Lithium battery outer shell drawing composite die

A composite mold, lithium battery technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of thinning, cracked parts, unqualified, etc., to achieve the effect of convenient use, guaranteed blanking, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

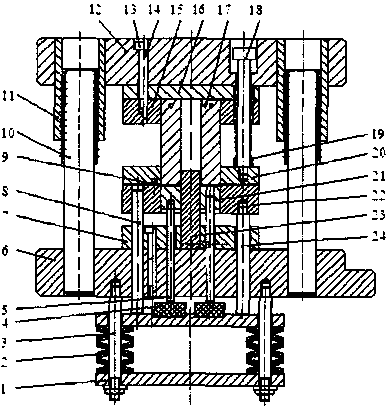

[0010] The present invention will be further explained below in conjunction with the accompanying drawings.

[0011] as attached figure 1 As shown, a lithium battery casing deep drawing composite mold is characterized in that: the upper mold base 12 is connected with the backing plate 16 and the convex and concave mold fixing plate 15 sequentially through the fillet screw 13 and the cylindrical pin 14, and the convex and concave mold fixing plate 15 is set There are convex and concave molds 17, the convex and concave molds 17 are connected with the pressing and unloading plate 20, the lower part of the pressing and unloading plate 20 is connected with the movable concave mold 22, the movable concave mold 22 is equipped with a movable insert 21, the bottom of the convex and concave mold 17 is connected with the convex mold 23 Connected, the punch 23 is arranged on the punch fixing plate 7, and the punch fixing plate 7 is connected with the lower mold base 6. Both sides below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com