A differential cable assembly assembly tool

A cable assembly and assembly tooling technology, applied in workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of inability to upgrade the assembly degree, single tool design, inconvenient to carry, etc., to achieve consistency and reliable performance. The effect of high flexibility, few parts, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

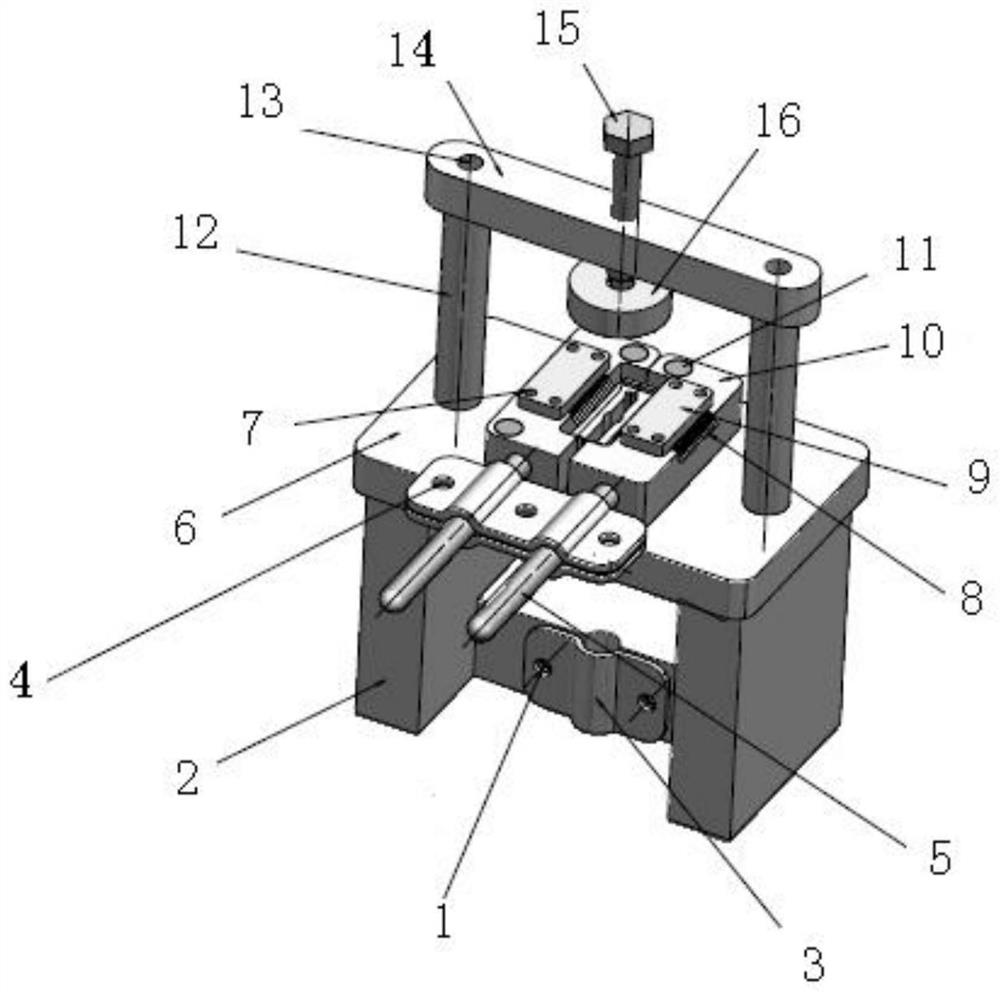

[0031] Such as figure 1 As shown, a differential cable assembly assembly tooling, including cable assembly assembly and fixing tooling, differential conductor wiring and fixing tooling, differential electrical connectors and crimping assembly tooling between wires,

[0032] The tooling for assembling and fixing the cable assembly is composed of a metal beam 1, a fixed holding block 2, a metal clamp 3, and a metal platform 6. The appearance of the metal beam 1 is a cuboid, and it is connected with the fixed holding block 2 by welding; Block 2 and metal beam 1 form the entire base part of the tooling. The appearance is "I"-shaped, which is used for fixing the entire tooling. It can be tightened with a vise to ensure that the entire tooling is in a static state. The "I"-shaped design ensures that the tooling The overall strength is strong; the metal clamp 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com