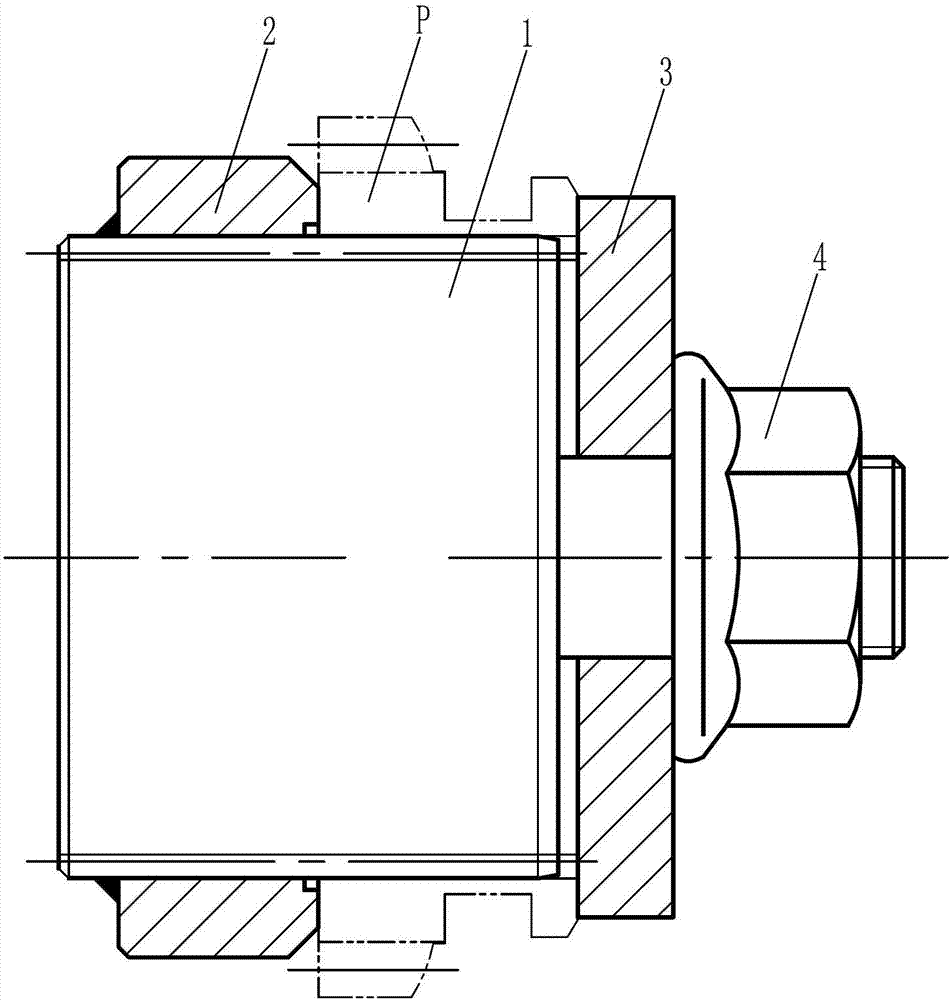

Grooving jig used for clamping synchronizer duplicate gear

A technology of double gears and synchronizers, applied in the direction of expanding the mandrel, can solve the problems of low positioning accuracy, poor clamping accuracy, complicated operation, etc., to achieve convenient installation and disassembly of gear blanks, overcome defects, and improve clamping accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

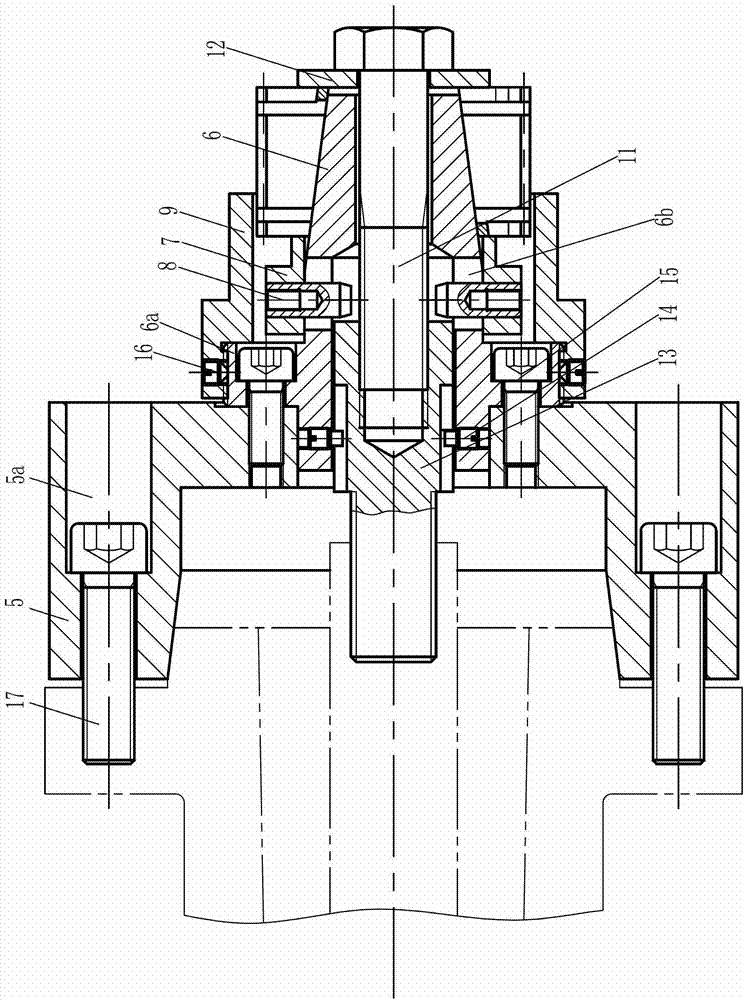

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0020] Such as figure 2 As shown, the present invention is mainly composed of connecting plate 5, mandrel 6, sliding sleeve 7, cylindrical pin 8, positioning sleeve 9, expansion sleeve 10, bolt 11, washer 12, pull rod 13, anti-rotation screw 14, screw 15 and taper end Set screw 16 constitutes. Wherein, a plurality of axial mounting holes 5a are opened on the connecting plate 5, and the connecting plate 5 is connected with the main shaft of the lathe through connecting screws 17 penetrated in the axial mounting holes 5a. The inner hole of the connection plate 5 is a two-stage stepped hole with a large diameter on the left and a small diameter on the right, wherein the left end surface of the large aperture section is a conical surface.

[0021] The axis line of the mandrel 6 is on the same straight line as the axis line of the connection plate 5, the left e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com