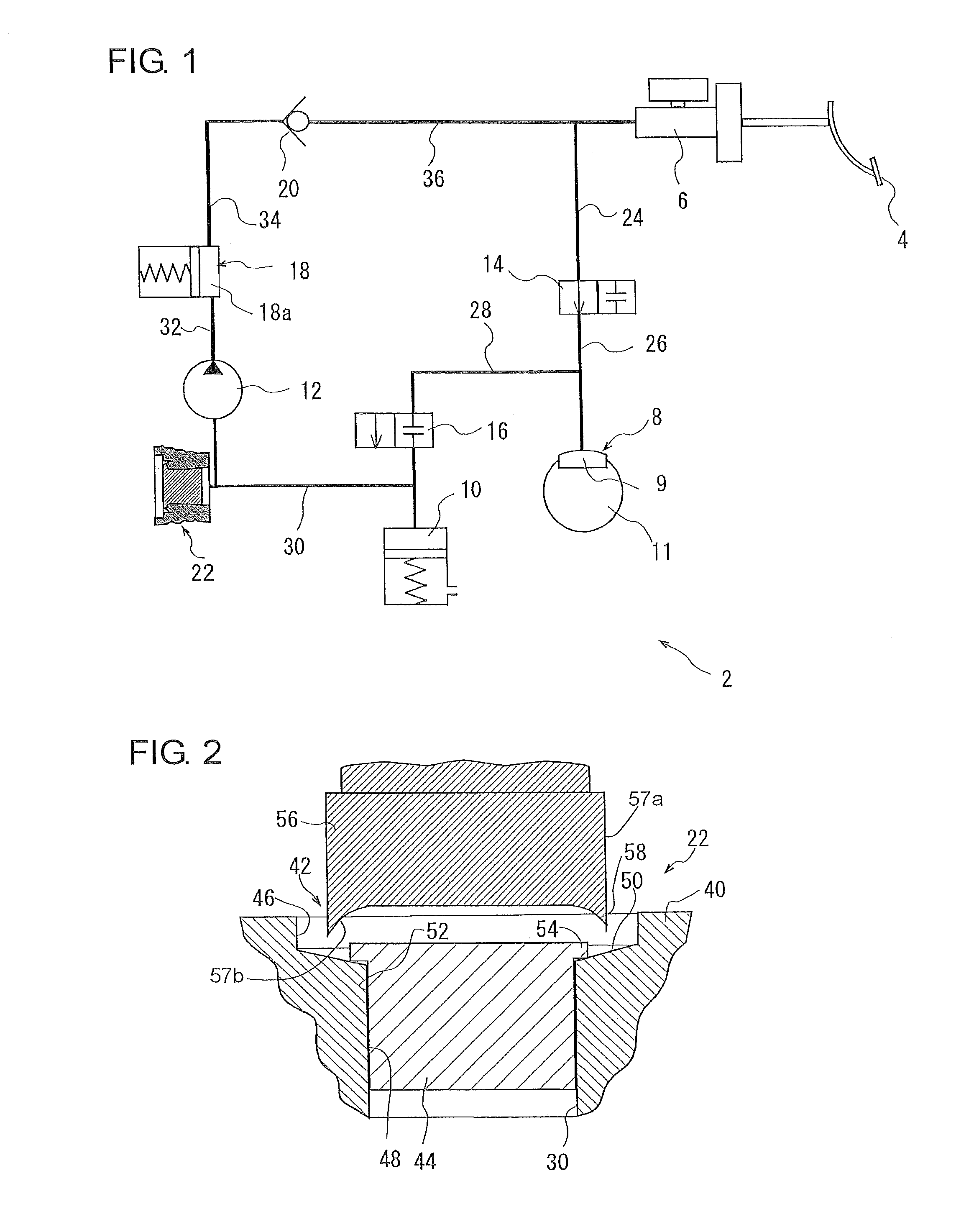

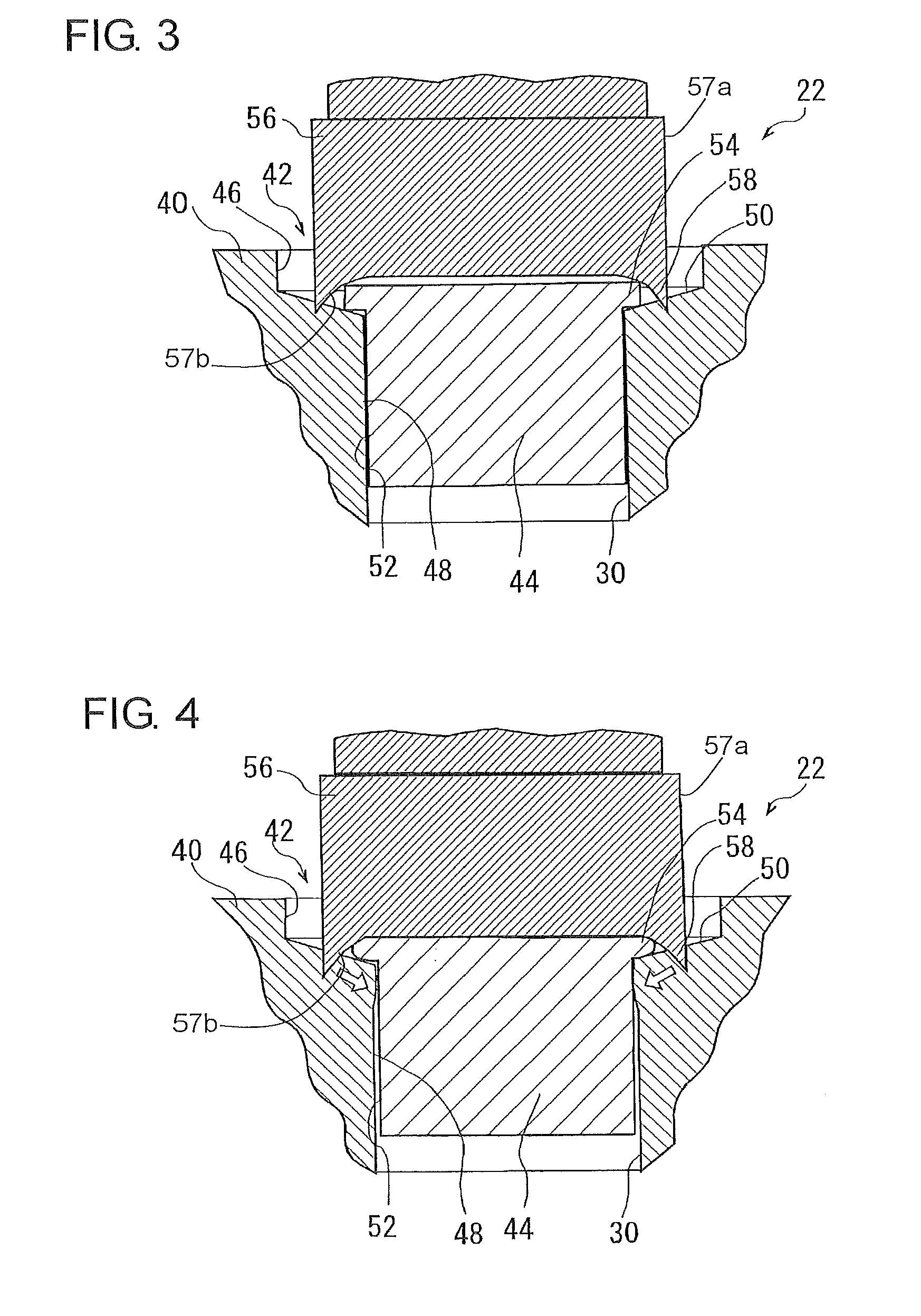

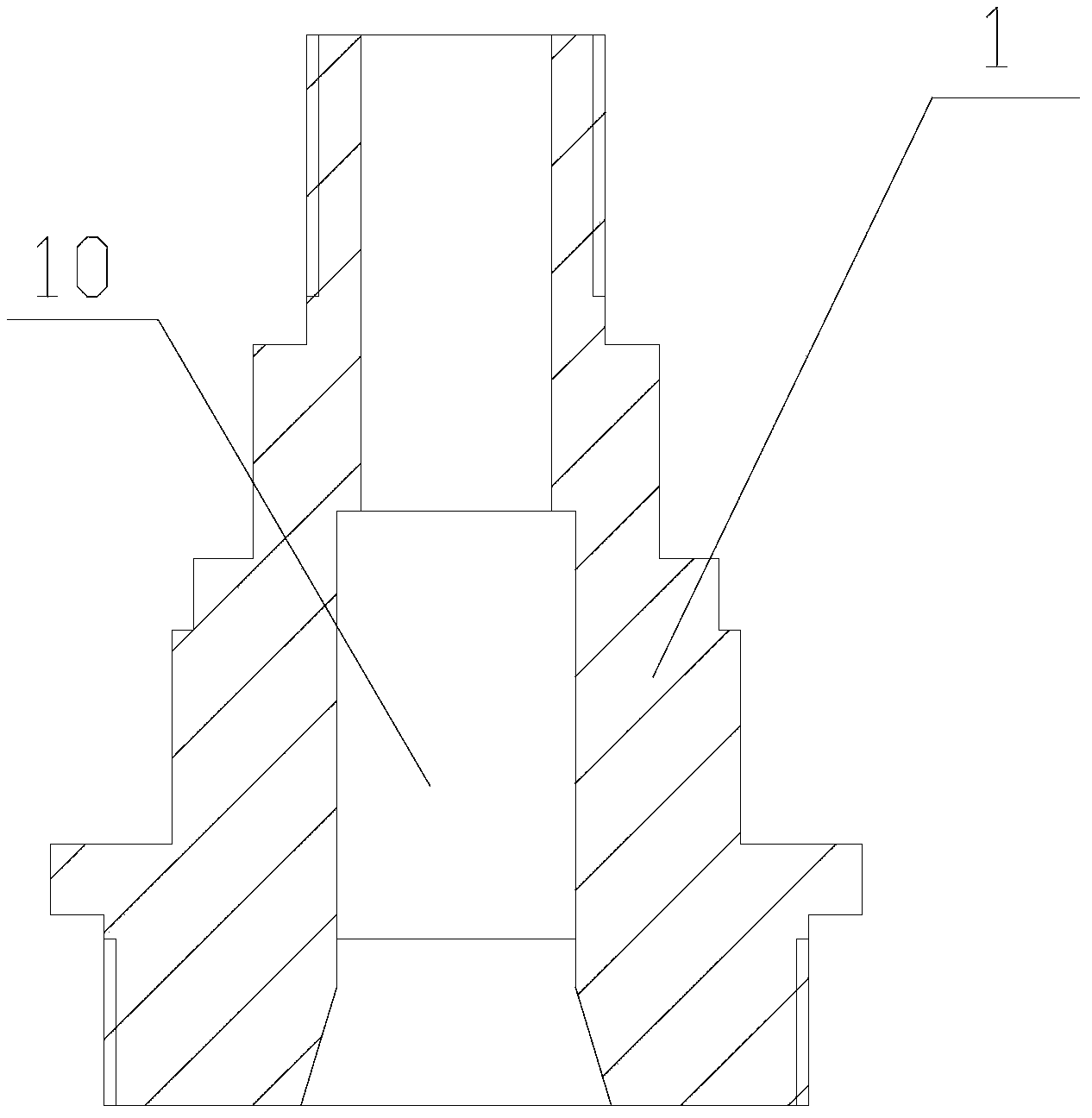

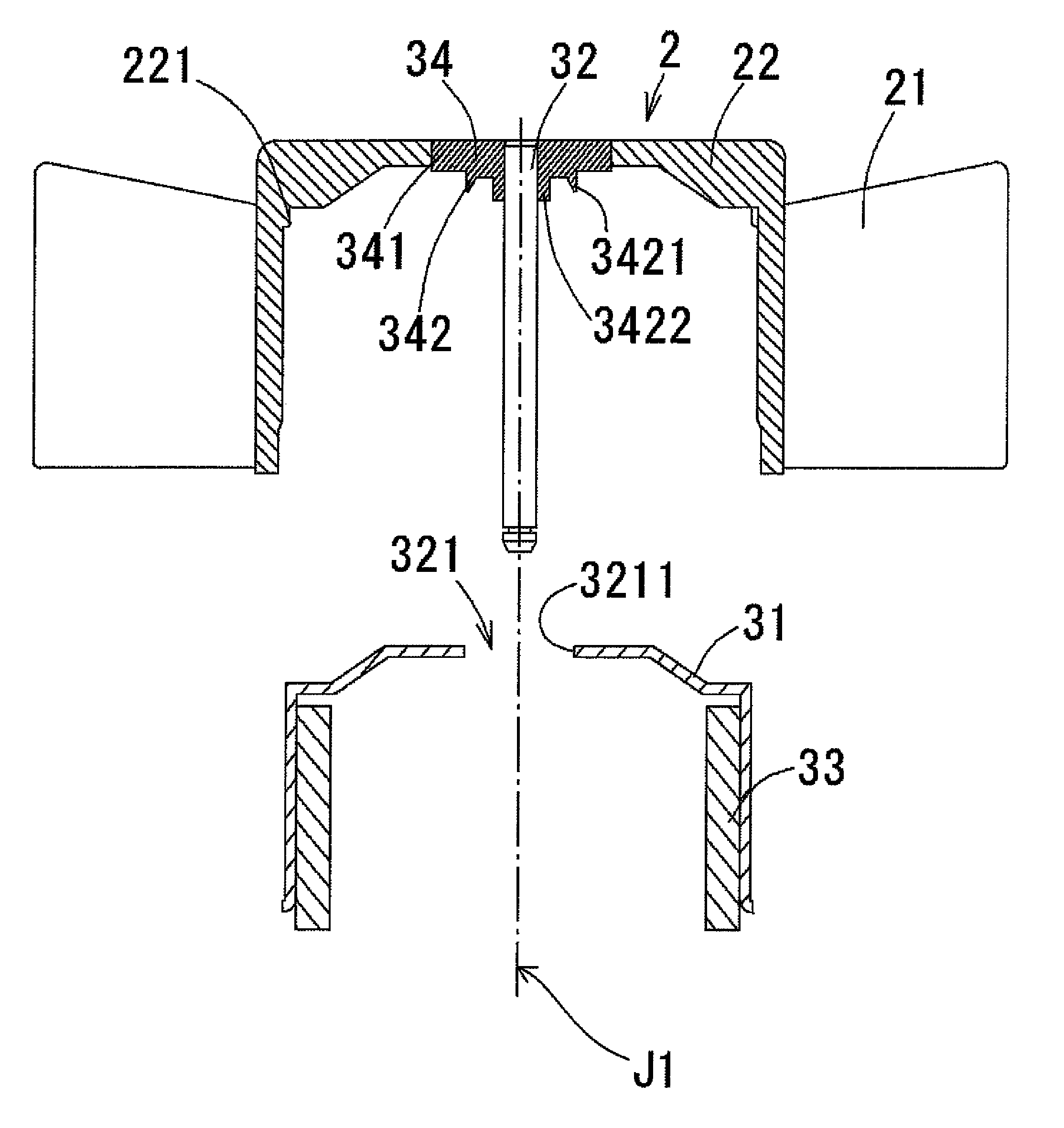

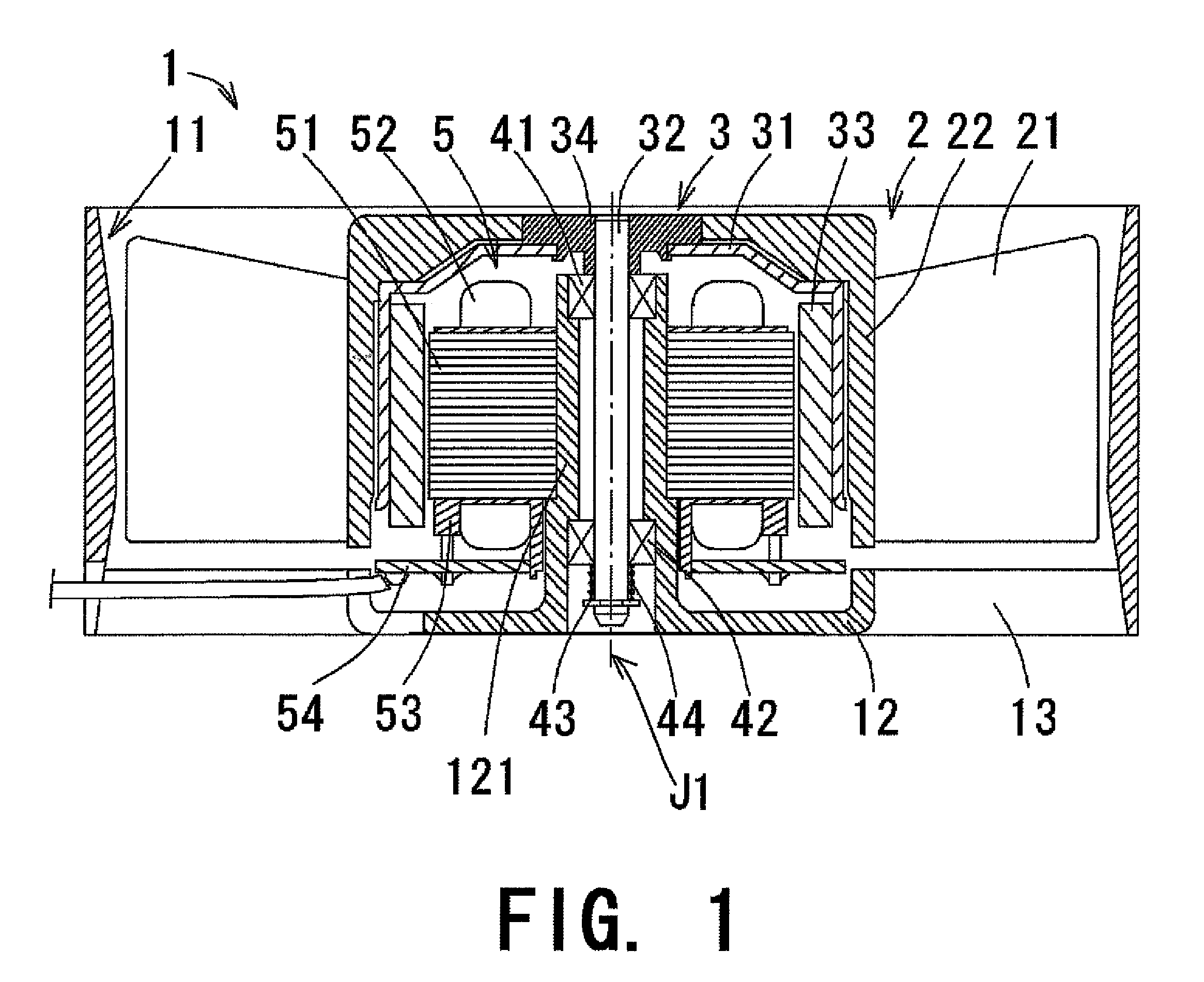

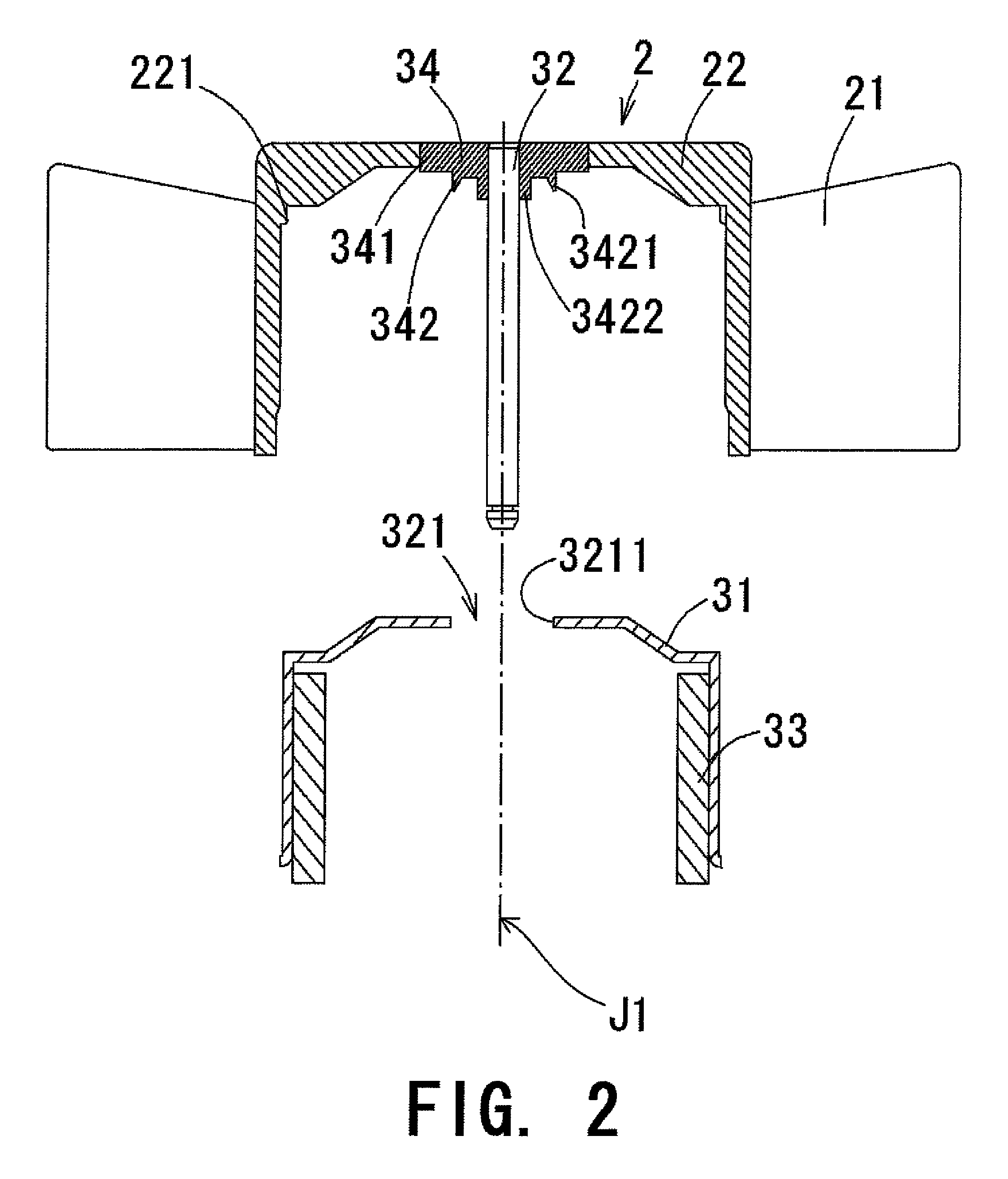

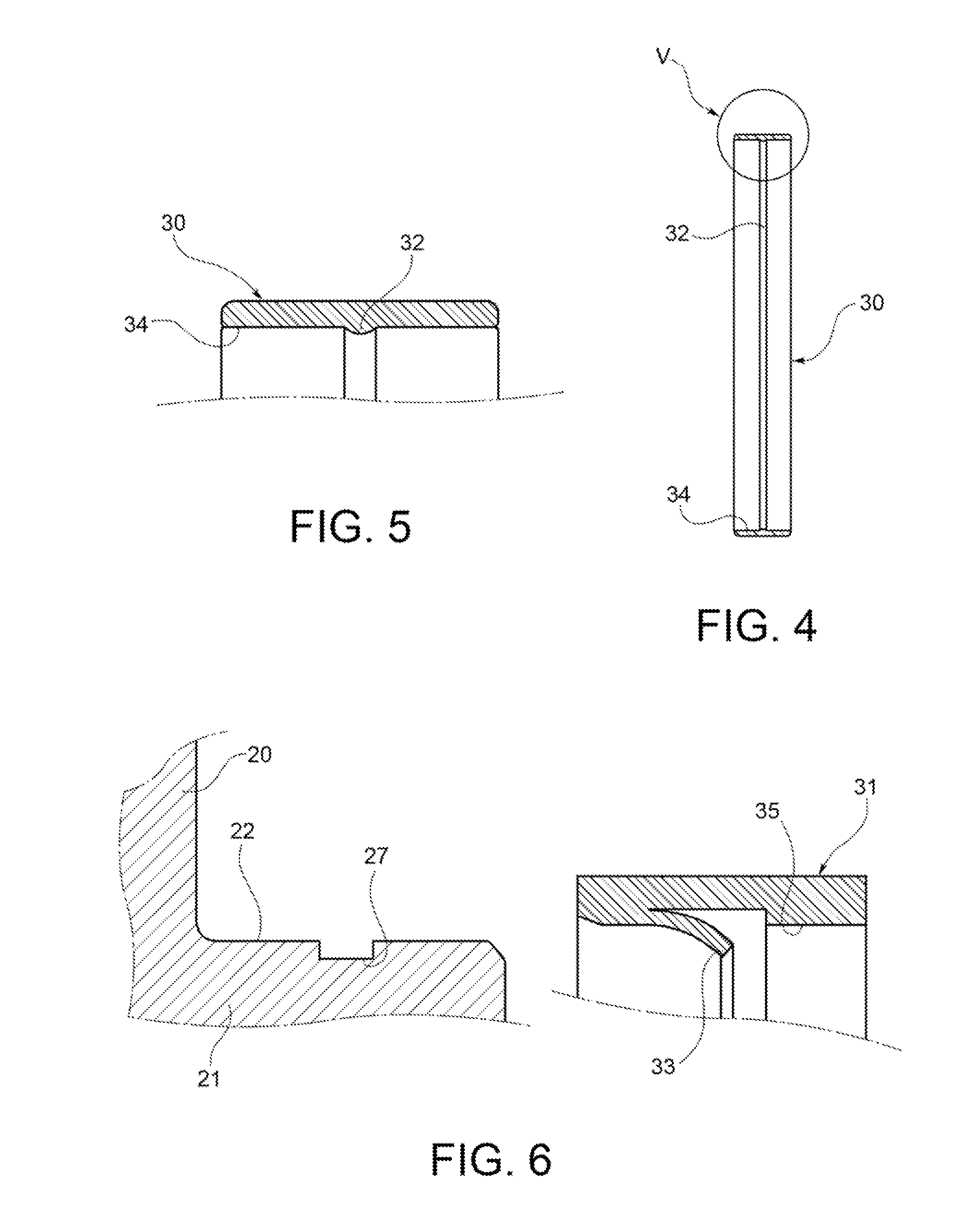

A vehicle seat includes a seat frame, a bushing having a shape of a hollow cylinder and a pipe. The pipe is fitted to the bushing and attached to the seat frame. The pipe includes a body portion having a fitting diameter different from a fitting diameter of the bushing and a fitting portion formed at an end in an axial direction of the body portion and fitted to an inner periphery or an outer periphery of the bushing. The fitting portion is formed in a diameter-reduced or diameter-increased hollow cylindrical shape that is fitted to the inner periphery or the outer periphery of the bushing.

Owner:TOYOTA BOSHOKU KK +1

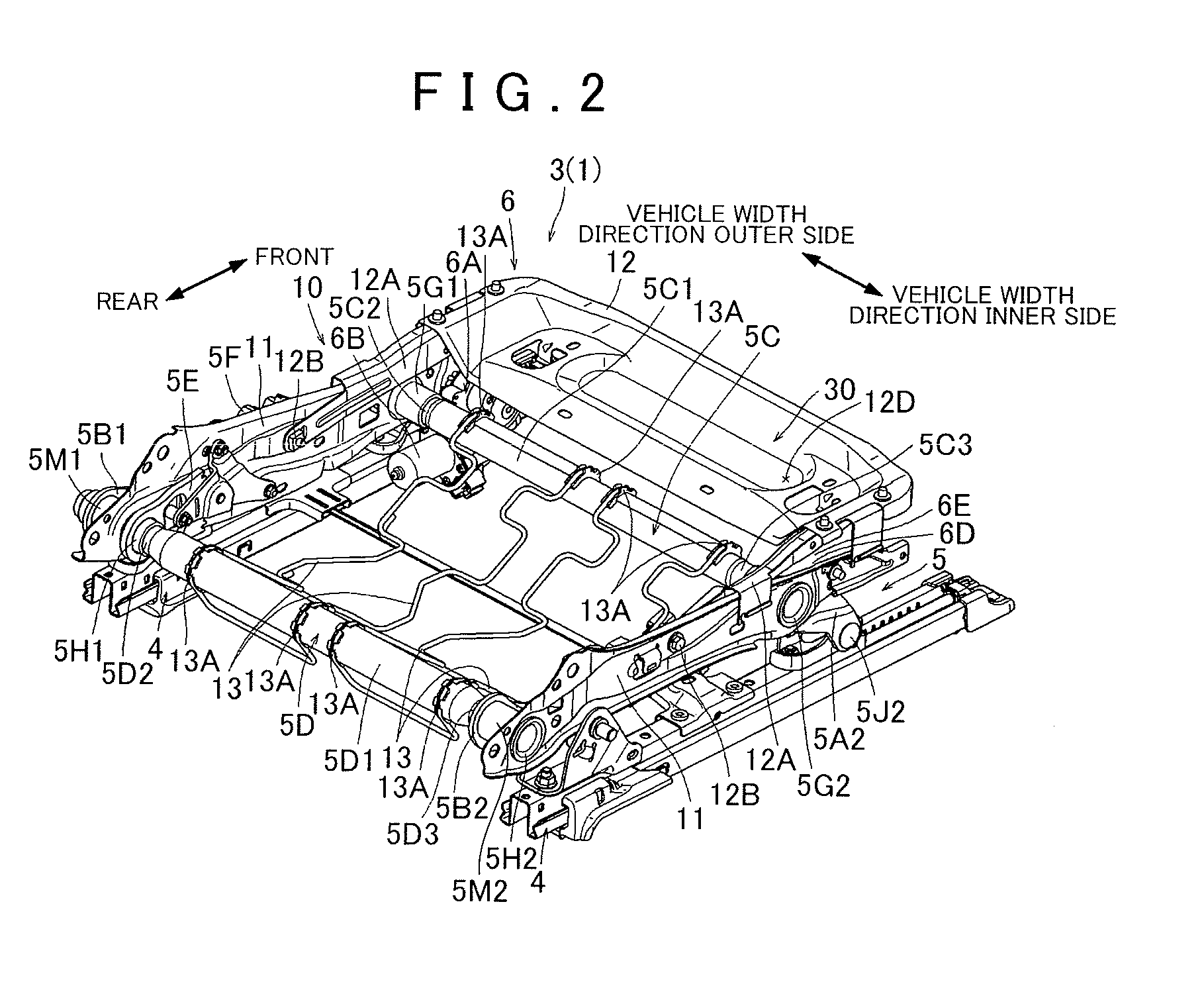

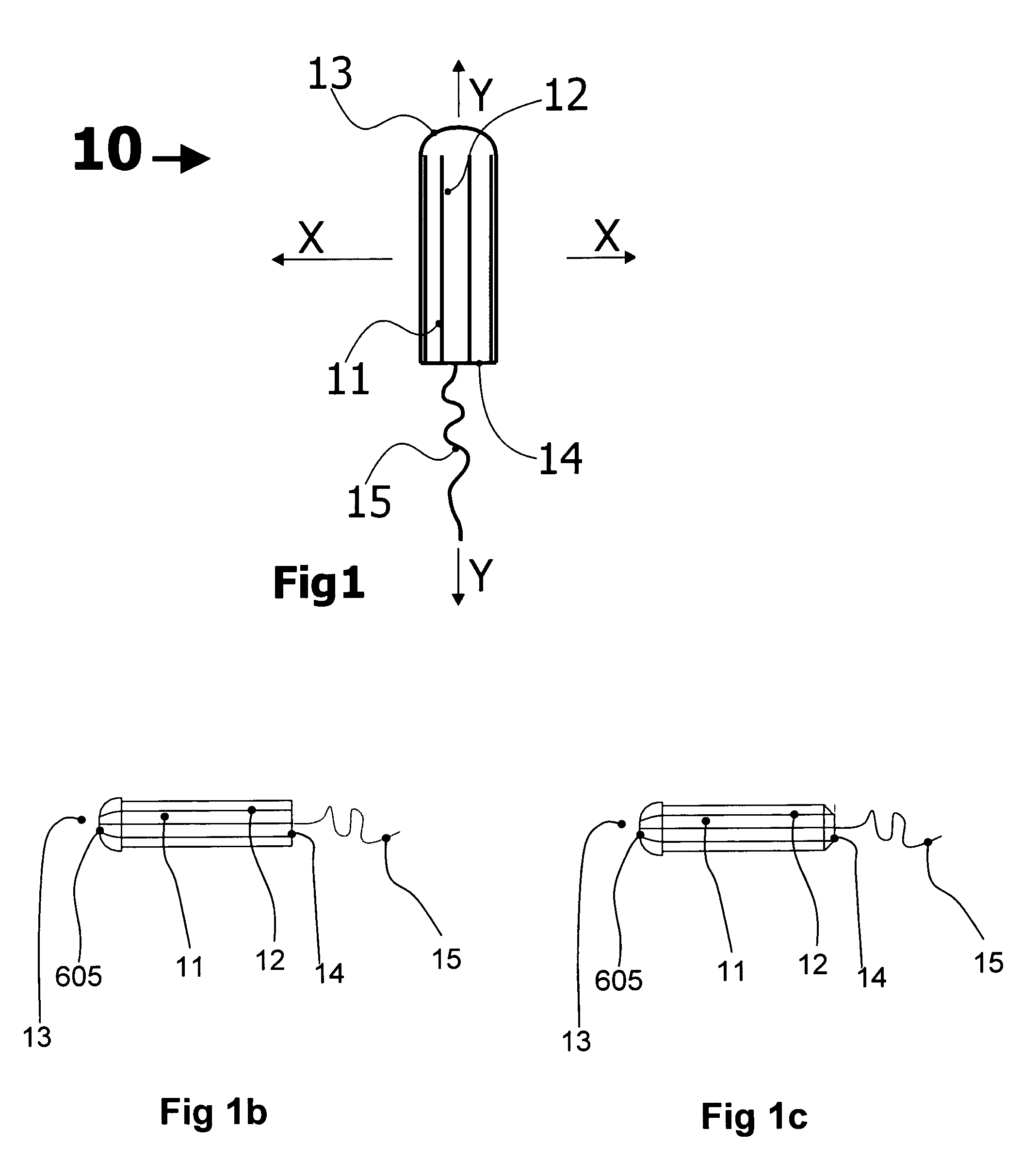

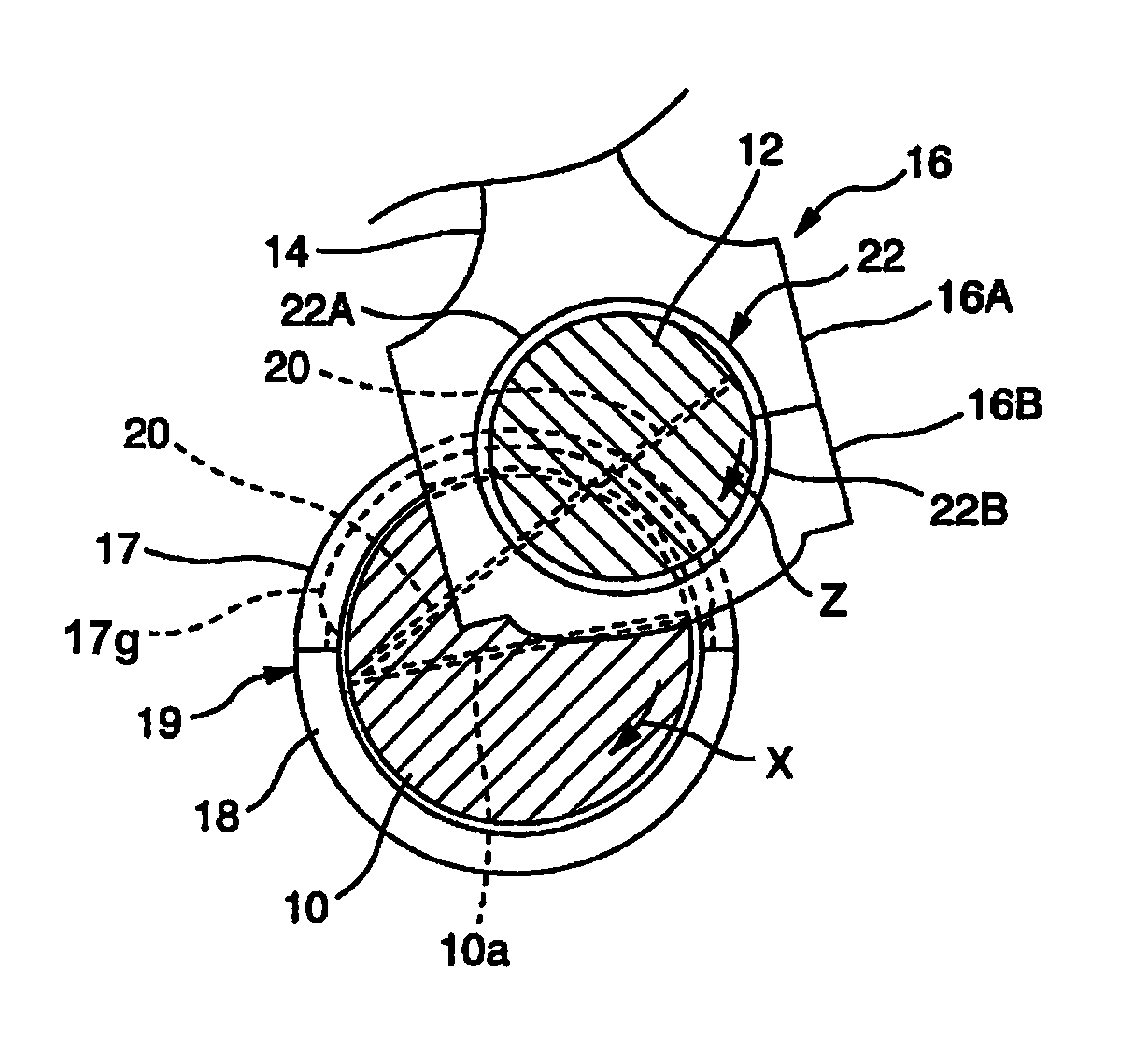

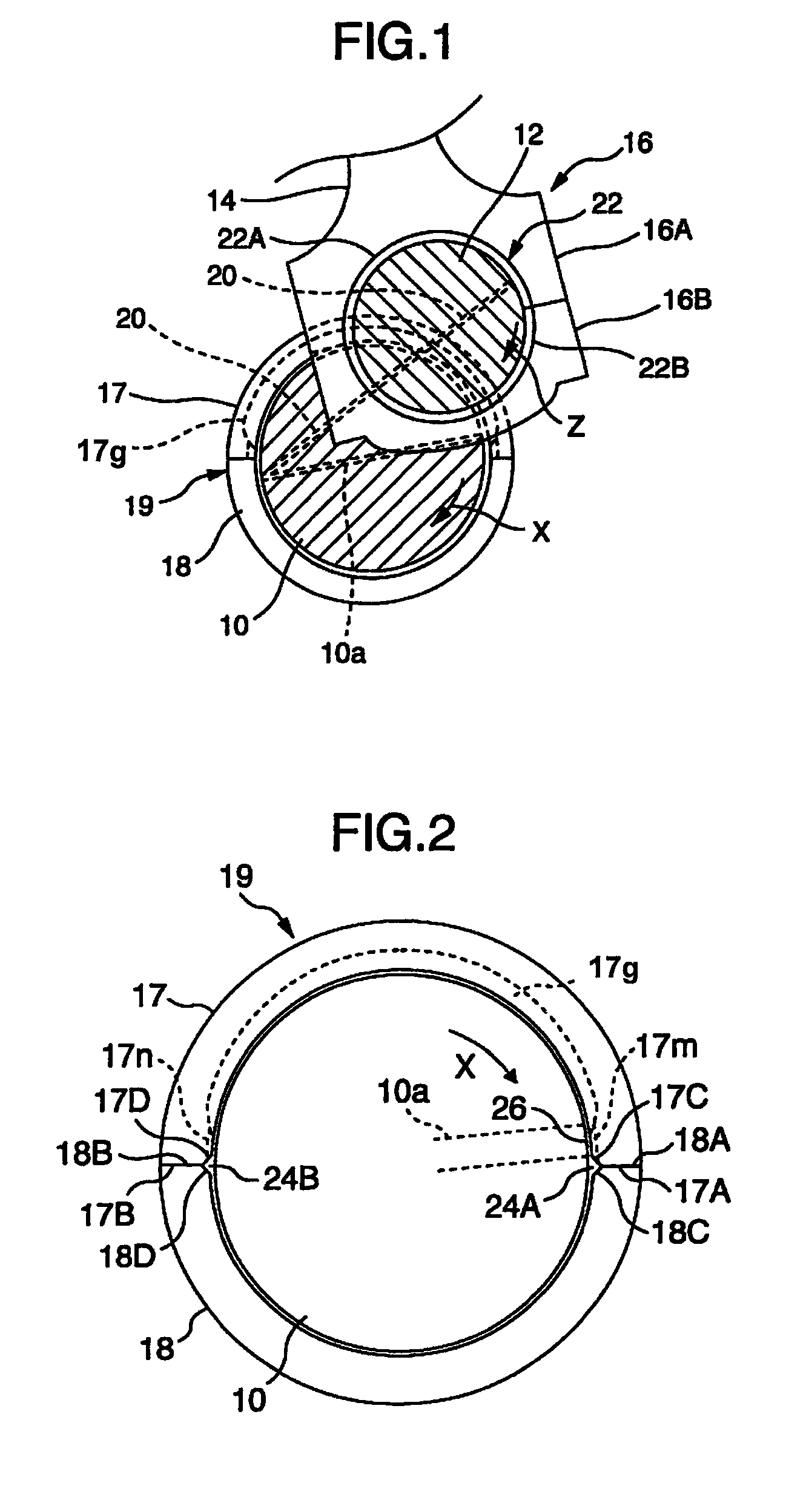

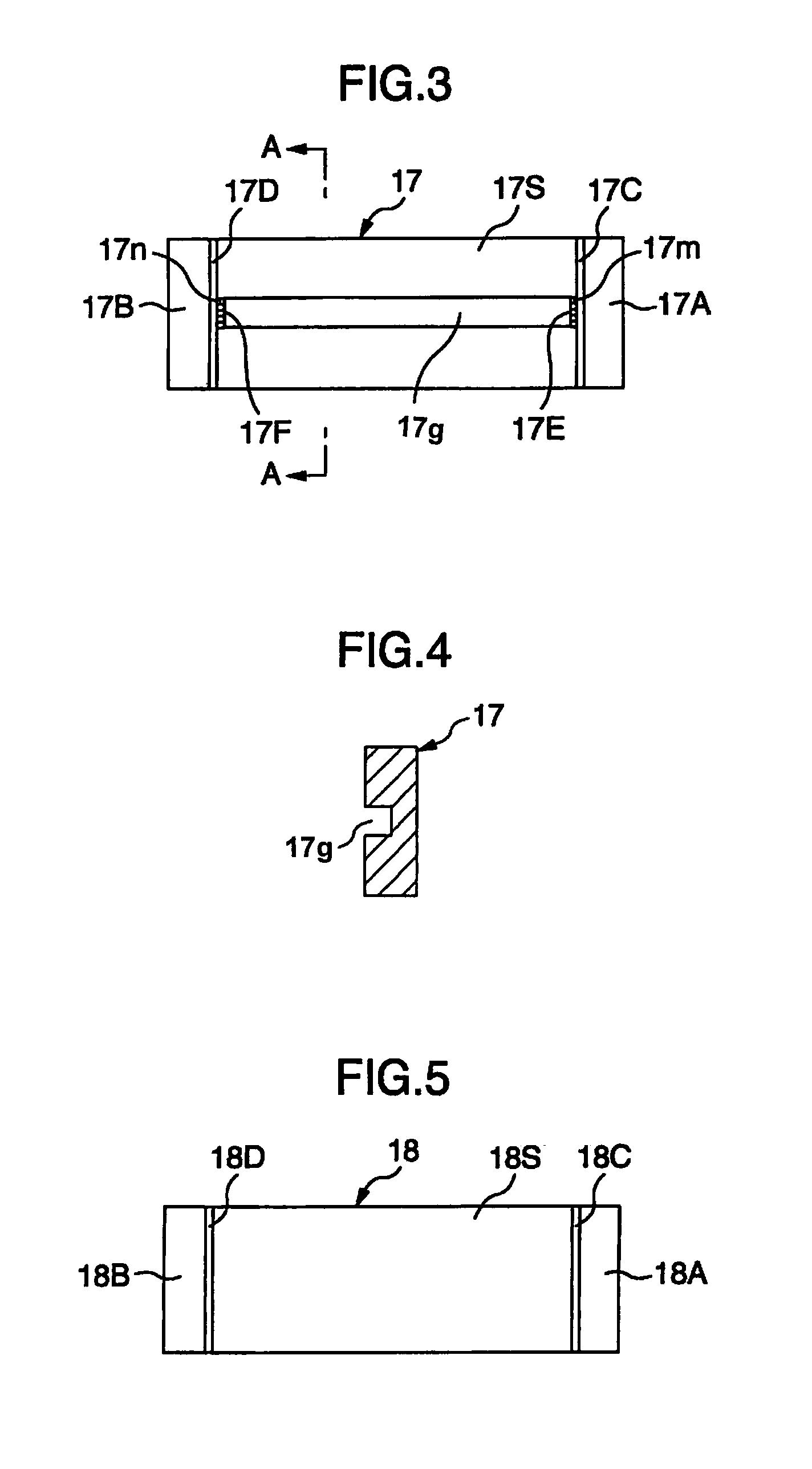

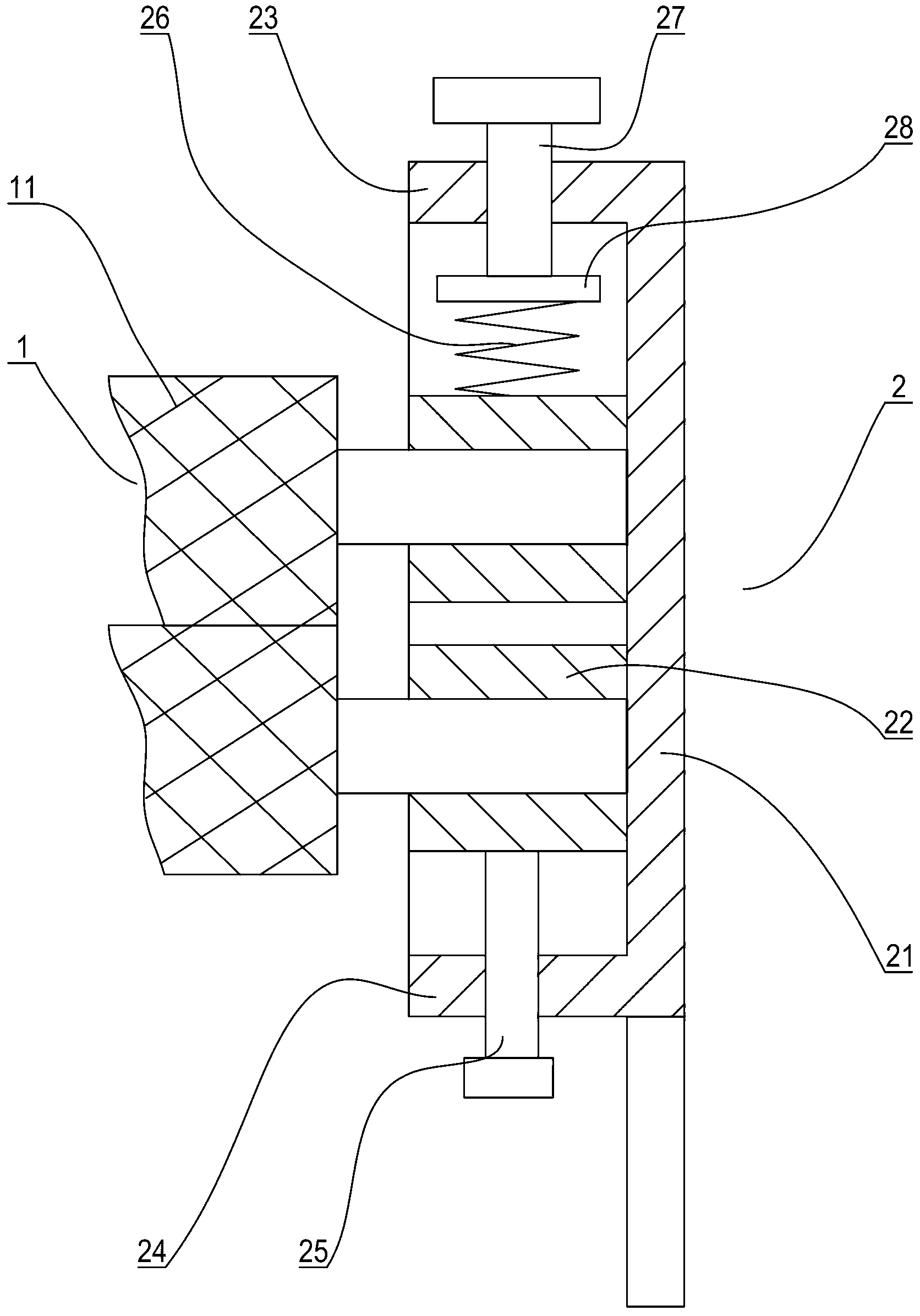

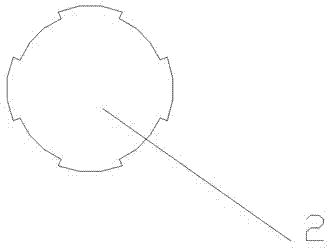

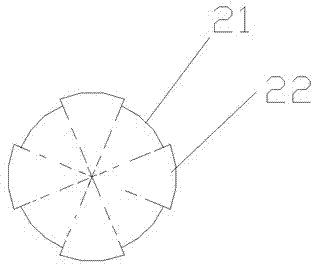

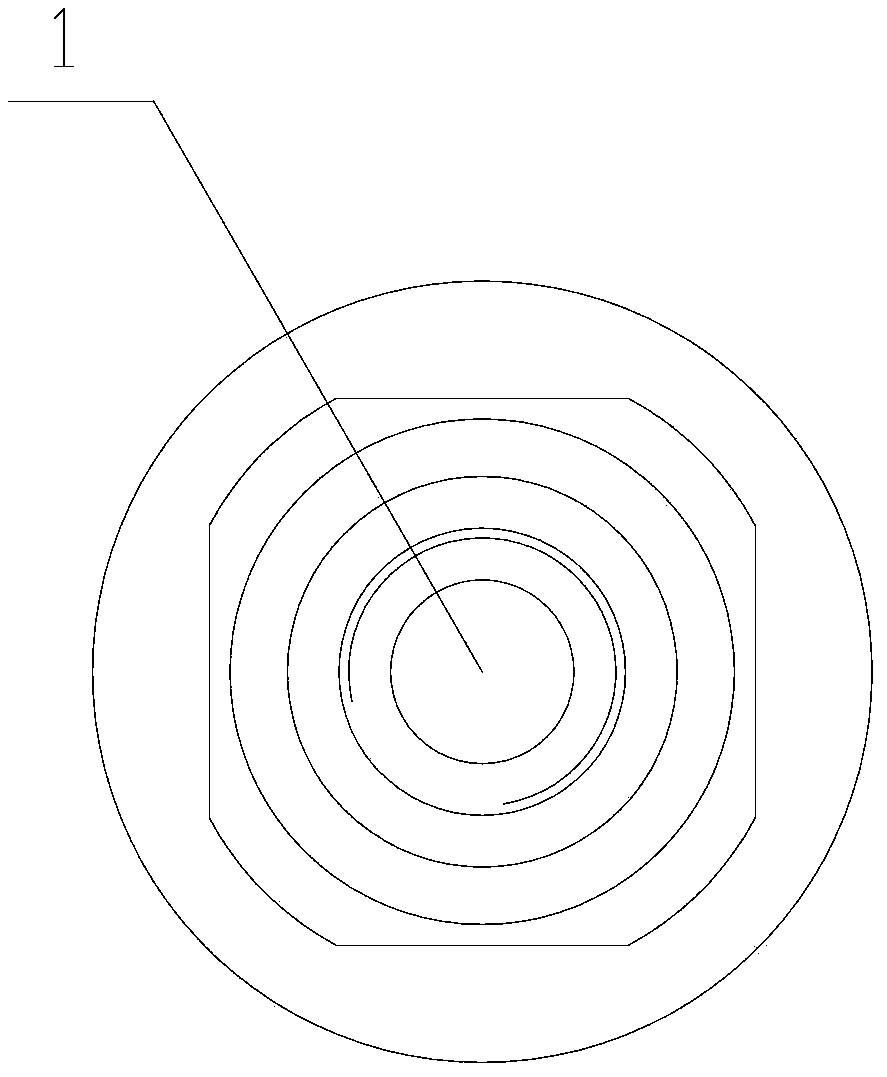

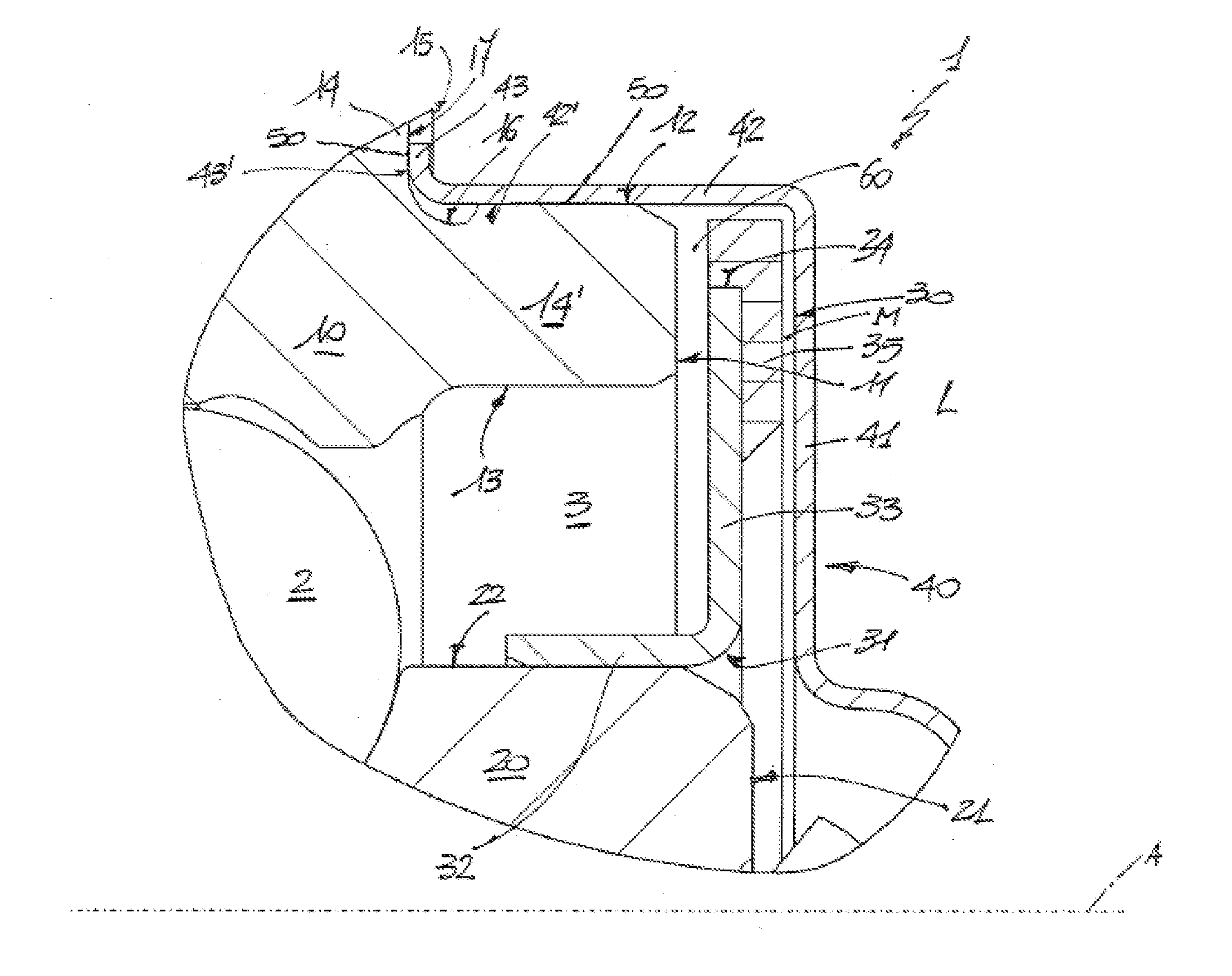

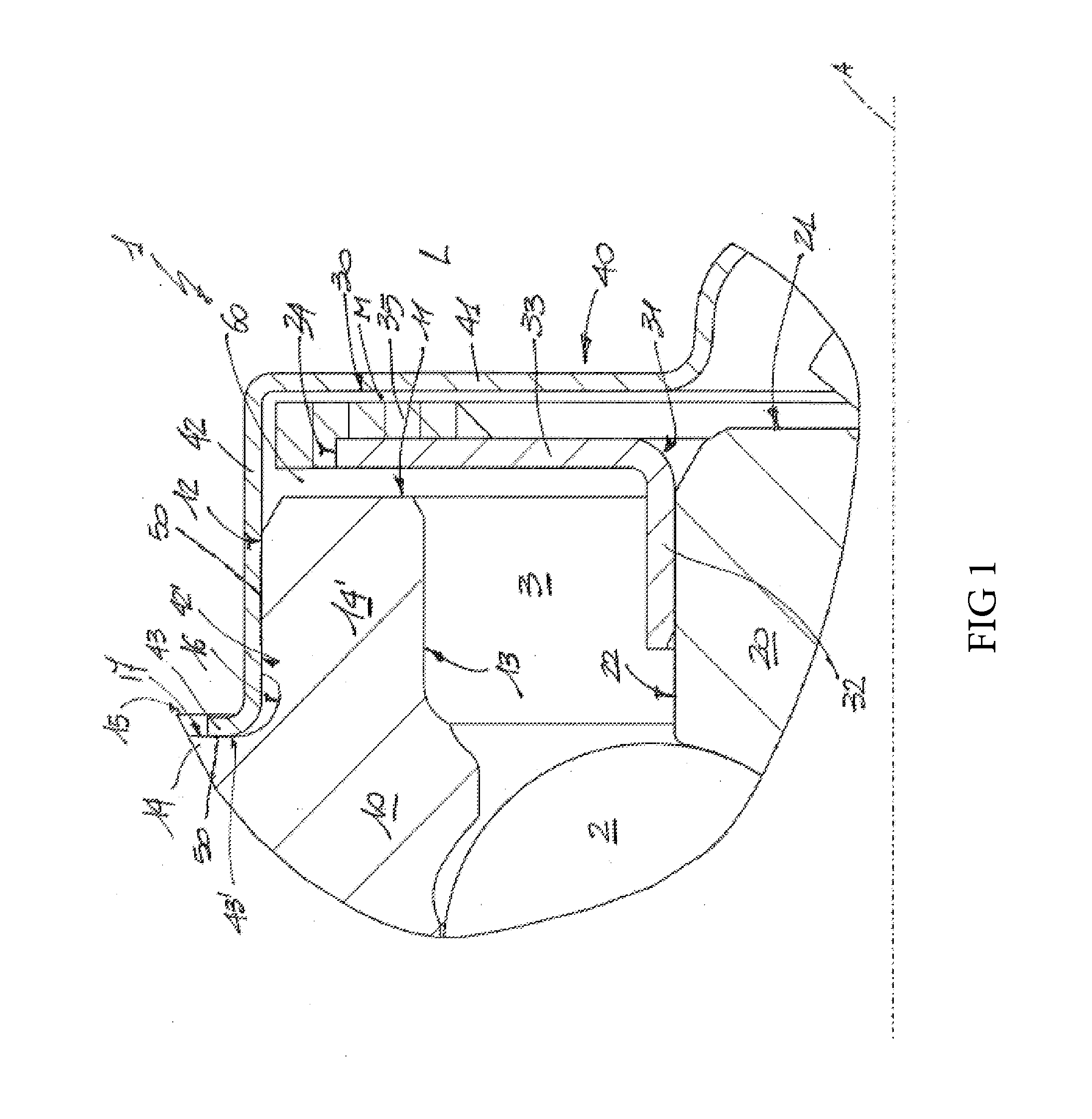

Tampon with ribs having a median diverging from the radius

The invention relates to a tampon, having essentially a cylindrical shape, which includes at least three ribs defined by grooves, characterized in that at least one rib or groove, in transverse cross-section, has a median at least partially diverging from the radius and to a process for manufacturing a tampon. The invention further relates to a press for manufacturing a tampon by pressing the absorbing material radially, with press jaws including penetrating segments for penetrating the absorbing material and pressing shoulders, characterized in that the median of at least one penetrating segment diverges from the radius of that penetrating segment.

Owner:ONTEX HIGIENEARTIKEL DEUT GMBH

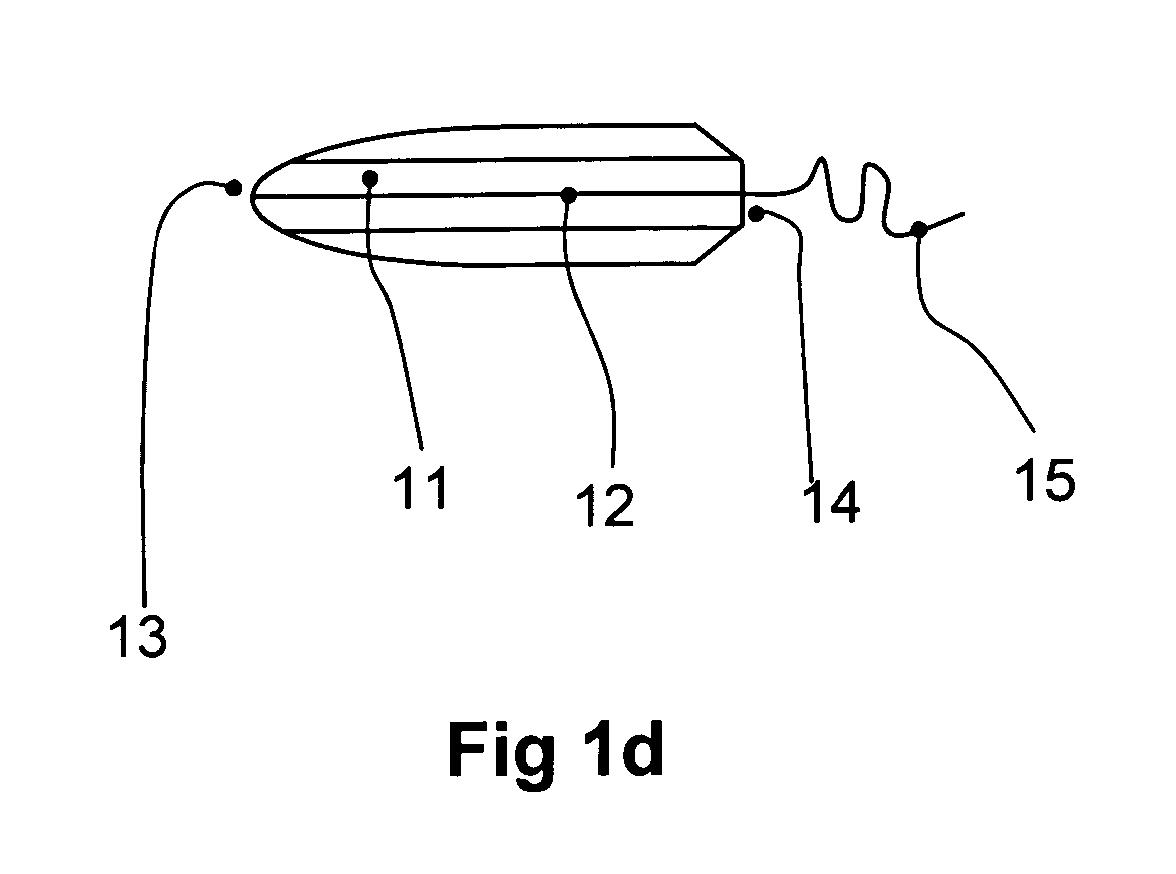

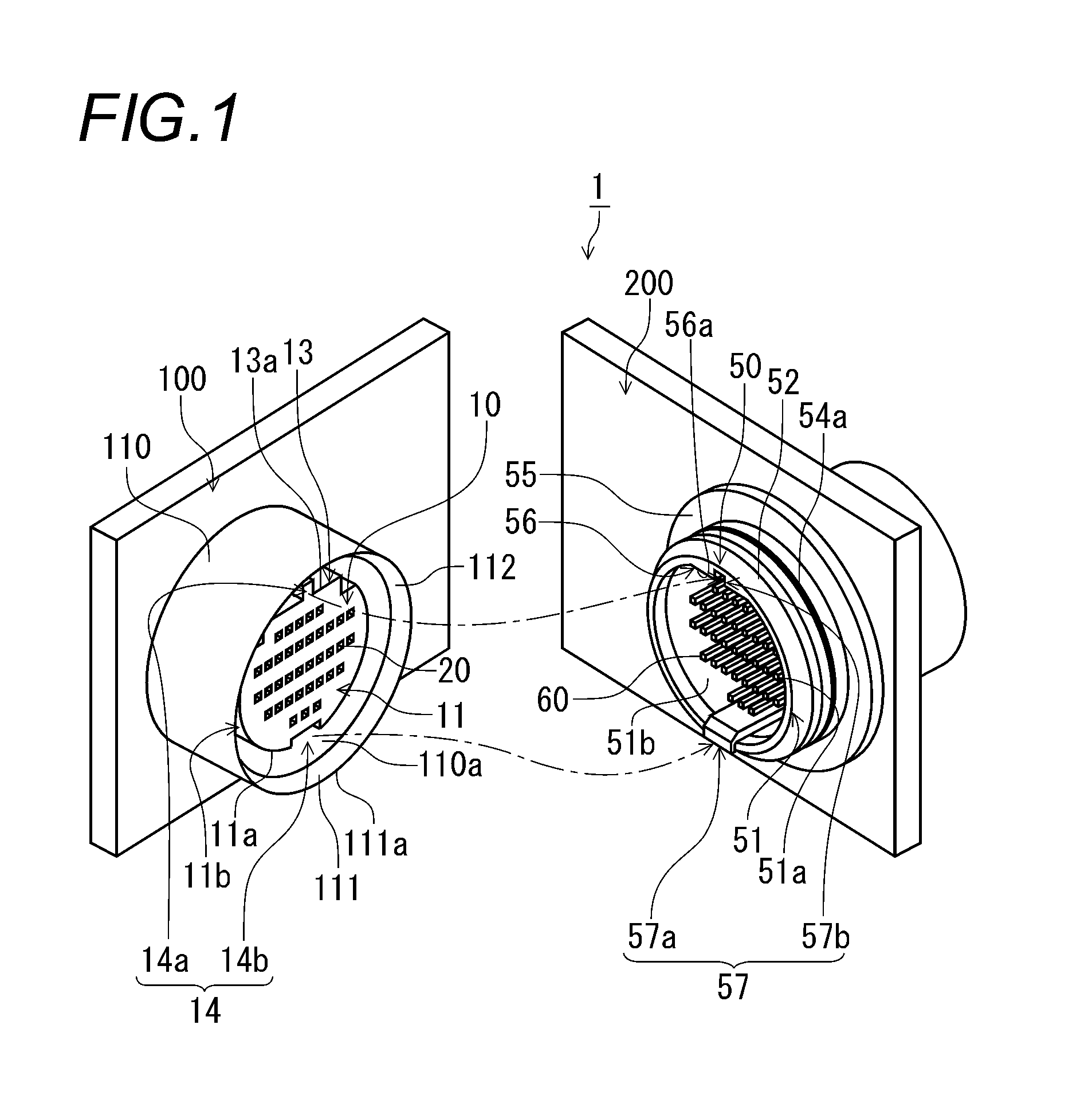

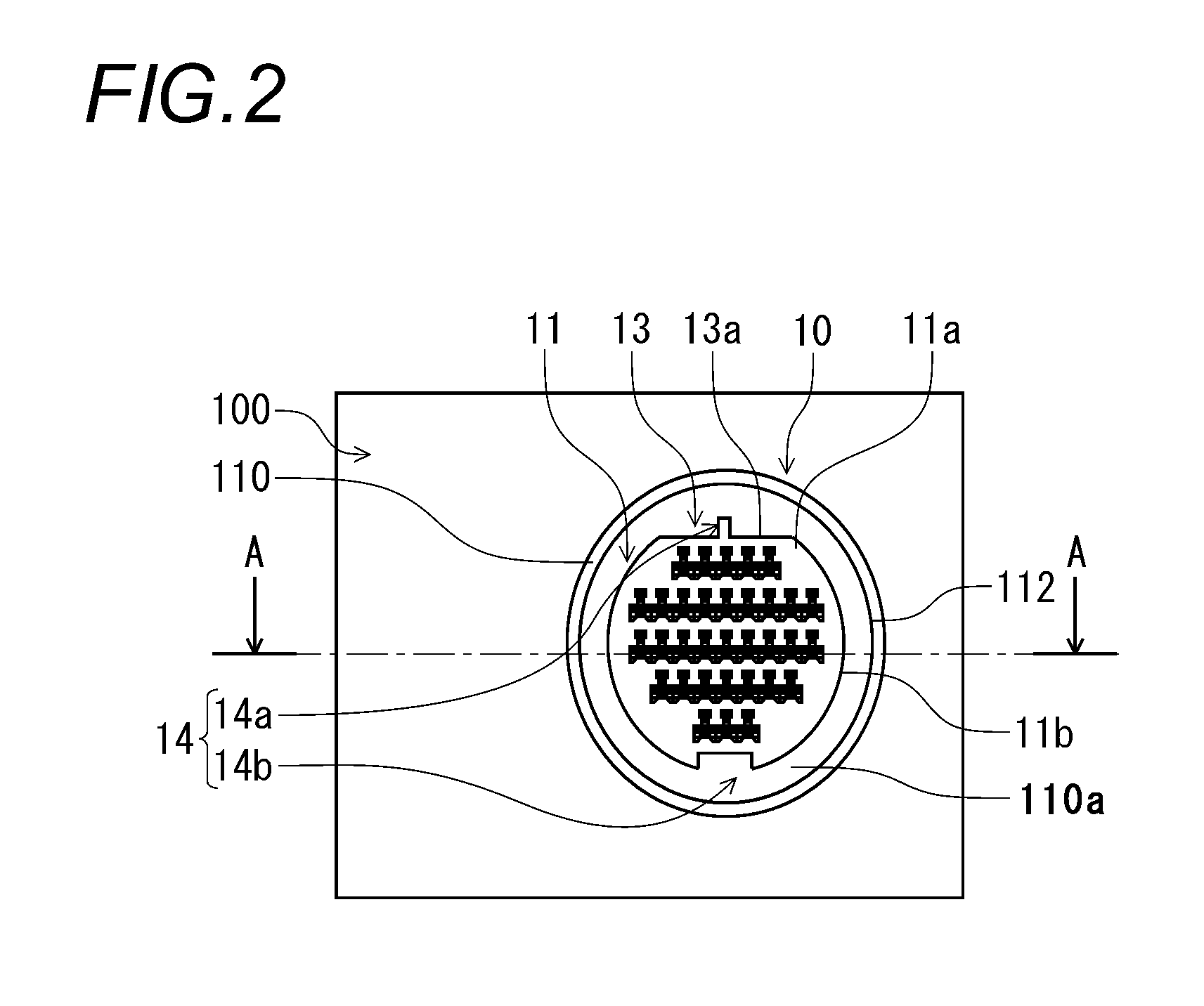

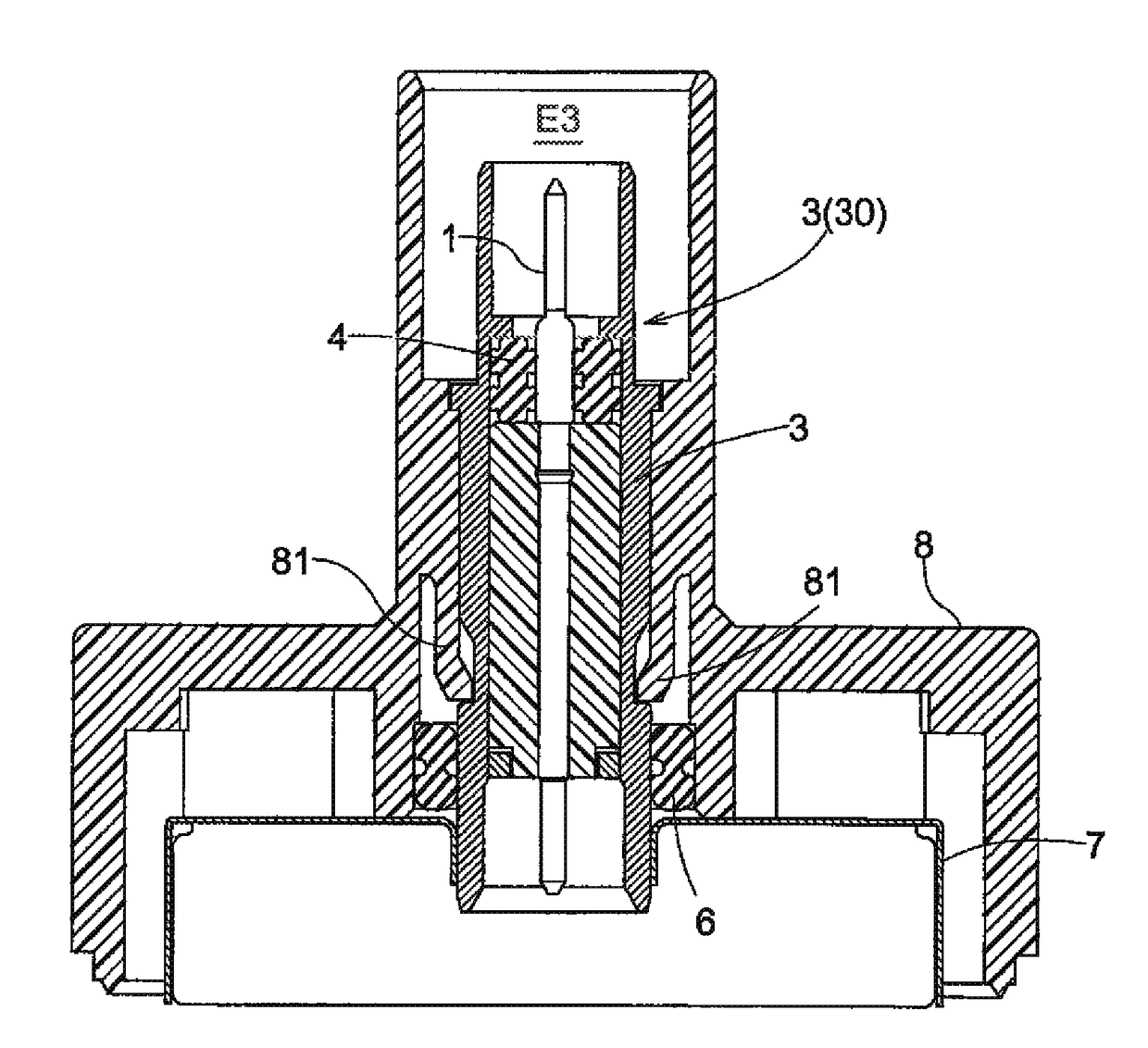

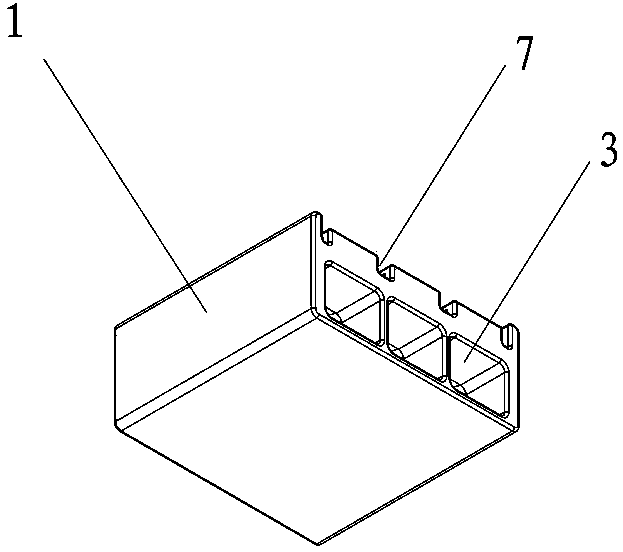

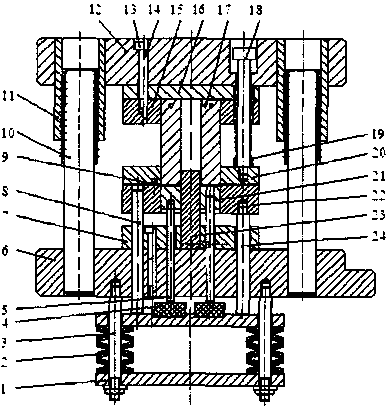

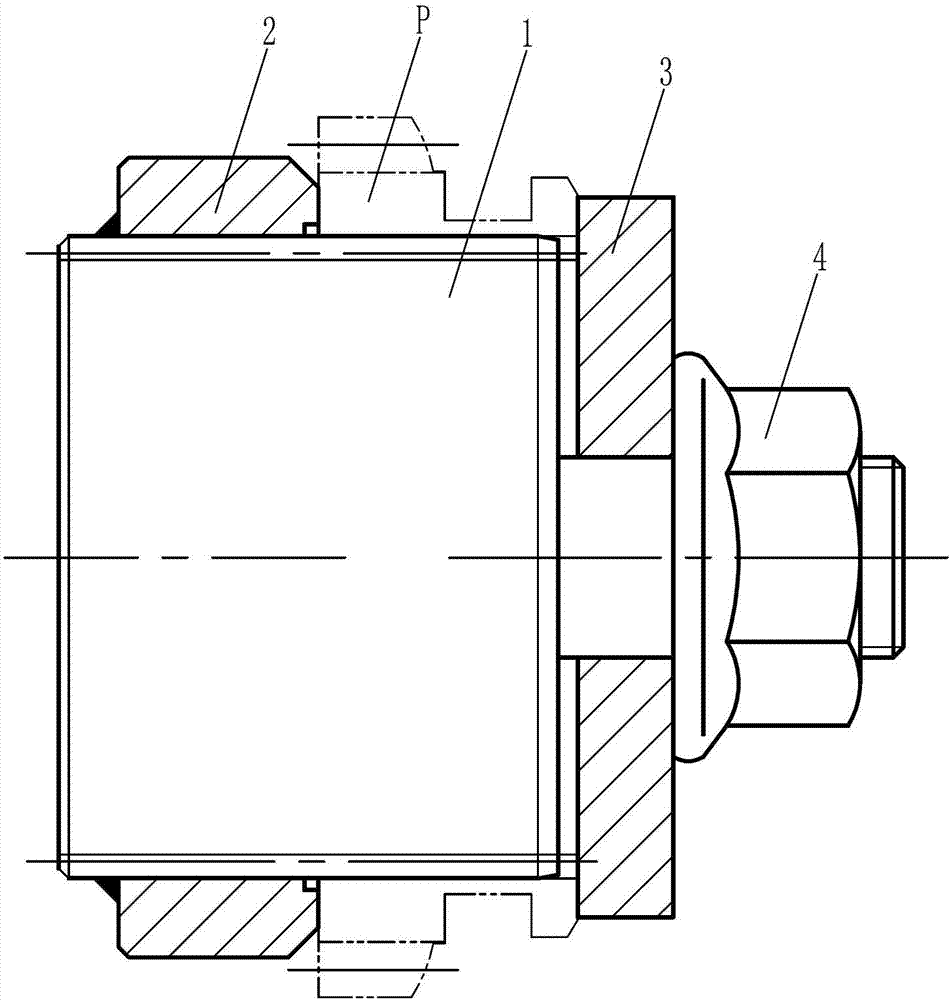

Connector Unit

ActiveUS20140335739A1Avoid damagePrevent rotationIncorrect coupling preventionMechanical engineeringTerete

Owner:YAZAKI CORP

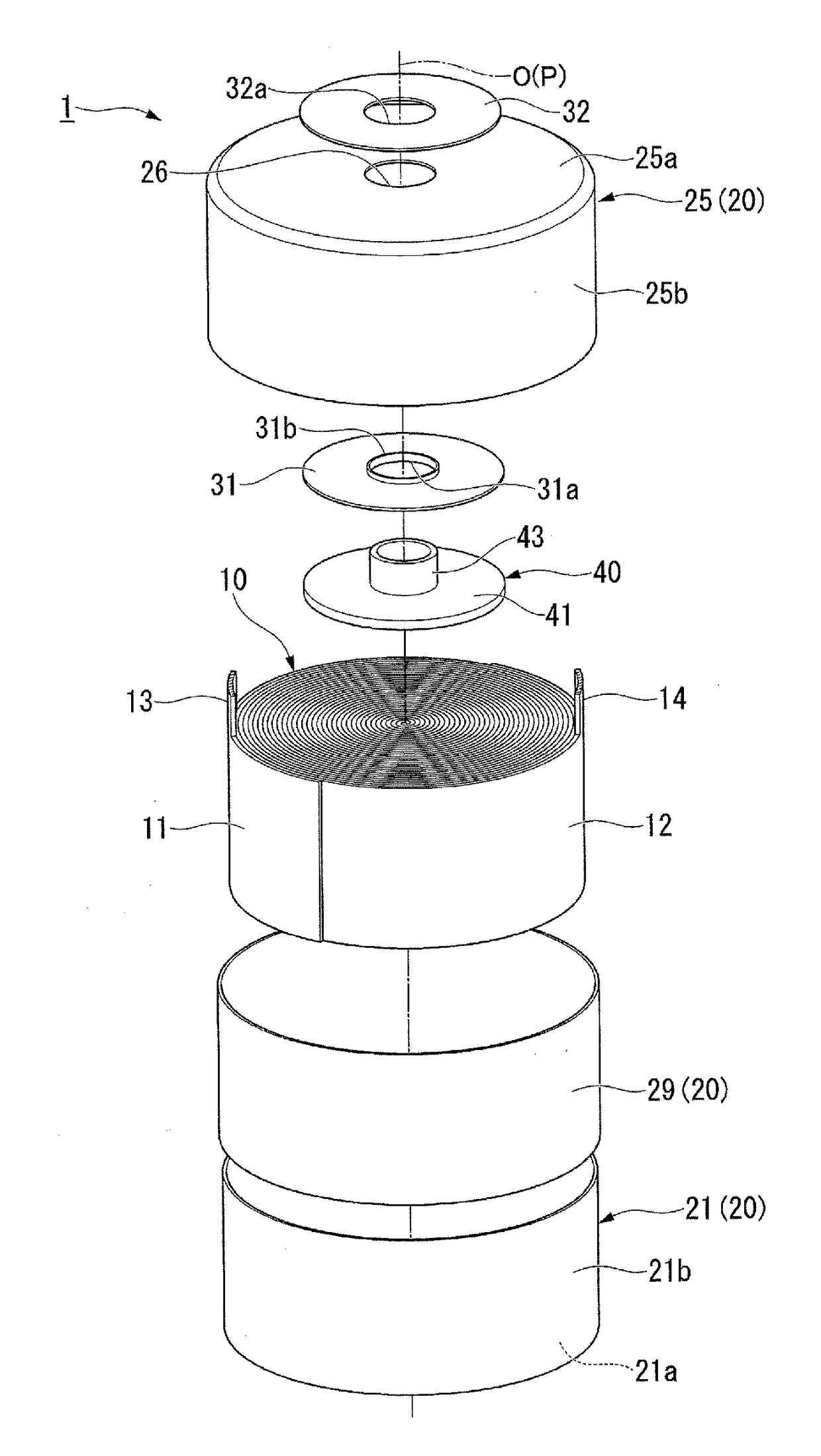

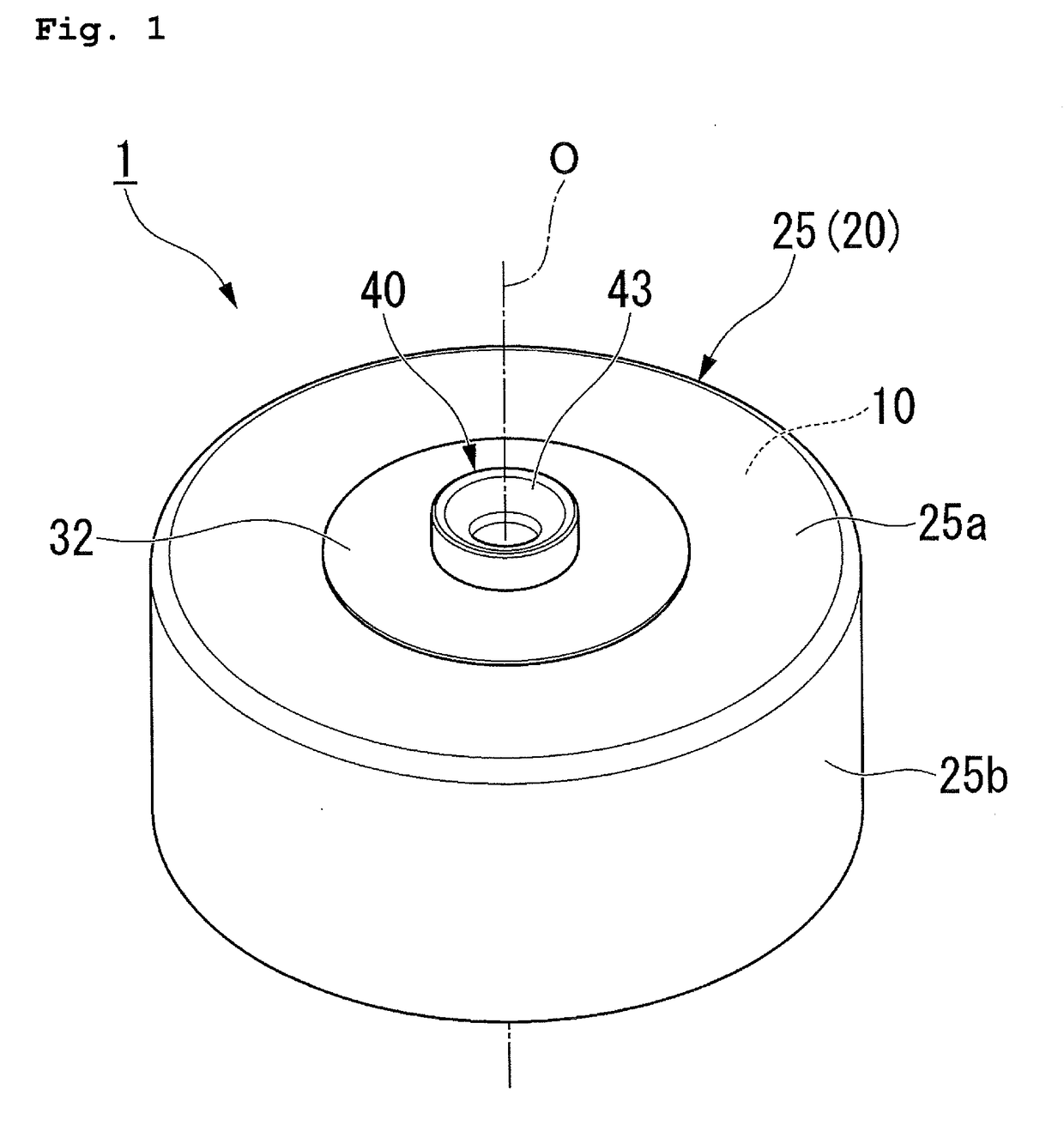

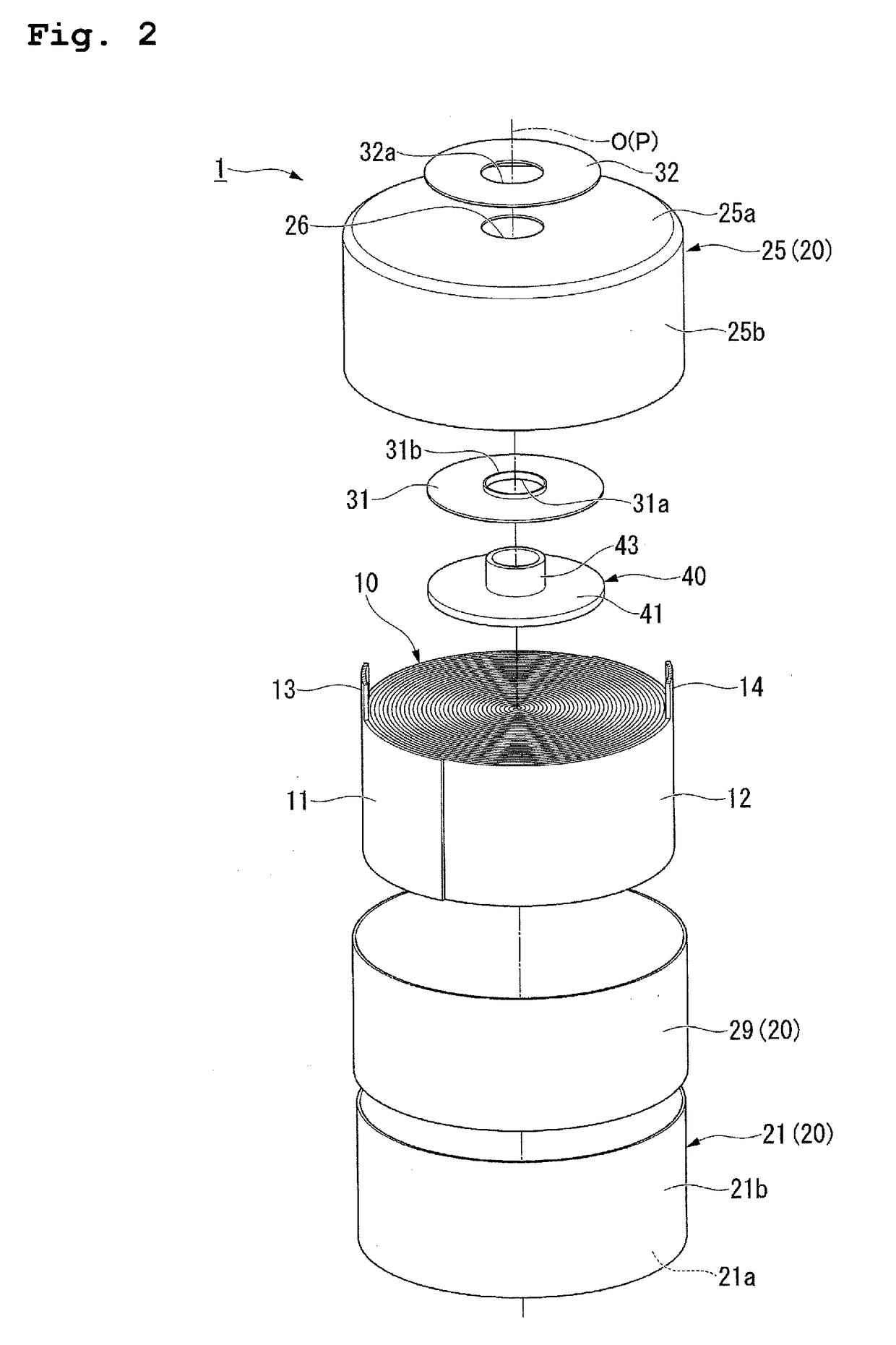

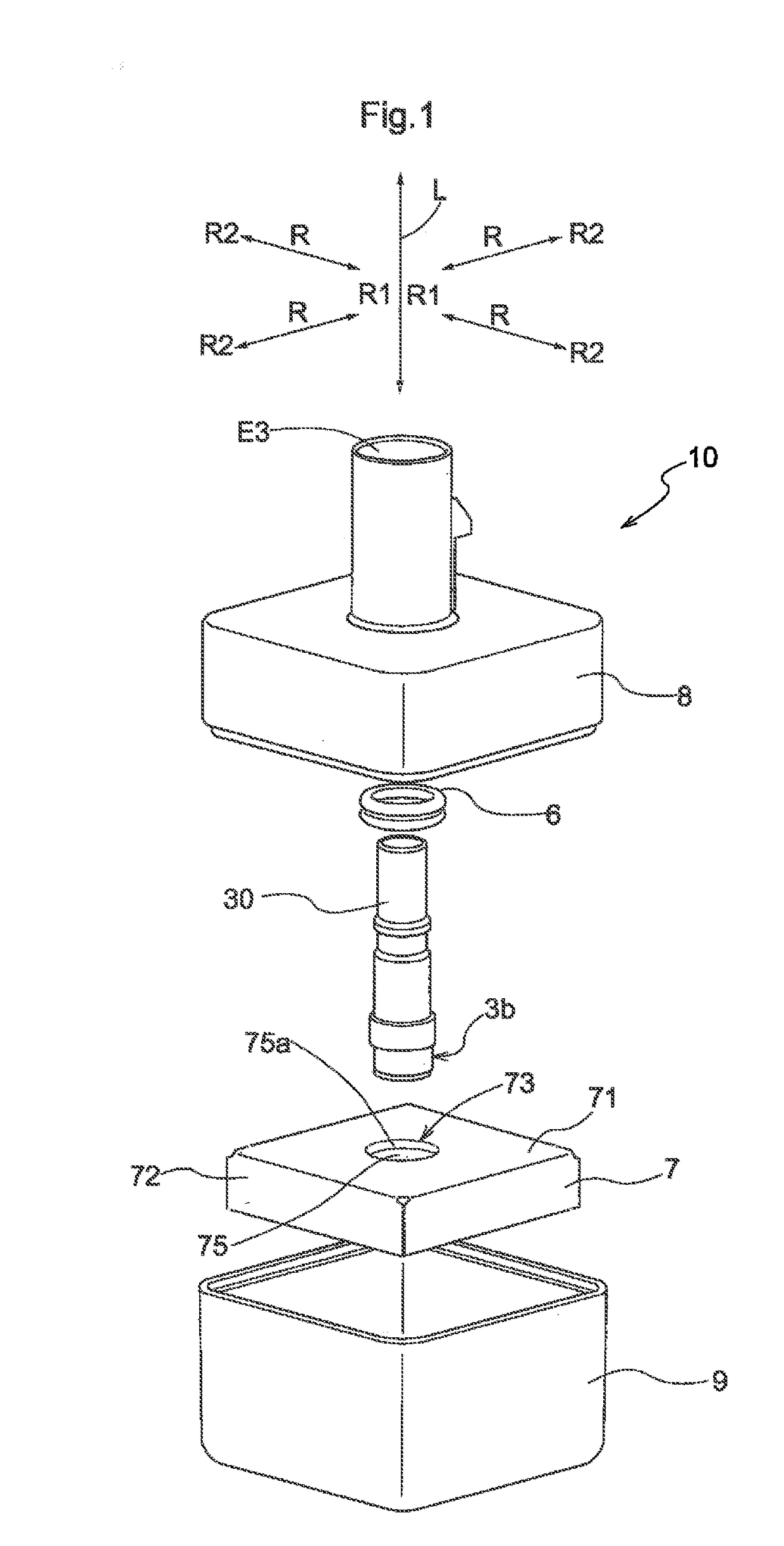

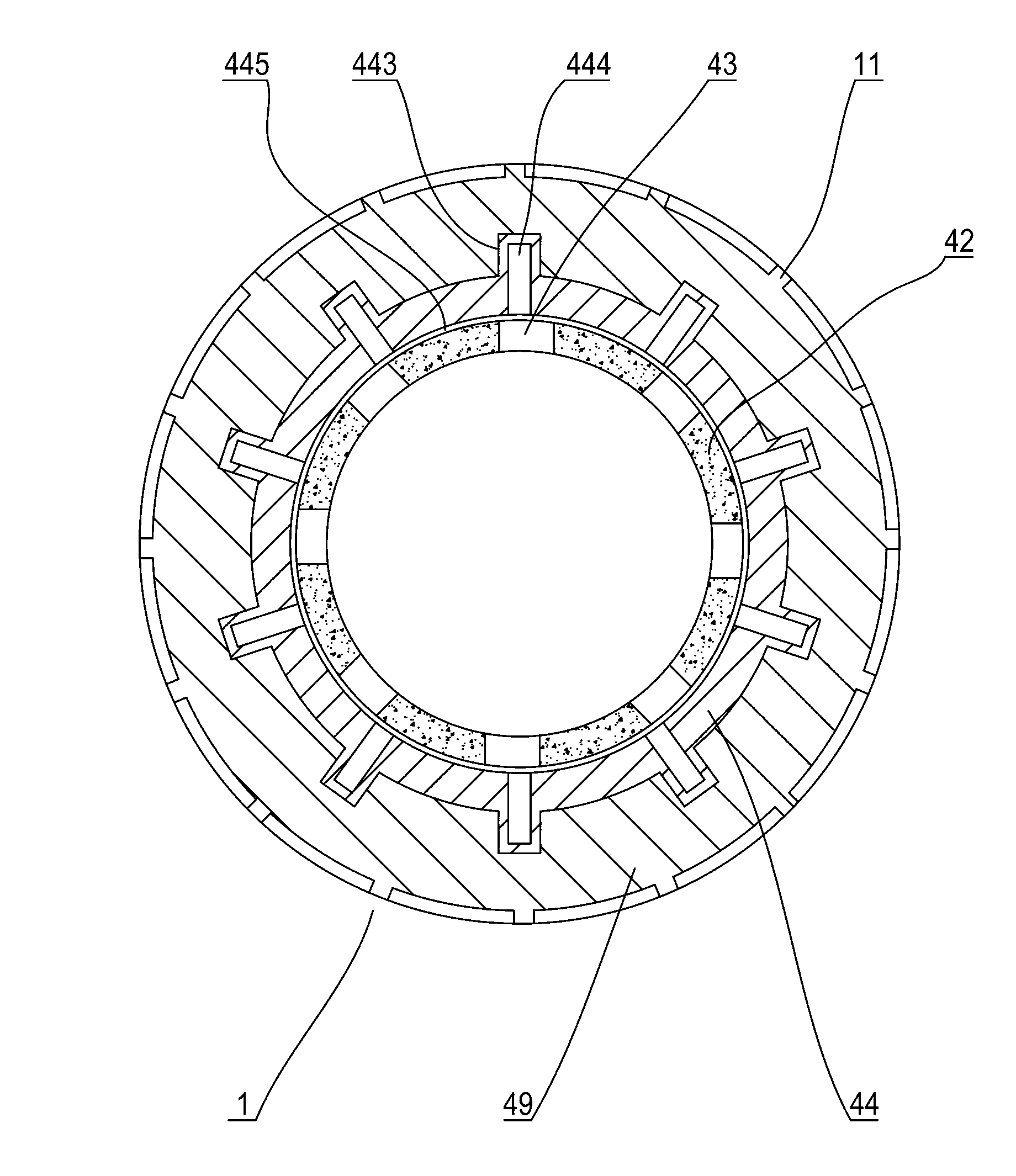

Electrochemical cell

ActiveUS20170207491A1Easy to optimizeAvoid structureProtecting/adjusting hybrid/EDL capacitorElectrolytic capacitorsEngineeringElectrochemical cell

A battery includes an electrode body including a positive electrode body and a negative electrode body and an exterior body in which the electrode body is housed. The exterior body includes a first container formed in a bottomed cylindrical shape and including a first circumferential wall section, a second container formed in a bottomed cylindrical shape and including a second circumferential wall section surrounding the first circumferential wall section, the second container housing the electrode body between the second container and the first container, and a fusing member interposed between the first circumferential wall section and the second circumferential wall section and fused to the first circumferential wall section and the second circumferential wall section.

Owner:SEIKO INSTR INC

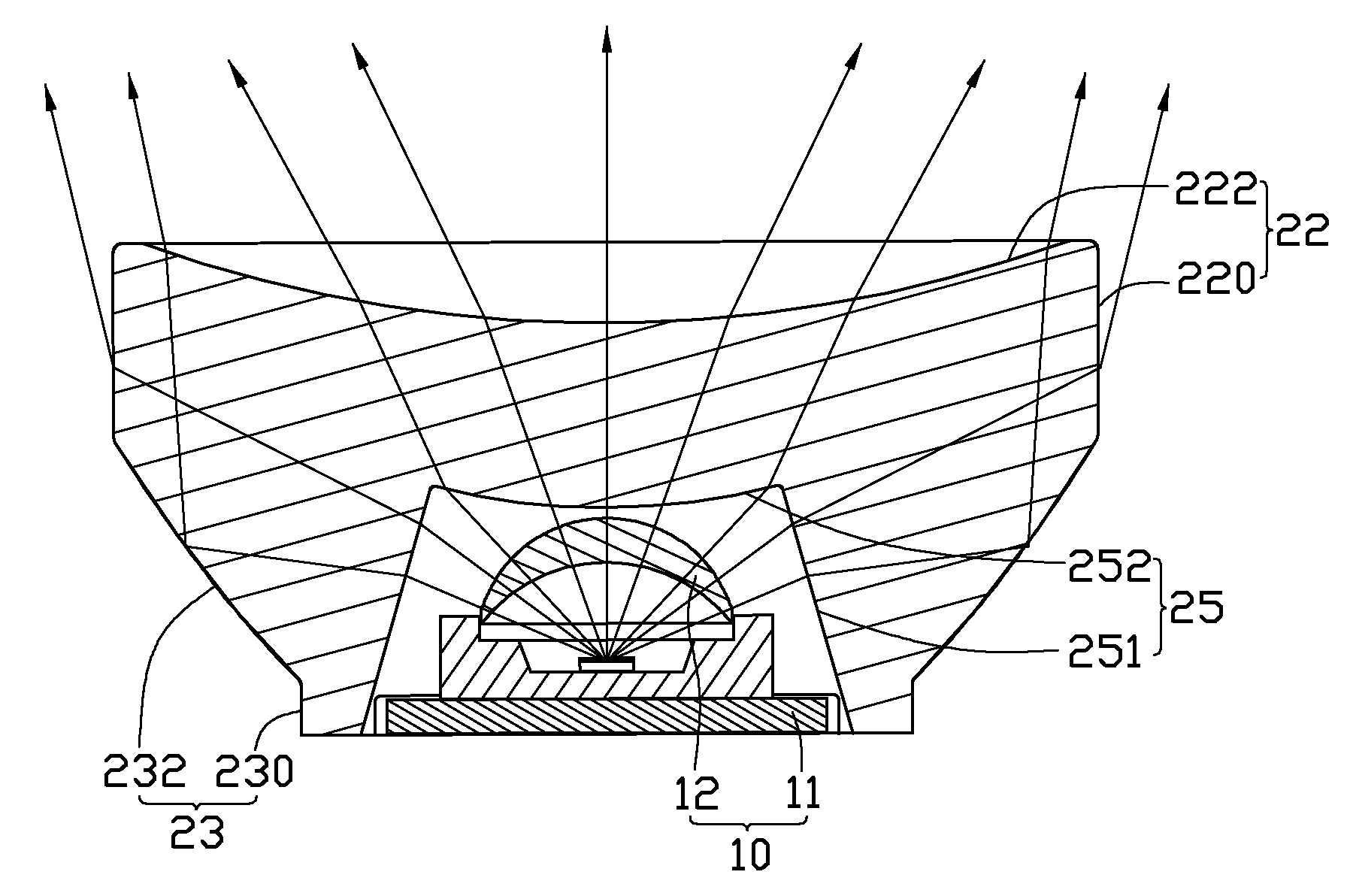

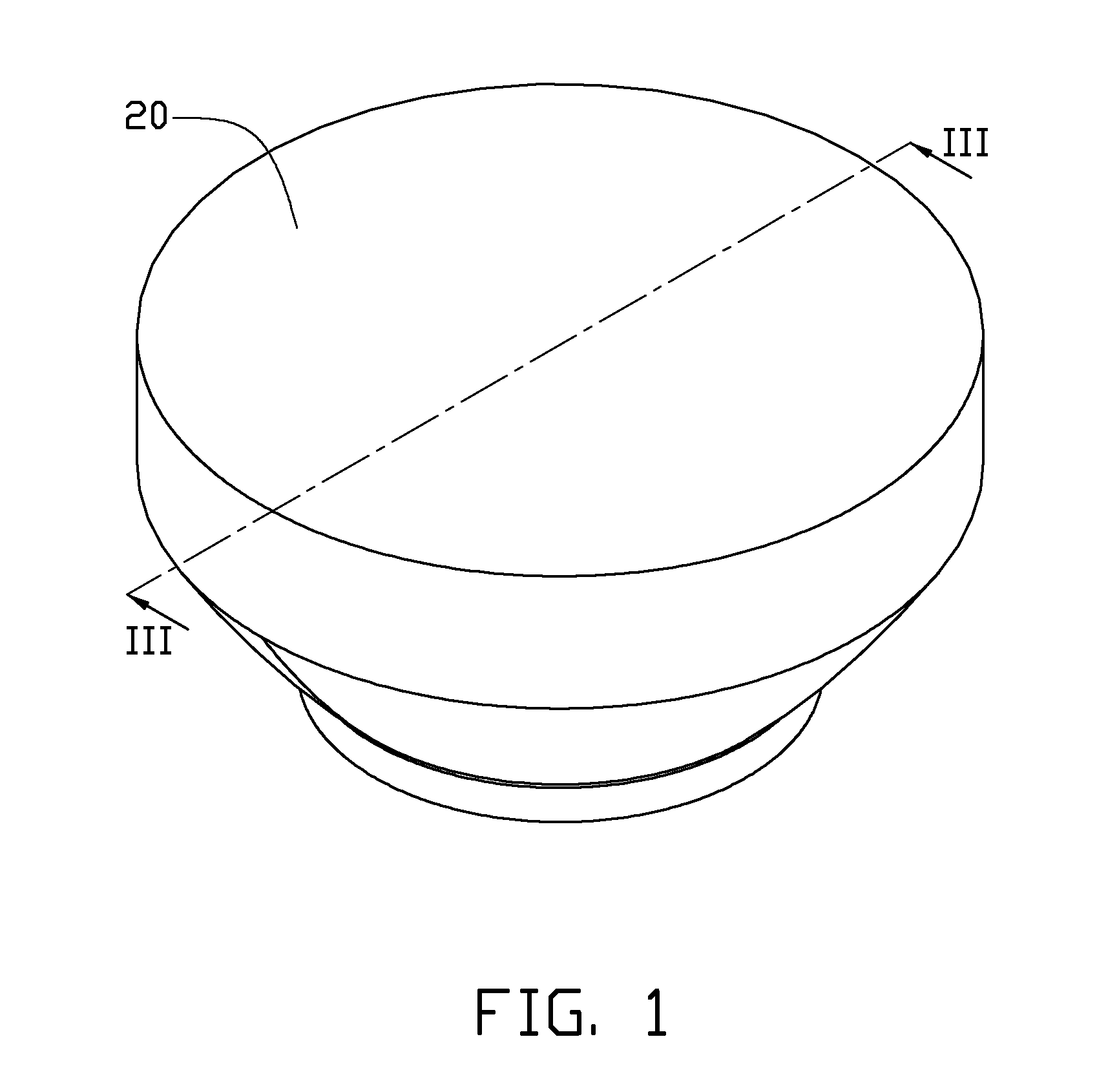

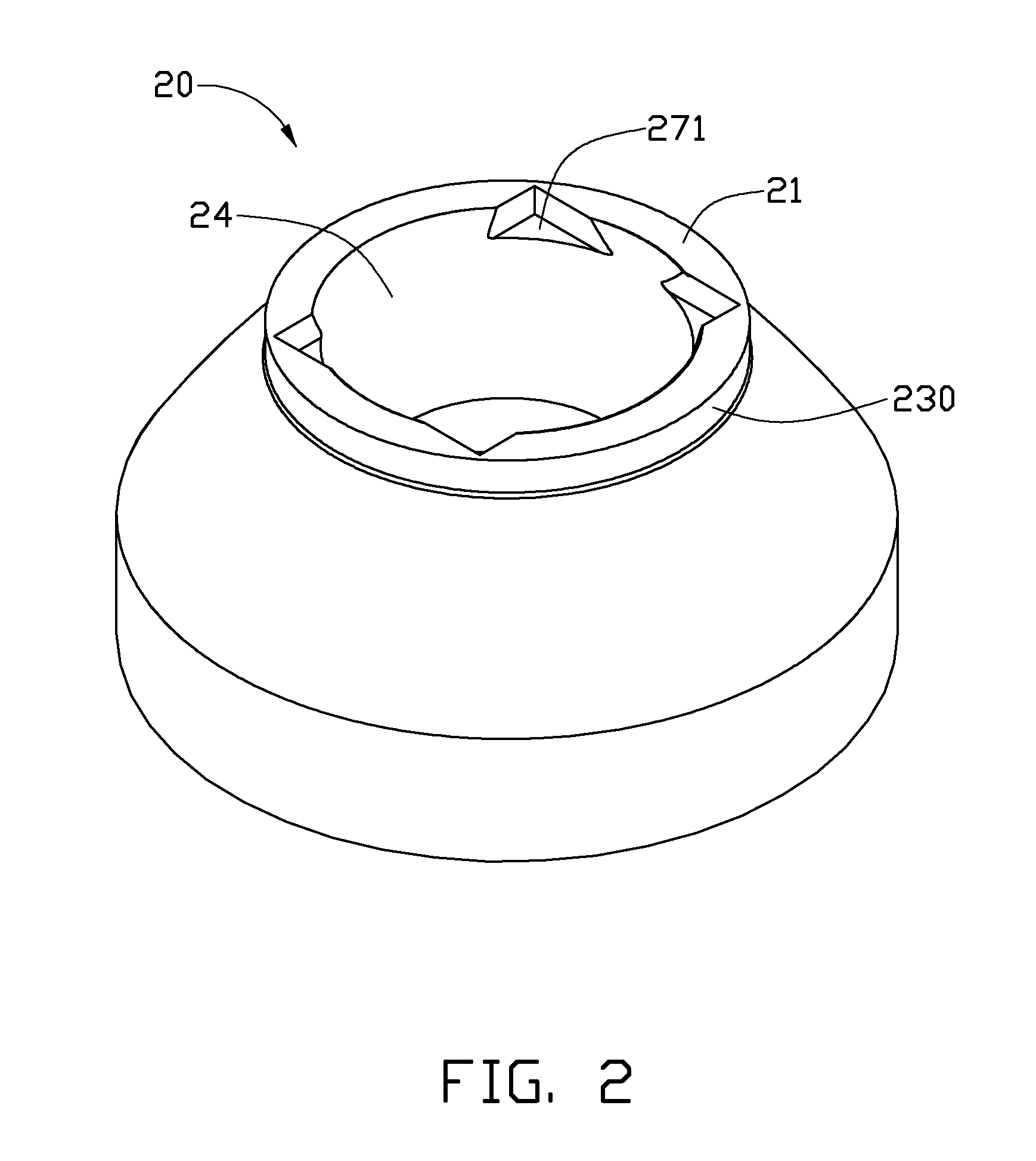

LED module

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Main bearing for crankshaft of internal combustion engine

ActiveUS8905639B2Reduce leakageSolution to short lifeCrankshaftsCrankshaft bearingsExternal combustion engineInternal combustion engine

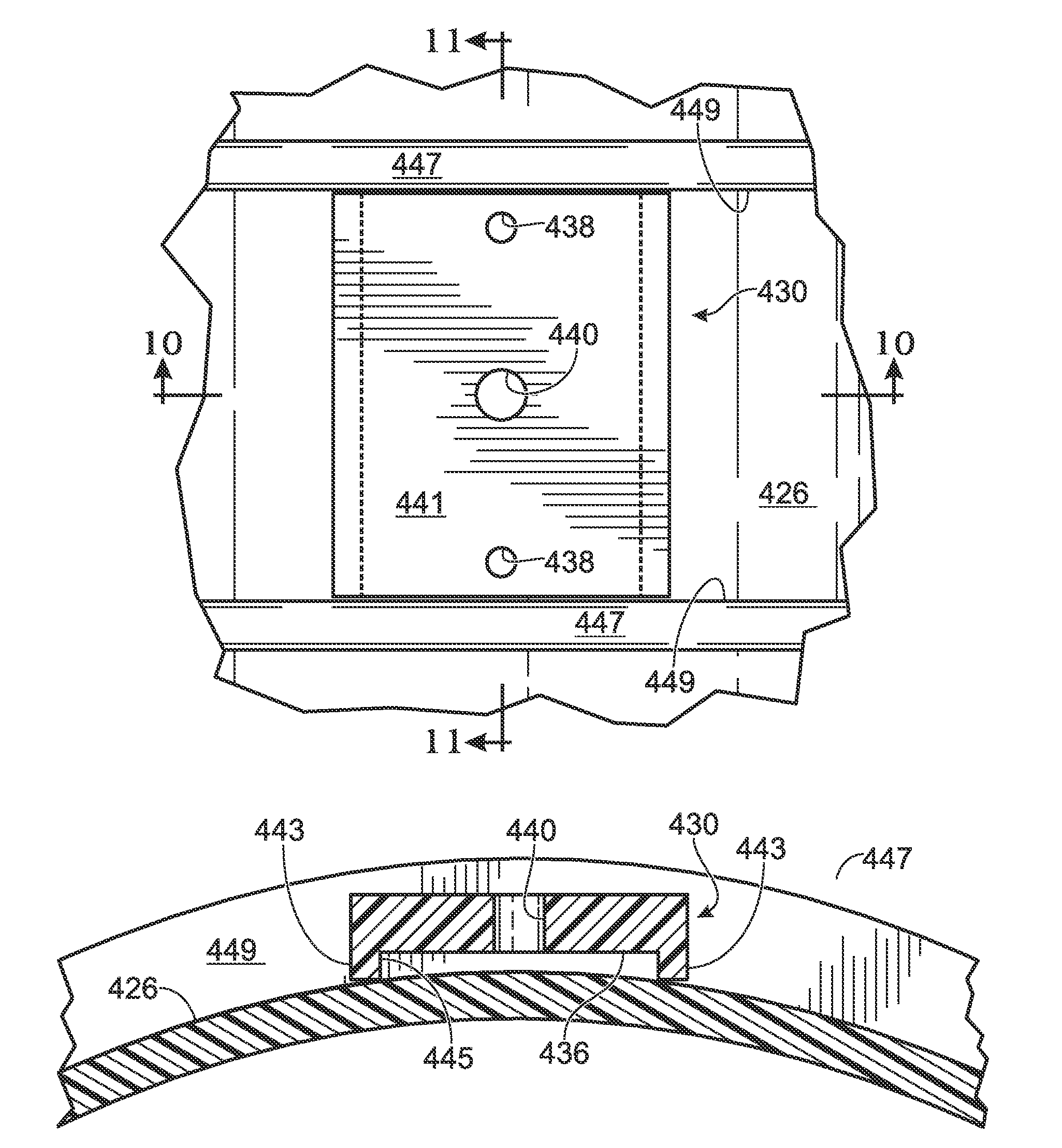

A main bearing for a crankshaft of an internal combustion engine is composed of a pair of semi-cylindrical bearings. An oil groove extending in a circumferential direction is formed on an inner circumferential surface of one semi-cylindrical bearing. The oil groove has the depth gradually decreasing toward a circumferential end surface of the one semi-cylindrical bearing, and defines a circumferential end portion on the circumferential surface without extending to an axial groove formed in a joint portion of the pair of semi-cylindrical bearings. An extension portion of the inner circumferential surface extends between the circumferential end portion and the axial groove, and a plurality of circumferential grooves extending in the circumferential direction is formed on the extension portion from the oil groove to the axial groove over an entire width of the circumferential end portion of the oil groove.

Owner:DAIDO METAL CO LTD

Connector module and vehicle-mounted camera using such module

ActiveUS20180006407A1Improve shielding effectIncrease manufacturing costEngagement/disengagement of coupling partsTelevision system detailsElectrical conductorComputer module

Owner:HOSIDEN CORP

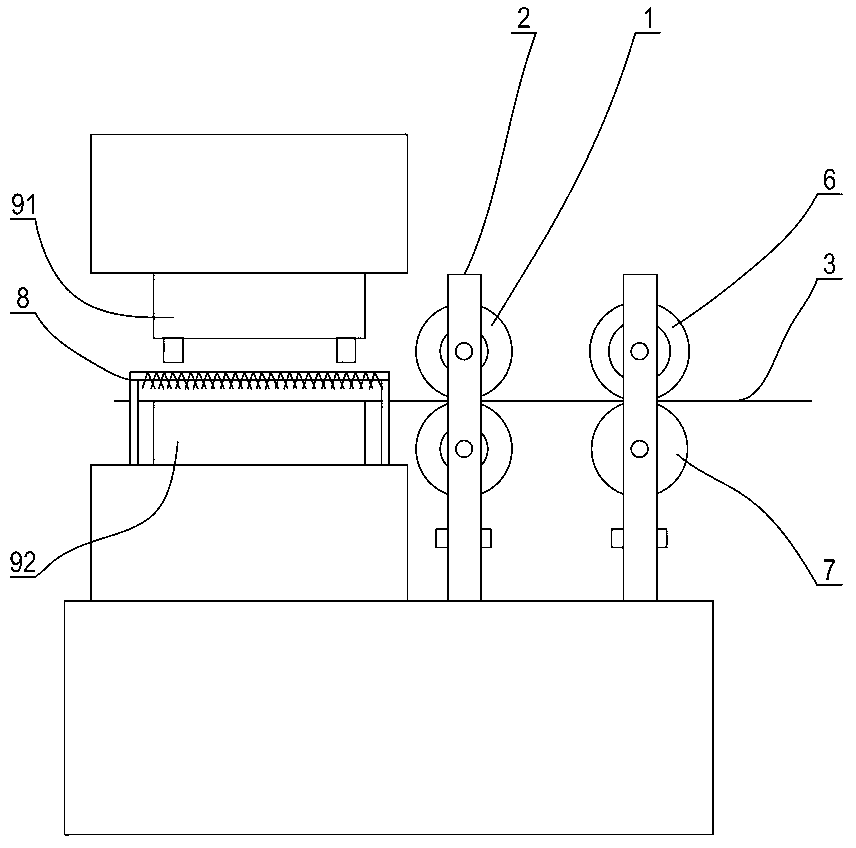

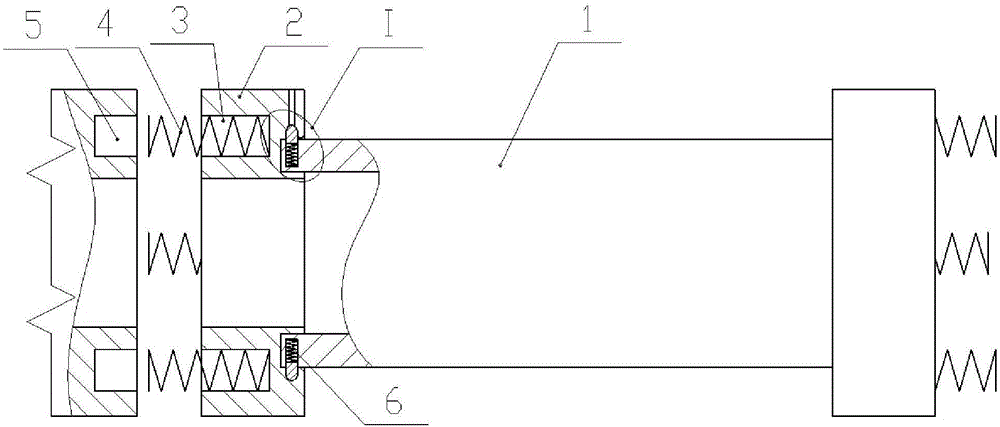

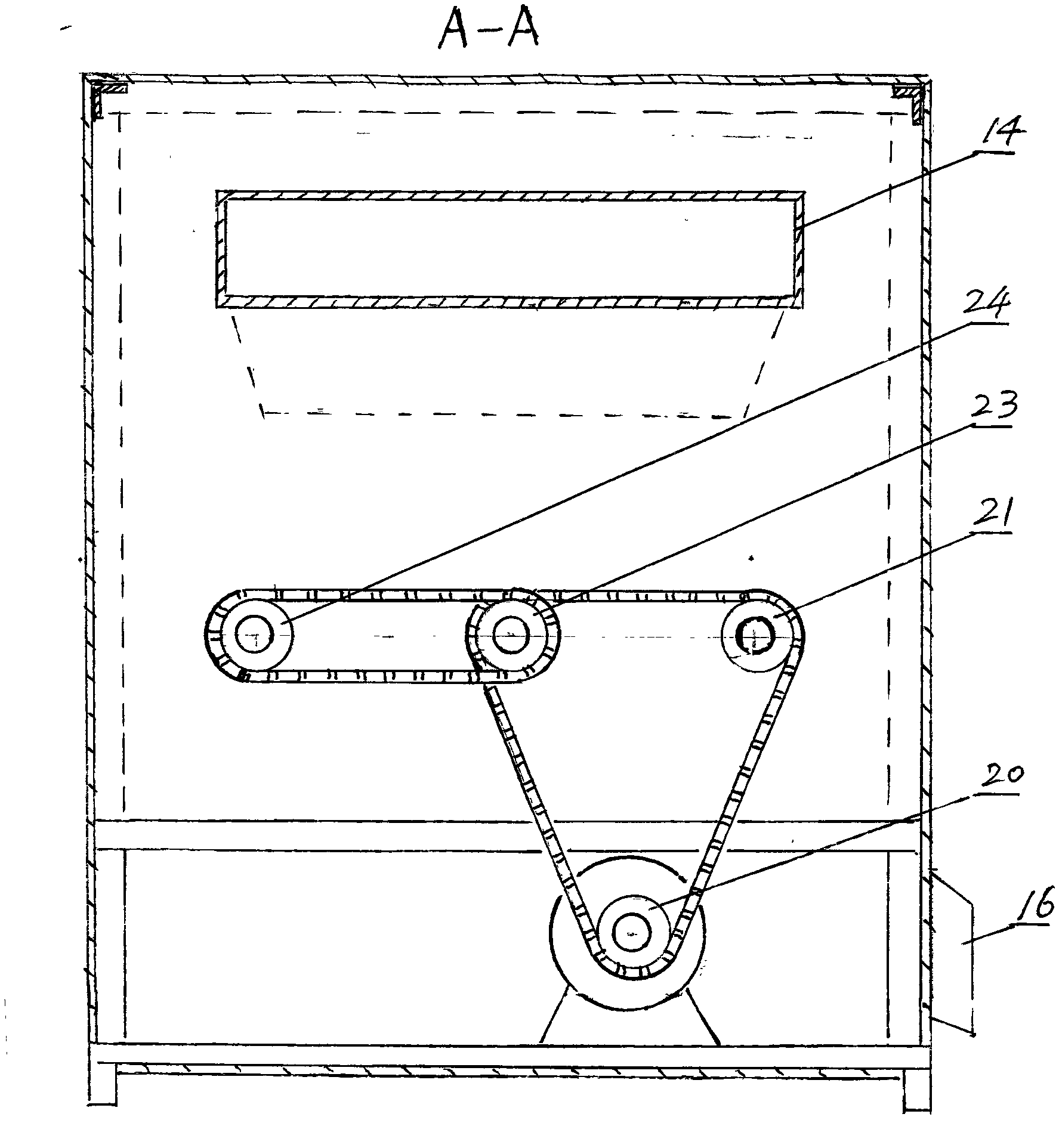

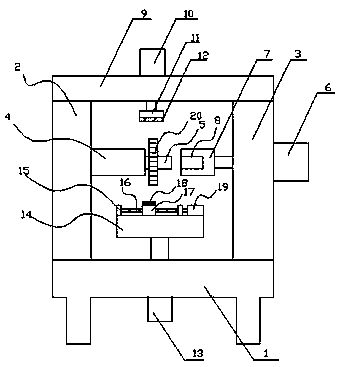

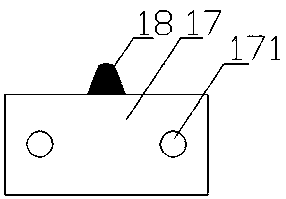

Stampings bonding prevention device for stamping die

ActiveCN103157728AAvoid it happening againAvoid downtime for cleaningShaping toolsCleaning using toolsPunchingTerete

The invention discloses a stampings bonding prevention device for a stamping die and is suitable for punching of coiled materials. The stampings bonding prevention device for the stamp die comprises two rotary cylinders which are located on one side of the die, and the coiled materials go in from the side. The two rotary cylinders are tightly attached to each other and arranged up and down. Each rotary cylinder comprises an oil storage drum with two sealed ends and an oil impregnating layer which is arranged on the outer side of the oil storage cylinder. The oil impregnating layer has elasticity. A plurality of oil impregnating holes are uniformly formed in the circumferential surface of each oil storage cylinder. One ends of the oil storage cylinders are connected with a punching oil conveying system through pipelines. A damping layer with elasticity is arranged between each oil storage cylinder and each oil impregnating layer. A plurality of oil impregnating cylinders are uniformly arranged on the circumferential surface of each damping layer and embedded in each oil impregnating layer. Oil outlet holes which penetrate through the inner surface of each damping layer are formed in each oil impregnating cylinder. Kerfs which are communicated with the oil outlet holes are uniformly arranged on the circumferential surface of each oil impregnating cylinder. The stampings bonding prevention device for the stamp die can prevent stampings from bonding with the die, and therefore continuous punching can be achieved, and influence of machine halt on production efficiency is avoided. Besides, the stampings bonding prevention device for the stamp die is beneficial for prolonging service life of the die and improving punching quality of products.

Owner:WANXIANG 123 CO LTD

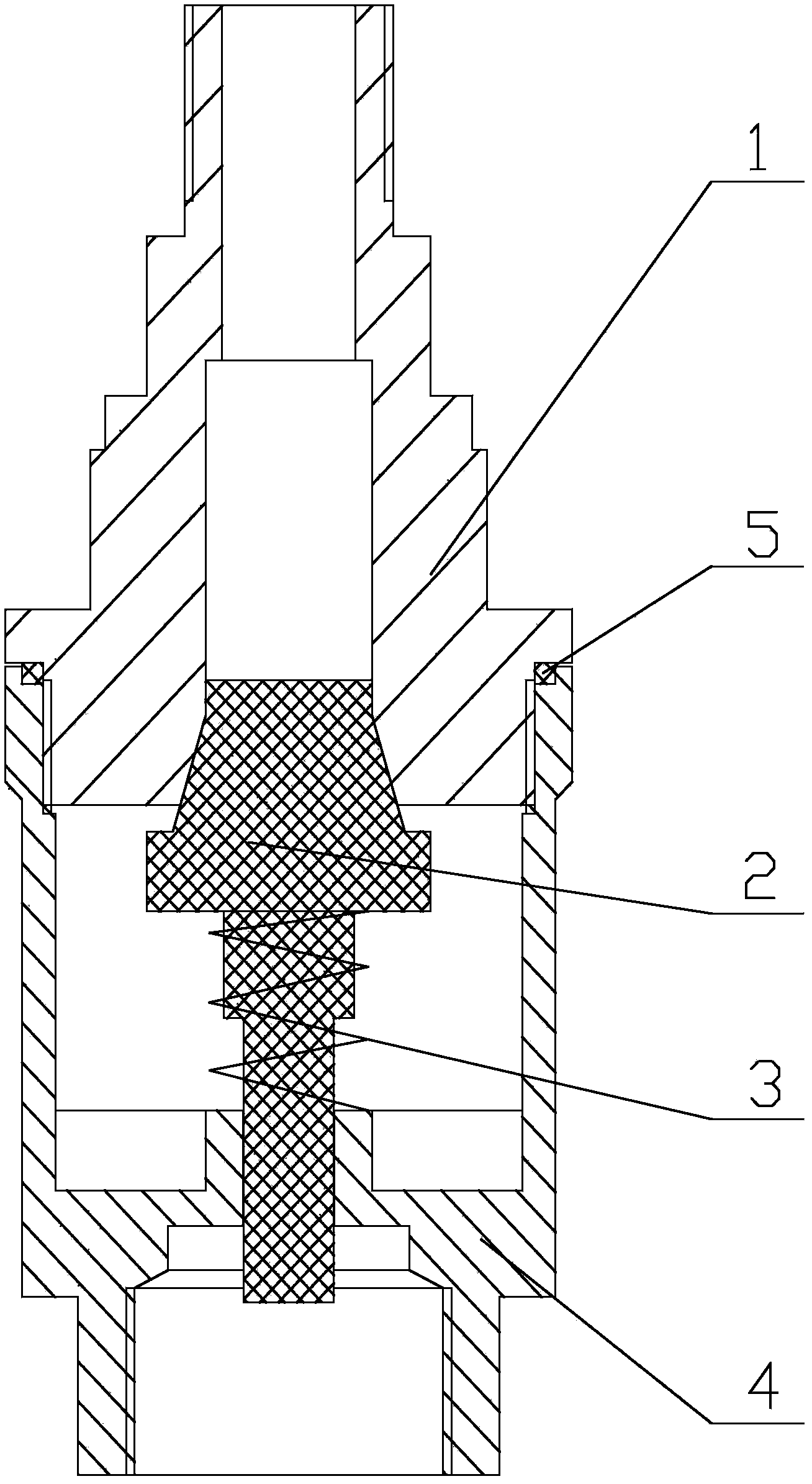

Plug structure

ActiveUS8171961B2Simple structureQuality improvementPipe elementsBrake action initiationsEngineeringFlange

A plug structure for sealing an opening end portion of a circular fluid passage formed in a housing comprises a plug being equal in resistance against deformation to, or smaller than, the housing and having an annular flange portion formed on an end portion of a circular column portion; a flange pressure-contacting portion of the opening end portion deformed to be pressure-contacted with a lower surface of the annular flange portion by being caulked with a caulking tool; a contracted diameter portion of a shape gradually narrow in the middle to which the circular column portion is deformed as a result that the fluid passage is deformed by the caulking to be contracted in diameter; and a deformed circumferential portion to which the circumferential edge of the annular flange portion of the plug is deformed by the caulking to be pressure-contacted with the flange pressure-contacting portion of the opening end portion.

Owner:ADVICS CO LTD

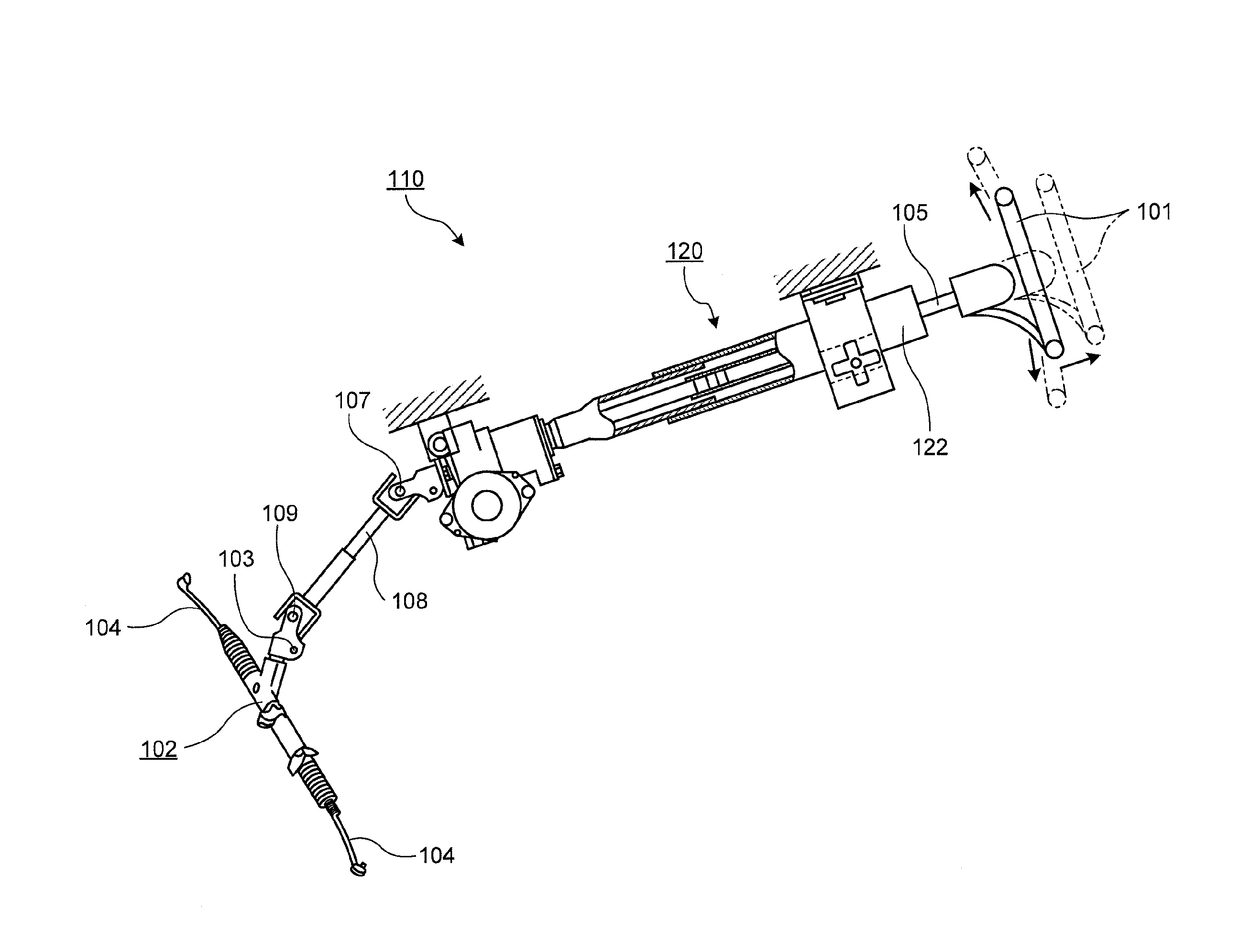

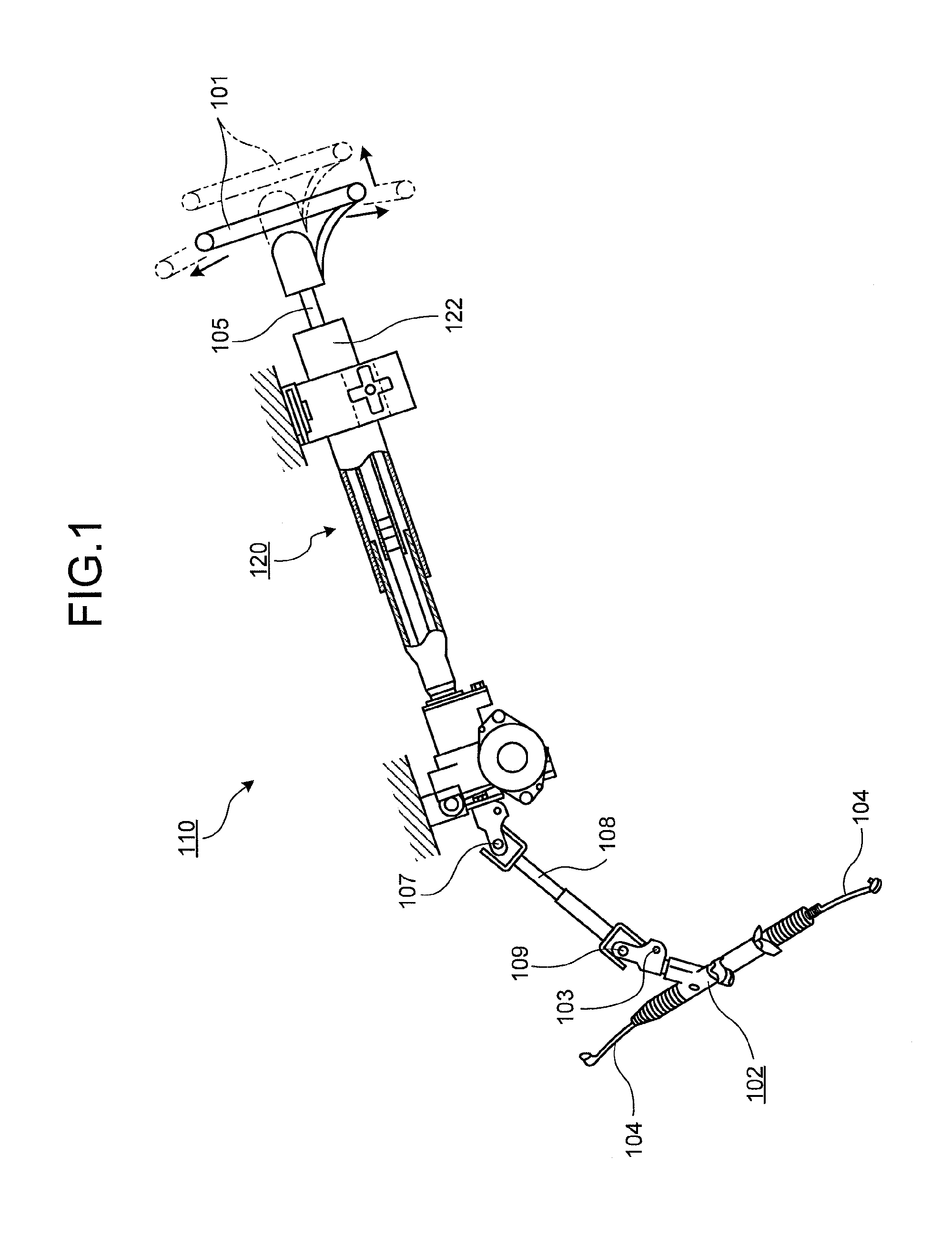

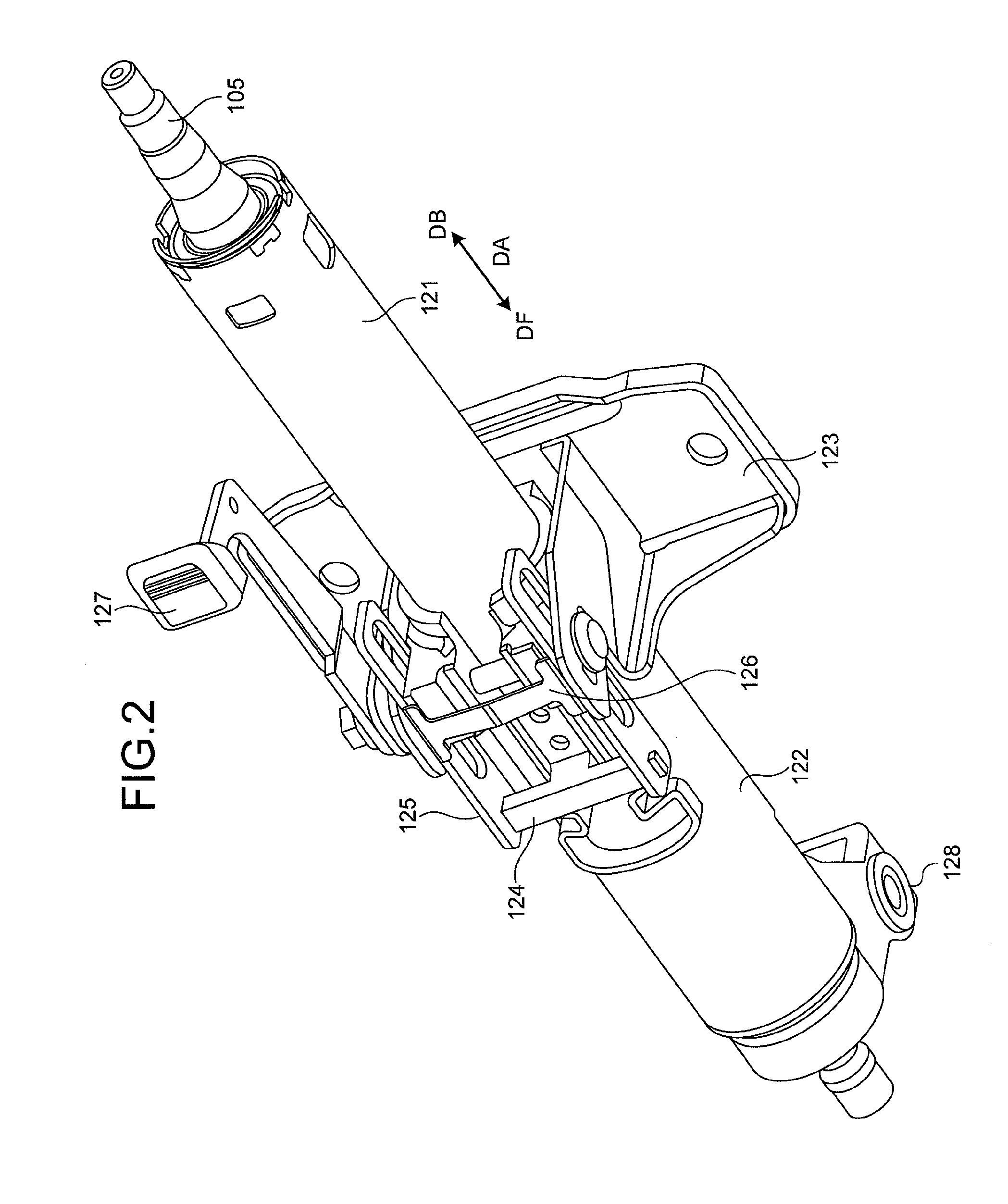

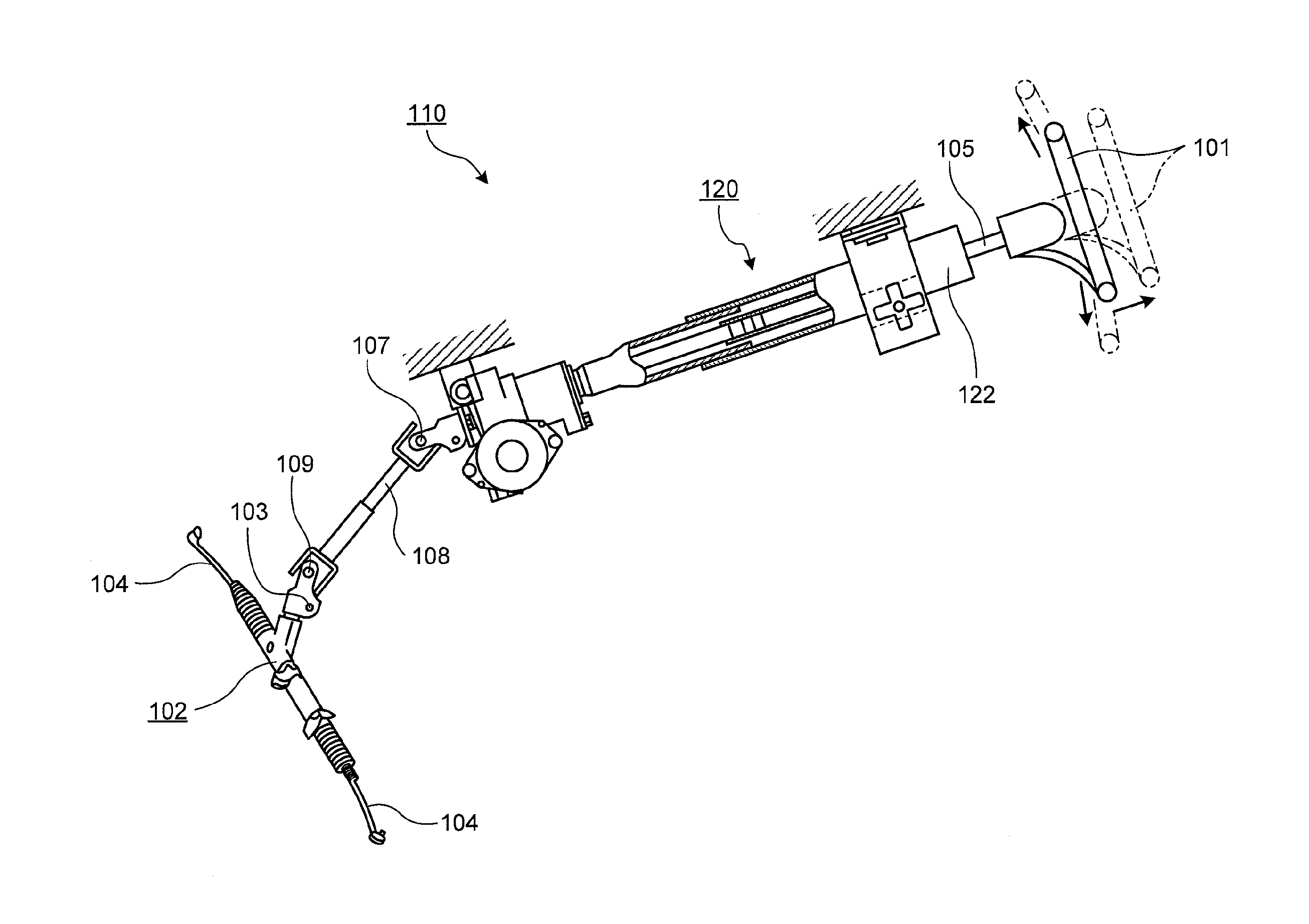

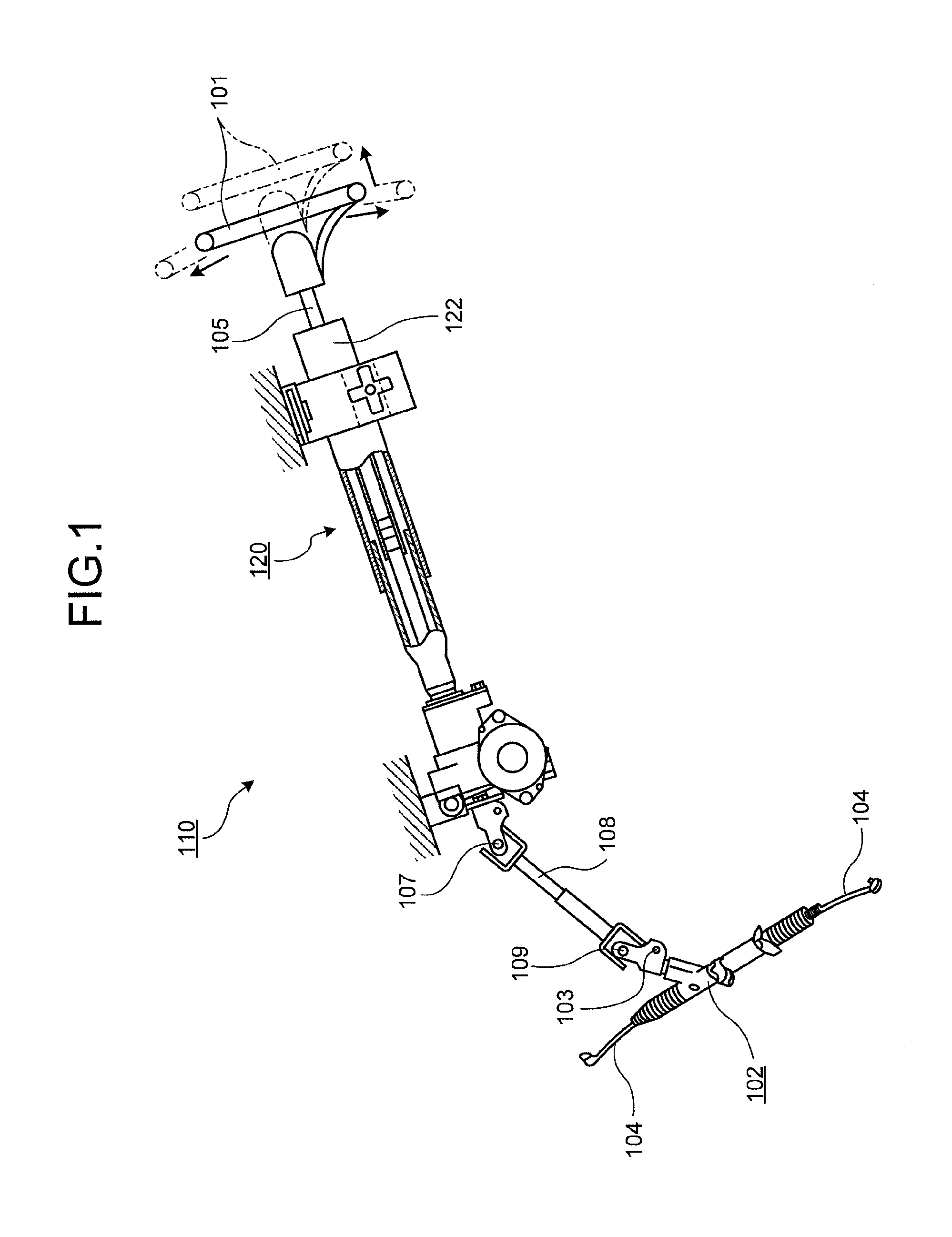

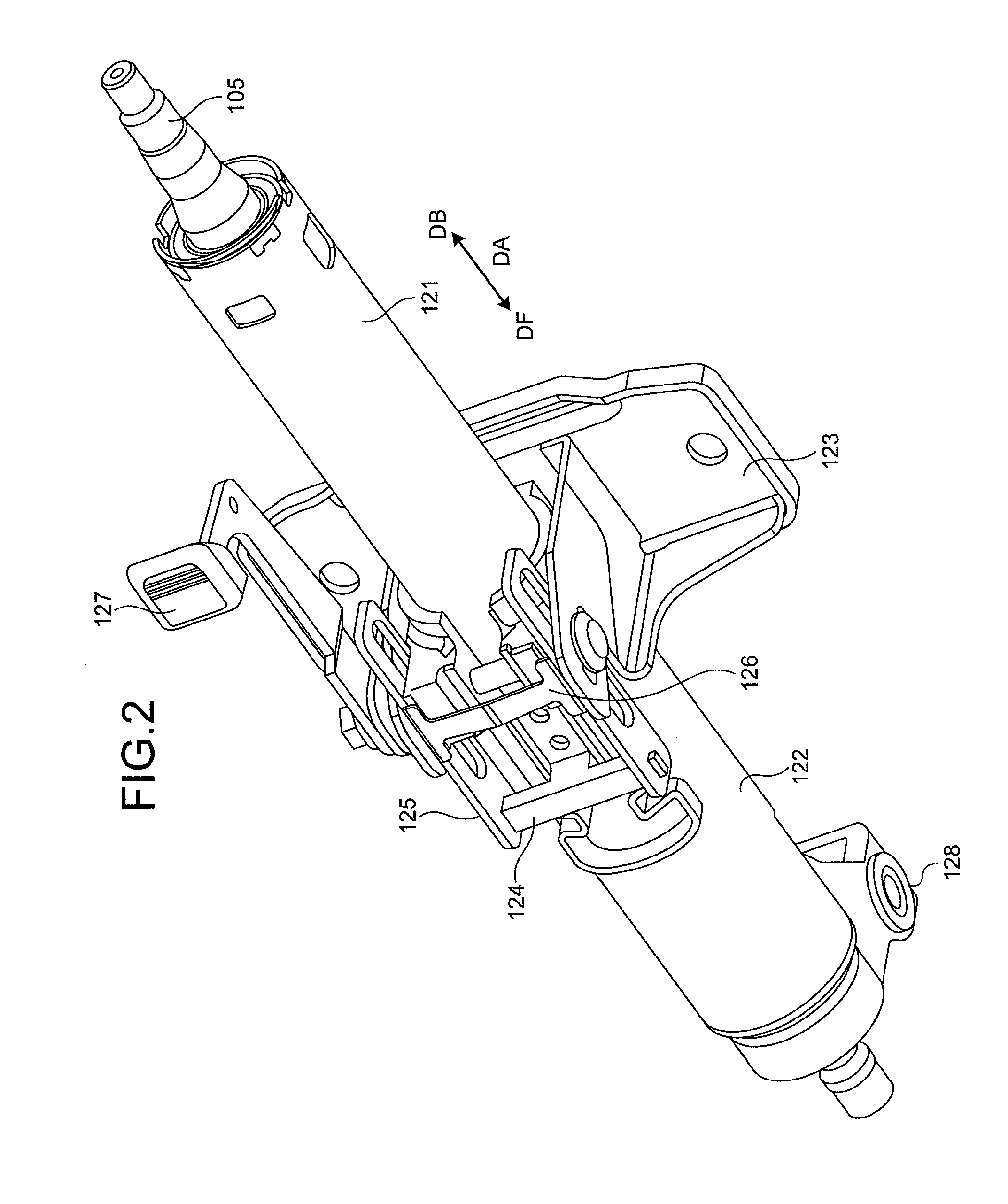

Steering device

A steering device which contracts by an impulse load. A steering device includes an inner column having a cylindrical shape, a base plate having a first hole opened therein, an outer column having a cylindrical shape into which at least a part of the inner column is inserted, and having a slit formed by notching one insertion side end of the inner column, an outer column bracket to tighten the outer column along with a telescopic friction plate, and a connection member provided at a position straddling the first hole and a second hole, and detachably connecting the base plate and the inner column bracket.

Owner:NSK LTD

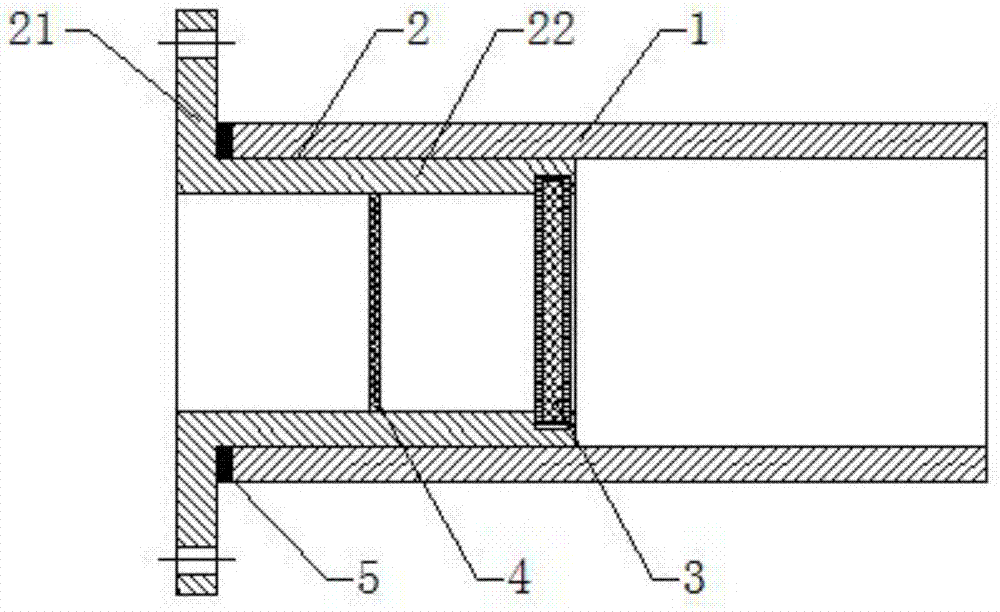

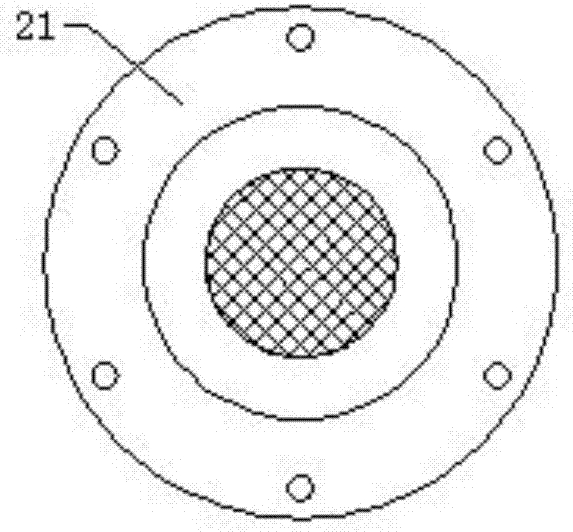

Filtering pipeline

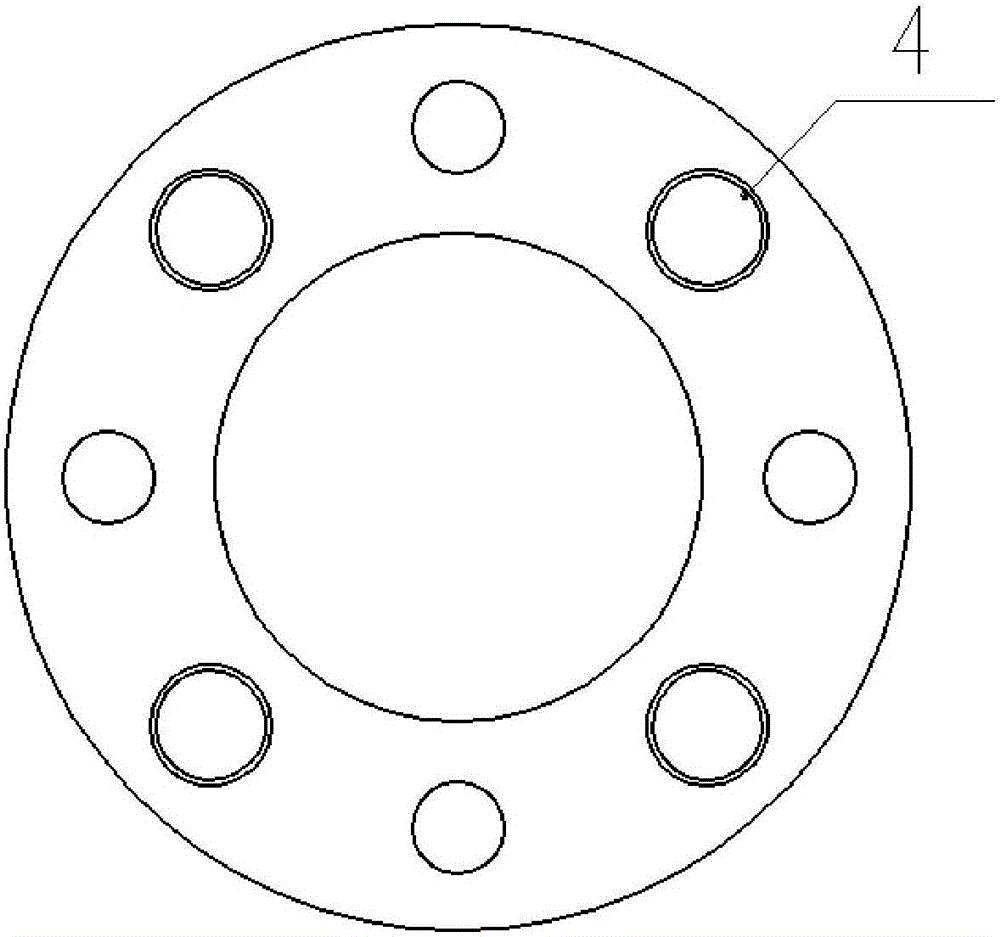

InactiveCN107477279AEasy to installEasy to disassembleFlanged jointsRigid pipesArchitectural engineeringFlange

The invention provides a filtering pipeline. The filtering pipeline comprises a main pipeline and a filtering core pipe, inner threads are arranged on the inner wall of one end of the main pipeline, the filtering core pipe is a hollow cavity, a flange plate is welded to one end of the filtering core pipe, and the other end of the filtering core pipe is a cylinder; the diameter of the flange plate is longer than that of the cylinder, and outer threads are arranged on the outer wall of the cylinder; and the main pipeline is in threaded connection with the filtering core pipe, the welding end of the flange plate is in contact with one end of the main pipeline, an annular groove is formed in one end, away from the flange plate, of the cavity of the cylinder, and the annular groove is filled with a filter layer. The filtering pipeline enables water to be filtered when the water is conveyed in the pipeline, and the filtering core pipe can be convenient to dismount to clean impurities.

Owner:安徽大地环保科技有限公司

Method for processing aluminum alloy cap

InactiveCN103522020AReduce processing burdenGuaranteed connection qualityThread cutting machinesClosure capsMetallurgyMaterials science

Disclosed is a method for processing an aluminum alloy cap. The method includes a vertical rib processing step and an inner thread processing step. The vertical rib processing step includes extruding an extruding head into a cap blank slowly from the opening of the cap blank, accordingly extruding a concave part and a convex part on the inner side of the cylindrical side wall of the cap blank, and acquiring the cap blank with the concave part and the convex part. The inner thread processing step includes assembling an executing component on the inner side of the cylindrical side wall of the cap blank with the concave part and the convex part, starting a hydraulic lifting device and a rotary motor, forming a thread on the convex part accordingly, and obtaining the aluminum alloy cap.

Owner:青岛亚华制盖有限公司

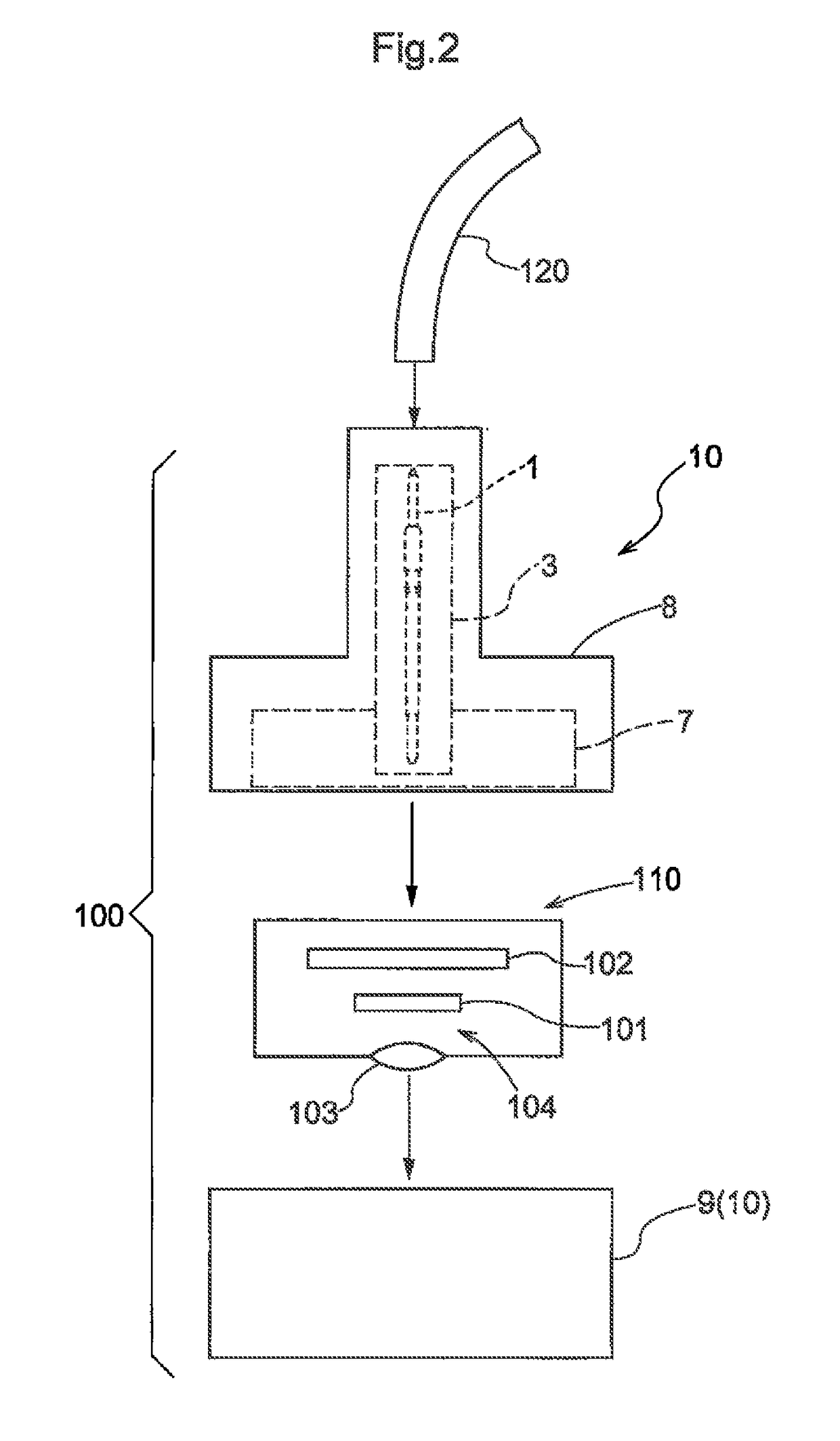

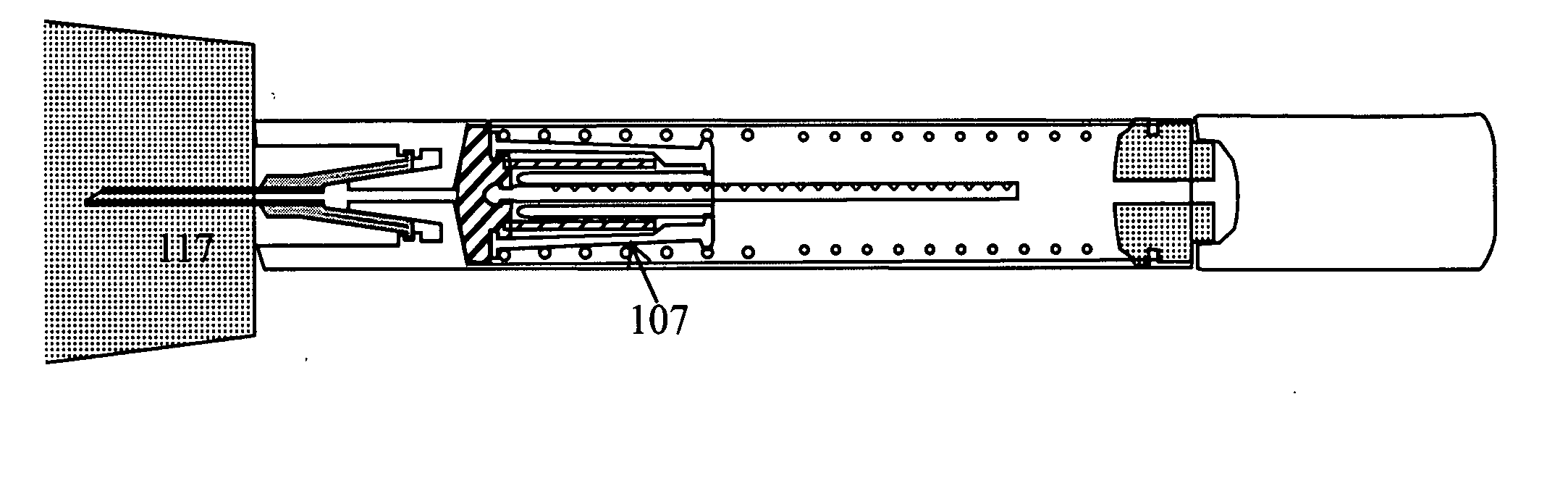

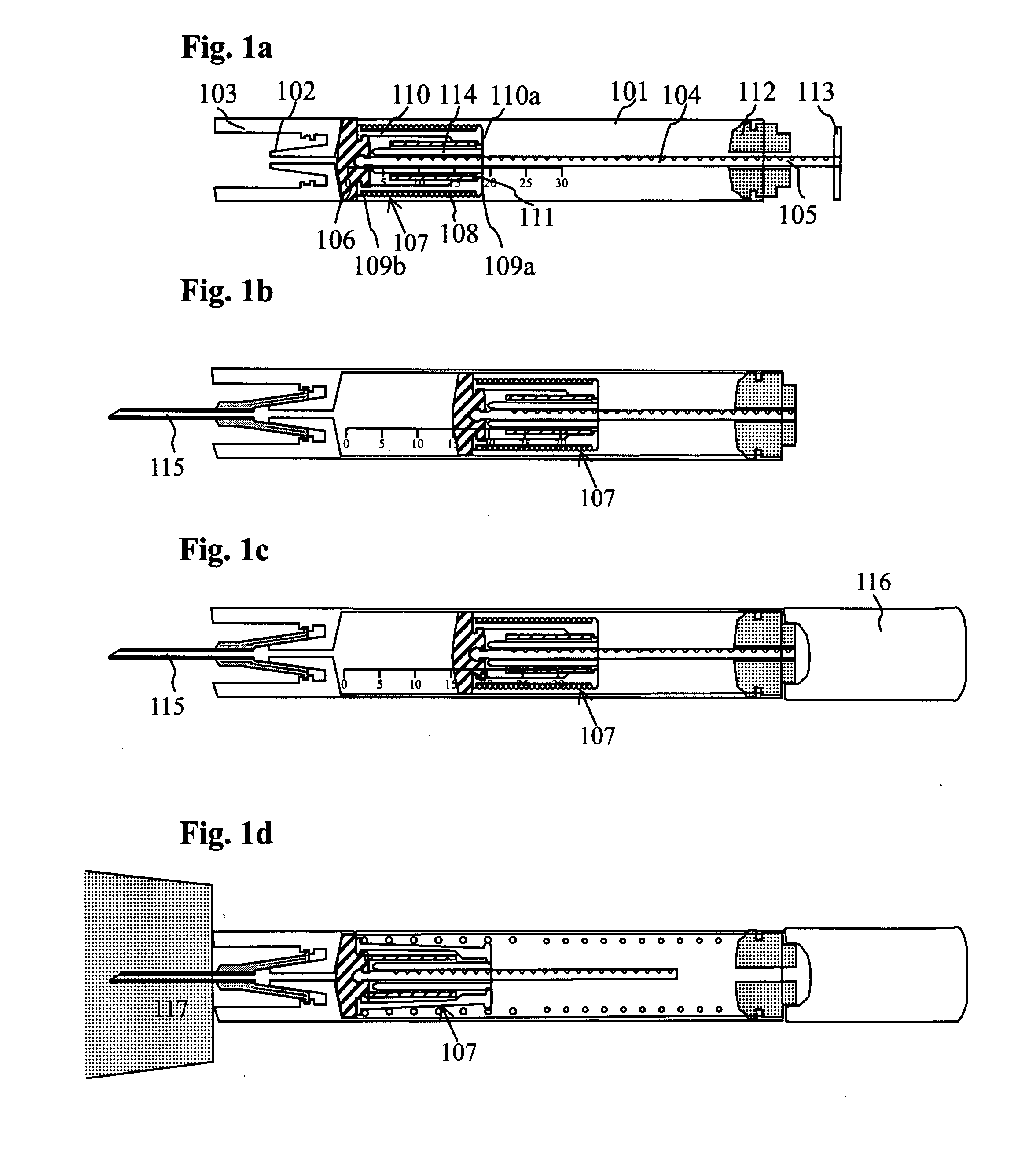

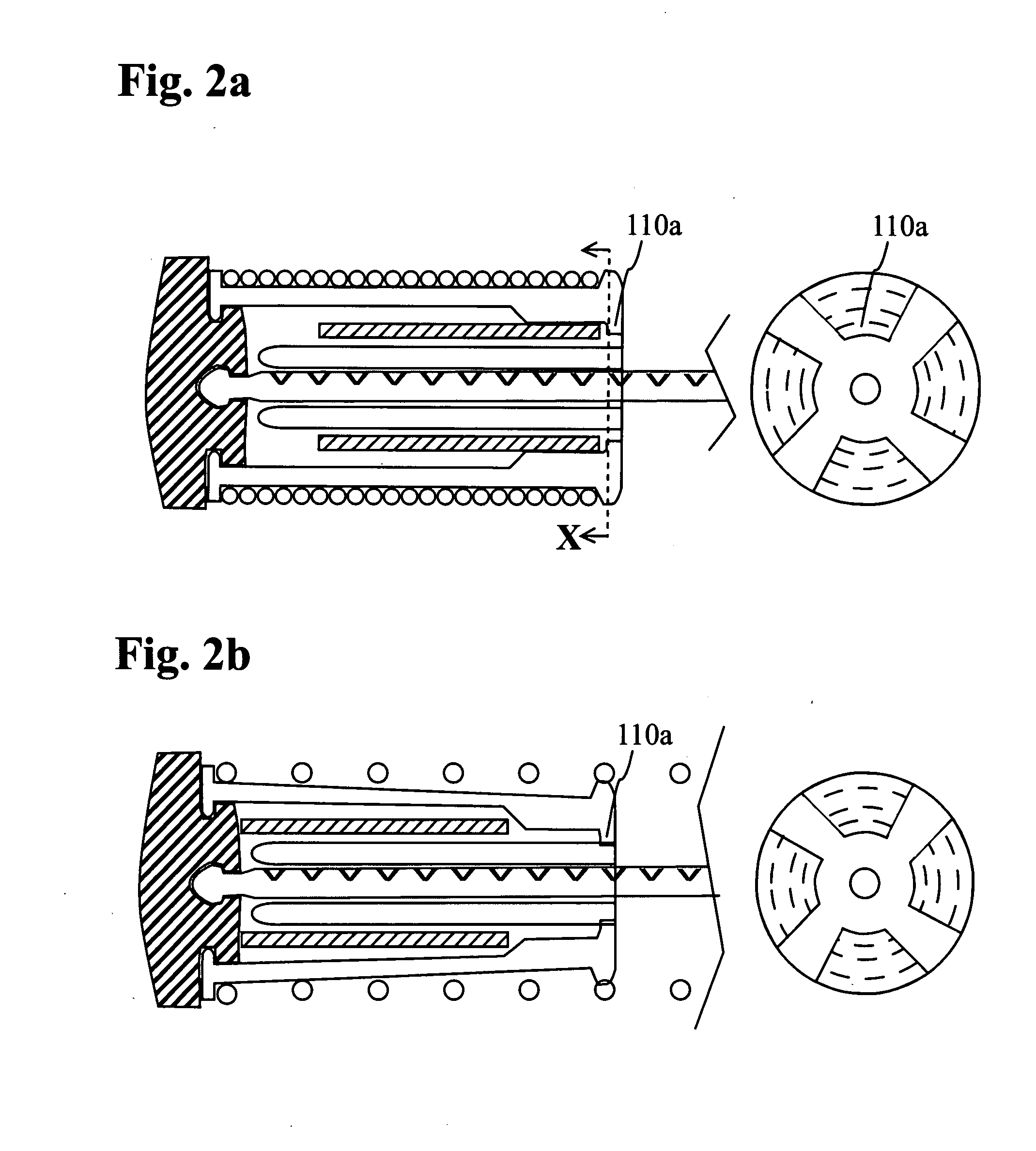

Projectile syringe system

InactiveUS20150282914A1Inexpensive and reliableEasy to operateAmmunition projectilesAutomatic syringesBiomedical engineeringPiston

A projectile syringe has a barrel, a spring loaded power assembly with an attached plunger, a notched plunger shaft terminating in a knob and a breach plug secured to the barrel. The spring loaded power assembly has a cylindrical sleeve with four dissected fingers, two projections on the sleeve's outer cylindrical surface securing a compressed compression spring. A cylindrical weight is captured within the sleeve by four fingers. The user attaches a needle and draws a desired amount medicament. The plunger shaft is broken flush against the breech plug. The user attaches a stabilizing tail to the breech plug end and the projectile syringe is aimed at a target animal. Stopping the syringe displaces the cylindrical weight, allowing the four fingers to displace. The proximal projections move inward, allowing the compressed compression spring to expand to the fixed breech plug, pushing the piston to deliver medicament to the animal.

Owner:GRAY JOHN M

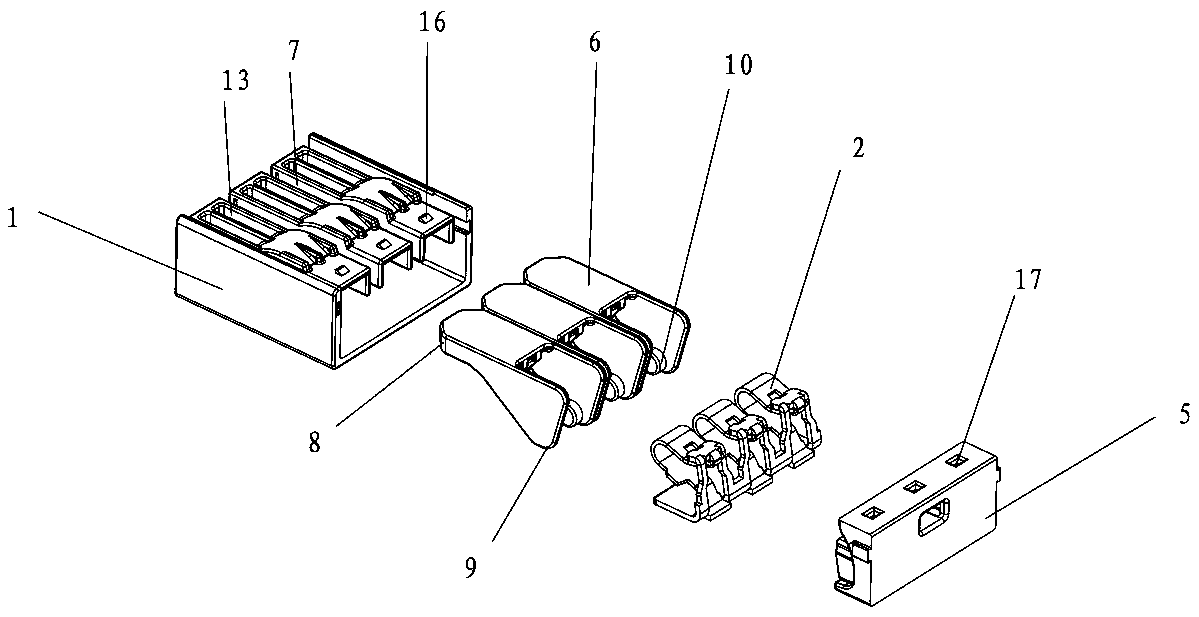

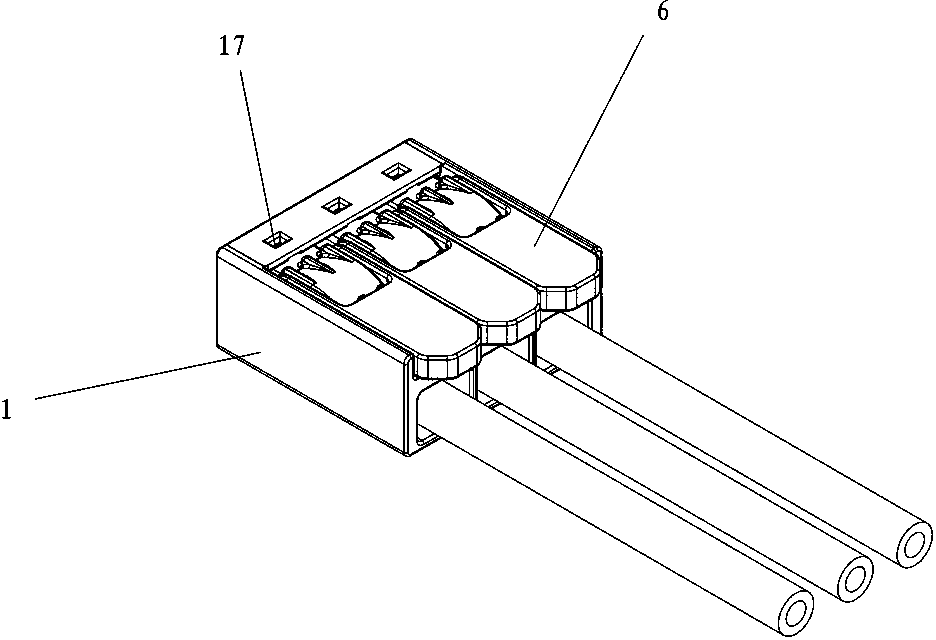

Wiring terminal with pluggable pulling covers

InactiveCN104300304ARealize one-time wiringConvenient wiring workCoupling device detailsMulticonductor cable end piecesEngineeringMechanical engineering

The invention discloses a wiring terminal with pluggable pulling covers. The wiring terminal comprises an insulation shell. Conductive metal parts are arranged in the insulation shell, wire insertion openings are formed in the front end of the insulation shell, installation ports are arranged at the rear end of the insulation shell, and the conductive metal parts are mounted in the insulation shell from the installation ports. The wiring terminal further comprises a rear cover and the turnover pulling covers, the rear cover is installed in cooperation with the installation ports and the turnover pulling covers are arranged on the top of the insulation shell. At least two through groove seams penetrating into a containing cavity are formed in the top of the insulation shell, one end of each turnover pulling cover is a pulled end, the other end of each turnover pulling cover is a rotated end, protruding cylindrical raised heads are fixedly arranged below the end portion of each rotated end, the cylindrical raised heads of each rotated end are eccentrically deviated from the central axis of the end portion of the corresponding rotated end, and the bottom surface of each cylindrical raised head is horizontally aligned to the bottom surface of the containing cavity; each conductive metal part is provided with a metal bottom plate and an elastic clamping piece cocked from the corresponding metal bottom plate to form a cage shape, and the wire clamping end portion of each elastic clamping piece is downwards and can be matched with the corresponding metal bottom plate to clamp a wire metal insertion end; each cylindrical raised head is located between the corresponding elastic clamping piece and the side portion of the corresponding metal bottom plate.

Owner:JIANGMEN KREALUX ELECTRICAL APPLIANCES

Steering device

A steering device which contracts by an impulse load. A steering device includes an inner column having a cylindrical shape, a base plate having a first hole opened therein, an outer column having a cylindrical shape into which at least a part of the inner column is inserted, and having a slit formed by notching one insertion side end of the inner column, an outer column bracket to tighten the outer column along with a telescopic friction plate, and a connection member provided at a position straddling the first hole and a second hole, and detachably connecting the base plate and the inner column bracket.

Owner:NSK LTD

Lithium battery outer shell drawing composite die

The invention discloses a lithium battery outer shell drawing composite die, and belongs to the technical field of lithium battery machining. The lithium battery outer shell drawing composite die is characterized in that an upper die base is sequentially connected with a base plate and a convex-concave die fixing plate through internal fillet screws and cylindrical pins, the convex-concave die fixing plate is provided with a convex-concave die connected with a material pressing and discharging plate, the lower side of the material pressing and discharging plate is connected with a movable concave die, a movable insert is arranged in the movable concave die, the bottom of the convex-concave die is connected with a convex die arranged on a convex die fixing plate, the convex die fixing plate is connected with a lower die base, the two sides of the lower side of the lower die base are provided with pull rods, the pull rods are provided with disc springs in a sleeved mode and are fixed between an upper supporting plate and a lower supporting plate in a penetrating mode, an upper die base and the lower die base are connected through precise guide columns fixed in the upper die base, and the precise guide columns are sleeved with precise guide sleeves. The lithium battery outer shell drawing composite die is simple in structure and convenient to use, the size of a produced lithium battery outer shell is stable, the qualified rate can reach 98% and good technical and economic effects are achieved.

Owner:洛阳特斯拉能源科技有限公司

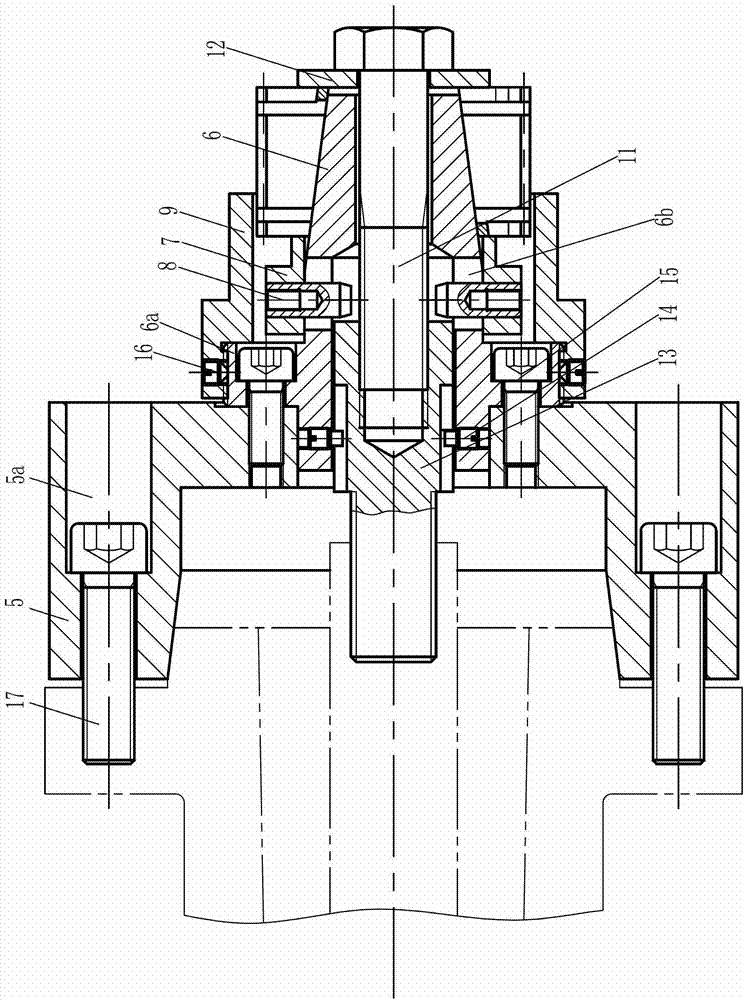

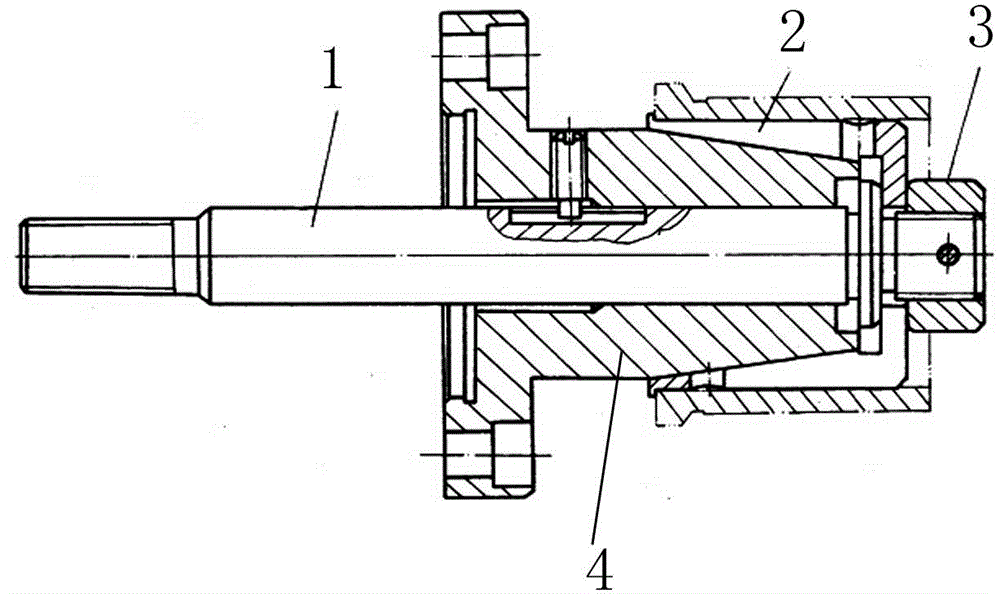

Grooving jig used for clamping synchronizer duplicate gear

The invention discloses a grooving jig used for clamping a synchronizer duplicate gear. The left end of a mandrel is inserted into a small diameter section of an inner hole of a connecting plate, and an annular installing boss on the left end portion of the mandrel is fixed with the connecting plate; a sliding sleeve is coaxially sleeved on the middle portion of the mandrel, a cylindrical pin is connected in a radial hole formed in the sliding sleeve, and the inner end of the cylindrical pin stretches into a center hole of the mandrel after penetrating through a strip-shaped sliding hole formed in the mandrel; a positioning sleeve is sleeved outside the sliding sleeve, and the left portion of the positioning sleeve is fixed with the annular installing boss; the right portion of the mandrel is a conical part with the left big and the right small, an expansion sleeve is sleeved on the right portion of the mandrel, a conical inner hole of the expansion sleeve is matched with the conical part of the mandrel, axial grooves are formed in the left portion of the expansion sleeve along the circumferential direction, and external splines are arranged on the positions, between every two adjacent axial grooves, of the expansion sleeve; after a washer is sleeved on the rod portion of a bolt, the rod portion of the bolt is inserted into the center hole of the mandrel and connected with an inner thread hole formed in the right end portion of a draw bar; and the draw bar is located on the left side of the cylindrical pin, and an outer thread section of the left portion of the draw bar stretches into a large hole diameter section of the inner hole of the connecting plate. Inner spline holes of gear blanks are positioned through the expansion sleeve, the expansion sleeve is even in deformation in the peripheral direction, the clamping precision can be thus improved, the jig can be used for installing and detaching gears very conveniently, and therefore shortcomings of a traditional grooving jig are effectively overcome.

Owner:CHONGQING WINSTAR PRECISE MACHINERY

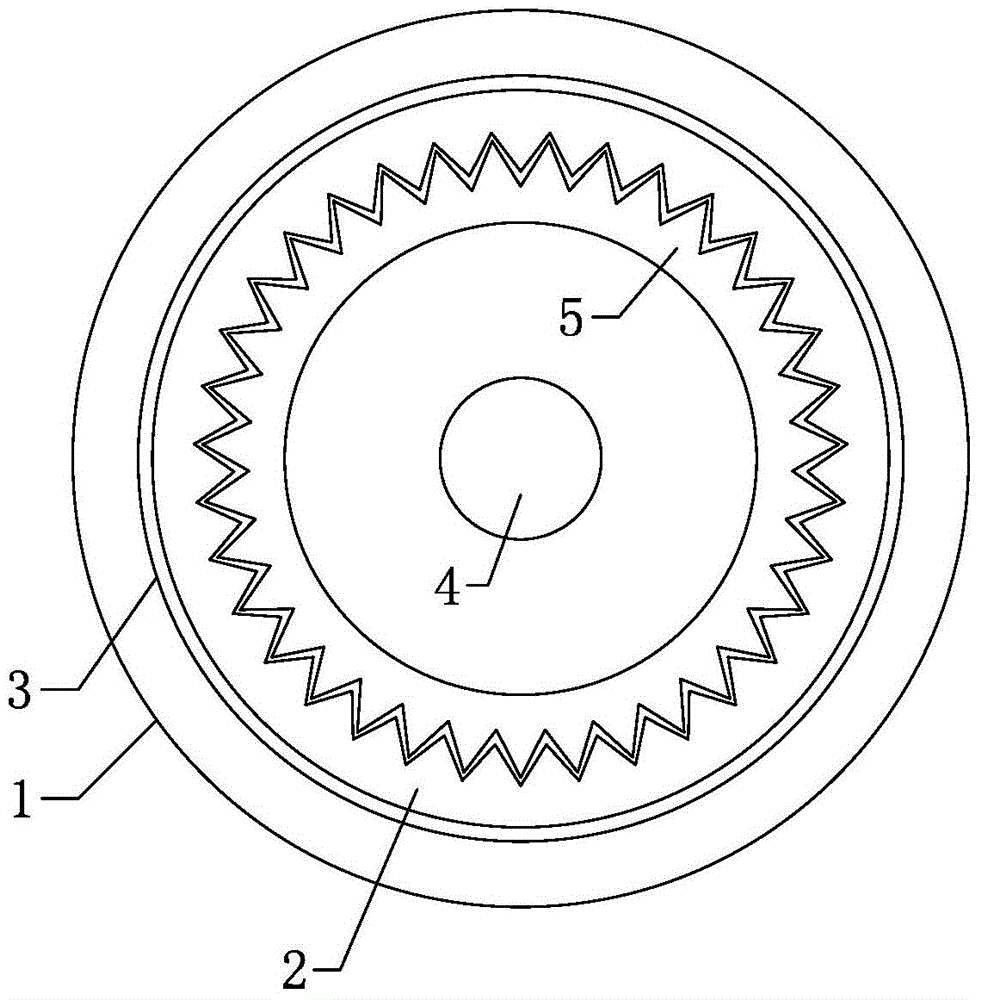

Gear casting mold

The invention discloses a gear casting mold, which comprises a cylindrical cast seat, a toothlike casting and a gear reducer casting mold, wherein a cylindrical groove is formed in the central axis of the cylindrical cast seat; a convex cylinder is arranged in the cylindrical groove; the cylindrical groove is a stepped hole; the toothlike casting is an inner gear ring casting mold; the gear reducer casting mold is annular; teeth are arranged at two side end parts of the gear reducer casting mold; teeth at one side surface are completely meshed with inner wall teeth of the toothlike casting; teeth at the other side surface are different from the toothlike casting in dimension and shape. By virtue of the technical scheme, a reference dimension gear can be cast through the cylindrical groove in the cylindrical cast seat, the convex cylinder and the toothlike casting; if the tooth shape of the gear and the gear dimension need to be changed, only the proper gear reducer casting mold needs to be put on the inner tooth surface of the toothlike casting; one end of the gear reducer casting mold is completely meshed with the toothlike casting; and the needed toothlike casting is arranged at the other end of the gear reducer casting mold, so that another gear can be directly cast, and further waste of the cast mold is avoided.

Owner:DALIAN ORIENT METAL

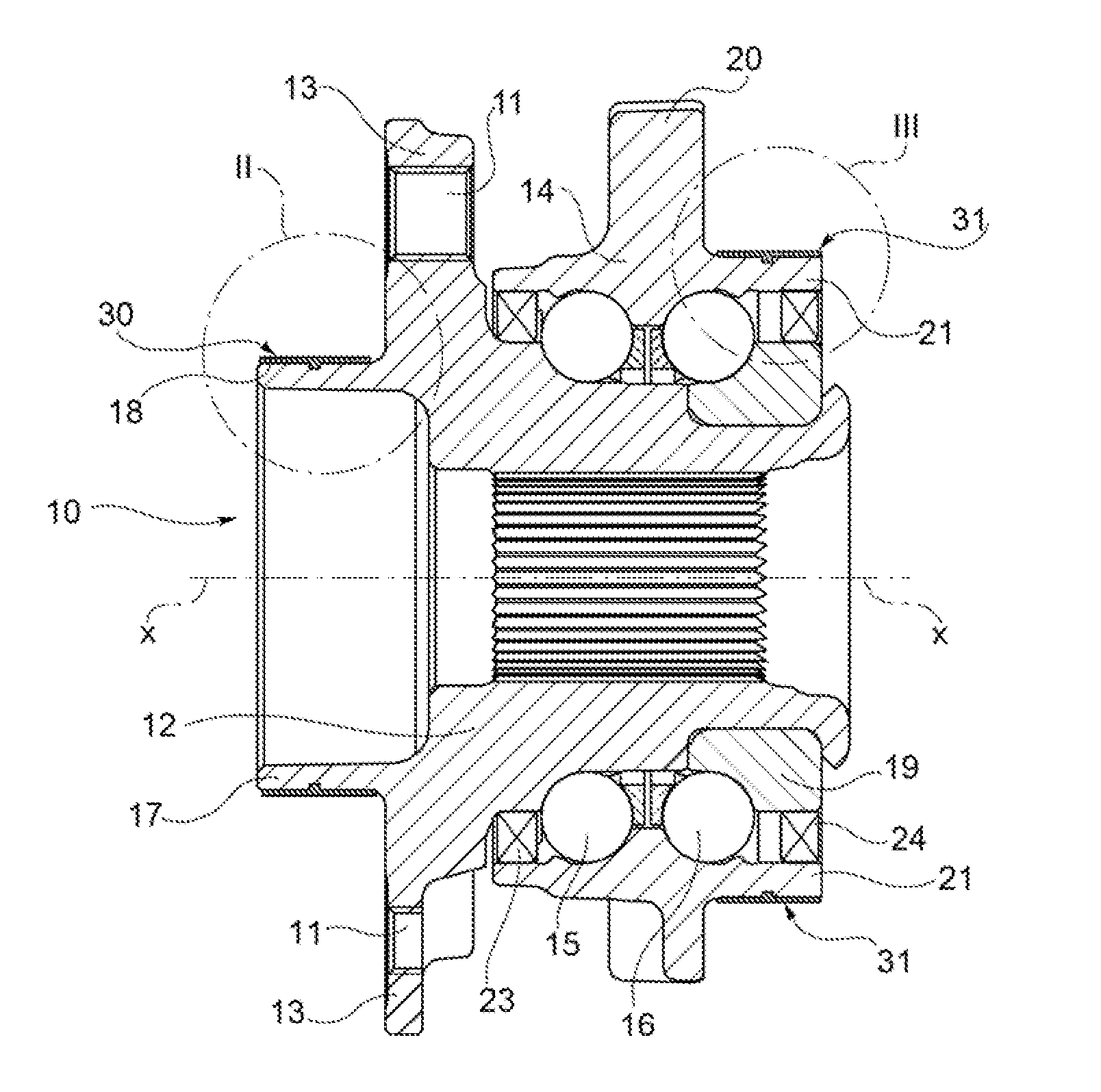

Scanner motor

InactiveUS20110170154A1Avoid shorter lifespanLong stabilityBearing assemblyShaftsEngineeringMechanical engineering

Disclosed herein is a scanner motor. The scanner motor includes a rotating shaft which is axially supported and rotatable, and a bearing which has the shape of a hollow cylinder. The bearing includes a hydrodynamic bearing portion provided on the upper portion of the bearing to rotatably support the rotating shaft, and an oil impregnated sintered bearing portion provided on the lower portion of the bearing.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Quick-changing expansion pipeline connecting structure

InactiveCN106838525AQuick assembly and disassemblyAvoid crackingFlanged jointsPipeline expansion-compensationEngineeringFlange

The invention discloses a quick-change expansion pipeline connection structure, which includes a pipeline section and first flanges arranged at both ends of the pipeline section. The first flange is provided with a first blind hole, and in the first blind hole is a A cylindrical spring that can be inserted into the second blind hole on the end face of the second flange. The second flange is arranged on another pipe section connected to the pipe. An elastic gasket is arranged between the end faces of the two flanges. The cylindrical spring Through the elastic gasket and the cylindrical spring is compressed. There are small blind holes on the outer surface of the pipe wall at the insertion end of each pipe section. The small blind holes are in a circular array centered on the center of the pipe section. The top of the small cylindrical spring in the small blind hole is fixedly connected with the pillar; After the flange is inserted in place, the small cylindrical spring lifts the pillar into the groove in the corresponding flange. A threaded hole communicating with the outside world is also provided at the bottom of each small blind hole. This structure can make the pipeline have a certain degree of expansion, and the assembly and disassembly are convenient.

Owner:秦朝东

Turning tool used for automobile sleeve part

The invention discloses a turning tool used for an automobile sleeve part. The turning tool comprises a central spindle, a pull rod, an elastic fixing sleeve and a nut. An inner hole is formed in the center of the central spindle, the central spindle comprises a fixing base at the left end, a cylindrical transition section in the middle and a conical section at the right end, and the pull rod is in clearance fit with the inner hole of the central spindle. The inner hole of the elastic fixing sleeve is an inner conical hole matched with the conical section, a fixing cover is arranged at the right end of the elastic fixing sleeve in an integrated mode, multiple expansion joints are arranged in the circumferential direction of the elastic fixing sleeve, rubber seal rings are arranged inside the expansion joints, a hook part is arranged in the circumferential direction of the left end of the elastic fixing sleeve, a through hole is formed in the center of the fixing cover and used for penetrating of the pull rod, a fixing boss and a first threaded part are sequentially and axially arranged at the right end of the pull rod, one end face of the fixing boss abuts against the left side face of the fixing cover, and the nut is connected to the first threaded part and abuts against the right side face of the fixing cover. According to the scheme, the turning tool is simple in structure, easy to operate and beneficial to clamping the sleeve part and greatly improves efficiency.

Owner:CHONGQING CHUANGLONG IND

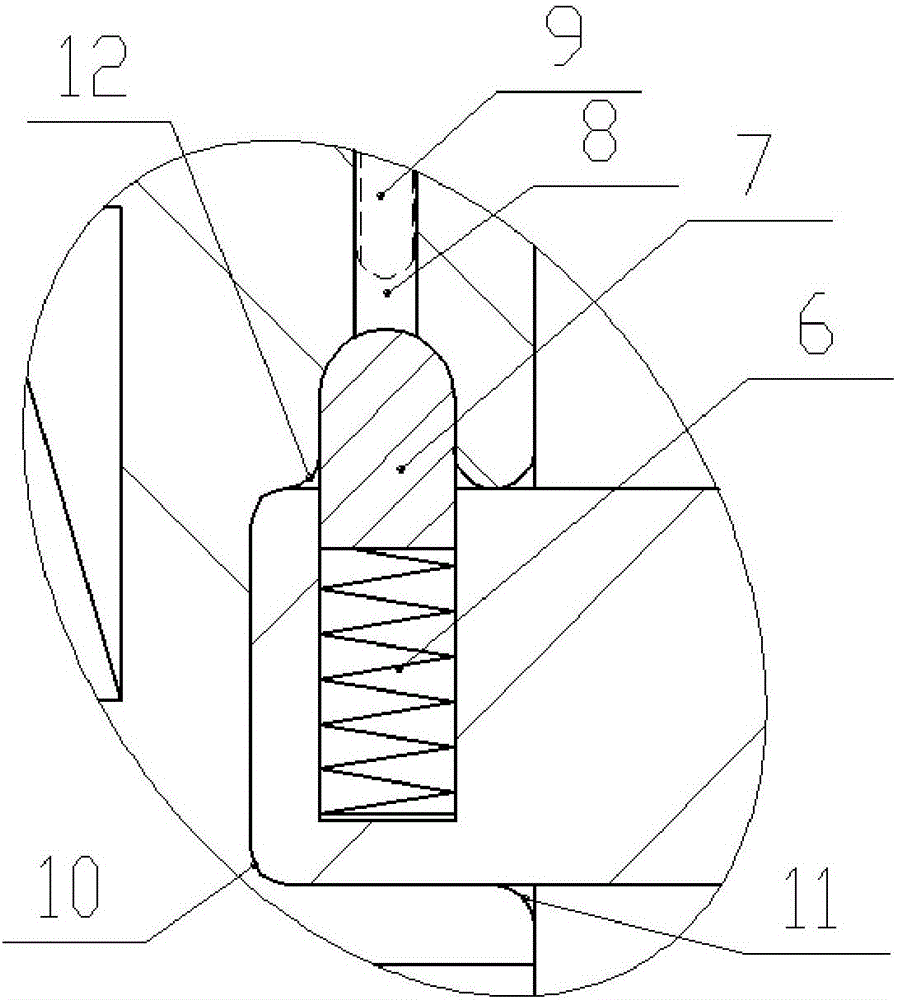

Check valve

The invention discloses a check valve which comprises an upper valve body and a lower valve body. The lower valve body is connected with the upper valve body, a cylindrical upper valve cavity is arranged on the central axis of the upper valve body, a lower valve cavity is formed by the lower valve body and the bottom of the upper valve body in an enclosed manner, a valve spool seat is arranged in the lower valve cavity, a valve spool is inserted in the valve spool seat, a conical opening is formed in the bottom of the upper valve cavity, the valve spool comprises a circular truncated cone matched with the conical opening of the upper valve cavity, a cylindrical head is arranged on the top of the circular truncated cone and is matched with a cylindrical cavity at the rear of the conical opening of the upper valve cavity, a stepped shaft is arranged at the lower end of the valve spool, the lower end of the stepped shaft is inserted into the valve spool seat, and a spring is arranged between the stepped shaft and the valve spool seat. Compared with an existing check valve with a valve spool abutted to a cavity, the check valve has the advantages that a cavity is of a cylindrical structure with the conical opening, the circular truncated cone which is matched with the conical opening is arranged at a seal end of the valve spool, and the cylindrical head is arranged on the top of the valve spool, so that the valve spool can be deeply arranged in the cavity when sealed, and a reliable sealed structure can be formed.

Owner:CHANGXING GOLD RUN WAS MACHINERY

Masterbatch for coloring synthetic resin

A masterbatch for coloring a synthetic resin of the present invention includes an aluminum pigment, a polyethylene wax, and a linear low-density polyethylene resin, and the masterbatch in a form of cylindrical pellets, each 2.5 mm in diameter and not less than 2 mm and not more than 5 mm in height, has a Rattler value of not more than 2.5%.

Owner:TOYO ALUMINIUM KK

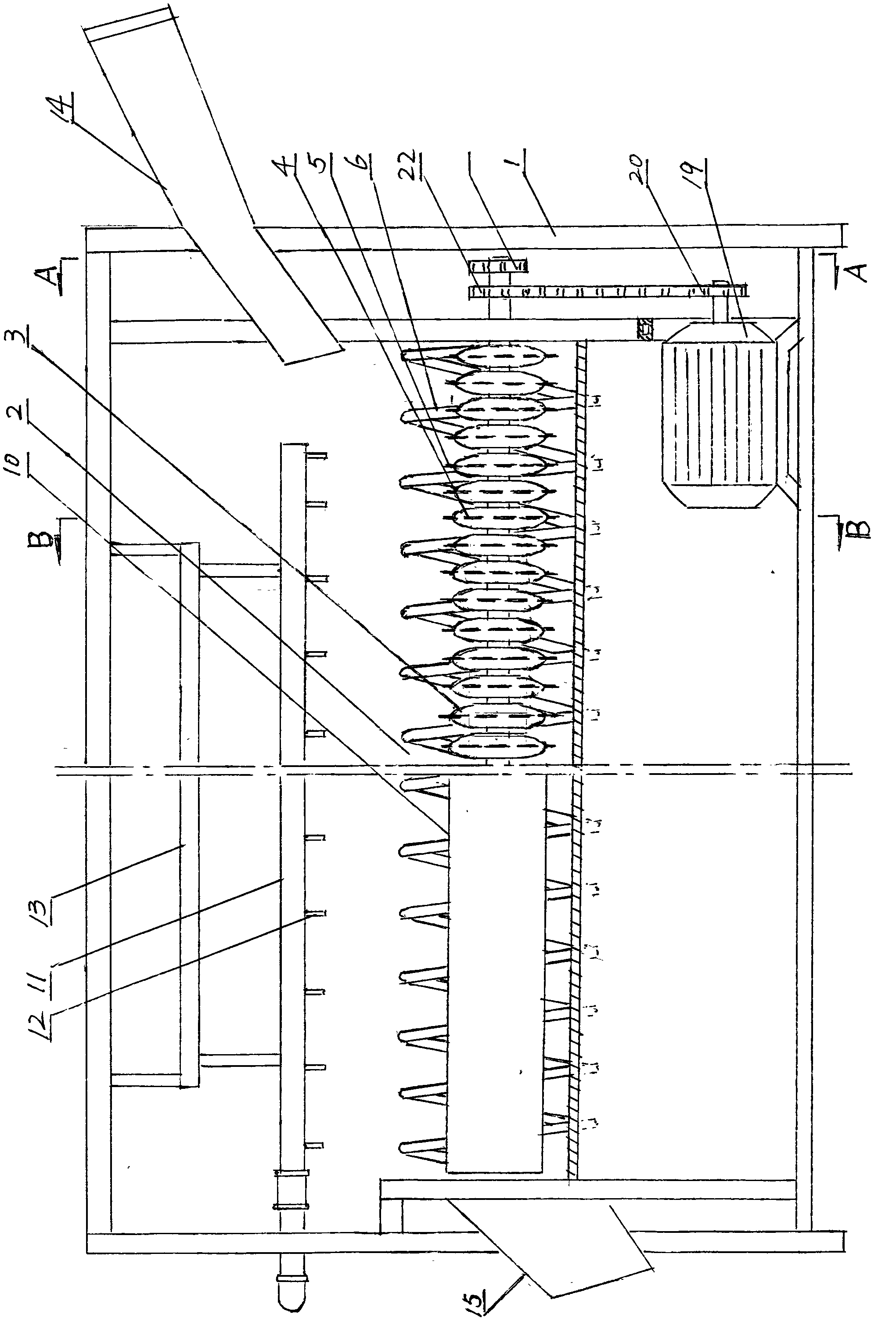

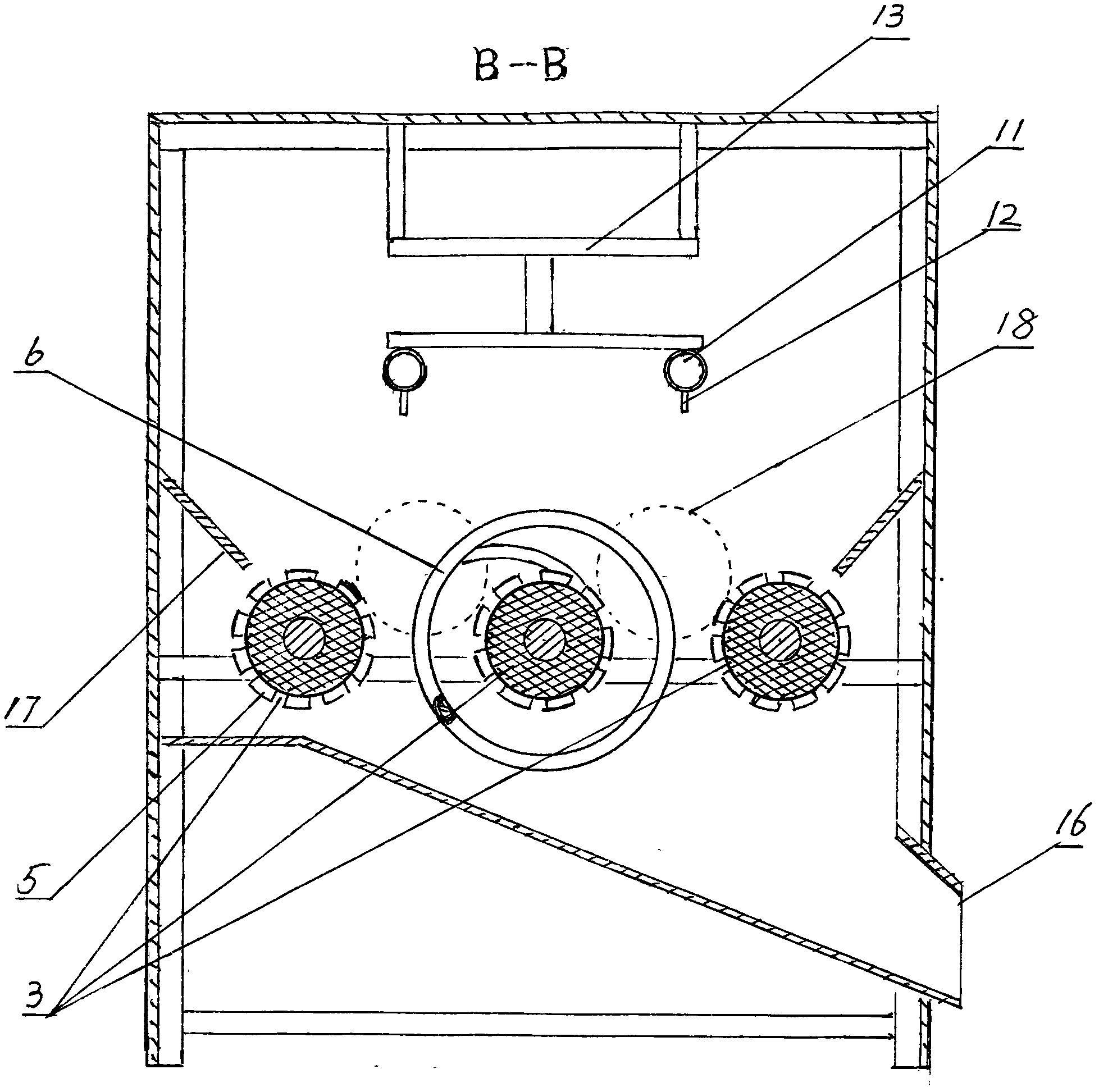

Onion peeler

The invention provides an onion peeler, relating to the onion peeler of vegetable processing machineries. The onion peeler comprises a frame, three peeling rollers which are arranged in parallel and a high pressure gas spraying pipe which is arranged above the peeling rollers; the middle peeling roller is provided with a screw 6; the three peeling rollers are formed by a front section and a back section, respectively; the peeling roller 3 at the front section consists of parallel assembling a plurality of cake shaped circular disc wheels 4; the peripheral edges of the cake shaped circular disc wheels are provided with skin scratching blades; and the peeling roller 10 at the back section is a plain cylindrical stick. The machine has the advantages of innovating design on the basis of the prior art, simplifying structure, and finishing the skin-scratching and peeling once without fault in operation. Compared with the prior art, the production efficiency is increased by 3-5 times; the peeling quality is good, and the requirements of export and deep-processing enterprises are completely satisfied. The machine has low manufacturing cost, which is only 1 / 5 of that of the original machine.

Owner:QINGDAO WEIMA MACHINERY

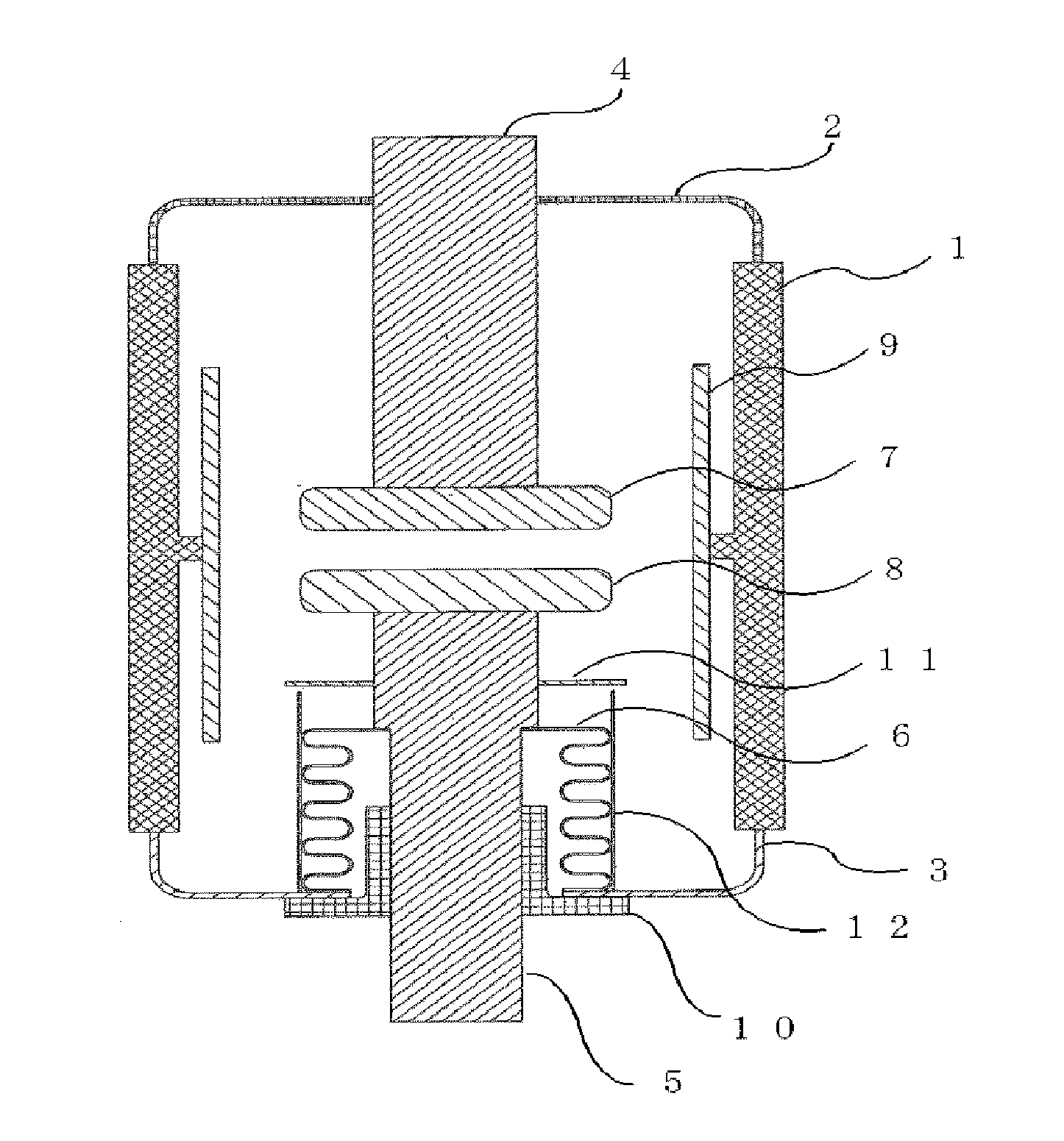

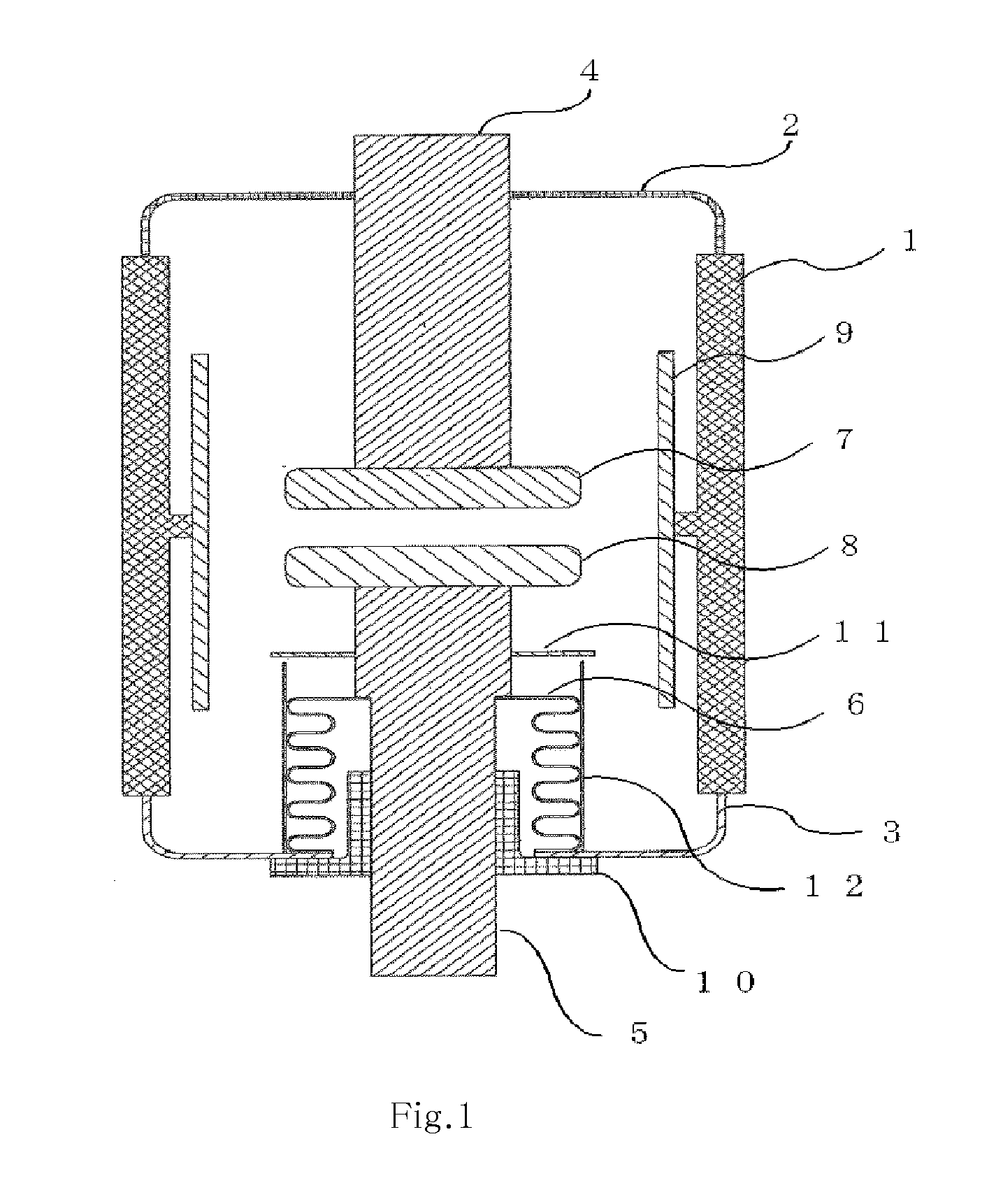

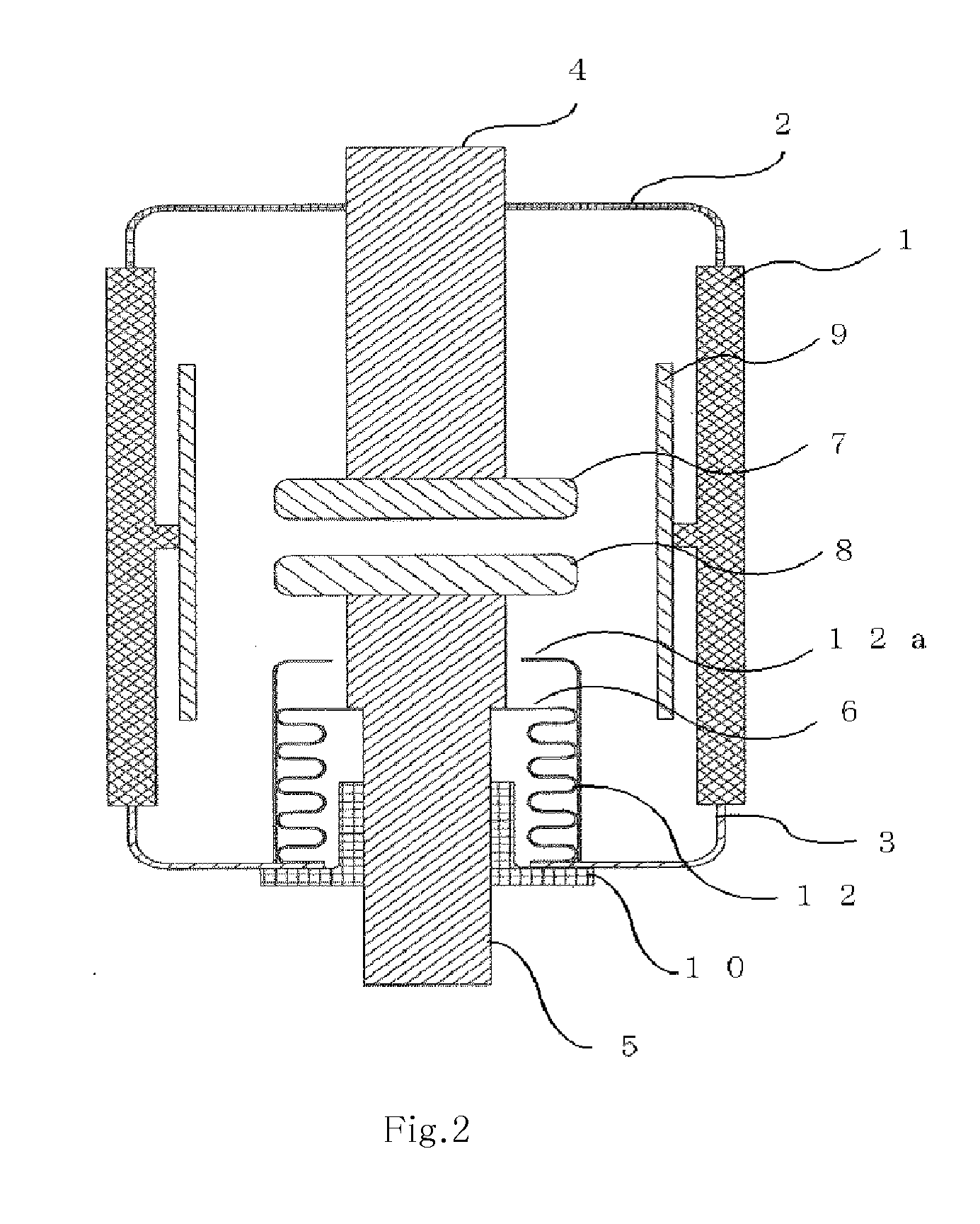

Vacuum interrupter

ActiveUS20130048611A1Increase of vacuum interrupter size is preventedBuckling of can preventedContact vibration/shock dampingHigh-tension/heavy-dress switchesElectrical conductorEngineering

A vacuum interrupter includes a vacuum vessel configured with an insulator, a fixed end plate and a movable end plate fixed to both ends of the insulator. A fixed contact and a movable contact face each other inside the vacuum vessel. A movable conductor has one end fixed to the movable contact and the other end is extracted outside the vacuum vessel. A bellows has an accordion portion expanding and contracting with linear movement of the movable conductor. A bellows support member having a cylindrical shape is fixed to the vacuum vessel so that the accordion portion of the bellows contacts the inside of the bellows support member.

Owner:MITSUBISHI ELECTRIC CORP

Gear polishing device

The invention discloses a gear polishing device. The gear polishing device comprises an underframe, a left supporting plate, a right supporting plate, a cylindrical block, an erection column, a rightgas cylinder, a limiting block, a cylindrical cavity, a top plate, an upper gas cylinder, a connecting plate, a clamping block, a lower gas cylinder, a base platform, fixed blocks, guide rods, a sliding block, a polishing head and an automatic reciprocating cylinder. The cylindrical block is fixedly connected with the upper part of the right end face of the left supporting plate horizontally. Theleft end of the erection column is fixedly connected with the center of the right end face of the cylindrical block. The tail end of a piston rod of the right gas cylinder is fixedly connected with the limiting block. The cylindrical cavity is formed in the left end face of the limiting block. The connecting plate is fixedly connected with the tail end of the piston rod of the upper gas cylinder.The clamping block is fixedly connected with the lower end face of the connecting plate. A piston rod of the lower gas cylinder upwards penetrates through the underframe, and then, the tail end of thepiston rod is fixedly connected with the center of the lower end face of the base platform. The two guide rods are horizontally and fixedly arranged between the two fixed blocks in a connected manner. The sliding block is in sliding connection with the guide rods through through holes. The polishing head is fixedly connected with the upper end face of the sliding block. The tail end of a piston rod of the automatic reciprocating cylinder is fixedly connected with the right end face of the sliding block. The gear polishing device has the advantages of being low in time and labor consumption, and high in efficiency.

Owner:安徽致精机电科技有限公司

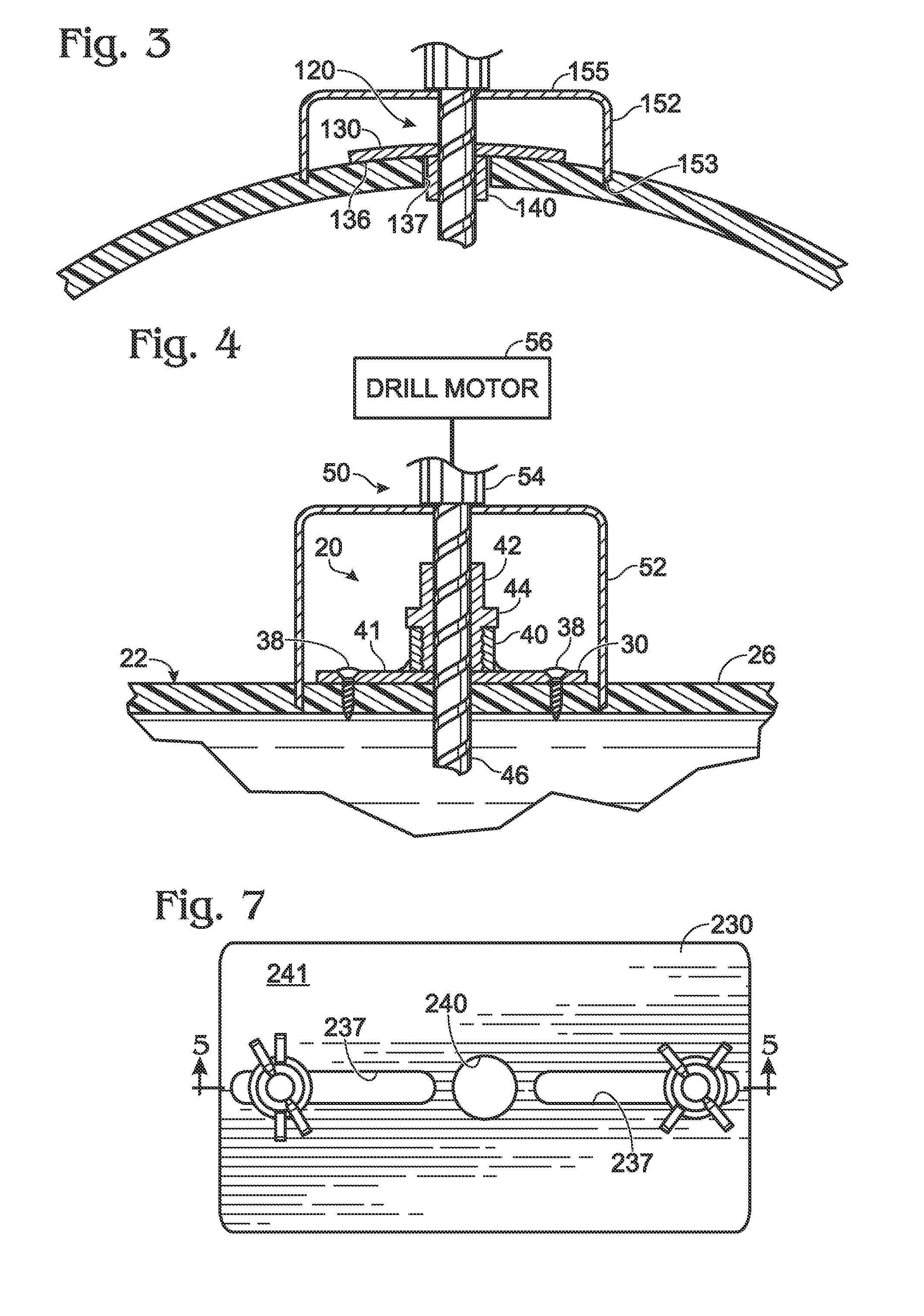

Bearing unit for a vehicle wheel

ActiveUS20140193109A1Simple and economical mannerRolling contact bearingsBearing assemblyEngineeringAbutment

A bearing unit for a vehicle wheel having a radially outer stationary ring provided with an axial lug, with a flange transverse to an axis of rotation and with an annular channel formed between the axial lug and the flange and delimited axially by a bottom surface. A radially inner rotatable ring defining, together with the stationary ring, a space; an encoder fixed onto the inner ring and extending outside of the space and in front of the axial lug; a protective cover mounted on the axial lug to protect the encoder and close off the space and provided with a side wall mounted on the outer cylindrical surface and having a bent edge arranged axially in abutment against the bottom surface of the annular channel; sealing means disposed between the cylindrical side wall and the tubular axial lug to seal the cylindrical side wall on the outer cylindrical surface.

Owner:AB SKF

Motor, fan and manufacturing method of the same

A motor according to the present invention preferably includes a boss portion preferably includes an inner ring portion including a substantially ring shaped convex portion at an axially lower end surface thereof. The boss portion preferably includes a through hole at which a shaft is press fitted at a central portion thereof. A rotor holder including a substantially cylindrical shape includes a through hole centered about a rotary axis. The through hole and the inner ring portion of the boss portion are fitted to one another. The convex portion includes a portion plastically deformed outwardly in the radial direction to sandwich an inner circumferential surface of the rotor holder. The inner circumferential surface of the impeller cup portion includes a plurality of convex portions near an upper portion thereof. The rotor holder is press fitted into the inner circumferential surface of the impeller cup portion via the convex portions.

Owner:NIDEC CORP

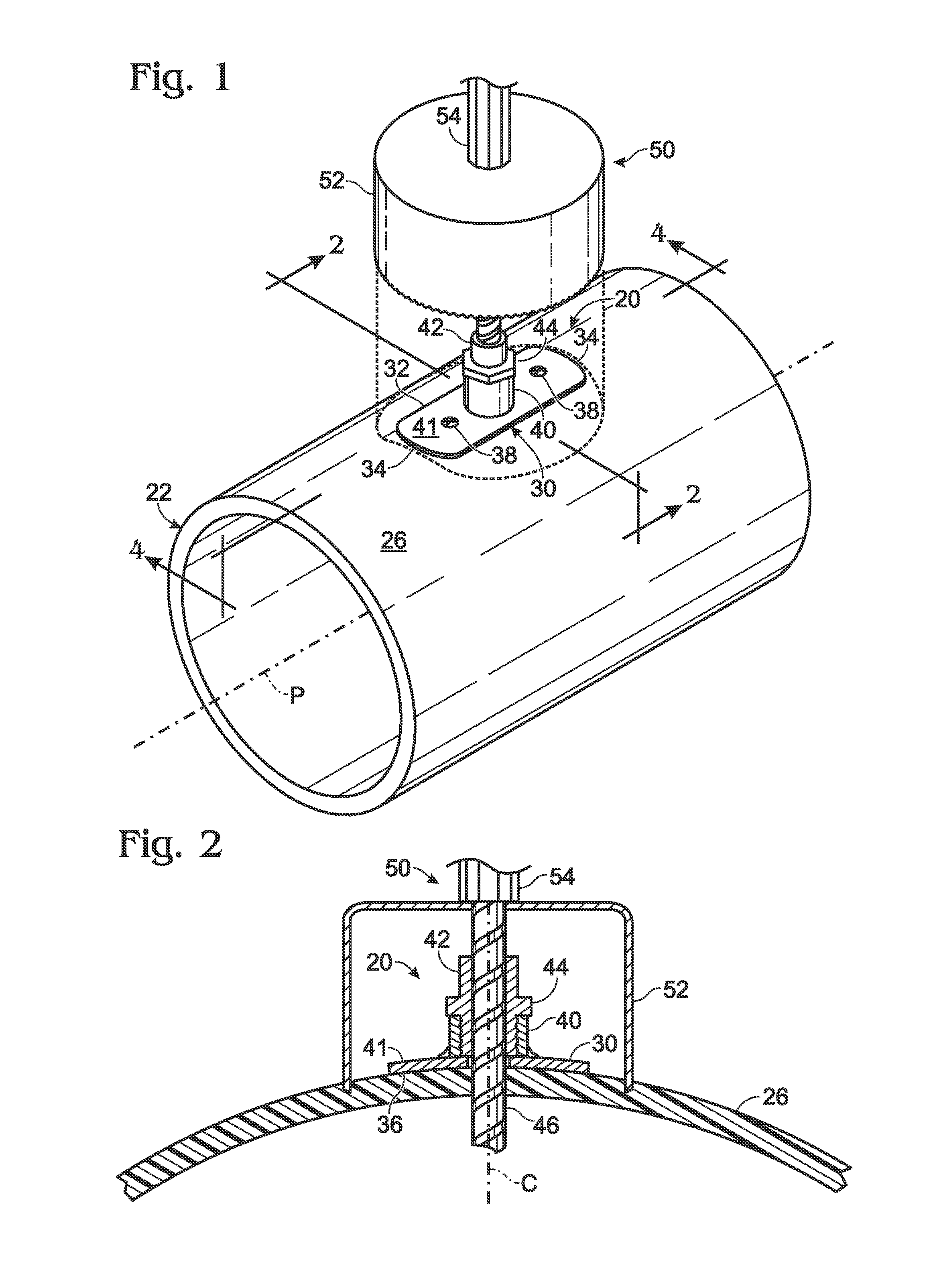

Coring tool alignment assembly

ActiveUS8770897B2Improve the immunityIncreased complexityDrilling/boring measurement devicesThread cutting machinesHole sawEngineering

A compact assembly for aligning a coring tool relative to a pipe sidewall. The coring tool includes a hollow, cylindrical hole saw mounted to an arbor that has an elongated pilot shaft centered in the hole saw. The assembly is made up of a base plate that is attachable to the pipe sidewall. In one embodiment, a tubular sleeve is mounted to the base plate and has a bore diameter sized for receiving the pilot shaft as the hole saw is advanced toward and saws through the pipe wall, and the entire assembly is sized to fit inside the hole saw as the hole saw saws through the pipe sidewall. In another embodiment, the base plate is configured for use with pipe sidewalls that include outwardly protruding ribs.

Owner:ADVANCED DRAINAGE SYST

Hub-bearing assembly for a vehicle wheel

InactiveUS20130300187A1Simple and low-cost and efficientQuick applicationRolling contact bearingsBearing assemblyPlastic materialsEngineering

A hub-bearing assembly for a vehicle wheel, the assembly being provided with at least one annular metal element having an axial tubular appendage adapted for being fitted into a central bore of a wheel or a bore of a suspension upright of the vehicle, wherein the tubular appendage has a cylindrical outer surface with an annular groove; the assembly also being provided with a sleeve of plastic material, which is mounted on the tubular appendage so as to cover the outer cylindrical surface and has an inner cylindrical surface with a radially inwardly protruding relief which snap-engages in the annular groove so as to axially lock the sleeve on the tubular appendage.

Owner:AB SKF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com