Method for checking assembling flexibility of long bolts between high-pressure rotor discs

A high-pressure rotor and inspection method technology, applied in the field of aero-engines, can solve the problems of large measurement errors, vague standard definitions, and inability to effectively evaluate the assembly quality of high-pressure compressor rotors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

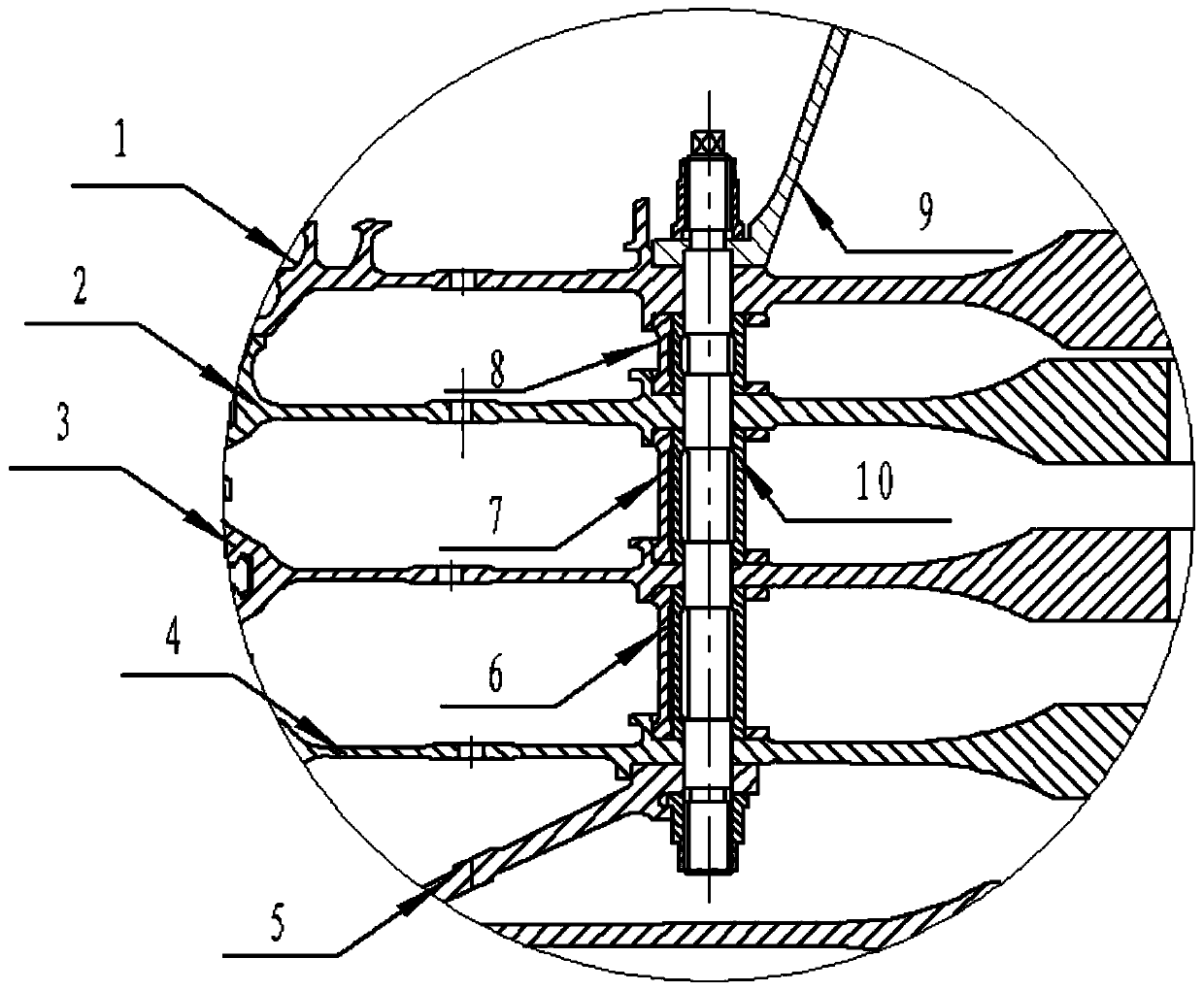

[0030] The invention provides a method for inspecting the assembly flexibility of long bolts between high-pressure rotor disks, which is characterized in that: the method for inspecting the assembly flexibility of long bolts between high-pressure rotor disks, the 7th, 8th, and 9th disks of the high-pressure rotors of the engine and The grate disc is connected by 24 long bolts evenly distributed around the circumference. When assembling the high-pressure rotor, every time a disc is assembled, it is necessary to check the rotation flexibility of each long bolt to evaluate the assembly quality of the high-pressure rotor. When checking the flexibility of bolt rotation, if the bolt stuck fault occurs, it means that when assembling a certain stage disk, the stage disk is not assembled in place, resulting in contact stress between the bolt holes on the disk and the mating surface of the long bolt, making the bolts unable to flexibly Rotation reflects the poor assembly accuracy of the ...

Embodiment 2

[0050] The invention provides a method for inspecting the assembly flexibility of long bolts between high-pressure rotor disks, which is characterized in that: the method for inspecting the assembly flexibility of long bolts between high-pressure rotor disks, the 7th, 8th, and 9th disks of the high-pressure rotors of the engine and The grate disc is connected by 24 long bolts evenly distributed around the circumference. When assembling the high-pressure rotor, every time a disc is assembled, it is necessary to check the rotation flexibility of each long bolt to evaluate the assembly quality of the high-pressure rotor. When checking the flexibility of bolt rotation, if the bolt stuck fault occurs, it means that when assembling a certain stage disk, the stage disk is not assembled in place, resulting in contact stress between the bolt holes on the disk and the mating surface of the long bolt, making the bolts unable to flexibly Rotation reflects the poor assembly accuracy of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com