Filtering pipeline

A technology of pipes and filter elements, applied in the direction of filter circuits, filter separation, pipes, etc., can solve the problems of inconvenient disassembly, inconvenient removal of dirt and impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

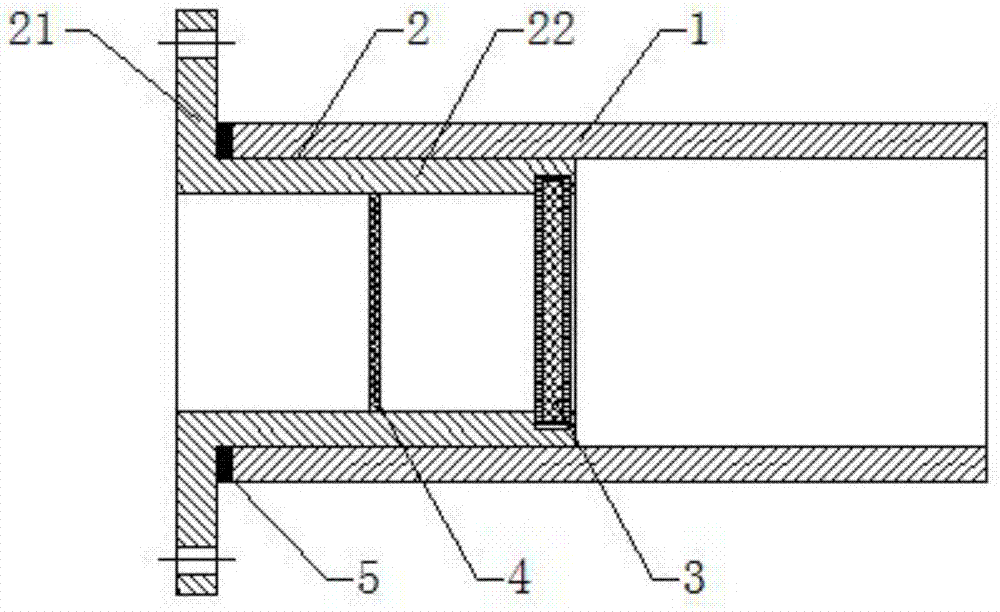

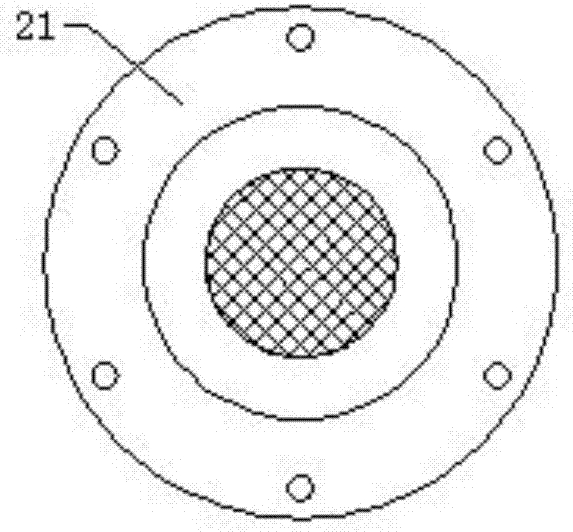

[0019] refer to Figure 1 to Figure 2 As shown, a filter pipeline includes a main pipeline 1 and a filter core tube 2. It is characterized in that: the inner wall at one end of the main channel 1 is provided with an internal thread, the filter core tube 2 is a hollow cavity, and one end is welded with a Blue plate 21, the other end is a cylinder 22, the diameter of the flange is greater than the diameter of the cylinder, the outer wall of the cylinder is provided with external threads, the main pipe is threaded with the filter core pipe, and the flange is welded The end is in contact with one end of the main pipe, and the end of the cylindrical cavity away from the flange is provided with an annular groove, and the filter layer 3 is filled in the annular groove.

[0020] There is a seal 5 between the welding end of the flange and the end of the main pipe. The seal is an O-ring, and the threaded connection is coated with waterproof sealant. Water seepage can be minimized throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com