Lifting device adapting to carrying of different cable trays

A lifting device, adapted to different technologies, applied in the direction of lifting devices, etc., can solve the problems of waste of resources, large space required for operations, etc., and achieve the effect of improving loading and unloading lifting requirements, improving handling efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

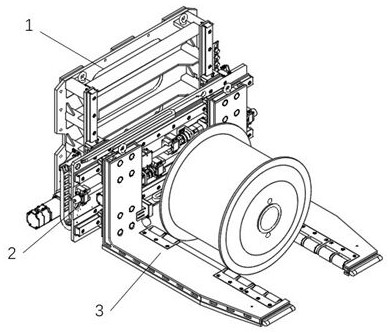

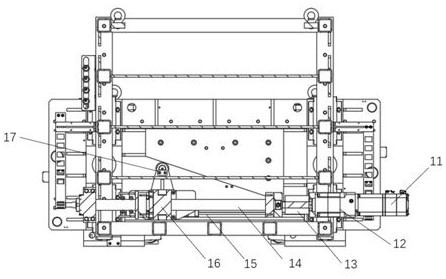

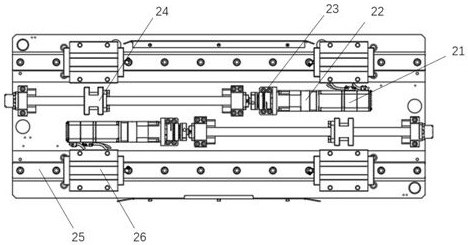

[0038] The embodiment is specifically: the lifting assembly 1 is used to realize the rise and fall of the whole device, and completes the main action when carrying goods, and the traversing assembly 2 is used to control and realize the left and right of the fork 32 support assembly 3 when handling plates with different specifications. Traversing, the support assembly 3 is used to complete the fixing and supporting functions when the cargo is transported. At the same time, the support assembly 3 is equipped with a guide mechanism for self-adaptive adjustment when the cargo is deflected. The traverse screw nut passes through the traverse guide rail 25 The movement of the triangular plate is more stable, avoiding the shaking and offset of the traversing screw nut, improving the stability of the movement of the support components 3 on both sides, and the inclined surface of the triangular plate can realize the extrusion and lifting of the traversing component 2 through the movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com