Turning tool used for automobile sleeve part

A sleeve and parts technology, applied in the production and processing of automotive sleeve parts, can solve the problems of poor rigidity of sleeve parts, affecting production efficiency, and difficult processing of sleeve parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

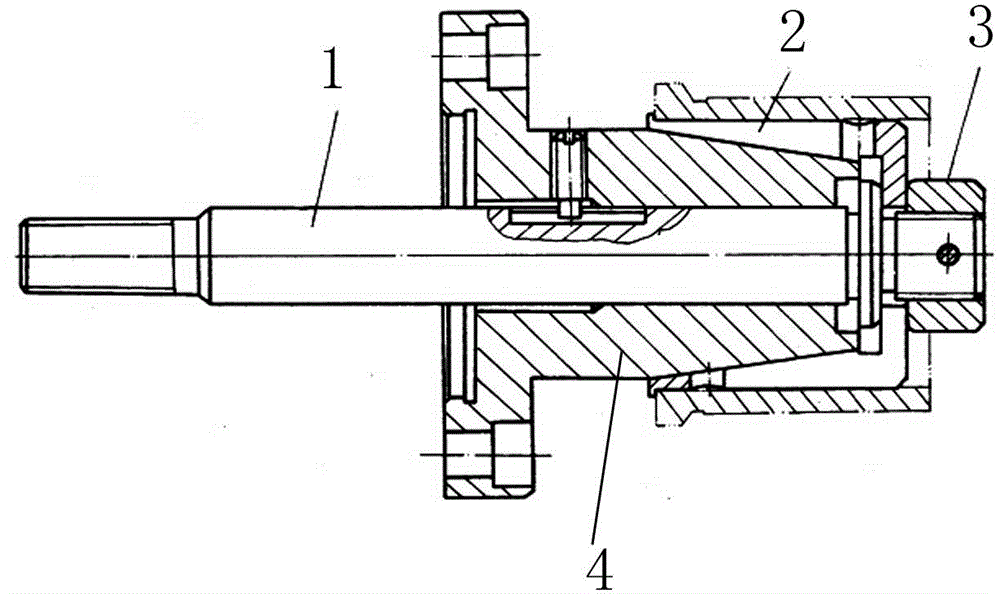

[0015] The reference signs in the accompanying drawings of the specification include: a pull rod 1 , an elastic fixing sleeve 2 , a nut 3 , and a mandrel 4 .

[0016] The embodiment is basically as attached figure 1 As shown: the tooling for turning automotive sleeve parts includes a mandrel 4, and also includes a tie rod 1, an elastic fixing sleeve 2 and a nut 3. There is an inner hole in the center of the mandrel, and the mandrel includes a fixed seat at the left end, a cylindrical transition section in the middle and The tapered section at the right end has six mounting holes in the circumferential direction of the fixing seat, which is convenient for the connection and fixation between the fixture and the spindle of the machine tool. The tie rod and the inner hole of the mandrel are clearance fit. The anti-rotation screw inserted into the anti-rotation groove prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com