Plastic cable bridge-carriage jointing structure

A technology of cable bridge and joint structure, applied in the direction of electrical components, etc., can solve the problems of high installation strength, high cost, poor corrosion resistance, etc., and achieve the effect of convenient installation and disassembly on site, light weight and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

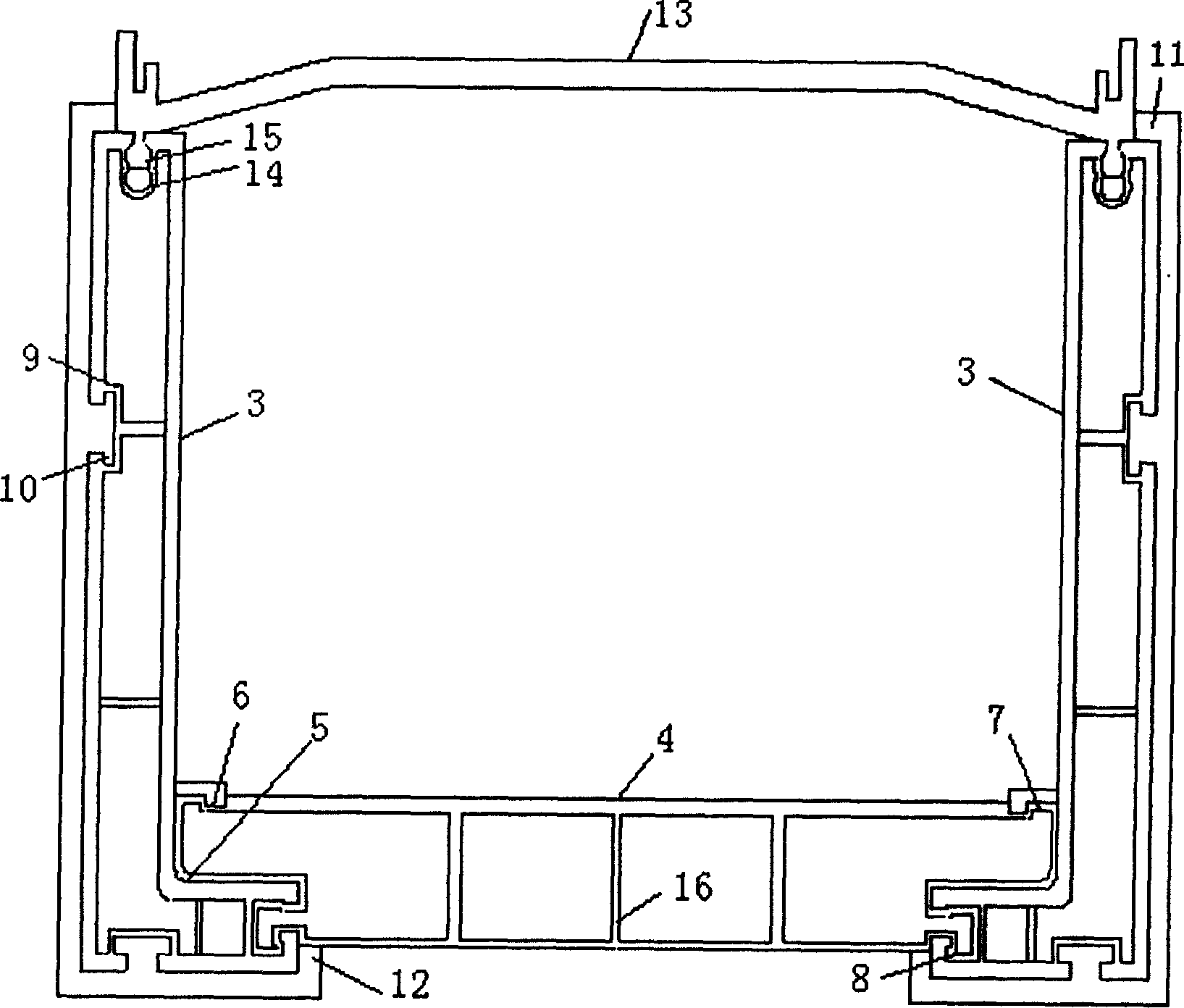

Method used

Image

Examples

Embodiment 1

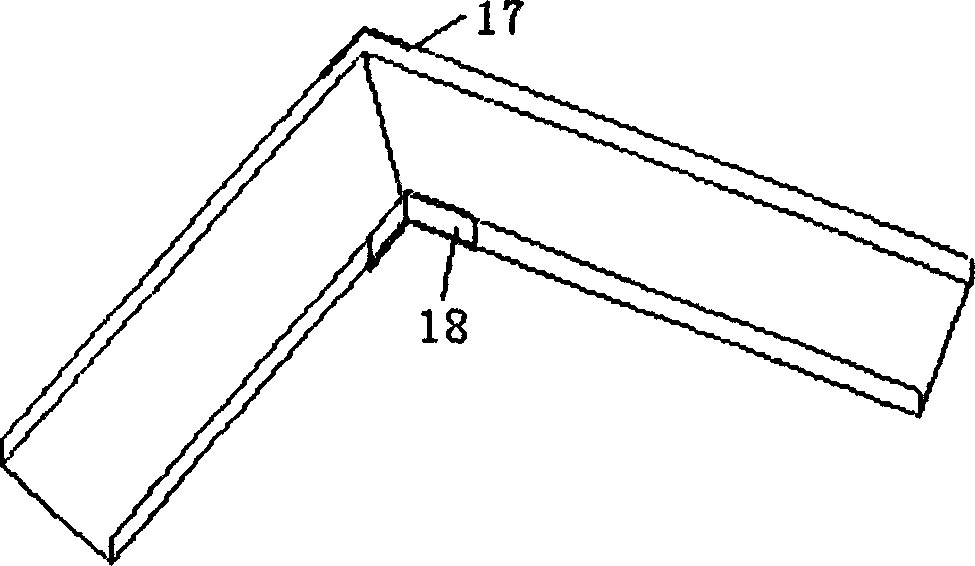

[0013] Example 1: See image 3 , when connecting the connecting ends of plastic cable trays at a certain angle, firstly cut the connecting ends to make them flat butt; then the snap joints are thermally deformed according to the connection angle, and are respectively made to be able to be interlocked with the plastic cable trays The outer curved joint [17] and the inner curved joint [18] are connected; the outer curved joint and the inner curved joint are respectively inserted into the outer curved part and the inner curved part of the joint of the two plastic cable trays , to fasten.

Embodiment 2

[0014] Example 2: see Figure 4 , when the head of the plastic cable tray is processed, the snap joint is thermally deformed according to the section width of the plastic cable tray to form a groove-shaped closed snap joint [19]; the convex strip of the closed snap joint and the plastic cable tray The grooves on the left and right side panels are interlocked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com